-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Polymer Science

p-ISSN: 2163-1344 e-ISSN: 2163-1352

2019; 9(1): 10-15

doi:10.5923/j.ajps.20190901.02

Olive Pomace Flour as Potential Organic Filler in Composite Materials: A Brief Review

Raid Banat

Department of Chemistry, Al al-Bayt University, Mafraq, Jordan

Correspondence to: Raid Banat, Department of Chemistry, Al al-Bayt University, Mafraq, Jordan.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The use of natural renewable fibers such as olive stone flour as novel organic fillers in polymer matrices is investigated. Properties of olive stone flour such as abundance, biodegradability, easy processing, low density and low cost make it apt to act as a promising novel organic filler. Environmental issues and the need for versatile polymer-based materials have led to increase interest in polymer composites filled with biodegradable natural-organic fillers. Interfacial filler-polymer adhesion and processing temperatures are the main obstacles facing composite productions. The use of coupling agents, thermal stabilizers, plasticizing agents and/or chemical modifications of the filler can overcome such limitations. This review covers novel works related to the most significant polymer types which are used as matrices for olive stone flour as a filler to prepare a bio-composite material.

Keywords: Olive stone flour, Filler, Polymer composite

Cite this paper: Raid Banat, Olive Pomace Flour as Potential Organic Filler in Composite Materials: A Brief Review, American Journal of Polymer Science, Vol. 9 No. 1, 2019, pp. 10-15. doi: 10.5923/j.ajps.20190901.02.

Article Outline

1. Introduction

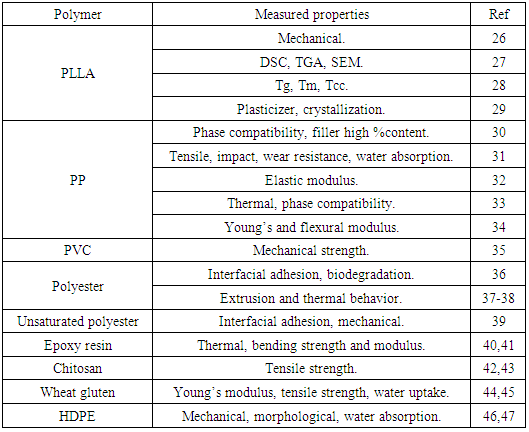

- Olive stone is an important by-product generated in the olive oil extraction industry [1-3]. The main components of olive stone are hemi-cellulose, cellulose and lignin as well as protein, fat, phenols, free sugars and polyols composition [4-6]. The main use of olive oil by-product waste is in producing heat and/or electric energy [7-10]. Other uses such as activated carbon, [11-12] furfural production [13], polymer filler [14-15], abrasive [16] and cosmetic materials [17-19]. Moreover, an emerging potential uses such as biosorbent [20-21], animal feed [22-23] or resin formation have been proposed by few studies [24].In this article, a brief review of olive stone flour (OSF) used as filler material in polymeric materials is described for the first time. In addition, this review discusses the potential use of this filler material based on several candidate polymer matrices. A new approach to olive stone as a reinforcement material with particle size ranging from 10 to 100 μ is described.In the last decade only limited number of articles discussing issues related to the characterization (Table 1) and potential use of olive stone as a filler material in polymer matrices. Research works are still in need to cover and investigate further potential applications of olive stone as a promising filler in various polymer matrices. The following sections summarize the main polymeric materials used as matrices for the OSF as filler.

|

2. Olive Stone Flour (OSF)

- Olive stone particle size distributionThe suitability of wastes from olive oil production industry for subsequent use in polymer composites was studied. In particular, residues of olive wet husk and olive pits were investigated. A wide particle size distribution was predicted in case of olive wet husk compared to olive pits which showed a narrower particle size distribution and better stability against thermal degradation. Moreover, pit and husk olive parts favor the compatibility with polar polymer matrices [25].

3. Polymer Matrices

- Polylactic acid (PLA)Fully biodegradable composites made out of (polylactic acid, PLA) reinforced with olive pit powders were manufactured and mechanically characterized. It was shown that with filler loading, an increase in the tensile modulus but a decrease of the flexural strength may be due to the poor interfacial bonding between olive pit powder and PLA [26].Various amounts of olive stone flour (0-25% OSF) were incorporated with poly(l-lactide) polymer (PLLA) to form a biodegradable (PLLA/OSF) composite material by using Brabender mixer and hot press. Thermal properties of (PLLA/OSF) composites were investigated. Differential scanning calorimetry (DSC) analysis showed a decrease in cold crystallization temperature which may account for certain kinds of interactions between the filler and the polymer under certain conditions. On the other hand, the glass transition temperature (Tg) and the melting temperature (Tm) values of PLLA in the composites were unaffected by the filler loading which may be due to poor interaction between filler and PLLA polymer matrix. Degradation of the filler-polymer composite was studied by using thermogravimetric analysis (TGA); PLLA degrades in one-step, PLLA/OSF composites in two and OSF in three decomposition steps. Thermal stability of PLLA decreases as OSF loading increases. Weak interactions between PLLA matrix and OSF were confirmed by the morphological studies carried out by scanning electron microscopy SEM [27]. The effect of the OSF filler content and plasticizer on the thermal properties of PLLA composite were investigated. It was found that the filler material in the absence of plasticizer material in PLLA polymer composite have no effect on the values of Tg, Tm and Tcc (cold crystallization temperature) of the polymer composite. On the other hand, PLLA polymer plasticized with tributyl citrate (TBC) and tributyl acetyl citrate (TBAC) (without filler) showed a lower Tm when compared to the plasticized polymer (with filler). Moreover addition of filler (OSF) and plasticizer (TBC & TBAC) individually to the PLLA polymer matrix increases crystallinity of the polymer composite and this increase is greater in case of using plasticizer with filler material [28].Different processing procedures applied to (PLLA/OSF) polymer composite production resulted in different thermal behavior of the polymer composite, whereas different kinds of plasticizers showed same thermal behavior effect on polymer composite. The results of DSC analysis indicate that thermal properties of the samples were greatly affected by processing procedure, regardless of any differences among the chosen plasticizers. The addition of OSF filler was reported to make only marginal effects on thermal properties of PLLA whereas filler loading greatly influences its crystallization behavior. Addition of a plasticizer to PLLA polymer was found to decrease its thermal transition temperatures while increasing its crystallinity. TGA analysis revealed that filler addition to PLLA polymer reduces thermal stability of the composite while plasticizer addition improves it. The weak interactions between PLLA and OSF phases with and without TBAC plasticizer were reported by studying SEM images of the polymer composite. Mechanical properties such as strength and flexibility were investigated. It has been found that the flexibility and strength of the polymer composite decrease with the increasing filler loading level. On the other hand, plasticizer (TBAC) reduces the strength but improves the flexibility of the PLLA polymer. Crystallization and melting behavior of PLLA affect the thermal properties of the polymer composite which in turn depend on the ageing process during the polymer composite production. Biodegradation of PLLA and its composite in soil environment was studied. PLLA filled with OSF and TBAC degraded more easily compared to version PLLA polymer [29].Polypropylene (PP)

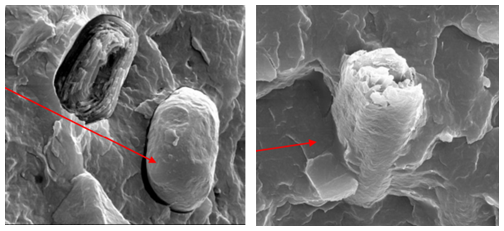

| Figure 1. SEM of the tensile fractured surface for OSF filled PP composite in the absence (left), and in presence (right) of MAPP coupling agent (magnification 2000x) [30] |

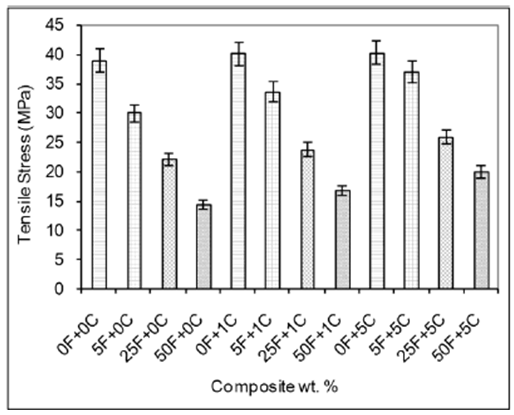

| Figure 2. Comparison of tensile stress of OPF filled HDPE composite as a function of the filler and coupling agent loading level. F: olive pomace flour % and C: coupling agent % (maleated PE) [46] |

4. Conclusions

- Availability and easy extraction of olive stone flour as a promising filler in olive oil mills makes it suitable for industrial manufacturing of bio-composites. The use of OSF as filler for several polymeric matrices was introduced. The effect of filler content, processing conditions, compatibilizing agent and plasticizer on the performance characteristics of bio-composites was partially investigated in literature. A completely biodegradable composite from OSF needs to be developed for future applications. The inclusion of such filler needs to be evaluated for many other existing polymers especially with those of biodegradable nature. Better bio-composite properties can be achieved through improvements in the interfacial adhesion between polymer and natural fillers to address the filler/polymer poor adhesion problems. Processing techniques and filler chemical modifications would be of significant importance to obtain a bio-composite with desired mechanical performance.

ACKNOWLEDGEMENTS

- The author would like to express his gratitude to Al al-Bayt University for their support of this research.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML