-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Polymer Science

p-ISSN: 2163-1344 e-ISSN: 2163-1352

2016; 6(1): 12-17

doi:10.5923/j.ajps.20160601.02

Structural Parameters and Dynamical Properties of the Radiative and Peroxide Vulcanizates Based on EPM Participation

Sh. M. Mammadov1, S. V. Rzaeva2, A. M. Guliev2, O. H. Akberov1, R. H. Mehdiyeva1, H. N. Akhundzada1, E. N. Ahmadov2, Mammadova R. R.3

1Institute of Radiation Problems of ANAS, Azerbaijan

2Azerbaijan State University of Oil and Industry, Azerbaijan

3Azerbaijan Technical University, Azerbaijan

Correspondence to: Sh. M. Mammadov, Institute of Radiation Problems of ANAS, Azerbaijan.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

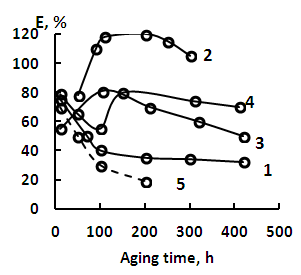

It is shown that irradiation of ethylene-propylene rubber (EPM) does not form a spatial network of small doses (150-300 kGy) that becomes fully soluble, indicating degradation of the molecular chains. It was found that irradiation of unfilled elastomer a low molecular weight radiation-chemical yield (RCY) cross-linking is 0,127 crosslinks on 100 eV absorbed energy. The introduction of the sensitizer DTBFM increases the speed of crosslinking, radiation-chemical yield of crosslinking (Gc) increased approximately 1.5-fold and 3.6-linking at 100 eV. By selecting the filler, and the dosage of sulfur, able to obtain vulcanizates of EPM, which are the source of physical and mechanical properties are not inferior peroxide vulcanizates. Structural changes in the aging process, was evaluated by the change in stress relaxation and conditional equilibrium modulus (ε, %).

Keywords: Ethylene-propylene, Radiation, Peroxide crosslinking, Vulcanization, Relaxation, Modulus, Aging, Vacuum, Oligomer, Rubber

Cite this paper: Sh. M. Mammadov, S. V. Rzaeva, A. M. Guliev, O. H. Akberov, R. H. Mehdiyeva, H. N. Akhundzada, E. N. Ahmadov, Mammadova R. R., Structural Parameters and Dynamical Properties of the Radiative and Peroxide Vulcanizates Based on EPM Participation, American Journal of Polymer Science, Vol. 6 No. 1, 2016, pp. 12-17. doi: 10.5923/j.ajps.20160601.02.

1. Introduction

- It is known that the elastomeric material (EM) on the basis of ethylene-propylene rubber (EPM) have a high ozone, oxygen, weather resistance and heat resistance number of aggressive media (alcohols, glycols, ketones, hydraulic fluids, bases). [1-6] The copolymers It is also characterized by high dielectric performance, relatively high strength, elasticity, high abrasion resistance. As dynamic properties and permeability EPM similar to natural rubber. Due to the absence of unsaturation in the side chains (EPM) curing it causes difficulties.Ethylene-propylene rubber (EPM) is one of the most promising general purpose elastomers [7-10]. Currently widely used of these copolymers vulcanization with peroxides in the presence of small amounts of sulfur [5, 11]. For vulcanizates with high physical and mechanical properties necessary to use large dosages of dicumyl peroxide (5.0 wt.h. per 100 wt.h. of elastomer), which is highly undesirable in a production environment because of the hazards of the product and decomposition of peroxides. [12-13] In addition, the presence of peroxides, as is known, adversely affected by the thermal aging of the elastomeric material. [14-16]It is known that crosslinking saturated low molecular weight organic compounds elastomers can improve the technological and dynamic performance vulcanizates. [5, 4]In particular, the high flexibility of chains and polar groups on the oligomers wasps basis maleimides leads to changes in the structure and properties of materials. [15]The lack of double bonds in the EPM is the reason for the low efficiency of the formation of the spatial grid, so that in order to achieve optimum properties requires more integral dose. [2, 13]Since radiation unfilled vulcanizates based on EPM does not have high strength. The introduction of the filler into the elastomer radiation-chemical yield (RCY) linking with increasing dosages of carbon should result in changes in the properties of vulcanizates [17-21].In this regard, of particular interest are the choice of carbon and low molecular weight organic sensitizers, containing functional groups of different nature [1, 22, 23]. The presence of functional groups as part of their offers additional possibilities for modifying the properties of the elastomer to reduce the radiation dose without impairing the basic properties of the vulcanizates. In addition, the introduction of carbon black (filler) of the EPM, is less affected by a decrease in the strength characteristics of vulcanizates temperature aging.The aim of this study was to investigate the possibility of holding for ethylene elastomer (EPM) method of radiation curing, which allows to exclude from the formulation curing agents, such as dicumyl peroxide. Development of methods for the study of cross-linking and curing process, as well as determine the effect of the sensitizer and the carbon black in the mechanical and dynamic properties of elastomeric materials.

2. Experimental

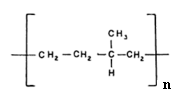

- The object of the study served as technical ethylene-propylene elastomer (EPM, Russia) catalyst prepared by copolymerization of ethylene and propylene in the presence of complexing catalysts. EPM molecules composed of alternating units of ethylene and propylene having the structural formula:

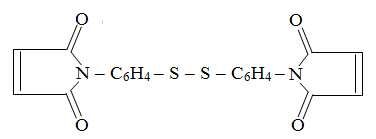

Propylene content was 50 mol/(%). Action fillers (furnace 324 and n-channel K354) under the action of mechanical and chemical properties of the composites was evaluated by the particle size (28-36 nm), bulk density (340 kg / m2) and surface area (84-106 m2 / kg). To reduce the irradiation dose and protect against radiation damage using a reactive low molecular weight compounds (LWC) as a sensitizing agent, 4,4'-dithiobis (N-phenyl maleimide DTBFM) of general formula:

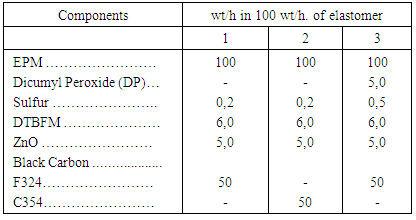

Propylene content was 50 mol/(%). Action fillers (furnace 324 and n-channel K354) under the action of mechanical and chemical properties of the composites was evaluated by the particle size (28-36 nm), bulk density (340 kg / m2) and surface area (84-106 m2 / kg). To reduce the irradiation dose and protect against radiation damage using a reactive low molecular weight compounds (LWC) as a sensitizing agent, 4,4'-dithiobis (N-phenyl maleimide DTBFM) of general formula: Bifunctional sensitizing agent 4,4'-dithiobis (N-phenyl maleimide) has a high binding energy of the atoms connecting malemidnye group which is active in the reactions of maleimides accelerates release radicals and crosslinking elastomers. Selecting zinc oxide activation process for crosslinking accounted for at a rate of vulcanization of elastomers degree.Composition investigated elastomeric compositions given in Table 1.

Bifunctional sensitizing agent 4,4'-dithiobis (N-phenyl maleimide) has a high binding energy of the atoms connecting malemidnye group which is active in the reactions of maleimides accelerates release radicals and crosslinking elastomers. Selecting zinc oxide activation process for crosslinking accounted for at a rate of vulcanization of elastomers degree.Composition investigated elastomeric compositions given in Table 1.

|

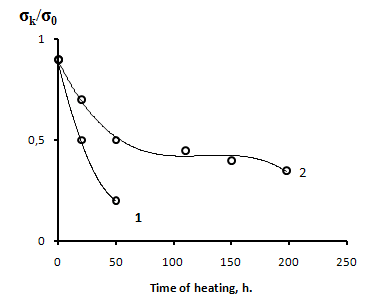

is defined by Flory Renera. [24]Mesh thickness and irradiated peroxide vulcanizates was determined by equilibrium swelling in benzene at room temperature. Samples were heated in benzene vulcanizates during the day. The degree of equilibrium swelling Q (%) was calculated by the equation:

is defined by Flory Renera. [24]Mesh thickness and irradiated peroxide vulcanizates was determined by equilibrium swelling in benzene at room temperature. Samples were heated in benzene vulcanizates during the day. The degree of equilibrium swelling Q (%) was calculated by the equation:

- the mass of the swollen sample ob - mg;

- the mass of the swollen sample ob - mg;  - weight of the dried sample mg.Tensile strength elongation was measured on a test tensile testing machine (RMI-500 company Tinius Olsen) with a load of 500 kgs. The dynamic properties of the samples was set to relaxometer axial compression VN 5305.Increasing the amount of force in the samples (equilibrium modulus) to the instrument PURM-1 (Russia).

- weight of the dried sample mg.Tensile strength elongation was measured on a test tensile testing machine (RMI-500 company Tinius Olsen) with a load of 500 kgs. The dynamic properties of the samples was set to relaxometer axial compression VN 5305.Increasing the amount of force in the samples (equilibrium modulus) to the instrument PURM-1 (Russia).3. Results and Discussion

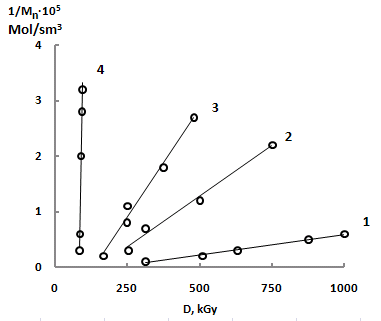

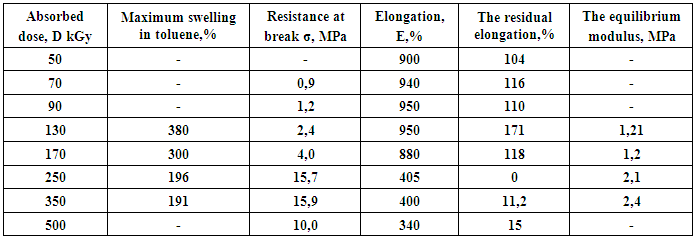

- Irradiation of elastomer without the addition of small doses does not form a spatial grid (Figure 1). When dissolved in toluene raw elastomer not subjected to irradiation, it has a gel fraction after the irradiation doses of 150-300 kGy elastomer becomes fully soluble, indicating degradation of the molecular chains. When high doses of irradiation, crosslinking increases output, until the formation of a continuous spatial grid. As expected, the irradiation of a polymer with a high molecular weight gel formation starts at a lower dose (Figure 1).

|

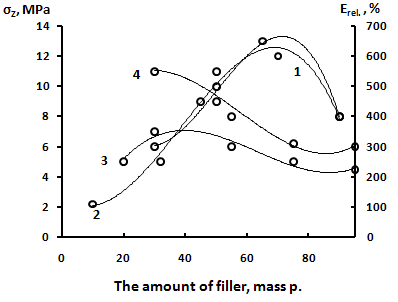

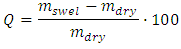

| Figure 3. Dependence of tensile strength (1,2,3) and elongation (4.5) vulcanizate sulfur content (1) and the irradiation dose (2.4) vulcanizate with 0.5 wt. h sulfur; (3-5) vulcanizate without sulfur |

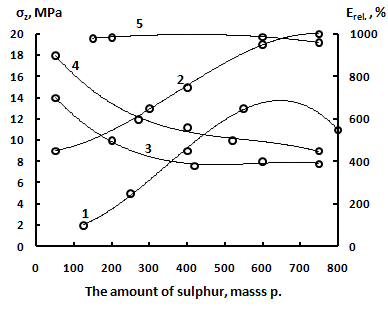

| Figure 5. Changes in the equilibrium of the module the duration of aging and peroxide radiation at vulcanizates (423K) on air; 1-radiation vulcanizate; 2-peroxide vulcanizate |

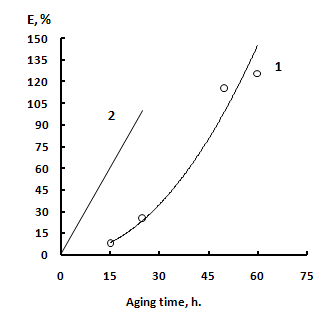

| Figure 6. Relaxation and stress radiation peroxide rubber in the air at 423 K.1- radiation vulcanizate; 2- peroxide vulcanizate |

4. Conclusions

- The paper discusses methods of structuring by radiation curing of unsaturated ethylene-propylene elastomers (EPM). For durable elastic material which is introduced into the low-molecular compounds of carbon different brands (furnace and channel) and sensitizer 4,4'-dithiobis-N-phenyl maleimide (DTBFM) the nature and dosage of which are selected according to strict and individual characteristics of the polymer. Reported an increase in download speed in the presence of the filler, the sensitizing effect DTBFM depends on the nature of the filler and which make it possible to obtain a variety of elastomeric materials with improved set of both technological and operational properties.Physical and mechanical properties of radiation and peroxide vulcanizates based EPM is influenced sensitizer (DTBFM), carbon black and irradiation conditions on the structural parameters of the grid vulcanizates, which causes long ethylene content in EPM.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML