-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Operational Research

p-ISSN: 2324-6537 e-ISSN: 2324-6545

2016; 6(2): 40-47

doi:10.5923/j.ajor.20160602.02

Problem Prevention in Industrial Production Process by Means of Manufacturing: An Empirical Study in an Equipment Industry

Ualison Rébula de Oliveira1, José Wilson de Jesus Silva2, 3, Rosinei Batista Ribeiro2, Nilo Antonio de Sousa Sampaio3, 4

1Universidade Federal Fluminense – UFF – Rio de Janeiro, RJ, Brazil

2Faculdades Integradas Teresa D’Ávila – FATEA – Rede Salesianas – Lorena, SP, Brazil

3Associação Educacional Dom Bosco – AEDB – Resende, RJ, Brazil

4Universidade do Estado do Rio de Janeiro – UERJ/FAT – Resende, RJ, Brazil

Correspondence to: José Wilson de Jesus Silva, Faculdades Integradas Teresa D’Ávila – FATEA – Rede Salesianas – Lorena, SP, Brazil.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Organizations are invariably subject to several weather in their production processes, such as machine breakdowns, absenteeism, demand variation, among other types of negative occurrences. As a solution, or at least minimizing unwanted effects of these problems, several authors recommend the adoption of Manufacturing Flexibility. This being so, the Manufacturing Flexibility can exist at different levels of the organization and in different types, and each type may contain different aspects. Given the complexity of the issue and seeking to deepen the knowledge of Manufacturing Flexibility, it was executed an empirical research on an equipment industry, analyzing the main dimensions of the flexibilities required for the studied company, in order to prevent the problems that occur in your industrial production process. As results it is observed various types of flexibility that are not demanded by the undertaking, which allows to conduct efforts and investments to those flexibility dimensions that are really necessary, providing reduction of efforts, costs and time.

Keywords: Manufacturing Flexibility, Problem prevention, Equipment Industry

Cite this paper: Ualison Rébula de Oliveira, José Wilson de Jesus Silva, Rosinei Batista Ribeiro, Nilo Antonio de Sousa Sampaio, Problem Prevention in Industrial Production Process by Means of Manufacturing: An Empirical Study in an Equipment Industry, American Journal of Operational Research, Vol. 6 No. 2, 2016, pp. 40-47. doi: 10.5923/j.ajor.20160602.02.

Article Outline

1. Introduction

- Some authors [1, 2] state that exposure to risk is one of the greatest challenges to the survival of organizations. Thus, taking preventive measures so that the risks do not become a problem is a factor determinant of business activity continuity [3].Others [4] cite the existence of several risks, of various types, which seem from the external environment up to the most basic level of operations, which requires preventive measures to avoid these risks to become problems. From this perspective, several authors [5-12] recommend the use of manufacturing flexibility to minimize risks in the operating environment.According to some other authors [13, 14] since that Hayes & Wheelwright defended in 1984 the idea that manufacturing flexibility was one of the main dimensions of competitive strategy in business, there has been a substantial growth in research amount about this theme. However, despite its relevance and it is one of the five competitive strategies in operations in Brazil, studies about manufacturing flexibility are still scarce and rare [15], and this is the primary motivation for the achievement of such a research.Some authors [16-19] indicate that different manufacturing situations are subject to different kinds of risks and variations, requiring different types of flexibility. However, the multidimensional characteristic of manufacturing flexibility impedes to fit the flexibility degree to be adopted before the existing variables, and this is the second motivation of this work.Thus, this article focused the flexibility dimensions influence upon risks and problems occurring in manufacture, based on a perception survey of tactical-level staff and being limited to the productive environment of an equipment industry located in Rio de Janeiro. The study uses a sample of five respondents who work in management positions (supervisor, coordinator and production manager), aiming to research the manufacturing flexibility dimensions required by such an enterprise, in order to be anticipated to the problems occurring in its production process. The approach was intentional non-probabilistic by trial, that is, five people were selected intentionally by the researcher because he judged that they had adjectives (knowledge, experience and maturity) that qualify them as ideal respondents.Thus, it was adopted a questionnaire as a data collection instrument, consisting of open, closed, quantitative and qualitative questions, with attitudinal scales, with priority classification, among other aspects, in order to collect information that answer the research goal with the least time, lowest cost, offering fill facilities for respondents, among other relevant aspects.In relation to the interface with respondents, it was decided to use an auto filled questionnaire, which can be read and filled directly by respondents in internet website. As for its specific objectives, this work aims to know the main problems occurring in manufacturing, their occurrence frequency and what kinds of flexibilities are indicated to compose an ideal group of flexibilities for the analyzed company.The paper is organized as follows: Section 2 addresses theoretical framework about manufacturing flexibility, which was the research basis; the following section presents results obtained in empirical research carried out with researched equipment industry and a discussion about them; and finalizing the work, it is found the main conclusions, followed by bibliographical references.

2. Theoretical Substantiation about Manufacturing Flexibility

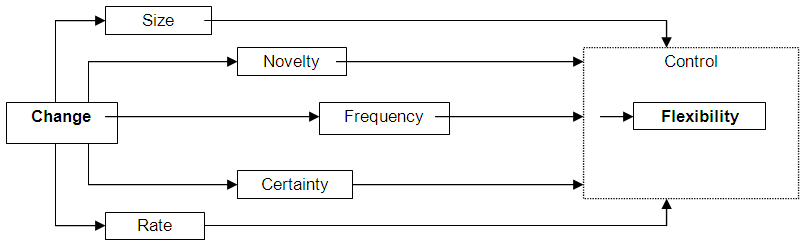

- Watts [20] defines manufacturing flexibility as an ability to implement changes in internal operating environment, in adequate time and acceptable cost, in response to changes in market conditions. As for Olhager [21], it is an ability to adapt to conditions changes by using the existing resources (in short-term).Slack [22] warns that manufacture needs to be flexible because it has to manage an operation under conditions of variety, risks and uncertainties, allowing the productive process to continue its work. According to the author, flexibility contributes to manufacture performance by improving variables such as reliability, costs and speed.According to Bengtsson [23], in order to react to changes increasing, reducing the products life cycle and global marketing, flexibility is becoming an important source of competitive advantage for manufacturing.Correa [24] believes that flexibility appears because of the need to deal with inherent uncertainties and process output variability. Uncertainties and variability lead to changes, which are both planned (they happen as a conscious decision of organization, taken to change the organization itself or its relationship with environment) and unplanned (they happen regardless of organization determination but which the organization really needs to adapt). For example, when the time required by the customer is less than the production time, or when the customer changes the applications deadline, flexibility will increase the ability to answer the needs of this client [9].Correa [24] also suggested that environmental uncertainty and variability in results are two main reasons (or stimulus) to manufacturing flexibility search. This being so, the stimulus sources could be process, suppliers, customers, society, corporation, other functions and competitors. According to him, the unplanned changes have five main dimensions: size, novelty, frequency, certainty and rate. As a consequence, managers seek to maintain control over the situation, being flexibility a way to be sought, as suggested by model of Figure 1.

| Figure 1. Links between change dimensions and flexibility - Source: Correa [24] |

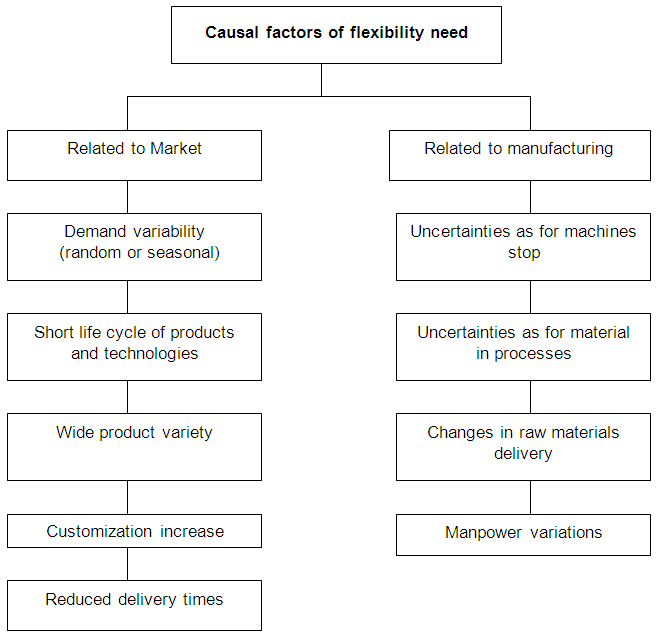

| Figure 2. Causal factors of flexibility need - Source: Kara [9] |

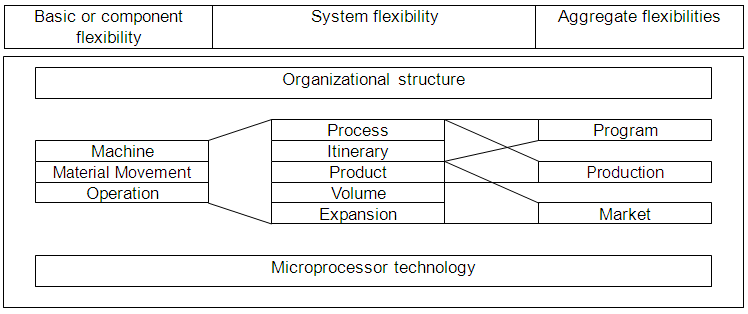

| Figure 3. Links among the several flexibility types - Source: Sethi [29] |

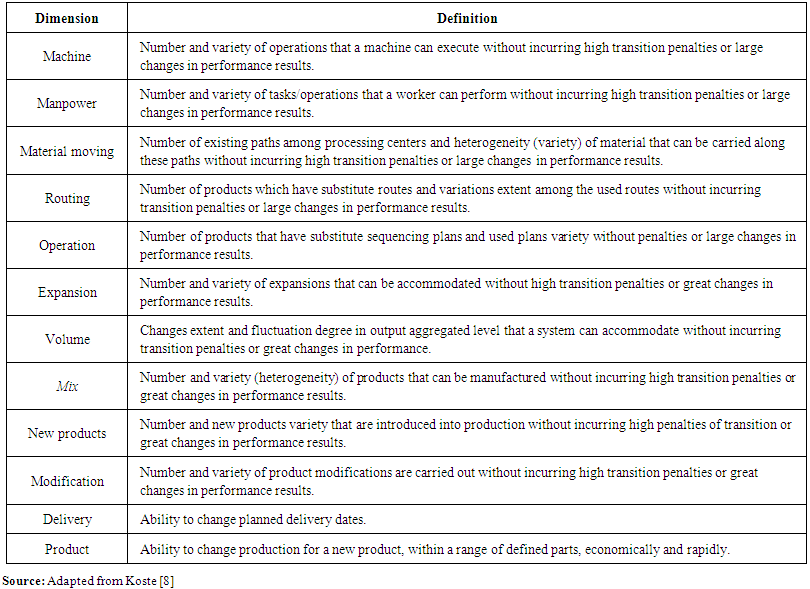

| Table 1. Definition about flexibility types used in empirical research |

3. Empirical Research in an Equipment Industry

- Empirical research has had two phases, the first one focused on problems analysis that occur in manufacturing process of an equipment industry, and the second to identify the dimensions of most required manufacturing flexibility for attenuation/elimination of problems occurring in the same company.

3.1. Problems Analysis Occurring in an Equipment Industry Manufacture

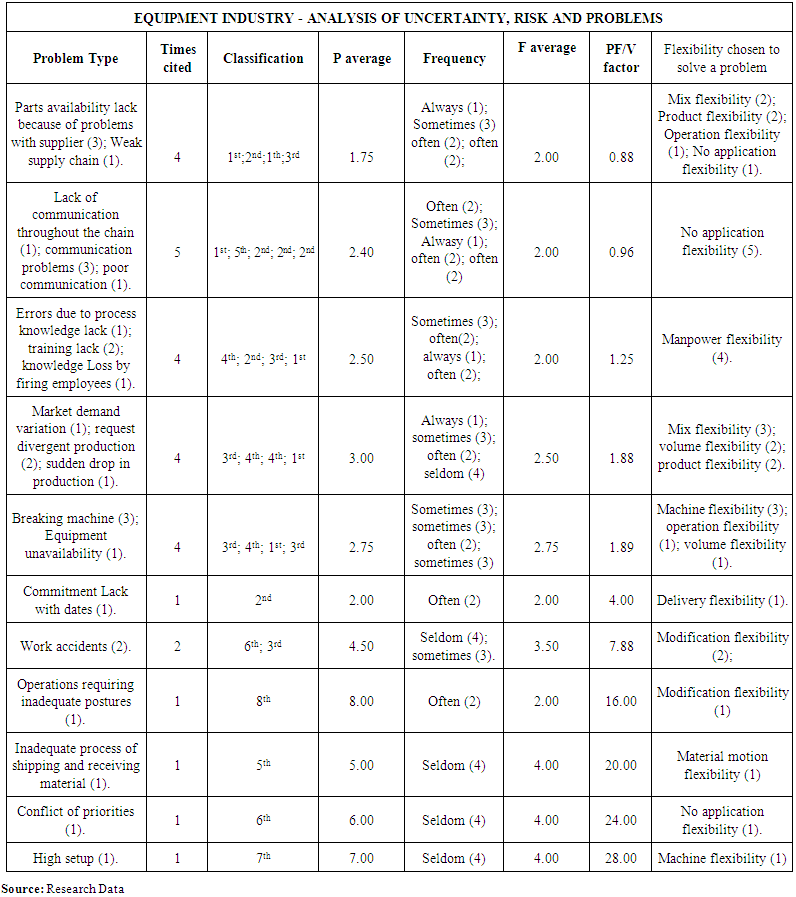

- Analyzing the interviewed respondents responses, it has been observed that the most critical problems in equipment industry are related, in this order, with: i) suppliers; ii) communication problems; iii) manpower, and; iv) demand variation. Other information about problems occurring in the searched company manufacturing with a better detail level, can be seen in Table 2, which has been developed to condense and facilitate data interpretation. Before exploring it, however, it is necessary to clarify its components, as follows:- The 'problem type' column informs problems types occurring in the studied company, according to respondents perception, agglutinating them by similarity; numbers in brackets represent how many respondents have cited the same problem;- The column 'times cited' reports the times amount that problems of the same family (similar problems) have been cited by a respondent;- The 'classification' column orders problems by means of negative impact degree to the researched organization, in an ordinal form; the lower the number, the worse the problem;- The 'p average' column indicates the ordinal classificassions average of previous column;- The 'frequency' column informs how often problems mentioned in the first column (problem type) occur in the researched organization; numbers in brackets represent the frequencies cardinal value: never (5), seldom (4), sometimes (3), often (2) and always (1);- Finally, the last column called 'flexibility chosen to solve a problem' may contain an amount of flexibility higher than the amount of mentioned problems.

| Table 2. Analysis of uncertainties, risks and problems for equipment industry |

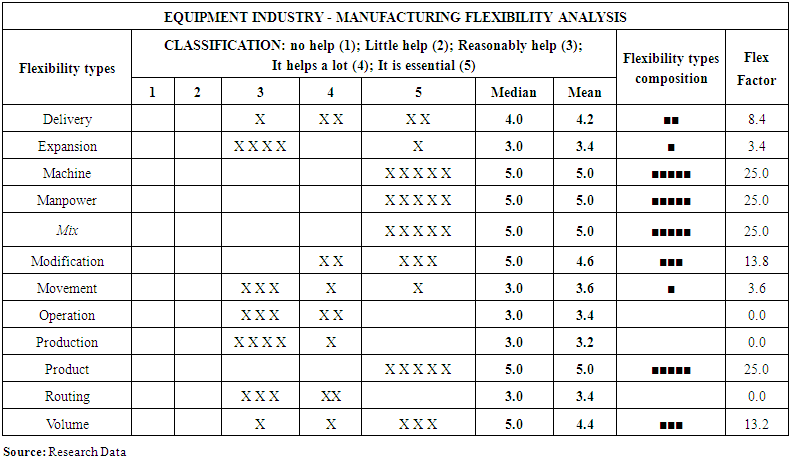

3.2. Manufacturing Flexibility Analysis Demanded by an Equipment Industry

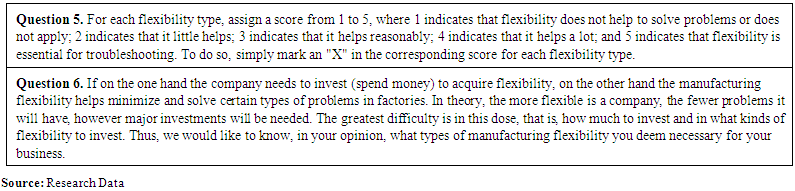

- Analyzing Table 2, specifically the "chosen flexibility to solve the problem" column, it is observed that for the most critical problems solution identified in previous subsection, the most recommended dimensions of flexibility are: mix, product, manpower and volume. Other flexibility types, properly correlated with their problems in an equipment industry, can be viewed in that table.Continuing the research, empirical study on flexibilities dimensions in equipment industry has been expanded, by means of Questions 5 and 6 of data collection instrument, as excerpt of it in Table 3.

| Table 3. Excerpt of data collection instrument applied to equipment industry |

| Table 4. Manufacturing flexibility analysis in equipment industry |

4. Conclusions

- During the theoretical framework development, it was found that there are, in fact, very few studies approaching the operational risks related to manufacturing, which is a gap that is intended to fill with this research. From the several studies reviewed (most of them not referenced here), approximately 50% used to address financial risks, 20% risks arising from work-related injuries, 20% environmental risks, and only 10% addressed other risk types, including operational risks. Thus, it is evident the relevance of some authors findings about the subject [2, 15] stating there are a lot of risks research in financial sector, however little or no attention has been given to risks in manufacturing.On the other hand, still relating to theoretical frame, it was found that manufacturing flexibility acts as a competitive advantage source to administer operation under conditions of changes, variety, risks and uncertainties, permitting the production process to keeps on its work at a low cost and with faster response.With regard to the empirical study, it was observed that the worst problems occurring in manufacture of an equipment industry are listed, in priority order, with suppliers, communication failures, manpower and demand variations. This foreknowledge is desired since the understanding of problems that require more management control assists in the process of systematization of risk monitoring activity.As to manufacturing flexibility to solve problems pointed in researched company, there are the machine, manpower, mix and product flexibilities. Therefore, if some other company in this business segment does not have time, qualified personnel, capital and other factors necessary to develop a research in its own manufacturing environment, the results presented here provide good indications of which flexibilities could be used in its production processes. Nevertheless, it is recommended the deepening for flexible studies in more companies of the same branch (for instance, three other equipment industries) so that the companies in this industrial sector can, with a greater degree of ownership, define which of flexibility types adopt and what kinds of problems.When analyzing the research goals, it is believed that the study developed for the company has achieved its purpose, since the main problems occurring in its manufacture have been raised as well as the flexibility dimensions required for these problems solution.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML 37.1

37.1 (Fall 1995): 25.

(Fall 1995): 25.