Sh. M. Mammadov1, S. V. Rzayeva2, O. H. Akperov3, E. N. Ahmadov2, T. N. Agayev1, E. O. Akperov3, R. F. Khankishiyeva1, S. Z. Malikova1, R. R. Mammadova4

1Department of Radiation Chemistry and Technology of Polymers, Institute of Radiation Problems, ANAS, Azerbaijan

2Department of Electromechanic, Azerbaijan State University of Oil and Industry, Azerbaijan

3Department of High Molecular Compounds Chemistry, Baku State University, Azerbaijan

4Departament of Composition Materials, Azerbaijan Technical University, Azerbaijan

Correspondence to: Sh. M. Mammadov, Department of Radiation Chemistry and Technology of Polymers, Institute of Radiation Problems, ANAS, Azerbaijan.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

It was studied the role of 4,4-dithio-bis-phenylmaleimide (DTBFM) and metal oxides (CaO, MgO, ZnO, CdO) in EPM-NBR polymer system under radiation peroxide vulcanization. With the help of mechanochemical analyzes, the elastomeric mixtures were plasticized at low temperatures with the participation of metal oxide. It was shown by the method of sol-gel analysis that the cross-linking of EPM-NBR polymer system proceeds slowly in the absence of metal oxides, the acceleration of crosslinking process of EPM-NBR polymer systems is observed only in the presence of MgO and ZnO. The spatial network parameters were determined: emergence of the yield of cross-link (1\Mc) and crosslinked molecules (1\Mnτ) in the presence of DTBFM. 2,4-diamino-6-phenyl s-triazine (DAFST) was used as the sensitizer. It was established that from the obtained combinations of the sensitizer (DAFST), the accelerator of crosslinking of DTBFM at 500 kGy dose of irradiation, forming cross-links of C-C bonds, provides elastomeric materials, resistant to aggressive media.

Keywords:

Ethylene-propylene rubber, Nitrile butadiene rubber, Gamma irradiation, Metal oxide, Vulcanization, Polymer

Cite this paper: Sh. M. Mammadov, S. V. Rzayeva, O. H. Akperov, E. N. Ahmadov, T. N. Agayev, E. O. Akperov, R. F. Khankishiyeva, S. Z. Malikova, R. R. Mammadova, Influence of Composition and Structure on the Property of Radiation-Chemical Vulcanizates on the Basis of the Combination of Copolymer of EPM-NBR in the Presence of Bis - Phenylmaleimide and Triazine Compounds, American Journal of Polymer Science, Vol. 8 No. 1, 2018, pp. 7-16. doi: 10.5923/j.ajps.20180801.02.

1. Introduction

Ethylene-propylene rubber (EPM) is one of the most promising general-purpose rubbers. EPM vulcanization is carried out mainly by organic peroxides in the combination with sulfur or some unsaturated elastomers [1-3].Due to the fact that EPM is a saturated elastomer, its vulcanization causes certain difficulties.For obtaining vulcanizates with high mechanical properties, it is necessary to combine EPM with diene rubbers, having increased unsaturation. As a result, a higher rate of vulcanization allows the vulcanizing agent, in particular sulfur, to be completely excluded from the elastomer formulation [4].It should be provided higher vulcanization rate at the combination of EPM with diene elastomers, having increased unsaturation.The interaction of elastomers with low-molecular compounds is an important issue in the radiation chemistry of elastomers, since radiation vulcanizates based on pure polymers, do not possess necessary complex of operational properties and, therefore, do not find practical application.It is known [5] that the type of oxide metals has an impact on the speed and properties of vulcanizates. It especially emerges at cross-linking of EPM-NBR copolymers with maleimides, where the role of oxide is reduced with the main formation of additional chemical bonds of adsorption type that contribute to an increase of tensile strength at break in the vulcanizates. Moreover, the proportion of these bonds is higher, the larger is the specific surface area of metal oxide [6, 7].It can be assumed that, the type of oxide will also influence on the rate of crosslinking of mixtures and the properties of obtained vulcanizates at the vulcanization of EPM-NBR copolymer with 4, 4-dithio- (bis) -n-phenyl maleimide (DTBFM). In all likelihood, the role of oxide in this system is more diverse: firstly, it can cause activation of double bond of both the elastomer and the vulcanizates.For the most elastomers, the rate of crosslinking is reported in the presence of carbon black (CB), and the sensitizing effect depends both on the nature of the filler and on its concentration. [1, 8, 9].According to the authors [2, 7, 10, 11], the observed effect in radiation cross-linking is due to the formation of a chemical bond between the surface of carbon particles and the molecules of elastomer, herewith the rate of cross-linking depends on the chemical nature of the surface of carbon black. The most active CB is furnace.With participation of the sensitizing agents (DAFST), kinetics of the cross-linking of the combination of EPM-NBR with bis-maleimide (DTBFM) significantly differs from the kinetics of peroxide vulcanization, the kinetics of sulfur vulcanization. The characteristic features of this process are the low content of non-saturation in the polymer chain.The use of accelerators (DTBFM) of active groups of metal oxide and sensitizers DAFST made it possible to significantly change the rate and properties of the interaction of DTBFM and DAFST with elastomers in order to obtain vulcanizates, containing cross-links of different nature and possessing better technological characteristics.It was of interest to study the features of cross-linking of elastomeric mixtures based on a combination of EPM-NBR in the presence of bis maleimide (DTBFM) and diaminophenyl sim-triazine (DAFST) sensitizer in the presence of metal oxide in peroxide-radiation vulcanization.

2. Method and Object of Research

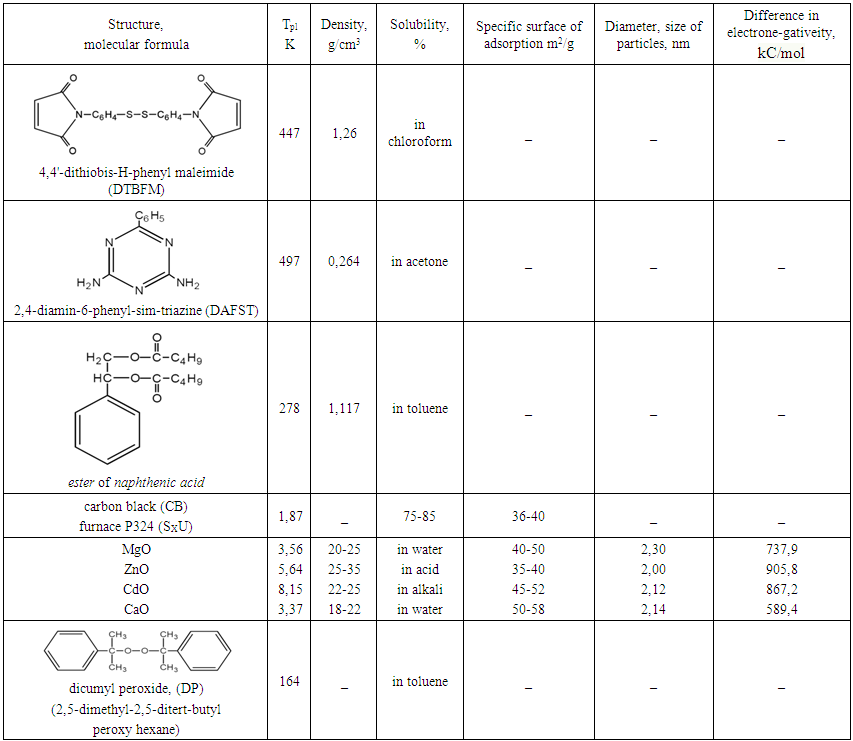

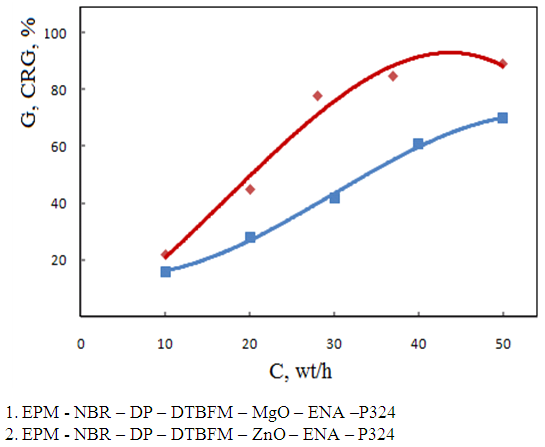

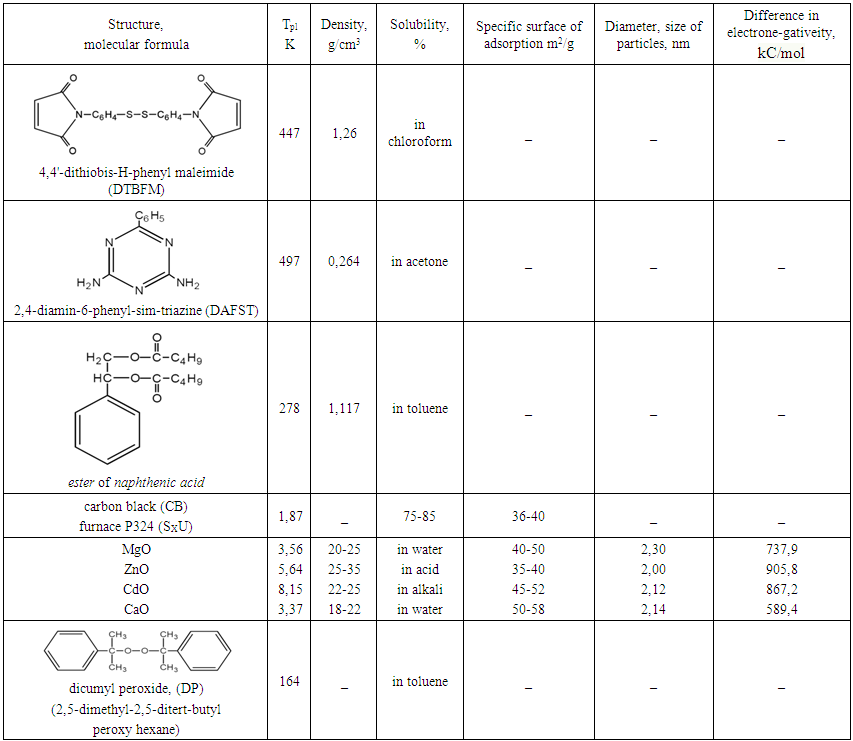

The copolymer of synthetic ethylene-propylene rubber (EPM-50, Russia) was taken as a research object and it was obtained catalytic copolymerization of ethylene and propylene in the presence of complex that forms catalysts. The content of bound propylene is 36-50%. For modifying EPM with unsaturated elastomer, butadiene-nitrile rubber (NBR-40, Russia) was used at the ratio of 60:40.According to the result of study carried out by the method of Fourier-spectroscopy in butadiene polymer part at 303K polymerization, the isomeric composition of the double bonds in the polymer is 1,2-isomer 14,3%; 1,4-isomer 14,8% and trans 1,4-isomers 70,9%. For the cross-linking of polymer system EPM-NBR, it has been used the crosslinking agent of dicumyl peroxide (DP, 2,5-dimethyl-2,5-tert-butyl peroxyhexa-ne), which on the one hand, is stable enough and safe under the conditions of work, and on the other hand, relatively easy decomposes at ordinary temperatures of vulcanization.Metal oxides for the study were chosen depending on the magnitude of the difference in electronegativity, which determines polarizing ability of oxide, as well as their chemical activity in cross-linking. The adsorption capacity of oxides, which is related to the specific surface area, was also taken into account [12, 13].As it is known, in order to achieve the optimal properties of vulcanizates, rather large doses are required, that increase the cost price of materials and the using possibilities of peroxide-radiation vulcanization, instead of sulfur vulcanization.Introduction allows decreasing irradiation doses without deterioration of the basic properties of vulcanizates by taking into account compatibility with the example of amino and nitrogen groups, capable of interaction with the oxide groups of elastomers. In connection with the foregoing, in polymer system, it seems appropriate to reduce the radiation dose of 2,4-diamino-6-phenyl-sim-triazine sensitizer (DAFST), which ensures operation time of elastomer under the conditions of temporary influence of heat, light, and oxygen.The use of 4,4-dithio- (bis)-n-phenylmaleimide for peroxide vulcanization as a vulcanization accelerator and determination of its influence on the spatial network parameter and vulcanizate properties are of practical interest.In order to facilitate the processing of the polymer mixture in the displacement stage, it was introduced a plasticizer of the ester of naphthenic acid (ENA) with the aromatic structure.According to the existing concepts [1, 13], necessary reinforcement is the formation of a structural network in a macromolecule (chain structures), on which a spatial network is adsorbed. Therefore, it was of interest to investigate the influence of carbon black (P324) on the plasto-elastic properties of polymer systems. At last, furnace CB was introduced into the system with high viscosity. With this order, introduction of CB significantly increases the shearing forces at mixture and the dispersion of CB is improved. The introduction of carbon black identifies the crosslinking process. While choosing CB (furnace) in the system, attention was mainly paid to the particle diameter, specific surface area and density (Table 1). | Table 1. Basic physical parameters of the components of low molecular compounds |

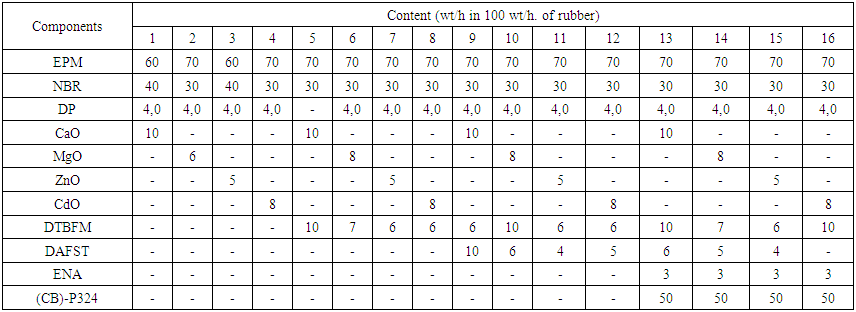

The reactionary shift of EPM-NBR and the vulcanizing system were carried out on laboratory rolls while simultaneously loading the relevant components. The ratio of rubbers was 70:30 (wt./h.). The amount of vulcanizing system was calculated taking into account the concentration of the brand of EPM and NBR (Table 2). | Table 2. Composition of the studied polymer systems EPM-NBR |

As a source of radiation energy, the radioactive isotope Co60 was used for the radiation vulcanization process.Radiation vulcanization in a molding tool is carried out according to the usual technological scheme, accepted in the production of molded elastomeric materials. After the rolls, the workpiece is given to pressing portion, where the elastomeric mixture is put into the molds after cutting. Molding of the product is carried out in the press within 5 minutes at 373-423K.Irradiation was carried out at the dose range of 0-700 kGy at radiation dose rate of 6.7 Gy/s.The absorbed dose in the test samples was calculated by comparing the electronic densities of the investigated and dosimetric systems [14, 15]. Subsequently, the molding tool is put into the chamber, the container, where irradiation is carried out, at the same time we comply with the condition that the total thickness of the product in molding tool does not exceed 60 mm. The intrinsic viscosity of irradiated samples was determined in toluene at 293 K by the known method of Ubellohde capillary viscometer. The calculation was carried out using the Mark-Hauwink equation [η] = KMα at the value of the constant K=1,9·104 and α=0,64 (for toluene). The nature of the interaction of metal oxides with an elastomer was judged by the change of yield of the number of cross-links (n'c), calculated from the results obtained by the method of equilibrium swelling in toluene [16, 17]. The surface of radiation non-polarized vulcanizates (EPM-NBR) containing metal oxides was studied by the method of scanning microscopy (JEOL JSM 7800 F, Japan).The parameters of the spatial network of samples were determined by sol-gel analysis and calculation was carried out by the Flory Rehner formula [18].The assessment of influence of metal oxides and cross-linking systems on the physico-mechanical and dynamic properties was carried out by the following indicators: conventional tensile strength and elongation after break. (AUTO GROPH AGH-H Company Shimadzu Japan)The rheological parameters and plasticity of vulcanizates were established on Mooney viscometer (BM-2004 firm Cibi Sri-Instruments) and the PSM-2 plastomer (Germany).

3. Results and Discussion

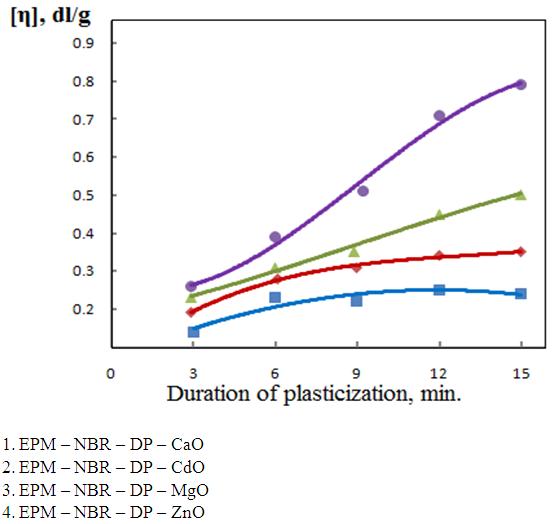

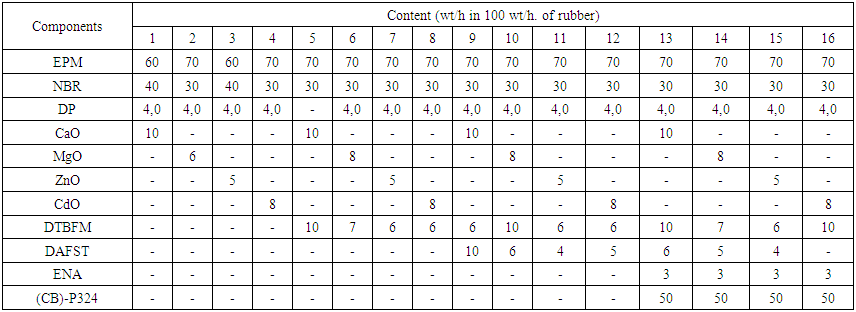

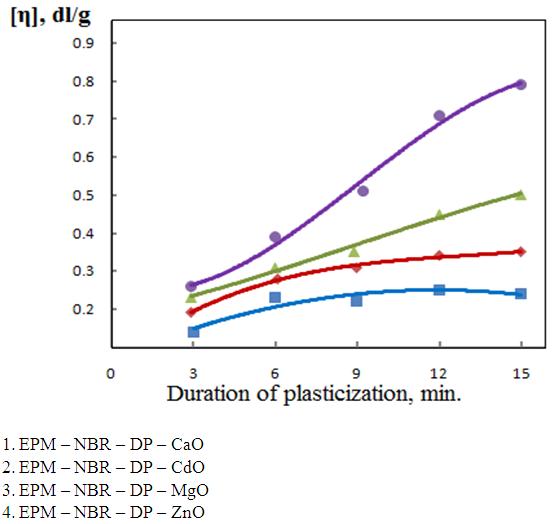

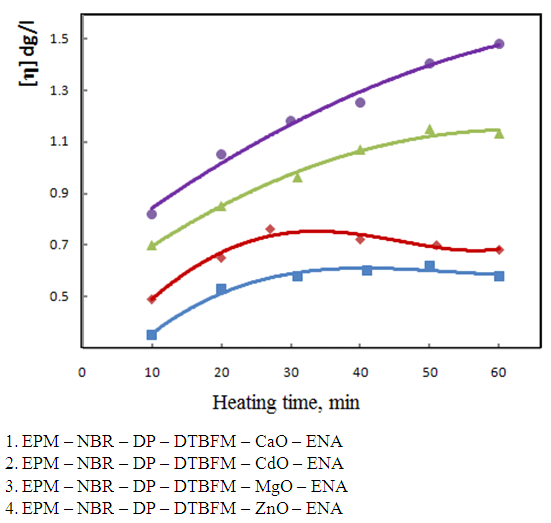

Plasticization of polymer systems. Method, evaluation in mechanical processing in low temperature conditions. EPM and NBR are characterized by a very weak tendency to mechanical destruction, which is consequence of the high mobility of their molecular chains.According to the generally accepted point of view [19], the plasticization of EPM and NBR is accompanied by processes of destruction and structuring. Experimental data on the behavior of polymer systems (EPM-NBR) in low-temperature processing on rolls show that, the accelerators and sensitizers usually consist of two components of different structures, with the use of low-molecular peroxides: principle of any technological characteristics and properties of polymer systems (EPM-NBR) will depend on the content of the sol and gel fraction after plasticization.The study of the influence of vulcanizing systems with the participation of metal oxide on the intrinsic viscosity [ηchar] showed that, in comparison with other used oxides, there is observed an increase in the molecular weight, containing zinc oxide, which is released from other used metal oxides CaO, MgO and CdO, depending on the time of plasticization (fig.1, table 2 system 1-4). The results of the study showed that the process of structuring the combination of EPM-NBR at peroxide vulcanization proceeds slowly in the absence of oxides. Acceleration of the process of EPM-NBR vulcanization is observed only after the duration of plasticization for 9-15 min. at the temperature of 313-320K (Figure 1, Table 2, System 1-4). | Figure 1. Kinetics of the yield of intrinsic viscosity at the mixing polymer systems on rolls (423K) |

Samples of Group I contain 38-51% of dense gel, the amount of sol fraction in these samples is small, their Mooney viscosity practically decreases in the initial period of rolling, and then remains constant (Table 3, System 1-4). | Table 3. Plasto-elastic characteristics of polymer systems after plasticization on rolls |

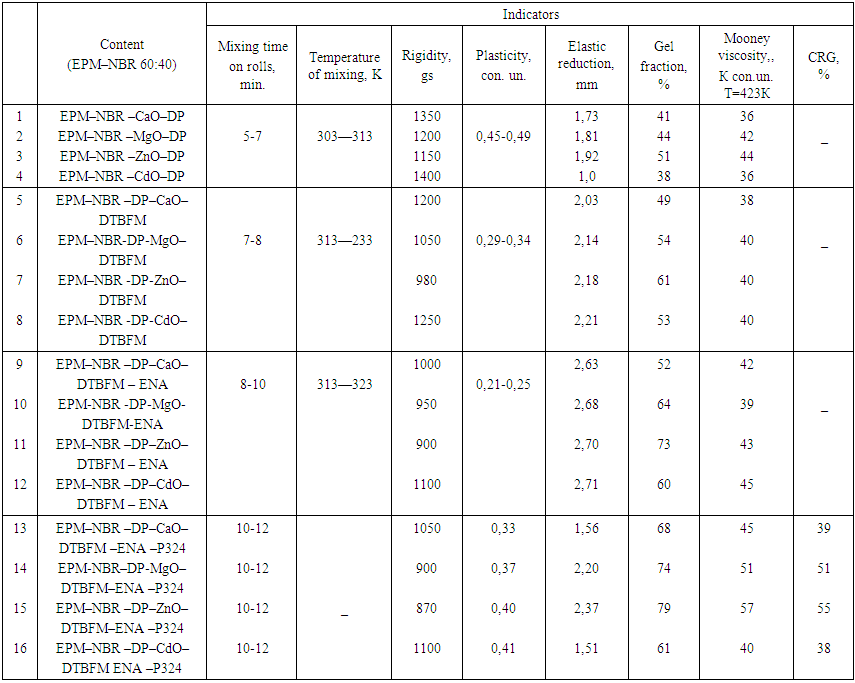

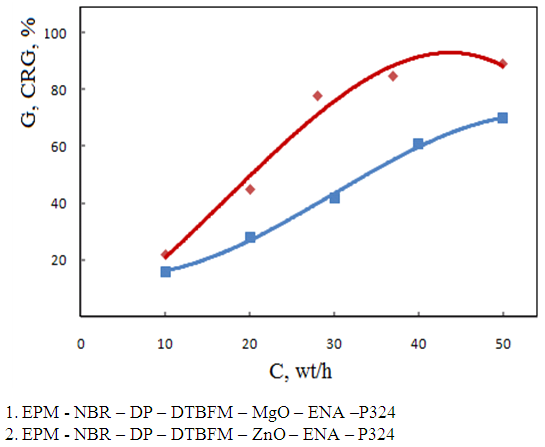

From the data (table 3), it is seen that, the dependence of plasto-elastic properties of samples in the presence of CdO and CdO has less elastic recovery and plasticity. At the same time, the rigidity remains unchanged. More (1,0; 1,75) decrease in rigidity is observed with the participation of magnesium oxide and zinc (1150,1200 hr).As the analysis shows (table 3, system 5-8), the introduction of crosslinking accelerator of DTBFM in the polymer system leads to a sharp change in the plasto-elastic properties, there is observed deceleration in the destruction process. Increasing the time of mixing and dosage of components sharply increased the growth of gel fraction. The influence of low temperature (313-323K) leads to a minimum increase in Mooney viscosity and a decrease in rigidity. The amount of sol fraction in these samples is small, and its average molecular weight is 5·104, mol/cm3.The influence of oil plasticizer on the properties of NBR was considered in [8]. Plasticizer (ENA) was introduced to achieve optimal plasto-elastic properties of polymeric system (see table 2, systems 9-12). ENA is essentially a general-purpose plasticizer. They have a good combination of properties, well combined with saturated and unsaturated elastomers. The presented data (table 3, system 9-12) show that the main structural and rheological units of the gel fraction – the micro-gel particles that appear in the stage of mixing, are resistant to large shear deformation.Dependence of Mooney viscosity of the rolled samples on the duration of the plasticization (5-8 min.) is explained in the stress field, when ENA is introduced into the polymeric systems forming microgel particles. It leads to a change in the polymer structure and plastic-elastic properties of polymer systems at 323K, which is accompanied by a decrease in rigidity and an increase in Mooney viscosity with the help of warming with the participation of sensitizing and plasticizing additives DTBFM-MeO- ENA.Rheological method of evaluating the effectiveness of the crosslinking acceleratorThe rheological method makes it possible to obtain important information on the structural features of high molecular compounds, to establish a connection between the features of the molecular structure of polymers by their technical properties. All this causes the great interest in the rheological method of polymer research as an effective reliable and fast method in solving the above problems It can be seen from the results of polymer systems in the nonpolarized mixtures that, the yield of intrinsic viscosity [η] has different reactivity at the cross-linking of EPM-NBR DTBFM with the participation of metal oxides (Fig. 2, Table 2, System 9-12). | Figure 2. Dependence of intrinsic viscosity of polymer system on heating period at 423K×60 min |

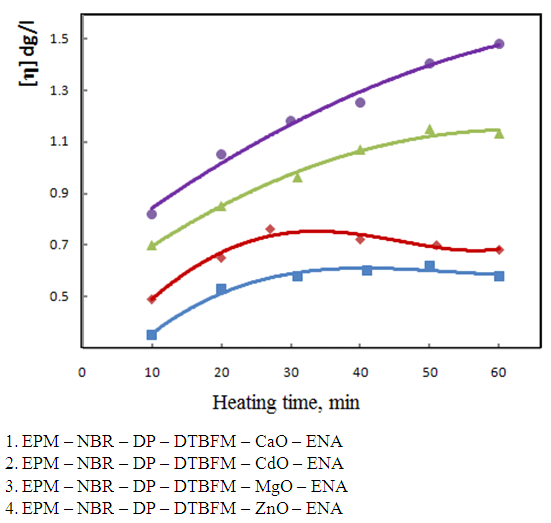

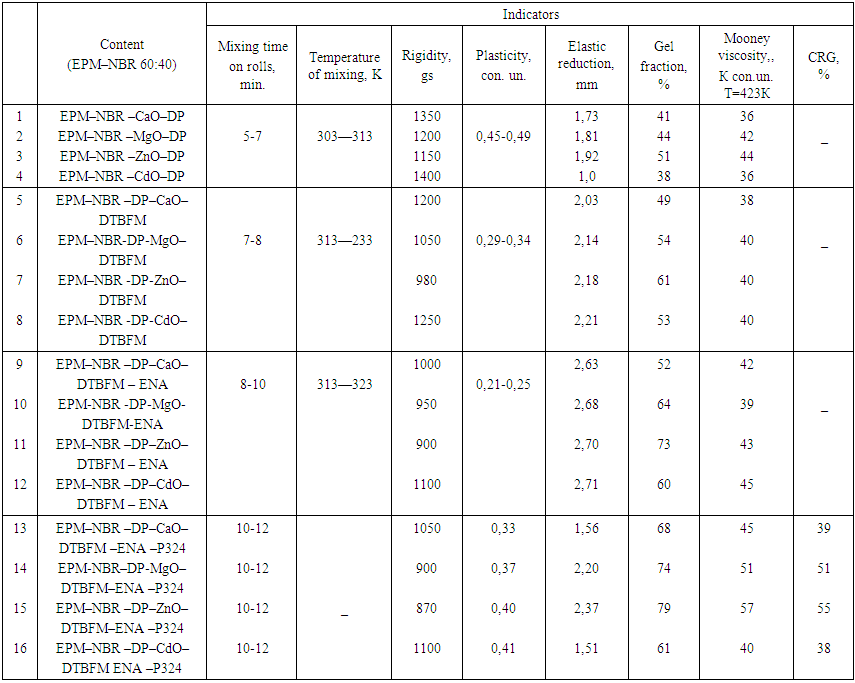

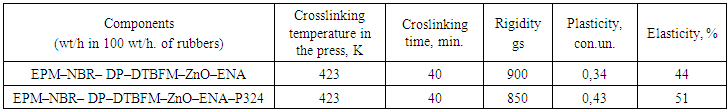

Change in viscosity with the required level leads to a significant change in the molecular weight of polymer systems. The most intensive growth of molecular weight is different in polymer systems in the presence of MgO and ZnO. Since the activity of oxides is determined by the ionization energy [20], the oxides of magnesium and zinc are highly active compounds, but CaO and CdO are not active.As it is seen from Table 3 (see table 2, systems 13-16), the behavior of CB is different in mixtures. For mixtures containing MgO and ZnO, there is observed an increase in Mooney viscosity, a decrease in rigidity, and minimum increase in the plasticity of the polymer systems. One of the reasons for increasing Mooney viscosity of filled mixtures in comparison non-filled ones, may be the presence of strong bonds between the structure of carbon black while using activators of metal oxides.Thus, with the participation of metal oxides, DTBFM, ENA and CB, it has been provided the best plasto-elastic and rheological parameters of polymer systems during mechanical processing on rolls (Table 2 system 14, 15). This is explained by the fact that as the molecular weight increases, their structural and plastic-elastic properties change.The degree of interaction of the polymer systems with the CB was judged by the content of the carbon of rubber gel (CRG), which was determined after extraction of the toluene samples at 293K within 24 hours. It was believed that since investigated polymer systems are characterized by approximately the same molecular weight and relatively narrow molecular weight and the molecular weight distribution (MWD), the degree of interaction of the EPM-NBR with the CB is influenced mainly by the nature of the polar units in the polymer chains.Figure 3 (system 14, 15) presents data on the change in the content of CRG in polymer systems with different molecular structures, depending on the degree of filling of polymer mixtures. The maximum CRG is formed in a polymer system filled with 10-50 wt/h. CB. The content of CRG remains practically constant at a higher degree of filling. | Figure 3. Dependence of the content of carbon-rubber gel in polymer systems on the dosage of carbon black P324 |

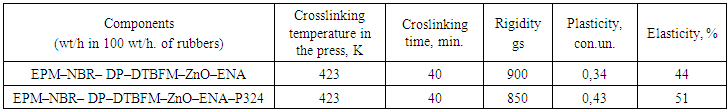

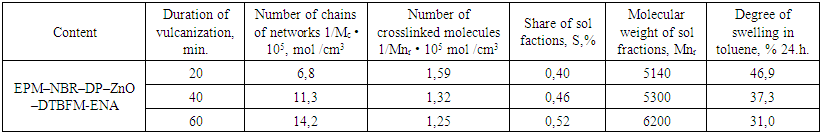

Thus, the best structurally dispersive characteristics can be obtained with presence of furnace CB, that under certain conditions allows improving the properties of both non-vulcanized and vulcanized polymer mixtures (viscosity).The choice of temperature for the crosslinking process is important, since these factors determine the mechanism of cross-linking of the polymer composition, the energy intensity of the process, the vulcanizates and the physical properties of the obtained vulcanizates. From the data presented in Table 4, ENA provides an increase of the plasto-elastic properties of the mixtures at crosslinking in the presence of DTBFM. Introduction of ENA to the mixture decreases the rigidity after heating during 40 minutes by 15-20%, and there is observed an increase in the plasticity of the filled and non-filled vulcanizates (Table 4). | Table 4. Plasto-elastic properties of filled and non-filled vulcanizates |

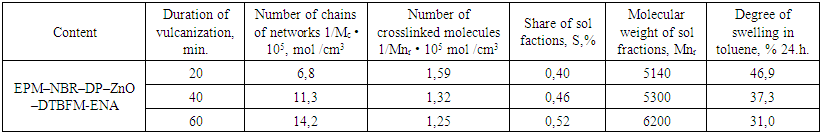

Low rigidity of the filled samples of polymer systems may be associated with a stronger interaction of EPM-NBR macromolecules with CB (P324) and more developed carbon chain structures.The study of the spatial network of peroxide vulcanizates on the basis of polymer systems EPM-NBRSince EPM does not have double bonds, it cannot be crosslinked by conventional vulcanization systems. Especially, compatibility and EPM with unsaturated elastomers and peroxides are of great practical importance.The character of the parameter of the spatial network of vulcanizates improves and its speed increases due to the introduction of not larger number of vinyl groups and reactive low-molecular components (DTBFM) into the chain.It can be seen from the presented data (Table 5) that, the acceleration of structuring process of polymer systems occurs in peroxide samples within 20-40 min heating (432K). The highest yield of the number of network chains (1/Mc) is observed at 60 min (14.2 × 105, mol/cm3). The same change is observed in the molecular weight of the sol fraction (1/Mnr). Simultaneously it should be noted that the low yield of the number of crosslinked molecules (1/Mnr) is probably associated with the consumption of the molecule in 1cm3 vulcanizate of new cross-links, which increases the density of the spatial network of vulcanizates. This is confirmed by a decrease in sample mass after swelling in toluene (Table 5). Results of the study show that homogeneous distribution of the cross-links (C-C) is observed around the polymer molecules at the vulcanization of non-filled elastomeric mixtures (EPM-NBR) with dicumyl peroxide (DP). | Table 5. The main structural parameters of a network of peroxide vulcanizates on the basis of polymer systems EPM-NBR at 423K x 60` |

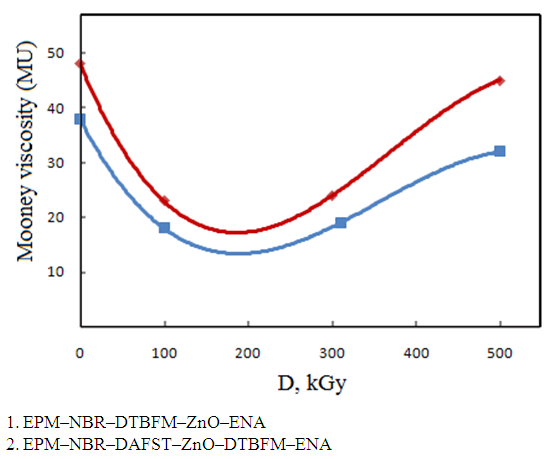

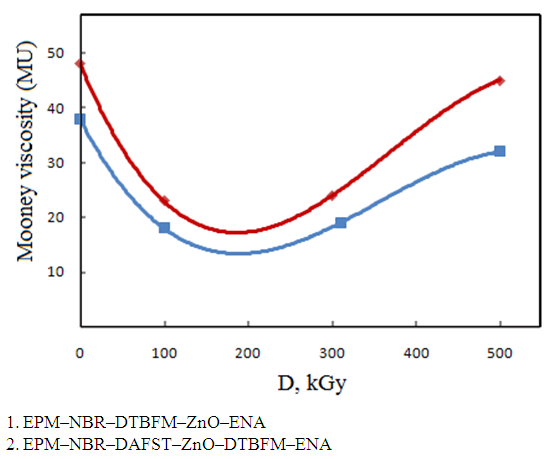

Assessment of the influence of sensitizers on the structural parameters of networks of radiation vulcanizatesThe use of the sol-gel method is of interest for estimating the effectiveness of γ-irradiation influence on the structure and composition of polymer systems (EPM-NBR), and it allows evaluating the influence of γ-irradiation on the cross-linking of polymer systems in contrast to peroxide vulcanizates.As it will be shown below, rather large doses are required in order to achieve the optimum properties of vulcanizates. The introduction of DAFST allows decreasing the dose of irradiation without deterioration of the basic properties of vulcanizates.One of the effective ways to solve this problem is the quality of the application of methods of decreasing the radiation dose which is necessary for obtaining optimal properties and, consequently, increasing the productivity of the process in the presence of polyfunctional monomers (PFM). Triazine compounds of 2,4-diamine-6 phenyl-sim triazine (DAFST) and maleimides, which are the main components of the polymer systems of EPM-NBR are of greatest interest among the compounds of this type. Therefore, it seems necessary, first of all, to study the influence of DAFST and DTBFM on the radiation cross-linking of polymer systems.From the data presented in Fig. 4 below, it can be seen that irradiation of samples (1, 2) exerts a great influence on crosslinked polymer systems. At the same time, in the system of low- molecular DAFST and DTBFM there is observed increased Mooney viscosity. Thus, the Mooney viscosity of crosslinked samples (1) increases by 30-40% after irradiation with a dose of 500 kGy. A less abrupt change in irradiation process of the properties of crosslinked samples (2) can be explained by the presence of labile cross-links in them. | Figure 4. Influence of duration of irradiation on Mooney viscosity of polymer systems of EPM-NBR |

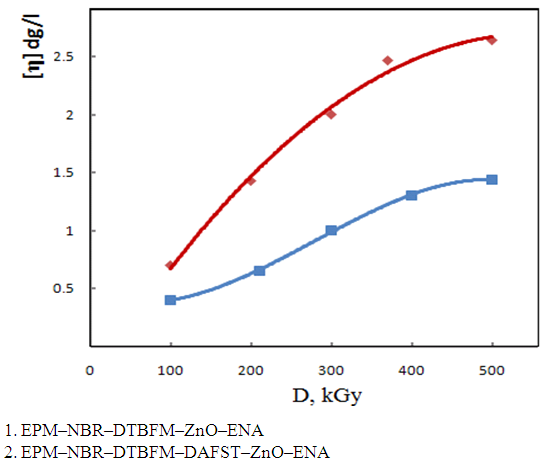

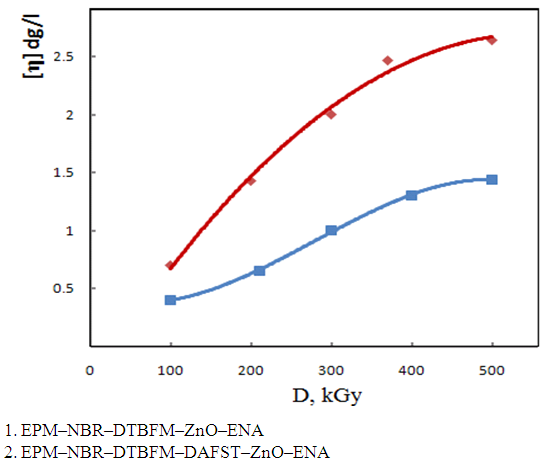

The experimental data show that the protective influence of DAFST, which has a polar group of amines and nitrogen in the molecule, is due to two reasons: on the one hand, amine enters into the role of the inhibitor of chain oxidation processes with the participation of oxygen of initiate radiation and conductive to additional cross-linking of polymer systems, on the other hand, protection is a consequence of the tendency of the amine to charge transfer, so its concentration remains unchanged [21]. It is very important to obtain fast and reliable information on the molecular weight of polymer systems for a preliminary evaluation of the properties of radiation vulcanizates and application fields of irradiated cross-linked materials. One of the most reliable and accurate methods for evaluating the molecular weight is the viscometric method.Fig. 4 shows the data on the change in the intrinsic viscosity of vulcanizates depending on irradiation dose. From Fig. 5 it follows that polymer systems (1) at low doses of 100 kGy have an intrinsic viscosity of 0.4. Molecular weight increases (1.4) with the growth of absorbed dose.Molecular weight increases at the irradiation of polymer systems together with the participation of DAFST and DTBFM in the dose range of 100-500 kGy. The intrinsic viscosity (IV) increases from 0.7 to 2.6. The IV decreases with an increase of the obviously absorbed dose above 500 kGy, and there occurs the destruction of the main chains of polymer systems, as evidenced by a decrease in the IV of the toluene solution of the polymer. | Figure 5. Influence of duration of irradiation on the intrinsic viscosity of polymer systems |

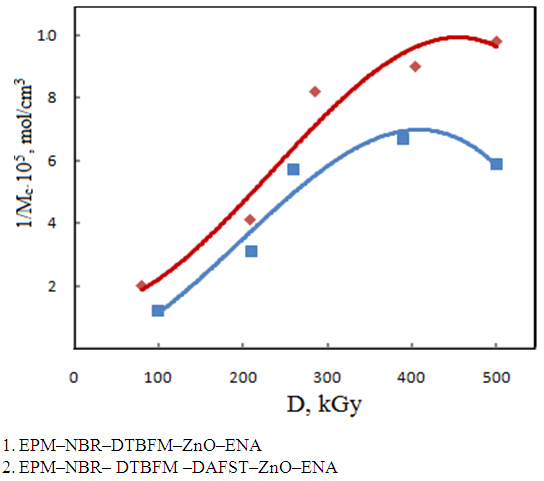

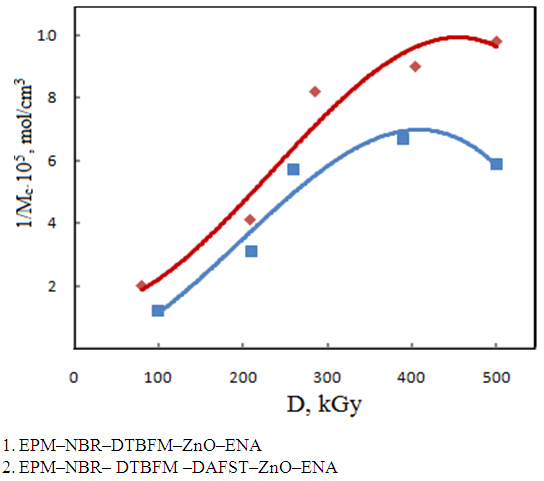

Analysis of the parameters of radiation-chemical yields (GМС) shows that, a spatial network is formed in the samples at the irradiation of polymer systems without DTBFM additives (1). The introduction of DAFST causes an acceleration of the crosslinking process of polymer systems. The highest speed of cross-linking of mixtures and the greatest number of cross-links in the sample (Fig. 6) is obtained by bringing together DTBM and DAFST (10·105, mol/cm3). Thus, DAFST simultaneously decreases the absorbed dose, herewith, irradiation of effective sensitizers appears under the indicated conditions. | Figure 6. Dependence of the number of network chains in the sample depending on irradiation dose |

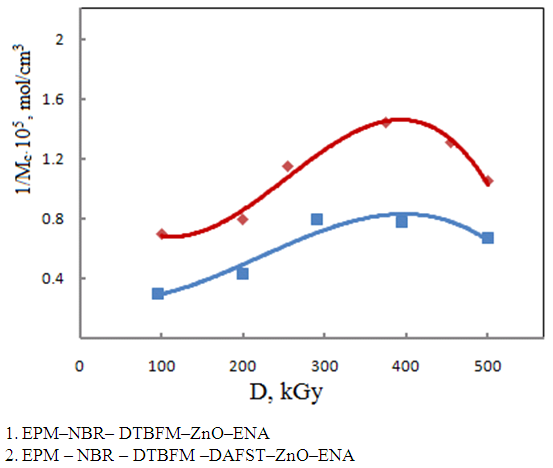

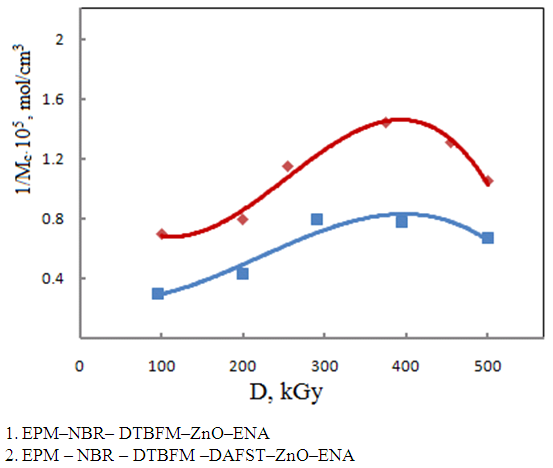

The concentration of the yield of crosslinked molecules (GMnτ) in the elastic part of the sample becomes smaller when absorbed dose is increased.The results of the sol-gel analysis of irradiated polymer systems showed that the destruction processes are more likely to occur in the elastic phase (Fig. 7) at a dose of 300-350 kGy. In the elastic phase, the intramolecular cross-linked molecules are likely to be consumed by the formation of additional cross-links between the elastomer molecules.  | Figure 7. Influence of the duration of irradiation on the yield of the number of crosslinked molecules (1/Mnr) of the samples on the basis of the polymer systems of EPM - NBR |

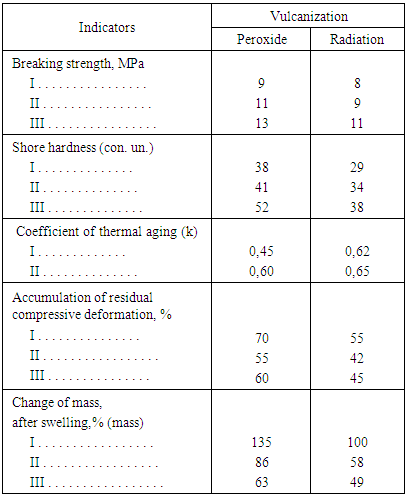

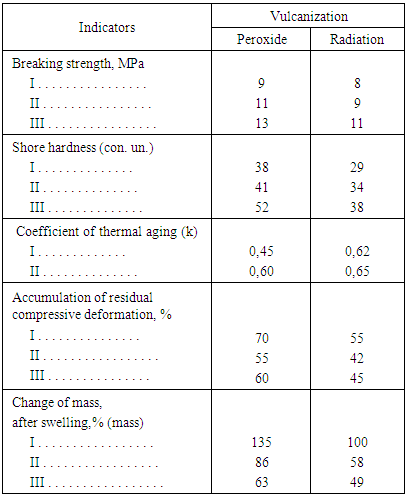

Features of radiolysis of multicomponent polymer systemsThe interaction of elastomers with low-molecular additives is an important issue in the radiation chemistry of elastomers, since radiation vulcanizates based on pure polymers do not possess the necessary complex of operating properties and therefore do not find practical application [22-25].For obtaining elastic materials by the method of radiation vulcanization, furnace carbon black (P324), of which nature and dosage was chosen according to the individual characteristics of the polymer, was introduced into polymer system.Radiation vulcanization in molding tools was produced according to the usual technological scheme accepted in the production of molded elastomeric materials. The formation of materials (plates) was carried out in the press during 5 minutes at 373 K, and then the composition was irradiated with γ-source of Co60. Analysis of the physico-mechanical characteristics radiation vulcanizates shows that C-C bonds are formed from the obtained combination of sensitizers (DAFST) and crosslinking accelerators (DTBFM), forming carbon rubber gel. Consequently, when carbon black (P324) is introduced into the cross-linked polymer system between polymer and carbon black, there are formed adsorption bonds that physico-mechanical characteristics of vulcanizing samples increase the strength by 15% at the dose range of 100-600 kGy. Consequently, when carbon black (P324) is introduced into the crosslinked polymer systems, between the polymer and carbon black, as a result of the interaction of the filler particles with polymer systems, adsorption bonds are formed, that the physico-mechanical characteristics of the samples vulcanized at a dosage range of 100-600 kGy increase the strength by 15%. Simultaneously with the increase in strength, the percentage elongation decreases.For elucidating the influence of temperature and operating conditions in the work, elastomeric molding materials were carried out by comparative tests of samples of obtained peroxide and radiation vulcanization in corrosive media (Table 6), where sealing rig pumps and other devices of the oil industry work. The obtained data indicate that the radiation degree in the samples has a swelling degree, the accumulation of residual compression deformation is smaller, and the coefficient of thermal aging in sea water is higher than that of peroxide samples. The tensile strength after contact with the medium was lower for radiation vulcanizates than peroxide. | Table 6. Mechanical properties of the filled peroxide and radiation samples based on polymer systems of EPM-NBR obtained in the presence of DTBFM and DAFST, after being used in seawater (1) with oil-bearing (2) and clay solutions (3) (test mode 423K x 72 h.) |

Thus, the results of analysis of conducted investigation allow us to conclude that one of the ways to improve the behavior of elastomeric materials based on the polymer systems EPM-NBR at peroxide and radiation vulcanization is the cross-linking of polymer systems by low-molecular reactionary compounds (DTBFM, DAFST, ZnO) through its partial crosslinking. However, the mechanism of radiation-chemical processes responsible for the observed change in properties is subject to further study.

4. Conclusions

When the saturated EPM is combined with the NBR, they have an increased unsaturation and, as a result, a higher vulcanization rate. The possibility of equal rates of crosslinking of both polymer phases is provided at the ratio of components 60:40.Unlike vulcanization of thiurams, direct proportionality is observed between the consumption of the cross-linking agent (DP), the number of formed cross-links and the increase in molecular weight. For this reason, it is likely that the DP decay proceeds homologously by the formation of radical products and crosslinking occurs by a radical mechanism.It has been found that triazine (DAFST) is a more effective sensitizer of radiation cross-linking of polymer systems based on the EPM-NBR.The effectiveness of the influence of DAFST and DTBFM was estimated by structural parameters. For this purpose, it has been determined the solutions of polymer system, gel swelling and the number of network chains formed was calculated by the Flory–Rehner formula.Mechanical indicators of radiation vulcanizates in accordance with their lower degree of cross-linking are lower than peroxide. A high degree of cross-linking at 423K promotes a greater heterogeneity of the spatial network, which is apparently explained due to an increase in structural defects. The heterogeneity of the structure is influenced by the DTBFM crosslinking accelerator and metal oxides and more homogeneous networks with large C-C bonds.Plasticization of the polymer systems of EPM-NBR-MeO at low temperatures (313-333 K) leads to profound changes in their structure and properties. It should be taken into account in all types of low-temperature mechanical processing of the EPM-NBR.The use of compounds with polar groups as an accelerator of crosslinking agents ensures the formation of heat-resistant cross-links in the process of vulcanization of polymer systems. DTBFB containing sulfur atoms, as well as initiators of the group of organic sulphides, which are simultaneously independent cross-linking agents, provides a high level of rheological and structural parameters of the vulcanizate network. ZnO, MgO is more active in the process of plasticization and cross-linking, except CaO and CdO, which cause the acceleration of the cross-linking process of EPM-NBR. In all probability, their differences are explained by electronegativity.

ACKNOWLEDGMENTS

This work supported by the Science Development Foundation under the President of the Republic of Azerbaijan-Grant № EIF-KETPL-2-2015-1(25)-56/10/1

References

| [1] | Sh. M. Mammadov, Fundamentals of the synthesis technology, processing and vulcanization of butadiene-nitrile rubbers, LAP. Lambert Ac. Germany (2015). |

| [2] | Sh. M. Mammadov, Radiation physics and chemistry of polymers, Germany, Saarbrucken, LAP Lambert Acad. Publishing, (2015). |

| [3] | J. Kruzelak, R. Sykora, I. Hudec, Sulphur and peroxide vulcanisation of rubber compound, Chemical Papers 70 (12) 1533–1555 (2016). |

| [4] | I. V. Garmonova, Syntetic Rubber. “Chemistry” (1986), Saint-Petersburg, 750 p. |

| [5] | O.V. Litvin, Basics technology of the rubber synthesis. “Chemistry” (1991), Saint-Petersburg 582 p. |

| [6] | D. Feldman, A. Barbalata, Synthetic Polymers: Technology, Properties, Applications; Chapman & Hall: London, (1996); pp 153-155. |

| [7] | Pat. I.2015 0103 AZE:ICU C08 9/02, L9/100, 2015. |

| [8] | Sh. M. Mammadov, S. V. Rzaeva, R. H. Mehdiyeva, H. N. Akhundzada, Structural parameters and dynamical properties of the radiative and peroxide vulcanizates based on EPM participation, American Journal of Polymer Science, (2016), pp.12-17. |

| [9] | J. George, K. T. Varguhese, S. Thomas, Dynamically Vulcanized Thermoplastic Elastomer Blends of Polyethylene and Nitrle Rubber. Polym. (2000), 41, 1507-1517. |

| [10] | Pat. I.2016 0028, AZE: ICU C08 L9/02, C07F 9/657. |

| [11] | K. Chatterjee, K. Naskar, Development of thermoplastic elastomers based on maleated ethylene propylene rubber (m-EPM) and polypropylene (PP) by dynamic vulcanization Express Polymer Letters Vol. 1, No. 8 (2007) 527–534. |

| [12] | T. Őzdemir, “Gamma irradiation degradation/ mo-dification of 5- ethylidene 2-norbornene (ENB)-based ethylene propylene diene rubber (EPM) depending on ENB content of EPM and type/content of peroxides used in vulcanization”, Radiation Physics and Chemistry, 77(6), (2008), pp. 787-793. |

| [13] | Chmielewski A. Haji Saeid. Radiation processing technologies: Past. Presentand future. Radiation physics and Chemistry. 71, 17-21, (2004). |

| [14] | Sh. M. Mammadov, J. Sh. Mammadov, Radiaton Chemical crosslinking of saturated elastomers with polymer peroxides, The fifth Eurasian conference nuclear science and ITS Application. 14-17 October, Ankara, Turkey. |

| [15] | A.E. Kornev, A. M. Bukanov. General technology of rubber. Moscow, Chemistry, 1994, p.420. |

| [16] | A.K. Pikaev, Modern radiation chemistry. Solid and polymers. Applied Aspects, 1988, p.448. |

| [17] | A. J. Swallow, Radiation Chemistry, Longman (1979), p.280. |

| [18] | Flory P. J., Rehner J.: Statistical mechanics of crosslinked polymer networks. II. Swelling. Journal of Chemical Physics, 11, 521–526 (1943). DOI: 10.1063/1.1723792. |

| [19] | Sh. M. Mammadov, S. V. Rzaeva, E.N. Ahmadov, J. Sh. Mammadov, Radiation-chemical modification of plastic elastomers. Journal of Radiation Researches. Vol.1, №1, p.63-68. |

| [20] | E. V. Kuznechov, S. M. Divchun, Practicum about physics and chemistry of polymers, Moscow, Chemistry (2004), p.380. |

| [21] | H.G. Dikland, T. Ruardy, L. Van der Does, A. Bantjes, New coagents in peroxide vulcanization of EPM, Rubber Chemistry and Technology, vol. 66, №5, (2003), p.693-711. |

| [22] | Sh. M. Mammadov, Radialise of the NBR rubber with polyvynilchlorid, High Energy Chemistry, 2010, Vol.44 №4, p.298. |

| [23] | A. Charlesby, Atomic radiation and polymers, Pergamon press, London, 1960. |

| [24] | Sh. M. Mammadov, Actual problems of radiation researches, Baku, Science 1991, p.211. |

| [25] | F. A. Maxlis. Radiation Chemistry of elastomers, Moscow, Atomizdat, 1990, p.196. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML