-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Polymer Science

p-ISSN: 2163-1344 e-ISSN: 2163-1352

2025; 14(2): 17-21

doi:10.5923/j.ajps.20251402.01

Received: Jun. 22, 2025; Accepted: Jul. 13, 2025; Published: Jul. 23, 2025

Development of Drilling Fluid Formulations Based on Synthetic Polymers

Umidjon Chuliev1, Mukhtar Amonov2, Umida Shabarova3

1Independent Researcher, Bukhara State University, Bukhara, Uzbekistan

2Professor, Bukhara State University, Bukhara, Uzbekistan

3Doctor of Philosophy (PhD) in Technical Sciences, Associate Professor, Karshi State Technical University, Karshi, Uzbekistan

Copyright © 2025 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This study investigates the impact of different compositions of water–soluble polymers, specifically hydrolyzed polyacrylonitrile (GIPAN), sodium carboxymethyl cellulose (Na–CMC), and carboxymethyl cellulose (CMC), on the physicochemical properties of drilling fluids. These polymers are widely used as stabilizers and additives in drilling fluids to enhance their rheological and filtration properties. The research focuses on how the concentration and combination of these polymers influence the key properties of drilling fluids, such as viscosity, filtration loss, and shear stress. The findings reveal that the optimal combination of these polymers improves the stability and performance of drilling fluids, especially in high salinity conditions, where individual stabilizers tend to lose effectiveness. A synergistic effect was observed when specific sequences of polymer additions were used, significantly reducing filtration loss and enhancing the rheological properties of the fluid. The results suggest that a complex approach, incorporating GIPAN, Na–CMC, and CMC, is effective in stabilizing drilling fluids in mineralized environments and can be used to enhance the performance of drilling operations.

Keywords: Drilling Fluids, Water–Soluble Polymers, Hydrolyzed Polyacrylonitrile (HPAN), Sodium Carboxymethyl Cellulose (Na–CMC), Carboxymethyl Cellulose (CMC), Filtration Loss, Viscosity, Shear Stress, Polymer Stabilizers, Mineralized Water, Rheological Properties, Drilling Operations

Cite this paper: Umidjon Chuliev, Mukhtar Amonov, Umida Shabarova, Development of Drilling Fluid Formulations Based on Synthetic Polymers, American Journal of Polymer Science, Vol. 14 No. 2, 2025, pp. 17-21. doi: 10.5923/j.ajps.20251402.01.

Article Outline

1. Introduction

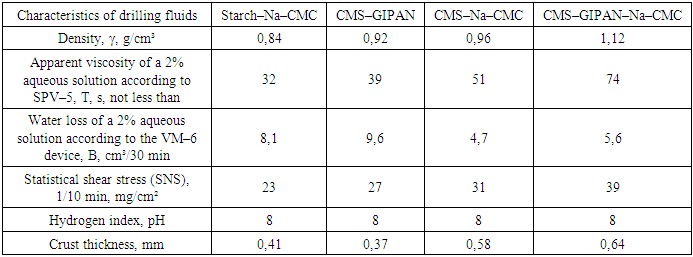

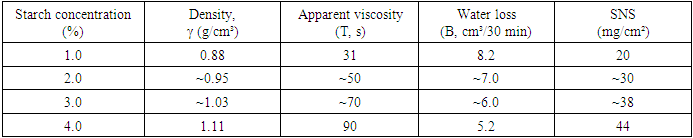

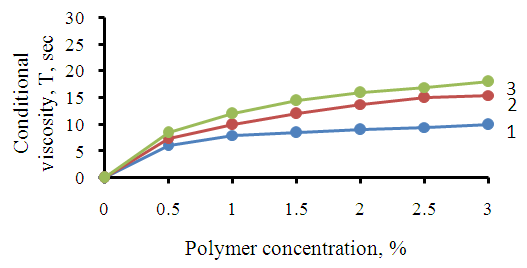

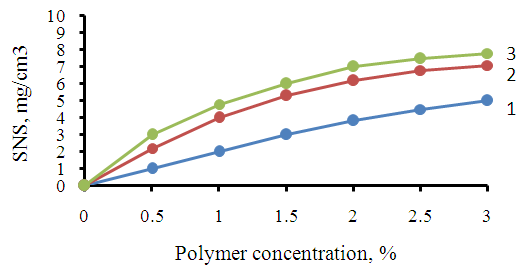

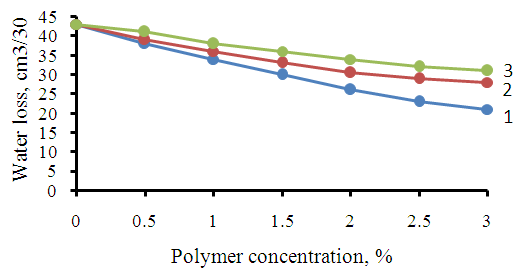

- The diversity of drilling fluid types and their formulations, on the one hand, demonstrates a vast arsenal of solutions that enables successful well construction under virtually any geological and thermobaric conditions. On the other hand, such a multitude of options reflects the complexity of the physicochemical processes occurring both within these heterogeneous systems and in the interactions between the drilling fluid and minerals, shales, formation waters, hydrocarbons, and other components of the geological section. It is precisely in the interaction with the components of the rock formations that the conditions are formed which determine the safety of the drilling process, the subsequent quality of the well casing, and its durability [1–3].In response to the need to prevent complications, an approach has been developed for selecting the type of drilling fluid based on its inertness. Simple examples of this approach include penetrating an oil–saturated reservoir with an oil–based fluid or drilling through salt formations with a salt–saturated solution. The specific gravity of the fluid can partially compensate for the redistribution of rock pressure, and maintaining the thermal regime is also crucial. The studied cryogenic drilling technology is based on the use of a drilling fluid at subzero temperatures, which aligns with this approach when drilling intervals composed of perennially frozen rocks.Another approach involves actively managing the interactions between the wellbore fluid and the rock formation. This method aims to eliminate processes that could lead to wellbore wall instability and, conversely, initiate interactions that enhance wall stability. At subzero temperatures, pore fluids can undergo phase transitions, thereby affecting the strength and filtration properties of the near–wellbore zone in the rock mass.To ensure the required properties of drilling fluids and to maintain them throughout the drilling process, various chemical reagents are added [4–6]. High bottomhole temperatures, formation pressures, and the intrusion of highly mineralized formation waters into the drilling fluid can lead to changes in its structural–mechanical and filtration properties.The chemical treatment of drilling fluids with certain reagents can result in foaming. The intensity and stability of foam formation depend on the composition of the additives introduced, the properties of the fluid, and the geological conditions of the well. Filtration reducers represent a separate class of reagents used in drilling fluids.Hydrolyzed polyacrylonitrile (GIPAN), carboxymethyl starch (CMS), and its derivatives are among the most widely used industrial water–soluble polymers due to their low cost and high molecular weight. The presence of hydrophobic fragments within the hydrophilic chain gives GIPAN high surface and interfacial activity, thereby enhancing its ability to adsorb at phase boundaries [7]. GIPANs are highly effective as flocculants for water treatment [8–9]. Additionally, polyacrylamides modified with hydrophobic segments have found application as rheology modifiers in various aqueous systems–such as drilling fluids [10], paints and coatings, for biomedical purposes [11], and in other fields.When discussing the technology of preparing drilling fluids, one cannot ignore the types and function of drilling fluid additives. Let us consider the most commonly used additives for drilling fluids:Emulsifiers–(fatty acids and chemical compounds for oil–based drilling fluids and amine–based cleaning compositions, various soaps, organic acids, as well as aqueous surfactants for water–based drilling fluids). When emulsifiers are used, a heterogeneous mixture (emulsion) of two immiscible liquids is formed. Emulsifiers can be anionic or cationic chemical reagents, depending on the application;Reagents–stabilizers (peptizers)–representatives of this group include alkaline salts of lignosulfonic and humic acids, soaps of naphthenic and sulfonaphthenic acids, tannins–tanning extracts in an alkaline solution. These substances peptize clay aggregates into primary particles and prevent their coagulation, thereby reducing the fluid loss of the solutions;Surfactants (surface–active substances)–reduce the interfacial tension between contacting surfaces (water/oil, water/solid impurities, water/air). These may include emulsions, demulsifiers, wetting agents, flocculants, and deflocculants, depending on the contacting media. These products increase the geological and filtration stability of drilling fluids exposed to high temperatures, thereby providing favorable conditions for the continuation of drilling. For this purpose, various chemical compositions are used, such as acrylic polymers, sulfonate polymers, and copolymers (lignosulfonates and tannin–based additives);Thickeners–bentonite, CMC (carboxymethyl cellulose), attapulgite clays, and polymers are used to increase viscosity; they are applied for wellbore cleaning;Structure–forming reagents–(soda ash, caustic soda, sodium silicate (liquid glass), and some phosphates). The presence of these components in small concentrations (up to 0.2%) reduces the fluid loss and viscosity of solutions. In larger quantities, coagulation and sharp thickening of the solution occur;Clays and weighting agents–(barite, iron oxides, calcium carbonate, attapulgite, bentonite, etc., increase density up to 2400 kg/m³) are used to control formation pressure, prevent complications associated with borehole integrity violations, and control oil and gas shows. Low-density weighting agents (chalk, limestone, marl, etc.) can increase the fluid density up to 1700 kg/m³, but due to their low density, they have to be added in large quantities, which reduces drilling efficiency. More effective weighting agents are barite, magnetite, hematite, which have a specific density of 4400–5300 kg/m³. The best weighting agent is barite, as it possesses high abrasiveness. In certain cases, higher–density weighting agents (6000 kg/m³) are used (ferrosilicon, ferromanganese, red lead (lead oxide));Corrosion inhibitors–used to control pH levels, neutralize the effects of hazardous acidic gases, and remove paraffin deposits;Lubricating compounds–(various synthetic fluids, oil–based suspensions, graphite, surfactants, glycols, glycerin, etc.) are intended to reduce friction, torque, and resistance;Flocculants–(salt or saline solutions, calcium hydroxide, natural gypsum, soda ash, sodium bicarbonate, etc.) are used to increase viscosity, improve wellbore cleaning efficiency, enhance bentonite flowability, and clean and dehydrate fluids with low solids content;Antifoaming additives–reduce foam formation in drilling fluids based on brackish or seawater;Foaming agents–chemical compounds that act as surfactants and are used to generate foam. These agents enable air or gas drilling through aquifers;Hydrate suppressants–alcohol–based additives used in deepwater or cold–water environments;Filtration reducers–(bentonite clay, CMC, polyacrylate, and peptized starch) are used to reduce filtration and modify the properties of liquid drilling fluids to facilitate their passage through the filter cake into the formation;Bactericidal agents–used to prevent the degradation of natural organic additives such as starch and xanthan gum;Polymeric reagents–(polyelectrolytes with various functional groups, modified celluloses, acrylic polymer derivatives, biopolymers, and copolymers) are used to minimize the consumption of materials and chemicals in the preparation and regulation of fluid properties. The characteristics of polymers include selective flocculating action toward the dispersed phase and drilled cuttings, lubricating and inhibitive properties, and the ability to control filtration performance [12–14].The complex use of additives in drilling fluids ensures the improvement of rheological and technological properties of the drilling fluid, resulting in high–quality drilling operations. For example, let’s consider the technology of preparing a non–aqueous–based drilling fluid with the use of various additives and how its properties change during this process. The dispersing medium of a non–aqueous drilling fluid consists of petroleum products, which contain 10 to 25% bitumen, up to 1.5% caustic soda, and 1.5% water, with the remainder being distilled petroleum products and diesel fuel, stabilized with sodium soap of oxidized paraffin or sodium soap of oxidized petroleum.The addition of organic acids to the system thins the fluid, while the addition of alkali increases its viscosity. The preparation process involves dissolving the bitumen and stabilizer in the dispersing medium. To emulsify the oil components introduced into the clay–based fluid, dispersers of various designs are used. By adding weighting agents to the drilling fluid, its density can be increased from 900 kg/m³ to 2500 kg/m³ [15–17].Based on the above, it can be concluded that the types, properties and technologies for preparing drilling fluids are diverse, so the main task when choosing a technology for preparing drilling fluid parameters is the correct selection of the composition and properties for the geological and technological features of the well. The use of drilling fluids should ensure the safety and trouble–free operation at high drilling speeds, high–quality opening of the productive formation, should not have a harmful effect on the drilling tool and downhole motors, should be easy to pump and clean from sludge and gas, be safe for personnel and the environment, be inexpensive and allow the possibility of repeated use. Fulfillment of all these requirements is the key to successful well drilling [18].In recent years, interest in associating copolymers of acrylamide and hydrophobic comonomers has increased in oilfield chemistry. Polymers of this type are considered the most promising reagents for enhancing oil recovery [19–20]. The use of GIPAN copolymers in polymer flooding processes during oil production has attracted particular attention from researchers [21–22], since they have improved thermal stability, resistance to high shear rates and the presence of salts compared to high–molecular homopolymer of other derivatives.Water–soluble polymers based on synthetic polymers are widely used in various sectors of the economy. They are employed as highly effective flocculants for drinking and wastewater treatment, for stabilizing emulsions and suspensions. Polymers based on polyacrylonitrile (GIPAN), carboxymethyl starch (CMS), and sodium carboxymethyl cellulose (Na–CMC) are used in the paper and petroleum industries as stabilizers for drilling fluids. They are also used as additives to liquids to reduce hydraulic resistance when flowing through pipes, and as soil structure–forming agents in construction. Therefore, the development and improvement of methods for producing polymers based on the aforementioned materials for various practical purposes is an important area of research in both fundamental and applied chemistry.We investigated the dependencies of the physicochemical properties of drilling fluids obtained using different compositions consisting of GIPAN, CMS, and Na–CMC. Figure 1 presents the results of the physicochemical properties of drilling fluids based on the developed composite compositions at different ratios. Table 1 shows the optimal compositions of the developed composite chemical reagents made from various synthetic polymers. The total content of polymers was kept within 2 wt.%. The concentrations of GIPAN, CMS, and Na–CMC in the drilling fluid were 0.8%, 1.2%, and 1.0%, respectively. Table 1 presents the physicochemical properties of the developed composite compositions.

|

|

| Figure 1. Effect of polymer concentration on the apparent viscosity of mineralized drilling fluids (NaCl 5%): 1) GIPAN; 2) Na–CMC; 3) CMS |

| Figure 2. Effect of polymer concentration on SNS of mineralized drilling fluids (NaCl 5%): 1) GIPAN; 2) Na–CMC; 3) CMS |

| Figure 3. Effect of polymer concentration on water loss of mineralized drilling fluids (NaCl 5%): 1) GIPAN; 2) Na–CMC; 3) CMS |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML