-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Polymer Science

p-ISSN: 2163-1344 e-ISSN: 2163-1352

2013; 3(3): 52-55

doi:10.5923/j.ajps.20130303.03

Degradation of Natural Rubber by Xanthomonas SP Using Dilute Solution Viscosity Measurement Technique

Ichetaonye S. I1, Ichetaonye D. N1, Tenebe O. G2

1Department of Polymer and Textile Technology, Yaba College of Technology, Yaba, Lago, Nigeria

2Department of Polymer and Textile Engineering, Federal University of Technology, Owerri

Correspondence to: Ichetaonye S. I, Department of Polymer and Textile Technology, Yaba College of Technology, Yaba, Lago, Nigeria.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Degradation of natural rubber by Xanthomonas species using dilute solution viscosity measurement technique was carried out. Natural rubber latex was dissolved in xylene and exposed to Xanthomonas species for 5, 10 and 15 days. The degradation by these species was monitored by measuring the intrinsic viscosity for the various time of exposure. In the absence of the organism (Xanthomonas), the intrinsic viscosity for rubber solution is 0.64 g/dl, while when subjected to 5, 10 and 15 days exposure in organism (Xanthomonas), the intrinsic viscosity for the rubber solution are 0.56 g/dl, 0.54 g/dl and 0.5 g/dl respectively. The results shows that the intrinsic viscosity decreased with an increase in time of exposure of rubber solution to the organism. This implies that an increase in time of exposure also decrease the degradation of the polymer.

Keywords: Degradation, Natural Rubber Latex, Xanthomonas Species, Viscosity, Xylene

Cite this paper: Ichetaonye S. I, Ichetaonye D. N, Tenebe O. G, Degradation of Natural Rubber by Xanthomonas SP Using Dilute Solution Viscosity Measurement Technique, American Journal of Polymer Science, Vol. 3 No. 3, 2013, pp. 52-55. doi: 10.5923/j.ajps.20130303.03.

Article Outline

1. Introduction

- It is important to improve microbial process for waste natural rubber disposal.[1] Natural rubber can be described as a coagulated or precipitated product obtained from latex of rubber plants (Hevea brasiliensis). They are plastically ductile and are important for elastomer production having elastic properties. The world production of natural rubber was about 6.6 million tons in 1998 and more than 70% of this rubber were been produced only in three countries (Thailand, Indonesia and Malaysia). About 40% were purchased by only three countries ( United state, China and Japan) and about 75% of most of the natural rubber were used for the production of automobile tires.[2] Natural rubber consists mainly of poly(cis-1,4-isoprene) and are still produced in large amounts (107 tons/yr) from the rubber tree. The main constituent of natural rubber is the poly(cis-1,4-isoprene) with an average molecular mass of about 106 Da. Natural rubber contains a small amount proteins, resins, fatty acids, sugars and minerals together with a minimum of 90% rubber hydrocarbon.[3] Organic impurities in natural rubber can support microbial growth.[4] More so, knowledge of rubber degradation at the protein, gene level and detectable degradation products should result in a detailedunderstanding of these new enzymatic reactions.During the previous decade, studies on microbial degradation were made and only little is known about the occurrence of natural rubber degrading bacteria.[5] The present study were initiated to isolate and characterized a number of natural rubber degrading bacterial from various ecosystems and its usefulness for the disposal of discarded rubber products.[6] Identification and development of rubber metabolizing micro organisms potentially could provide a biotechnological solution to this problem. The only example of a Gram-negative and a Xanthomonas species was published by Tsuchii et al.[7]

2. Experimental

2.1. Materials Used for Culturing Organism

- • Incubator• Wire lobe• Flame barrier • Microscope• Petri dishes • peptone• Glass Hockey• Distilled water• Agar plate• Autoclave

2.2. Equipments Used for Viscometric Test

- • Test tubes• Micro wave oven• Solvent (xylene)• Stirrer rod• Stop watch• Measuring cylinder / beaker• Electronic weighing balance• Rubber stopper• Suction pump• Ubbelohde viscometer (size 3)• Volumetric flask• Latex / latex crumb

2.3. Preparation of Culture Medium

- In 850 ml of diluted water, 5 g of peptone were dissolved after which 3 g of meat extract were then added followed by 15 g of agar. The pH was adjusted to 7.0 after which it was diluted to 1000 ml of distilled water and the content was sterilized in an autoclave.

2.4. Procedure for Culturing Organism

- A composite sample of a long exposed latex coagulum / organic soil were soaked for a period of one week in water and then filtered. About 10 – 15 ml of the filtrate were poured in an agar plate and then incubated for a period of 2 days to enhance the growth of the organisms present in the filtrate. 1g of inoculums specie was collected for several dilutions. Sub inoculums of (0.1 and 1.0) ml were separately cultured using agar plate by spread plate technique and pour plate technique respectively.0.1 ml of the sample diluted in the spread plate were placed on a sterile agar plate with the aid of a glass hockey after which it was spread evenly over the surface of the plate, incubated and then monitored daily for growth.About 1.0 ml of the sample diluted in the pour plate were carefully spread on a sterile Petri dish and 1 ml of culture medium were added to mix with inoculums, incubated at 35 – 37℃ and then observed daily for growth.

2.5. Degradation Process by Microbes

- Latex freshly tapped from rubber tree were measured and stored in the beaker for inoculation of the organism. A wire loop was used to introduce the organism into the different latex concentrates in the beakers. About 10 ml of the culture medium were then introduced into the latex, stirred thoroughly and then incubated for 5 days. On incubation, the latex coagulated and the following observation were made• Spores formation on crumb• Surface irregularities of crumb• A choking smell emitted• Dark red coloration patches made on the crumb and beaker

2.6. Viscometric Test

- Prepared samples were sterilized in an autoclave to terminate the activities of the organism. 1 g of latex was weighed, dissolved in 50 ml of xylene and stirred carefully to obtain a homogenous solution. Various concentrations such as 0.2, 0.4, 0.6, 0.8, and 1.0 g/dl were formed as solution and were diluted by pipeting some amount of xylene into the solution. The water bath temperature was equilibrated at 60℃ and 20 ml of pour solvent (xylene) was added into the viscometer held by retort stand. This was done to determine the flow time of the solvent after which the viscometer was rinsed with distilled water, dried at 50℃ in an oven and allowed to cool at room temperature. The experiment was repeated at interval of days during the degradation period.

3. Results

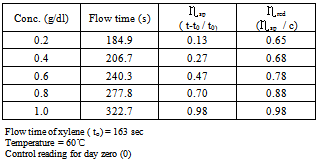

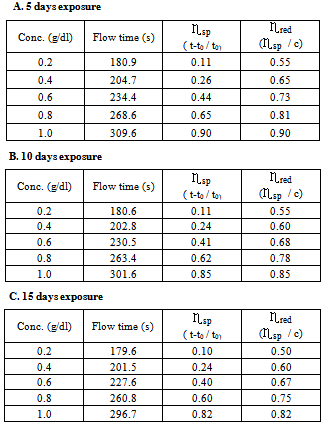

- The flow time, concentration, specific

and reduced

and reduced  viscosity values are shown in the various tables below.

viscosity values are shown in the various tables below.

|

|

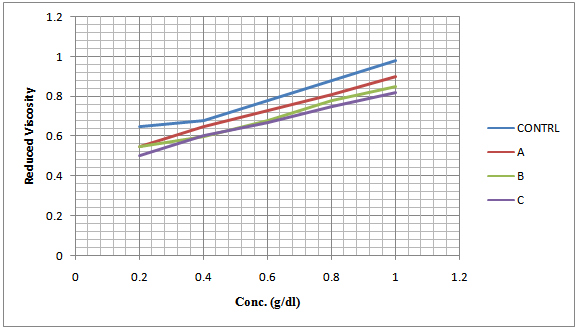

| Figure 1. The graph of the reduced viscosity(ɳred) against concentration |

4. Discussion

- It was observed that even at low concentrations of dissolved polymer, the viscosity of a solution relative to that of pure solvent is increased appreciably. This is due to the unusual size and shape of polymer molecules and the nature of their solutions. Incubation with the gram negative, clear zone forming organism Xanthomonas sp resulted in a weight loss of 60 percent in natural rubber after only 7days[6]. Degradation products obtained after incubation of natural rubber with crude enzymes extract, revealed compounds with apparent molecular weights of less than 104 and 103. Biodegradation of polymers or natural rubber takes place by different chemical processes and much attack by micro organism do however bring enzymes which speed up the process or cause it to follow pathway leading to unusual product[9]. However, the Xanthomonas strain secretes a protein having an apparent molecular mass of 65kDa during growth on latex[8] which was referred to as rubber oxygenase[Rox A]. Incubation of the purified Rox A protein with latex and Oligo resulted in accumulation of major 236Da degradation product which was also isolated and identified.On incubation, the following observations were made as the latex coagulates: • Spores formation on crumb• Surface irregularities of crumb• A choking smell emitted• No fermentation• Dark red coloration patches made on the crumb and beaker.The gradual decrease in intrinsic viscosity with increasing period of exposure of the micro organism leads to increase in degradation with increasing period of exposure. In other words, the continual decrease in intrinsic viscosity leads to the decrease in molecular weight since intrinsic viscosity is related to molecular weight according to Mark Houwink equation

Using xylene as a solvent and at a temperature 60℃, the study of degradation of natural rubber by Xanthomonas sp using dilute solution viscosity measurement technique was determined.

Using xylene as a solvent and at a temperature 60℃, the study of degradation of natural rubber by Xanthomonas sp using dilute solution viscosity measurement technique was determined. 5. Conclusions

- Based on the experiment carried out, the intrinsic viscosity of the rubber solution is 0.64 g/dl in the absence of the organism (Xanthomonas), while when subjected to 5, 10 and 15 days in the organism (Xanthomans) the intrinsic viscosity for the rubber solution are 0.56 g/dl, 0.54 g/dl and 0.5 g/dl respectively.This then shows that the intrinsic viscosity decreases with increase in the period of exposure of the rubber solution as well as degradation.However, this result confirmed that biodegradation of vulcanized rubber material is possible despite that fact that the cross linkages of the poly(cis-1,4-isoprene) chains makes it more difficult due to reduced water absorption and gas permeability of the material. Moreover, since Xanthomonas is a gram negative rod shaped bacterial, which allows the bacterial to move throughout an infected plant, secreting several hypersensitive reaction proteins causing an interaction with the plant and also since intrinsic viscosity of polymer depends on the overall chain structure of the polymer due to the effect of chain branching and the extent to which it occurs. Therefore, dilute solution viscosity measurement techniques should be employed because it provides information about monomer molecular weight, molecular weight distribution and other material characterization parameters in the study of degradation of natural rubber by Xanthomonas species and more research should be carried out using this technique.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML