-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Polymer Science

p-ISSN: 2163-1344 e-ISSN: 2163-1352

2014; 4(3): 94-100

doi:10.5923/j.ajps.20140403.04

Mechanical, Rheological and Flammability Properties of Poly(acrylonitrile-co-methyl acrylate) / Poly(3,4-ethylenedioxythiophene) / Modified Nanoclay Hybrids

Ayesha Kausar

Nanosciences and Catalysis Division, National Centre for Physics, Quaid-i-Azam University Campus, Islamabad, Pakistan

Correspondence to: Ayesha Kausar, Nanosciences and Catalysis Division, National Centre for Physics, Quaid-i-Azam University Campus, Islamabad, Pakistan.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

The matrix of novel hybrids is composed of poly(acrylonitrile-co-methyl acrylate) and poly(3,4-ethylenedioxythiophene) in ratio 90:10. Hybrids were prepared by melt blending of the polymers with amino-modified nanoclay (montmorillonite) in various contents. Effect of nano-clay on the mechanical properties, rheology, morphology, and flammability was considered. Transmission electron microscopy (TEM) was used to investigate the effect of melt blending on reducing the clay collapse in the nanocomposites. PAN-co-MA/PEDT and surface modified nano-clay composite at 10 wt. % nano-clay was found to have fine dispersion of individual nano-platelets. 10 wt. % loading also increased the Young’s modulus and tensile strength of 27% and 25% respectively, compared to the PAN-co-MA/PEDT/A-MMT 1. The rheological behavior including storage modulus and complex viscosity at 200°C was also analyzed in relation to the layered silicate content. UL-94 test verified V-1 rating in 5 and 10% loaded PAN-co-MA/PEDT/A-MMT 5 and PAN-co-MA/PEDT/A-MMT 10 hybrids.

Keywords: Poly(acrylonitrile-co-methyl acrylate), Amino-modified montmorillonite, Melt blending, Young’s modulus, Rheology

Cite this paper: Ayesha Kausar, Mechanical, Rheological and Flammability Properties of Poly(acrylonitrile-co-methyl acrylate) / Poly(3,4-ethylenedioxythiophene) / Modified Nanoclay Hybrids, American Journal of Polymer Science, Vol. 4 No. 3, 2014, pp. 94-100. doi: 10.5923/j.ajps.20140403.04.

Article Outline

1. Introduction

- Polymer/clay nanocomposites have enticed great attention over the last two decades due to their prospective for improved barrier, thermal, mechanical and physical properties than those of other traditional composite materials. Numerous techniques have been utilized for the purpose of compounding clay and polymer matrix, together with melt blending [1], in-situ polymerization [2] and solution blending [3]. Most important disadvantage of solution blending and in-situ polymerization method is the use of organic solvent which could be environment unfriendly and costly. Melt blending treatment is deliberated more cost-effective, commercially compatible and favorable for formulation [4]. However, the uniform distribution of nano-clay and resultant substantial property developments were attained in polymers with the exception of those inclosing polar functional groups [5]. An extensively accounted flame retardant in the polymer resins is montmorillonite since it has the capability to decrease polymer flammability with relatively lower auxiliary levels [6, 7]. The montmorillonite particles retard the heat transference in the compressed phase and shrink the contribution of released degradation commodities to the gaseous phase, thereby considerably dropping the highest heat liberation rate of blazing polymer. Nevertheless, the overall released heat is not considerably curtailed. It has been testified that the fire retardation property of polymer nanocomposites accompanied by clay merely is not satisfactory to accomplish the industrial requirements, for instance, meeting desired rendition levels in the standard of UL-94 [8, 9]. Supplementary fall in the flammability of polymer/clay nanocomposites is desired for prospective industrial requisitions [10]. Commonly, the char formation, which endures in the compressed phase throughout burning, lessens carbon supply to the glare and hence decreases the overall heat release and heat liberation rate. However, the incorporation of clay particles does not every time boost the char formation [11]. The polymer/clay nanocomposites ignite more gradually, but most part of the polymer is ultimately ingurgitated [12, 13]. So use of additives or modified clay in polymer/clay nanocomposites, might be anticipated to enhance the fire retardancy. An investigation has designated that the notable volume of char has been achieved consuming zinc chloride with poly(acrylonitrile-co-styrene). However, no preferred synergism has been observed with montmorillonite clay on flame retardation and additional physical features probably since the char formation occurred in the late pyrolysis stages [14]. A close association between the material properties and structure is familiar which is mainly factual for polymer nanocomposites and polymer/clay blends [15]. In general, it is presumed that mixing the clays with continuous polymeric matrix, the idyllic state of completely exfoliated nanocomposites is not performed; relatively partially exfoliated nanocomposites are usually shaped [16]. Additionally, the role of polymer/clay boundary/interface in speculating the polymer nanocomposites properties is investigated. The idea of constrained interface or region in nylon 6/montmorillonite nanocomposites was investigated at the start [17]. The interface/boundary is referred to an area near the surface of clay where the concentration of surfactant is enlarged and the mobility of polymer is minimized [18]. For the microscale particle size and the nanometeric scale interface, the interface impact on all-inclusive properties is insignificant. During the past decads, intensive research has been carried out on the rheology of nanocomposites filled with organically modified clays [19]. The rheological properties of nanocomposites are sensitive to the structure, particle size, and surface characteristics of the silicate phase. The rheology may also be used to assess the state of the dispersion of nanocomposites directly in the melt state [20]. Due to the large surface area (50-400 m2/g) of these particles, the inter-particle interactions have foremost impact on the rheological and reinforcement properties of nanocomposites. The cluster structure may be viewed as primary particles assembly in the structure. In this study, the compression molding method has been used for the blending of poly(acrylonitrile-co-methyl acrylate), poly(3,4-ethylenedioxythiophene) and modified nanoclay hybrids. Potential of ball milling was also used to improve clay dispersion in nanocomposites. Morphology, rheology, mechanical and flame retardant properties of the hybrids were investigated to explore the effect of the nano-clay addition. Research objective is to produce mechanically stable non-flammable materials-based on poly(acrylonitrile- co-methyl acrylate), poly(3,4-ethylenedioxythiophene) and kaolin. The poly(acrylonitrile-co-methyl acrylate) and poly(3,4-ethylenedioxythiophene) composition was taken as 90:10. The poly(acrylonitrile-co-methyl acrylate) was opted as matrix material because of the fine mechanical characteristics and processing stability. This polymer may also exhibit good non-flammability when blended with clay and another less flammable matrix. Secondly, poly(3,4-ethylenedioxythiophene) was selected as a part of the matrix. The poly(3,4-ethylenedioxythiophene) was capable of developing physical interaction with the matrix, which may intern increase its stability. Another purpose for the addition of poly(3,4-ethylenedioxythiophene) was that sulfur based moieties are capable of inducing flame retardancy in the materials. This research in effect studied that how a physically linked copolymer of poly(acrylonitrile-co-methyl acrylate) and poly(3,4-ethylenedioxythiophene) intercalate the functional nano-clay. Kaolin was opted as nanofiller to increase the non-flammability properties of the matrix. Moreover, one of the intentions of research is to develop composites via melt processing the matrix materials with adequate amounts of nano-clay while maintaining its strength. The melt processing is a simple method and would be more environmentally friendly.

2. Experimental Section

2.1. Materials

- Poly(acrylonitrile-co-methyl acrylate) (acrylonitrile ~94 wt. %), poly(3,4-ethylenedioxythiophene) nanoparticles, dispersion, and montmorillonite nanoclay (contains 0.5-5 wt. % aminopropyltriethoxysilane, 15-35 wt. % octadecylamine) were obtained from Aldrich.

2.2. Instrumentation

- Transmission electron microscopy (TEM) was conducted with a JEOL JEM 2100F TEM. The sample was prepared with a Leica UC-6 ultramicrotome with a Diatome diamond knife at room temperature. Rheological measurements of the nanocomposites were performed using an ARES rheometer from TA Instruments. The ~3 mm thick samples were stamped into 25 mm diameter disks. Dynamic frequency sweep experiments were performed under a continuous nitrogen atmosphere using a 25 mm parallel plate fixture at 200°C in the linear viscoelastic region of the materials. The linear viscoelastic limit was determined using strain sweeps at a frequency of 10 rad/s and at the same temperature (200°C), and it was found that dynamic frequency sweep experiments could be conducted at a strain of 5%. The elastic moduli (G') and complex viscosities (η*) of the materials as functions of angular frequency (ranging from 0.1 rad/s to 100 rad/s) were obtained at a temperature of 200°C. LOI value was measured on samples (120×8×3 mm3) according to the standard oxygen index test ASTM D2863-77 using FTA IL. UL-94 test was performed (134×17×3 mm3) according to ASTM D635-77 for UL-94 test. Electrical conductivity was measured with four probe technique in order to avoid the contact resistance.

2.3. Milling of Nano-Clay

- The powdered form of aminopropyltriethoxysilane modified montmorillonite was introduced into the vial of the SPEX mill. Four large balls (diameter ¼ 12.68 mm, weight ¼ 8.18 g) and six small ones (diameter ¼ 6.32 mm, weight ¼ 1 g) were used for milling. The weight ratio of ball/material was 10:15. The milling time of 4 h was applied. The ball milled formulation was used as nano-filler in the fabrication of nanocomposites.

2.4. Preparation of Poly(acrylonitrile- co-methyl acrylate) / poly(3,4-ethylene-dioxythiophene) / Modified Nanoclay Hybrids

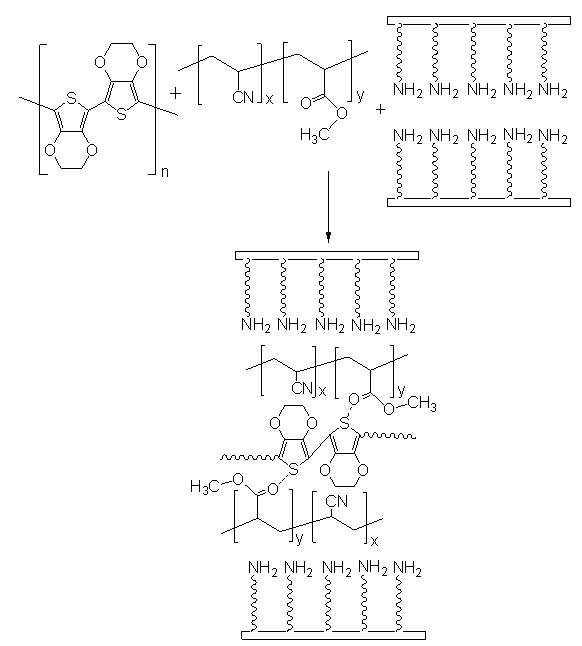

- Before melt compounding, polymers and nano-clay were dried separately at 80°C for 24 h. The composites were prepared by mechanical reflexology using two-roll mill at 130°C for 1 h (Fig. 1). The poly(acrylonitrile-co-methyl acrylate) and poly(3,4-ethylenedioxythiophene) were mixed in ratio 90:10. The collected molten materials were compression-molded into 3 mm-thick pellets by hot pressing at 100°C (100 bar). The composites containing 1, 3, 5 and 10 wt. % of montmorillonite nanoclay were prepared [21].

| Figure 1. Schematic formation of PAN-co-MA/PEDT/A-MMT |

3. Results and Discussions

3.1. Transmission Electron Microscopy Analysis

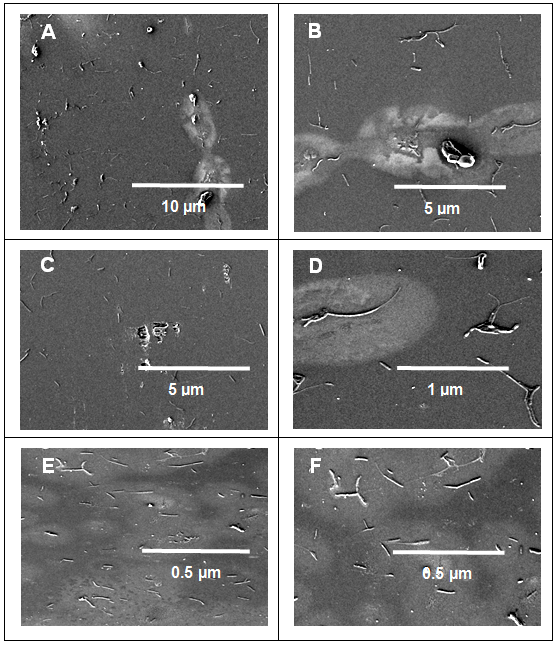

- TEM analysis was carried out as a characterization method to evaluate the morphology of the nano-clay in the matrix. TEM images of the 1 wt. % PAN-co-MA/ PEDT/A-MMT 1 nanocomposite prepared are presented in Fig. 2 A & B. As can be seen from Figs. some clay aggregation in the direct blended nanocomposite was found with the addition of 1 wt. % MMT. The system appears to be a phase separated morphology with some tactoids and individual silicate layers. These tactoids may consist of in the order of tens of individual clay layers. In the case of PAN-co-MA/PEDT/A-MMT 3 (Fig. 2 C & D), tactoids were relatively less visible showing that the higher clay content and melt intercalation are effective in exfoliating/ intercalating the nano-clay at this loading. Better clay dispersion can be observed in the composite prepared by 5 and 10 wt. % MMT (Fig. 2 E & F). In general, the intrinsic incompatibility of hydrophilic clay layers with hydrophobic polymer chains prevents the dispersion of clay nanolayers within the matrix and weakens the interfacial interactions. Moreover, the incompatibility and weak interfacial interactions hinder the exfoliation and preparation of dispersed stable nanocomposite with improved properties. Modification of clay layers is, therefore, necessary in order to render the clay layers more compatible with polymer chains. Amine modification of the platelets causes to the reduction of surface energy of clay layers and contest their surface polarity with polymer polarity. The organoclays with lowered surface energy are more compatible with polymers and are able to intercalate within their interlayer space or galleries. Moreover, the amine functionalities can provide functional groups which interact with polymer chains therefore increase the interfacial interactions. Increase in clay content, as a result, develops good interaction with chains. Fig. 1 shows the organically modified clay layers using alkyl amine groups. The morphology of the composites prepared by direct blending of higher filler content showed good dispersion of the nano-clay. No aggregates or tactoids were seemed in these micrographs. Individual nanoclay platelets were visible in all the micrographs. Better dispersion and individual nano-platelets could be the reason for high modulus for the 10 wt. % PAN-co-MA/PEDT/A-MMT 10 (Fig. 2 F), which will be discussed in the subsequent section. This type of morphology has been often observed for the polymer/clay composites [22].

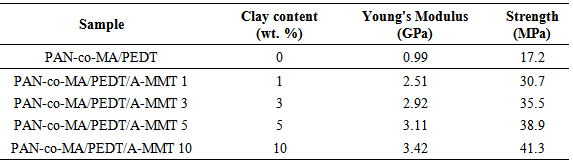

3.2. PAN-co-MA/PEDT/A-MMT Nanocomposite Mechanical Properties

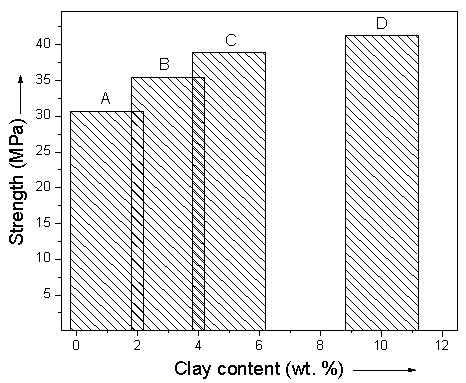

- In this section, effects of different clay content on the mechanical properties of the composite materials have been discussed. The mechanical properties of the compression- molded PAN-co-MA/PEDT and PAN-co-MA/PEDT/A- MMT nanocomposite are shown in Table 1. Tensile strength of PAN-co-MA/PEDT was found to be 17.2 MPa and tensile modulus was around 0.99 GPa (lower than all the composites prepared). Tensile strength of PAN-co-MA/PEDT/A-MMT 1-10 is given in Fig. 3. PAN-co-MA/PEDT/A-MMT 1 has tensile strength of 30.7 MPa. By adding 3 wt. % of MMT using the melt blending method, the nanocomposite is found to have a tensile strength of 35.5 MPa, an increase of about 14% compared to the PAN-co-MA/PEDT/A-MMT 1. The tensile strength was further increased to 38.9 MPa with the addition of 5 wt. % of MMT in PAN-co-MA/PEDT/A-MMT 5. The increase was 21% with respect to the PAN-co-MA/PEDT/A-MMT 1. Inclusion of 10 wt. % of MMT revealed the tensile strength of 41.3 MPa in PAN-co-MA/PEDT/A-MMT 10, an augment of about 25% was observed compared to the PAN-co-MA/PEDT/A-MMT 1. Young’s modulus of PAN-co-MA/PEDT/A-MMT 1, PAN-co-MA/PEDT/A-MMT 3, PAN-co-MA/PEDT/A- MMT 5 and PAN-co-MA/PEDT/A-MMT 10 are found as 2.51, 2.92, 3.11 and 3.42 GPa. Here again, the biggest improvement is seen in the PAN-co-MA/PEDT/A-MMT 10 nanocomposite prepared. The Young’s modulus of 10 wt. % sample was, so, maximum i.e. 3.42 GPa. It was observed that the melt blending of 5 wt. % nano-clay provided about a 19% increase of Young’s modulus relative to 1 wt. % of nano-clay. Further improvement (about 27% compared to PAN-co-MA/PEDT/A-MMT 1) of the modulus was obtained by the aid of 10 wt. % loading. Moreover, it appears that there is a continuous increase of the modulus with increasing clay loading [23].

| Figure 3. Tensile strengths of (A) PAN-co-MA/PEDT/A-MMT 1; (B) PAN-co-MA/PEDT/A-MMT 3; (C) PAN-co-MA/PEDT/A-MMT 5; (D) PAN-co-MA/PEDT/A-MMT 10 nanocomposites |

|

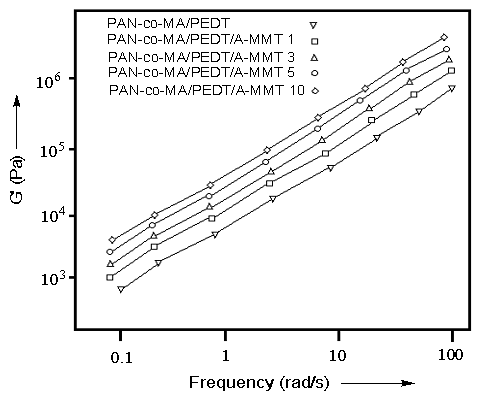

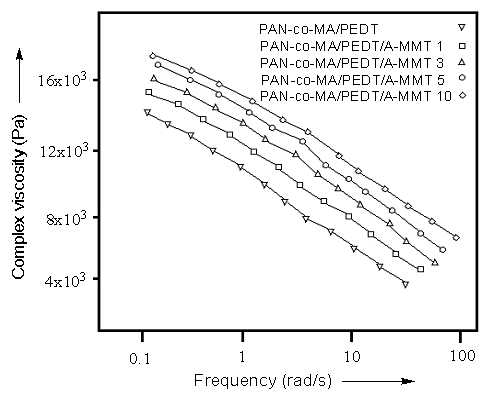

3.3. PAN-co-MA/PEDT/A-MMT Nanocomposite Rheological Properties

- The rheological behavior of the different nanocomposite showing melts at various nano-clay loadings have been studied. The storage modulus (G'), and complex viscosity (η*) of the matrix and nanocomposite melt prepared by different methods at various A-MMT content are given in Fig. 4 and Fig. 5 respectively. Repeat rheological measurements on the same sample reveal that G' and η* are accurate to about 3%. As can be seen that the clay content has no significant effect on the nanocomposite rheological behavior. The G' and η* of the PAN-co-MA/PEDT and PAN-co-MA/PEDT/A-MMT samples prepared with different clay content may overlap with each other and are well within experimental error. The rheological characterization is capable of monitoring the networks formed in the melt system, but does not provide sufficient information for accurate particle morphologies. Using rheology to determine the microstructure and morphology of the nanocomposites is still ambiguous. It seemed that the nano-clay concentration has a slight impact on the nanocomposite rheological behavior. As can be seen in Fig. 4, as the nano-clay concentration increased, the complex viscosity increased slightly. The increases in G' are minimal but they have the same trend as the changes of η* with various clay loadings. By increasing the nano-clay concentrations, the interactions between the clay to polymer chains are obviously stronger. The inter-particle distances also decrease and the chance of clay-to-clay interaction may increase as well. These can all contribute to the increase of the melt viscosity (Fig. 5). While neat blend has lower melt viscosity.

| Figure 4. Storage modulus (G') vs. frequency of PAN-co-MA/PEDT and different PAN-co-MA/PEDT/A-MMT nanocomposites at 200°C |

| Figure 5. Complex viscosity (η*) vs. frequency of PAN-co-MA/PEDT and different PAN-co-MA/PEDT/A-MMT nanocomposites at 200°C |

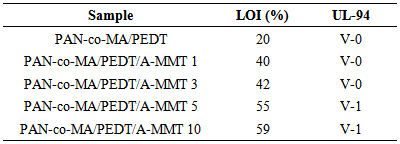

3.4. Non-flammability Studies of PAN-co-MA/PEDT/A-MMT

- The flame retardancy of PAN-co-MA/PEDT and PAN-co-MA/PEDT/A-MMT 1-10 hybrids was measured using LOI and UL-94 tests (Table 2). Neat PAN-co-MA/PEDT has LOI value of 20% and V-0 rating according to UL 94 tests. The flame retardancy of the neat material was lower compared with the composites. Firstly, limiting oxygen index of PAN-co-MA/PEDT/A-MMT 1, PAN-co-MA/PEDT/A-MMT 3, PAN-co-MA/PEDT/ A-MMT 5 and PAN-co-MA/PEDT/A-MMT 10 was found to be 40, 42, 55 and 59% respectively. The values are adequately high for the higher clay loading (5 and 10 wt. %) indicating that the materials are fairly non-flammable due to the synergetic effect of the blend and clay. To enhance the non-flammability of the clay, the addition of poly(3,4-ethylenedioxythiophene) was also seemed to be competent. Maximum LOI value was obtained for PAN-co-MA/PEDT/A-MMT 10 with 10 wt. % filler loading. UL-94 tests were also carried out for PAN-co-MA/PEDT/ A-MMT 1-10 to verify the results obtained by LOI. All the nanocomposites executed fine in UL-94 tests. The hybrids with 1 and 3 wt. % clay content loaded PAN-co-MA/ PEDT/A-MMT 1 and PAN-co-MA/PEDT/A-MMT 3 attained V-0 rating. On the other hand, PAN-co-MA/ PEDT/A-MMT 5 and PAN-co-MA/PEDT/A-MMT 10 with 5-10 wt. % clay loading performed better than PAN-co-MA/ PEDT/A-MMT 1 and PAN-co-MA/PEDT/A-MMT 3 and achieved V-1 rating in UL-94 test. Flammability results were also superior to the reported clay hybrids [24, 25].

|

4. Conclusions

- The improvement in nanocomposite properties were achieved using melt blending method and dispersing the modified nano-clays into the poly(acrylonitrile-co-methyl acrylate)/poly(3,4-ethylenedioxythiophene) blend matrix. The continuous improvement in the properties of the nano-clay hybrids with increasing clay concentration was obtained for nanocomposites containing up to 10 wt. % of nano-clay in PAN-co-MA/PEDT. The acrylate functional groups of PAN-co-MA were believed to promote the interaction with the amine moieties of nano-clay. This interaction between blend matrix and montmorillonite led to better dispersion of the silicate platelets. Based on TEM observations, the incorporation of acrylate polymer greatly improved the dispersion of individual clay nanoplatelets within the polymer matrix at lower as well as higher clay levels by direct melt compounding. The tensile results also indicated high degree of exfoliation of the nano-clay at higher clay loading (10 wt. %). The Young’s modulus of 10 wt. % PAN-co-MA/PEDT/A-MMT 10 is found to be 3.42 GPa, an 27% increase compared to that of lower clay loaded hybrids, without sacrificing other mechanical properties such as tensile strength. An enhanced storage modulus (G') at low frequencies also indicated fine rheological behavior. The relationship between nanocomposite morphology and rheological behavior was not readily apparent from the results; however the fine processability, non-flammability and other superior physical properties of the nanocomposite at 10 wt. % nano-clay loading using the proposed technique was suggested.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML