-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Polymer Science

p-ISSN: 2163-1344 e-ISSN: 2163-1352

2013; 3(1): 1-5

doi:10.5923/j.ajps.20130301.01

Water Repellent Polymer Coating Based on Oligopiperillenestryrene and Alkoxysilane

V. Yu. Chukhlanov, M. Ionova

Department of Chemistry and Ecology, Vladimir State University, Vladimir, 600000, Russia

Correspondence to: V. Yu. Chukhlanov, Department of Chemistry and Ecology, Vladimir State University, Vladimir, 600000, Russia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

In the present article a creation of new water repellent materials based on oligopiperillenestyrene modified by tetraethoxysilane is considered. A nanostructure of coating surface and influence of polymer material component's staff and nature on polymer properties are researched. The materials are dedicated for protection of buildings from negative factors.

Keywords: Oligopiperillenestyrene, Organosilicone, Tetraethoxysilane, Protecting Coating, Water Repellent

Cite this paper: V. Yu. Chukhlanov, M. Ionova, Water Repellent Polymer Coating Based on Oligopiperillenestryrene and Alkoxysilane, American Journal of Polymer Science, Vol. 3 No. 1, 2013, pp. 1-5. doi: 10.5923/j.ajps.20130301.01.

Article Outline

1. Introduction

- At present time polymer water repellent coatings have found the widest application in absolutely different fields of industry. A special interest is to apply polymer coatings as a boarder to protect building’s construction elements against negative natural and anthropogenic factors, such as a damage of contraction materials due to a freezing of moisture inside of material at negative temperature, acid rains, UV-light, fire and so on.The most of hydrophobic polymer materials that are produced in industrial amounts doesn’t have enough resistance to above mentioned factors. Organosilicone materials are resistant to these working conditions but have very bad physical and mechanical properties. Due to this fact the great interest is to apply organic polymers modified by organosilicones with forming block-co-polymers or interpenetrating nets as a result[1-4]. These materials have both good physical and mechanical properties and a high resistance to atmosphere moisture and UV-lights. It can be explained by the fact that at such modification it appears a very strong hydrophobic effect. In earlier published articles[5-11] it was considered protective compounds possessed hydrophobic effect based on polyurethane modified by alkoxysilane and polyorganosilicones created in Vladimir State University. As matrix it’s a copolymer of styrene – oligopiperillenestyrene, as an alkoxysilane it’s tetraethoxysilane in the present work.

2. Objects and Methods of Research

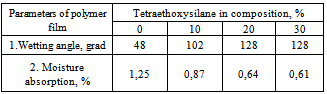

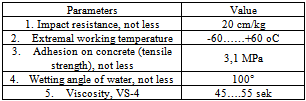

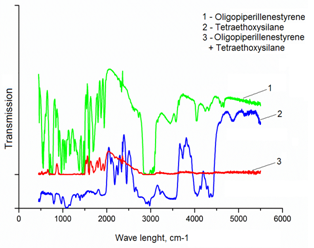

- At work we used chemical productsoligopiperillene–styrene and alkoxysilane, which are manufactured serially in Russia. Oligopiperillenestyrene is a product that is produced on synthetic rubber’s factories and that is used as polymer binding material. It’s made as oligomer PS-70 trademark as 50% solution of oligomer in white-spirit. Tetraethoxysilane is a product of interacting a silicon tetrachloride and ethanol. Tetraethoxysilane is applied in organic synthesis very often. In order to research a surface’s nanostructure of repellent coating it was used an atomic force probe microscopy with scanning probe device Integra Aura, made by NT-MDT, Zelenograd, Russia. The scanning was made by polysilicon probes HA_NC at intermittent contact method. At using of this method the pressure of cantilever on prototype surface is less and that allows to work with soft and fragile materials such as polymer films and biomaterials.To determine possible forming of chemical bonds we used Fourier infrared spectrophotometer Avatar 360 FT-IR ESP and samples for these investigations as thin films at polished surface of discs made from cesium iodide. Moisture absorption of polymer films in saturated environment by moisture vapors (relative humidity 95%). The method is concluded in determination of moisture mass that is adsorpted by polymer film with mass 0.2 grams and that is put in desiccator over Glauber's salt during 24 hours.In order to define a wetting angle it were used a way of micro photographies of distilled water drop on the polymer film surface and sequential measuring of wetting angle with protractor.Adhesion was defined by tearing off steel discs with diameter 1.5 cm from covered by polymer film surface. The tearing was made by using of digital adhesiometer PSO – MG4, which is an electronic dynamometer with processor and is able to calculate the force in tensile strength. The discs were glued to polymer film by cianacrylate. Relative hardness was determined by comparing of the number of oscillations of a pendulum and of ball joints on glass and polymer film by pendulum ASTM D4366-95 (ISO1522:2001). Compositions were laid on surface for followingexperiments at standard environment conditions: temperature 20°С, relative air humidity 75%. The work viscosity was got by addition of solvent. At investigation of relative hardness and adhesion we used special die hole with adjustable gap to lay the coating on surface.

3. Results and Discussion

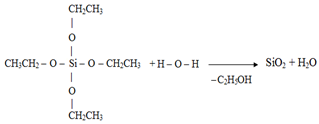

- At first step of research it was studied a possible way of interaction oligopiperillenestyrene and tetraethoxysilane. In this case it’s possible to have both physical interaction and forming of chemical bonds between these substances due to reactive groups in tetraethoxysilane and double bonds in oligopiperillenestyrene. To confirm or to refuse our suggestions about chemical interaction of components, researches were done on Fourier infrared spectrophotometer. According to figure 1, forming hydrophobic film based on oligopiperillenestyrene and tetraethoxysilane possesses strong absorption of infrared rays. Besides of it, on spectrogram in diapason 500-2500cm3 there are picks which are matched to picks of spectrogram of original oligomer. There are no any new forms or displacements of existing picks. That fact confirms, perhaps, lacks of some chemical interactions between original parts. However, why does hydrophobic polymer film absorb IR-rays intensively? Probably, due to not only partial hydrolysis of tetraethoxysilane but complete also, which goes by the form of colloidal silicon dioxide.

| Figure 1. Complete hydrolysis of tetraethoxysilane |

| Figure 2. IR-spectrum of modified polymer |

|

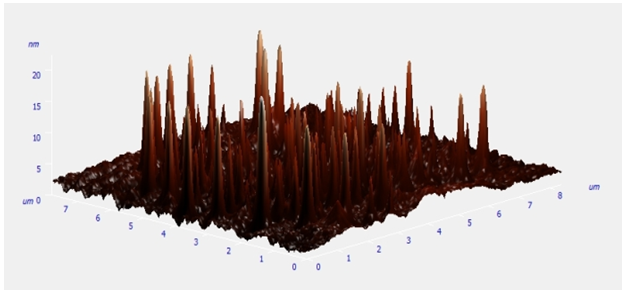

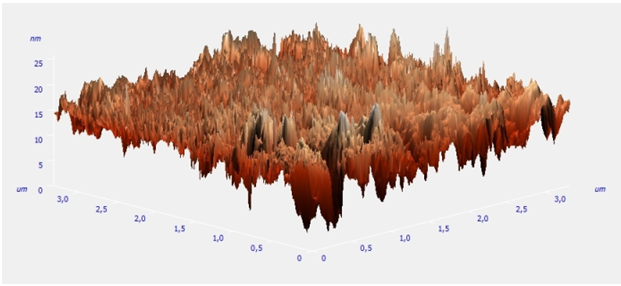

| Figure 3a. Oligopiperillenestyrene surface |

| Figure 3b. Oligopiperillenestyrene modified by tetraethoxysilane |

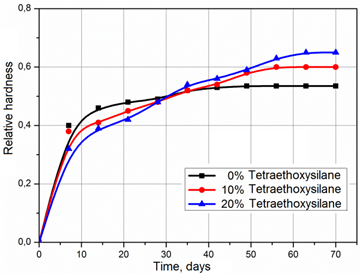

| Figure 4. Depending relative hardness on tetraethoxysilane content and curing time |

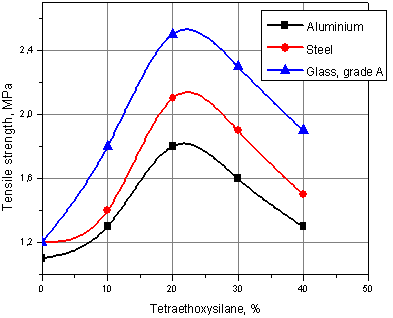

| Figure 5. Tensile strength |

|

| Figure 6. Town across river Klyazma (Vladimir) |

4. Conclusions

- Made experiments with repellent coating show a possibility of creation new polymer materials to protect buildings against negative natural and anthropogenic factors.Modification by tetraethoxysilane allows to form a repellent coating as regular organosiloxane liquids applying more available and cheaper components. Repellent coating in contrast to regular silicone coatings is characterized higher adhesive properties to surface of constructional materials containing silanol groups. Using of such coatings solves a problem of application of piperillene, which is synthesized in big quantities at manufacturing of synthetic rubber and can be applied in other fields on industry very seldom.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML