-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Polymer Science

p-ISSN: 2163-1344 e-ISSN: 2163-1352

2018; 8(1): 17-21

doi:10.5923/j.ajps.20180801.03

Reinforcement of High Density Polyethylene with Snail Shell Powder

Pauline U. Chris-Okafor, Caleb C. Okonkwo, Martin S. Ohaeke

Department of Pure and Industrial Chemistry, Nnamdi Azikiwe University, Awka, Nigeria

Correspondence to: Pauline U. Chris-Okafor, Department of Pure and Industrial Chemistry, Nnamdi Azikiwe University, Awka, Nigeria.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The effects of snail shell powder on the mechanical properties and morphology of high density polyethylene, HDPE /snail shell powder composites were studied. The snail shell powder of particle size 83µm was incorporated into HDPE polymer resins at varying percentages of 0%, 5%, 15% and 25%. The test samples were prepared by using injection moulding machine. The mechanical and morphological properties of high density polyethylene/snail shell powder composites have been characterised by an Instron machine in accordance with ASTM standard and optical microscopy respectively. From the results, hardness was observed to increase while the tensile strength, flexural strength and elongation at break decreased as the filler load increased. The result of the optical microscopy showed that the composites are more compatible than the unfilled composites. The filler improves the compatibility by finely dispersing the filler in the polymer matrix and a better interaction adhesion between the polymer matrix and filler particles.

Keywords: Snail shell powder, High density polyethylene, Mechanical properties, Optical microscopy

Cite this paper: Pauline U. Chris-Okafor, Caleb C. Okonkwo, Martin S. Ohaeke, Reinforcement of High Density Polyethylene with Snail Shell Powder, American Journal of Polymer Science, Vol. 8 No. 1, 2018, pp. 17-21. doi: 10.5923/j.ajps.20180801.03.

Article Outline

1. Introduction

- Recently, polymer composites containing natural fillers have been more and more widely used in the processing industry, particularly in polymer processing [1]. Composite materials are those that are formed by the combination of two or more materials to achieve properties that are superior to those of their constituents [2]. Polymer composites consist of a polymer resin as the matrix, with fillers as the reinforcement medium [3]. Polymer composites have unique properties which include good mechanical properties, thermal stability, and a reduced product cost [4-5]. In order to obtain products with the required functional properties, polymers are physically modified by the use of fillers. The properties of the thereby produced composite material are significantly affected by interactions between the polymer matrix and filler particles. In some cases, particularly when their concentration is low, powdered fillers can act as heterogeneous nucleates in the polymer crystalline phase [6-7]. These fillers can enhance some physical and chemical properties, but at the same time, other properties may decrease. This results from the differences in the interaction between polymer matrix and filler particles [8]. Due to the combination of more than one material, the properties of composites are influenced by many factors such as filler characteristics, filler content, and interfacial adhesion [9-10]. This can cause the behaviour of filled polymers to be more complex than their unfilled counterpart [11]. From literature, some researchers have studied the effects of different materials on some polymer composites like low density polyethylene, high density polyethylene, polypropylene and so on. These materials include saw dust [12], wood flour [13], coconut fibre [14], egg shell and fish bone [15], starch [16].Igwe et al [15] prepared polypropylene composites filled with egg shell and fish bone at varying % weights. The results showed that the tensile strength, flexural strength and hardness were increased, while %elongation at break at break decreased as filler load increased. Banat et al [17], investigated the thermo-gravimetric stability of high density polyethylene filled with olive shell flour. They observed that the incorporation of the olive shell flour into the HDPE matrix reduced the melting temperature, melting enthalpy and crystallinity of the HDPE composites. Also, Ofora et al [18] studied the effects of bamboo-corn husk as filler on the mechanical properties of polypropylene. The results showed that the mechanical properties were increased.Thus this study is aimed at determining the effect of powdered snail shell, an agro waste, on the mechanical properties of high-density polyethylene (HDPE) filled composites. More so, it attempted to explain the observed trend via surface morphology analysis of the polymer matrix-filler system.

2. Materials and Methods

2.1. Sample Collection and Preparation

- High density polyethylene used in this study was obtained from Ceeplast Industries Limited Aba, Abia State, Nigeria. The snail shells were sourced locally from Ochanja Market in Onitsha South, Anambra State, Nigeria. The snail shells were washed with clean water to remove the adhered contaminants and sun-dried for 3 days. The snail shells were crushed, ground and sieved using an electrical standard sieving machine of Model D210, Made in Italy. Fine powder with particle size of 83µm was obtained.

2.2. Polymer Composite Preparation

- The high density polyethylene/ snail shell powder composites were prepared by thoroughly mixing 208.10g of crystalline HDPE polymer resins with the filler (snail shell powder) at varying percentages of 0%, 5%, 15% and 25% were properly weighed. These were pelletised to ensure a homogenous mixture of the polymer and filler. The mixed pellets were then poured into the hopper of an injection moulding machine of Model 4.6KW, 10H Made in Chain, with a rectangular shaped mould with dimensions of 57mm X 13.5mm X 3.2mm.

2.3. Mechanical Tests

- The following mechanical tests; tensile strength, elongation at break, flexural strength and compressive strength tests were carried out as described in American Standard testing and measurement, ASTM D638 by using the Instron universal testing machine 5569, Model 6.5KW, Made in China. While the surface hardness of the polymer composites were determined according to the American Standard Testing and Measurement Method ASTM D2240 by the means of Avery Hardness Testing machine, Type 6406, Number E65226, manufactured by Avery Birmingham, England. The corresponding value of the diameter of the indentation at that surface was recorded and the hardness was calculated with the formula as Birnell Hardness Number measured in N/mm2.

2.4. Optical Microstructure

- The optical microstructure analysis was performed using Nikon Eclipse ME600 optical microscope to show the surface morphology of the filler and polymer matrix.

3. Results and Discussion

3.1. Results of Mechanical Properties

3.1.1. Tensile Strength Result

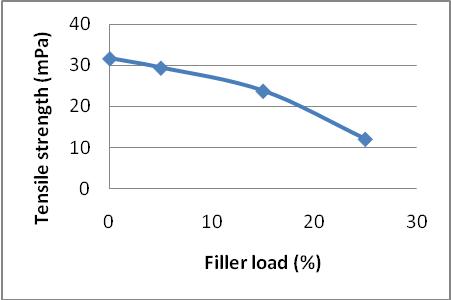

- It can be seen from Fig. 1 that the tensile strength for the composites decreases with increasing filler load. This could be due to the stress concentration at the particle/matrix boundary region, leading to weakness of the particle/matrix interaction and consequent reduction in tensile strength. This may be responsible for the reduced strength as indicated for all the filler loadings. Also excessive incorporation of filler may lead to filler agglomeration (weak bonding) in the polymer matrix leading to formation of micro filler due to the difficulties in achieving a homogeneous phase. This result is similar to reports of some researchers [19-20]. According to Salmah et al. the decrease in tensile strength is due to the poor adhesion of the filler-matrix and the agglomeration of filler particles [21].

| Figure 1. Effect of filler loading on the tensile strength of the HPDE composites |

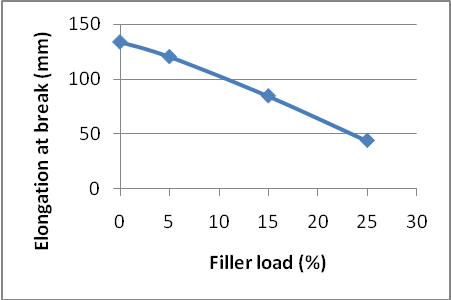

3.1.2. Elongation at Break

- Elongation at break is a reflection of the ductility of a material, a direct opposite of brittleness.It can be seen from Fig.2 that the elongation at the break for the composites decreases with increasing filler loading. Increased filler loading in the HDPE matrix resulted in the stiffening and hardening of the composite. This reduced its resilience and toughness, and led to lower elongation at the break [22]. The reduction of the elongation break with the increasing filler loading indicates the incapability of the filler to support the stress transfer from polymer filler to matrix. This increase in hardness resulted in decrease in ductility of the material. Hence, as filler content increases, the ductility decreases [23].

| Figure 2. Effect of filler loading on the % elongation at break of the HPDE composites |

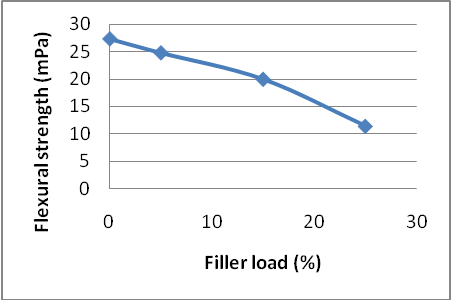

3.1.3. Flexural Strength

- The flexural strength of filled samples is observed to be lower than the unmodified sample as shown in Fig.3. This decrease in flexural strength could be attributed to the low rigidity and stiffness as a result of uneven dispersion and distribution of the fillers in the polymer matrix, which inefficiently hinders chain movement during deformation.

| Figure 3. Effect of filler loading on the flexural strength of the HPDE composites |

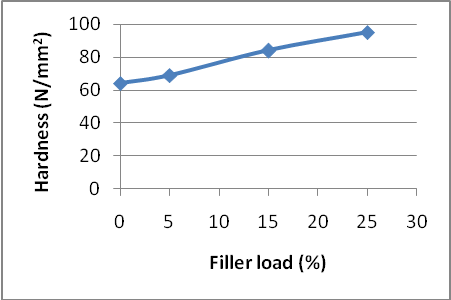

3.1.4. Hardness

- It is observed that the hardness increased with increase in filler loading as seen in Fig. 4 below. The increase in hardness may be attributed to the strengthening effect of the filler incorporated into the polymer matrix. Fillers are usually added to polymeric materials to improve their rigidity and strength. This is attributed to the nature of the filler. The higher the percentage of the fillers incorporated, the harder the material, and the more rigid it becomes. This is evident even from the results obtained for elongation at break, a direct opposite of hardness, which was noticed to decrease with increase in filler content.

| Figure 4. Effect of filler loading on the hardness of the HPDE composites |

3.2. Optical Microstructure of Snail Shell Powder Filled HDPE Composites

- The micrographs of the filled polymer composites are shown below.

4. Conclusions

- The addition of snail shell powder as filler into high density polyethylene (HDPE) resins to produce polymer composites was successful. The use of this filler leads to an increase in the hardness of specimens. However, one can observe a decrease in the tensile strength and the corresponding strain; the maximum tensile strain at yield decreases rapidly, too. The above results and the results reported in the literature demonstrate that this phenomenon is typical of natural fillers. The variations in hardness depend to a greater extent on the filler type and its properties – the filler either increases the samples hardness. Thus, the mechanical properties of the composites produced were found to depend on polymer matrix-filler interaction, particle size and distribution of the fillers particles within the matrix.Generally it is observed as the filler load increased the stronger the product became and the quantity greatly increased but the elastic nature reduced a little. So it is expedient that the ratio of HDPE to snail shell powder would be observed to have a perfect desired shape, strength, and elastic nature, smooth and brighter colour.This study has also pointed out the advantages of using snail shell powder as filler for high density polyethylene which has a vast application especially in the production of drainage pipes. Hence, from the results obtained, it can be suggested that snail shells which are agro wastes, cheap, available and eco-friendly should be used as filler in the production of plastics since they are much economical, effective and more viable. The plastics produced would decompose readily on disposal.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML