-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Polymer Science

p-ISSN: 2163-1344 e-ISSN: 2163-1352

2018; 8(1): 1-6

doi:10.5923/j.ajps.20180801.01

Novel Thermoplastic Vulcanizates Prepared by Dynamic Vulcanization: Undergraduate Experiments for Polymers

Zhaobo Wang, Baoxiang Wang, Zhiyan Guo, Tong Liu, Yalong Shao, Fanglin Du

College of Materials Science & Engineering, Qingdao University of Science & Technology, Qingdao, China

Correspondence to: Zhaobo Wang, College of Materials Science & Engineering, Qingdao University of Science & Technology, Qingdao, China.

| Email: |  |

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Novel thermoplastic vulcanizates (TPVs) based on high impact polystyrene (HIPS)/high vinyl polybutadiene rubber (HVPBR) blends were prepared by dynamic vulcanization where styrene-butadiene-styrene (SBS) block copolymer was used as a compatibilizer. The effect of SBS dosage on the mechanical properties of the TPVs was investigated. Compared with those of HIPS/HVPBR blends, the tensile strength, elongation at break and tearing strength of HIPS/HVPBR blend with 12 phr SBS incorporation were improved remarkably. The morphological evolution during the dynamic vulcanization was observed by field-emission scanning electron microscopy (FE-SEM). Energy dispersive X-ray microanalysis system (EDX) was used to confirm that the protruding particles in the etched TPV surface were the vulcanized HVPBR particles.

Keywords: Thermoplastic vulcanizate, Dynamic vulcanization, Morphological evolution, Compatibility

Cite this paper: Zhaobo Wang, Baoxiang Wang, Zhiyan Guo, Tong Liu, Yalong Shao, Fanglin Du, Novel Thermoplastic Vulcanizates Prepared by Dynamic Vulcanization: Undergraduate Experiments for Polymers, American Journal of Polymer Science, Vol. 8 No. 1, 2018, pp. 1-6. doi: 10.5923/j.ajps.20180801.01.

Article Outline

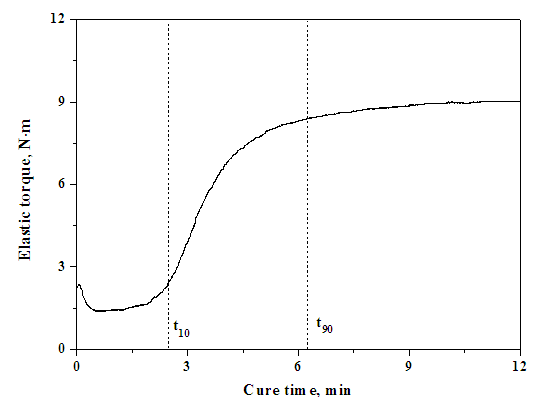

- 3.2. Mechanical Properties of the Dynamically Vulcanized HIPS/HVPBR Blends and HIPS/SBS/HVPBR Blends

- 3.2.2. Influence of SBS on the Mechanical Properties of the Dynamically Vulcanized HIPS/HVPBR Blends

1. Introduction

- Thermoplastic vulcanizates (TPVs), as a special case of thermoplastic elastomers (TPEs), are produced via dynamic vulcanization of blends of a rubber and a thermoplastic polymer in the presence of a vulcanizing system. [1-8] TPVs have the processing behavior of thermoplastics in a molten state but rubbery behavior at ordinary temperatures similar to rubber vulcanizates. Morphologically, the resulting TPVs are characteristic of finely dispersed, micrometersized, crosslinked rubber particles distributed in a continuous thermoplastic matrix. [9] Compared with those blends comprising of uncured or slightly crosslinked components, dynamic vulcanization possesses significantly improved mechanical properties that can be attributed to the stabilized morphology of rubber particles resulting from crosslinking. Because a thermoplastic and a rubber are usually incompatible, this will inevitably result in poor mechanical properties due to the gross phase separation and poor interfacial interaction. However, the further improvement of TPV properties can be achieved by the addition of compatibility components, which can effectively enhance the interfacial interaction. [10-14]The work presented here aims at the development of an integrated research-education activity on novel TPVs. Because of their unique characteristics, TPVs play a very important role in the applications of automotives, buildings, constructions, wires and cables, etc. In recent years, there has been great interest and significant progress in the preparation of various TPVs based on novel thermoplastic resin/rubber blends. Therefore, novel TPVs become an active research subject in some important fields.The determination of an optimal preparation condition of novel TPVs is described below. This easy and convenient method uses a two-roll mill and a Brabender Plasticorder, which can be carried out in the polymer processing laboratory, and requires thermoplastic resin, rubber materials and related additives used in the crosslinking recipe. The characterization of the novel TPVs by moving die rheometer, universal testing machine, field-emission scanning electron microscopy (FE-SEM) and energy dispersive X-ray microanalysis system (EDX) benefits the students by exposing them to a few important instruments that will be widely used in the future academic research or industrial work.

2. Experiment Description

2.1. Materials

- HVPBR rubber (with the mass fraction of vinyl content 83.5%, ML1+4 (100°C) =50 and Mn=1.5*104) was supplied by the Key Laboratory of Rubber-Plastics (Qingdao University of Science & Technology), Ministry of Education, China. HIPS resin was the product of Shanghai SECCO Petrochemical Co., Ltd., China. The HIPS was injection grade 622P with a melt flow index (MFI) of 4.8 g•10min-1 (200°C/5.0 kg). The polybutadiene content in the graft copolymer was 7.5 wt.%. SBS, grade YH-792, was produced by the Yueyang Petrochemical Co., Ltd., China. It was a linear SBS with a total polystyrene block percentage of 40 wt.%. Sulfur, used as a vulcanizing agent, was obtained from Hengye Zhongyuan Chemical Co., Ltd., China. N-cyclohexyl-2-benzothiazole sulfenamide (CZ) and tetramethylthiuram disulfide (TMTD), used as accelerators, were manufactured by Northeast Auxiliary Chemical Industry Co., China. Zinc oxide (ZnO) was used as an activator and obtained from NewLe Qinshi Zinc Co., Ltd., China. Stearic acid was used as an activator and obtained from Wanyou Co., Ltd., China. N-phenyl-N’-cyclohexyl-p-phenylenediamine (Antioxidant 4010) and N-phenyl-2-naphthlamine (Antioxidant D) were used as an antioxidant and obtained from Shengao Chemical Co., Ltd., China.

2.2. Instruments and Characterization

- HVPBR and crosslinking ingredients were compounded in a two-roll mill (X(S) K-160, Shanghai Qunyi Rubber & Plastic Machinery Co., Ltd., Shanghai, China) at room temperature.The vulcanization cure of the HVPBR based preblend was determined by using a moving die rheometer (GT-M2000, GoTech Testing Machines Co., Ltd., Taiwan, China) at 165°C and vibration angel was ±1°.TPV compounds were prepared by melt-mixing using a Brabender PLE 331 Plasticorder (Brabender Gmbh, Duisburg, Germany).For the measurement of tensile properties, dumbbell-shape specimens were prepared according to ASTM D412. The tearing strength was tested according to ASTM D624 using unnotched 90° angle test pieces. Both tensile and tearing tests were performed on a universal testing machine (TCS-2000, GoTech Testing Machines Inc., China) at a crosshead speed of 500 mm/min. The Shore A hardness was determined using a hand-held Shore A Durometer (LX-A, Shanghai Liu Ling Instrument Factory, China) according to ASTM D2240. All tests were carried out at 23°C. The average value of tensile strength was calculated for 5 test specimens and those of tearing strength and Shore A hardness were calculated for 3 test specimens.Morphological study was carried out using field-emission scanning electron microscopy (FE-SEM, JEOL-6700F, Japan Electron Co., Ltd., Japan). For the etched specimens, the HIPS phase was extracted by immersing the dynamically vulcanized blends into xylene for 60 min at 80°C. Then, the samples were dried at room temperature. The etched surfaces of the specimens were sputtered with thin layers of gold and imaged using FE-SEM.Elemental analysis on the etched surface of the specimens was measured using an energy dispersive X-ray microanalysis system (EDX, Oxford Instrument Co., UK) with a beam size of below 1 nm.

3. Experimental Procedure

3.1. Preparation of Dynamically Vulcanized HIPS/HVPBR and HIPS/SBS/HVPBR Blends

3.1.1. Preparation of HVPBR Preblends

- The concentrations for crosslinking the HVPBR are expressed in parts per hundred HVPBR rubber by weight (phr). The sulfur-containing accelerating system recipe for crosslinking the HVPBR is consisted of the following ingredients: 100 phr HVPBR, 1.0 phr sulfur, 1.2 phr CZ, 0.4 phr TMTD, 5.0 phr ZnO, 2.0 phr stearic acid, 1.5 phr Antioxidant D and 0.5 phr Antioxidant 4010. The preblends containing HVPBR and the crosslinking ingredients were compounded in a two-roll mill at room temperature. After 3 min of mixing time, the preblends were removed from the mixer.

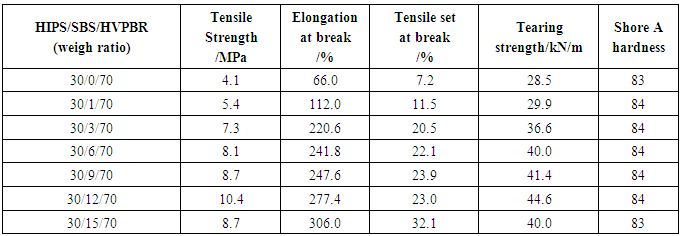

3.1.2. Curing Characteristic of HVPBR Based Preblend

- The vulcanization curve of the HVPBR preblend is illustrated in Figure 1. As observed in Figure 1, the cure characteristic was shown an obvious plateau curing, indicating the relatively high thermal stability of the HVPBR preblend; moreover, it was favourable for controlling the later melt mixing of dynamic vulcanization. The t10 and t90, which are defined as the scorch time and the optimum cure time, were 2.5 and 6.2 min respectively. According to the analysis of the vulcanization curve, the proper dynamic vulcanization time should be 6 min or so.

| Figure 1. Vulcanization curve of HVPBR based preblend at 165°C |

3.1.3. Preparation of Dynamically Vulcanized Blends

- The TPV compounds were prepared by melt-mixing the HVPBR preblends with HIPS resins using a Brabender Plasticorder. The mixing temperature was kept at 165°C with a constant rotor (cam type) speed of 80 rpm. The HIPS/HVPBR blending ratio was varied from 20/80 to 60/40. For the compatibilized TPVs, the HIPS/HVPBR blending ratio was fixed at 30/70 and the SBS amount was varied from 0 to 15 phr. During the dynamic vulcanization, the requisite quantities of HIPS resin and SBS were charged into the mixer and allowed to melt. After 3 min, the HVPBR based preblend was added. The mixing was continued for another 6.2 min to allow the dynamic vulcanization. Finally, the compound was removed from the mixer and passed through a cold two-roll mill in the molten state to obtain a sheet. The sheet, about 2 mm thick, was compression-molded under a pressure of 15 MPa at 180°C for 6 min, followed by cold compression in another molding machine for 8 min at room temperature. Test specimens were die-cut from the compression-molded sheet and used for testing after 24 h.

3.2. Mechanical Properties of the Dynamically Vulcanized HIPS/HVPBR Blends and HIPS/SBS/HVPBR Blends

3.2.1. Mechanical Properties of the Dynamically Vulcanized HIPS/HVPBR Blends

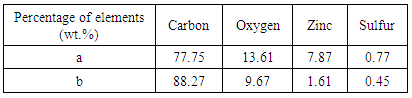

- Figure 2 illustrates the stress-strain behaviors of the dynamically vulcanized HIPS/HVPBR blends with different weight ratios. As shown in Figure 2, the stress-strain curves of dynamically vulcanized blends present a character of being relatively soft when the HIPS content was less than 40 phr. Increasing HIPS content, the stress-strain curves showed a quick increase in tensile stress and modulus. Unfortunately, the elongation at break of the dynamically vulcanized HIPS/HVPBR blends was lower than 100%, according to ASTM D1566-11, the HIPS/HVPBR blends should not be considered to be TPEs. However, the mechanical properties of the dynamically vulcanized HIPS/HVPBR blends were expected to be improved by modification of the interface interaction.

| Figure 2. Stress-strain curves of dynamically vulcanized HIPS/HVPBR blends |

3.2.2. Influence of SBS on the Mechanical Properties of the Dynamically Vulcanized HIPS/HVPBR Blends

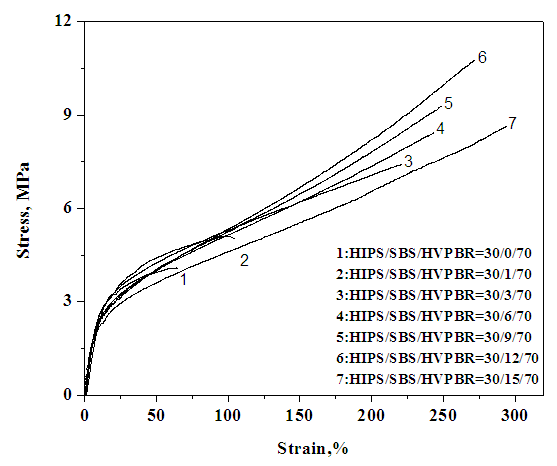

- Figure 3 shows the stress–strain behaviors of the dynamically vulcanized HIPS/HVPBR blends compatibilized by different SBS dosages. As shown in Figure 3, the stress-strain curves of HIPS/SBS/HVPBR TPVs were similar in the shape. Initially, an obvious increase in tensile stress and modulus could be observed (for 10% strain). Upon further deformation, the slope of the curves decreased with the stress increasing almost linearly until fracture occurred. All the stress–strain curves showed the representative elastomeric character of being soft and tough. It can also be seen from Figure 3 that the tensile strength and the elongation at break of the HIPS/HVPBR blends were improved greatly with the incorporation of SBS.

| Figure 3. Stress-strain curves of dynamically vulcanized HIPS/HVPBR blends compatibilized by SBS |

|

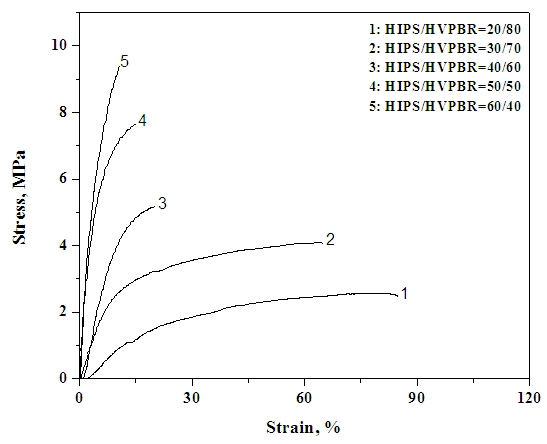

3.3. Morphological Research of HIPS/HVPBR TPVs

3.3.1. Morphological Evolution of SBS Compatibilized HIPS/HVPBR TPV

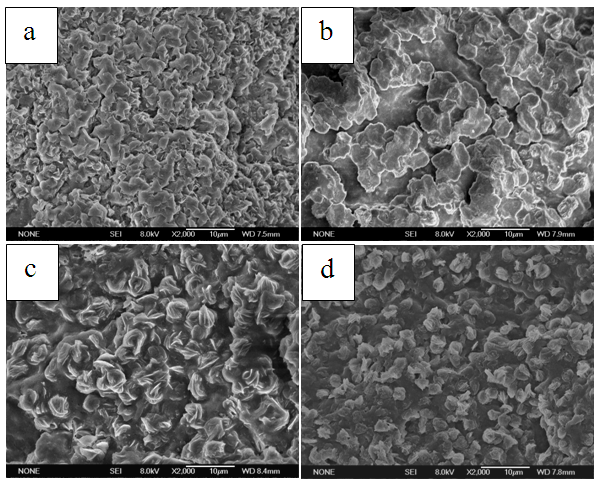

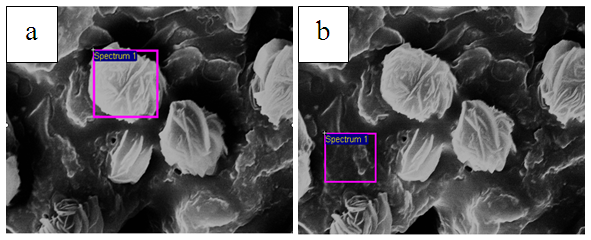

- Figure 4 shows the morphological evolution of HIPS/SBS/HVPBR (weight ratio 30/12/70) TPV varying with the dynamic vulcanization time. For these TPV specimens obtained at specific dynamic vulcanization time, they were etched in xylene after molded into sheets; therefore, the thermoplastic HIPS matrix in the TPV surface could be selectively etched, and the vulcanized HVPBR particles were prominent and could be found clearly in the etched surfaces, as shown in Figure 4. During the early stage of dynamic vulcanization, the HVPBR preblend was still in the scorch stage without obvious crosslinking, and the HVPBR preblend and HIPS were melt-compounded fully in the mixer. Both the HIPS and the HVPBR preblend could be etched in the xylene, so there was no obvious two-phase microstructure which could be observed clearly in the surface of the etched specimen, as shown in Figure 4a. With prolongating dynamic vulcanization time, the pre-vulcanization stage was started and the HVPBR preblend began to enter the crosslinking reaction, leading to dramatic increasing viscosity of HIPS/SBS/HVPBR blends; as a result, the crosslinking HVPBR preblend was gradually torn into particles and dispersed in the HIPS matrix under the strong shear force in the mixer. At this moment, the obvious two-phase microstructure could be observed, and the size of the vulcanized HVPBR particles was about 10 μm, as shown in Figure 4b. Increasing dynamic vulcanization time to 5 min, under the effect of the continuous shear force, the crosslinking HVPBR particles were torn into smaller particles with the more uniform morphologies, and the size of the HVPBR particles was 4-6 μm, as shown in Figure 4c. When the dynamic vulcanization time was 6 min, the vulcanized HVPBR particles were continued to be torn into smaller particles with the size of 3-5 μm and uniformly dispersed in the etched TPV surface.

| Figure 4. Morphological evolution of HIPS/SBS/HVPBR TPV (weight ratio=30/12/70): (a) 1 min, (b) 3 min, (c) 5 min, (d) 6 min |

| Figure 5. EDX testing area in the etched HIPS/SBS/HVPBR (30/12/70) TPV surface: (a) the dispersed particle area, (b) the blank area |

|

3.3.2. Influence of SBS Compatibilizer on the Morphology of Dynamic Vulcanized HIPS/SBS/HVPBR Blends

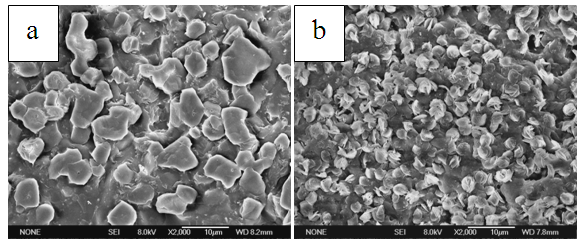

- During the dynamic vulcanization, the viscosity of the HVPBR preblend was increased quickly due to the initiation of the crosslinking reaction and then the HVPBR phase was gradually broken down into dispersed particles under the strong shear force. The etched surfaces of the dynamically vulcanized HIPS/HVPBR and HIPS/SBS/HVPBR blends are shown in Figure 6. As it can be seen from Figure 6a, the crosslinked HVPBR particles, with irregular morphologies, were dispersed evenly in the thermoplastic matrix. The dimensions of the discrete HVPBR particles in Figure 6a were in the range of 5-8 µm. It should be noted that the presence of compatibilizer SBS in the matrix decreased the average size of the HVPBR particles considerably, as shown in Figure 6b.

| Figure 6. FE-SEM images of etched HIPS/HVPBR and HIPS/SBS/HVPBR TPVs: (a) HIPS/HVPBR (30/70), (b) HIPS/SBS/HVPBR (30/12/70) |

4. Application of the Obtained TPVs

- These prepared HIPS/SBS/HVPBR TPVs can be further used as the raw materials for polymer physics experiments, the preparation of functional TPVs and polymer processing, etc. There experiments are performed at atmospheric pressure conveniently and making them suitable for materials physics and materials chemistry laboratories.

ACKNOWLEDGEMENTS

- This work was financially supported by Shandong Provincial Natural Science Foundation, China (ZR2017MEM021), Upgraded Project of Shandong Province for Guidance Ability of Graduate Tutors (SDYY17044), and National Training Programs of Innovation and Entrepreneurship for Undergraduates, China (201710426008).

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML