-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Operational Research

p-ISSN: 2324-6537 e-ISSN: 2324-6545

2015; 5(2): 29-38

doi:10.5923/j.ajor.20150502.02

Modeling Productivity and Costs of Timber Harvesting in Plantation Forests Using Two Man Crosscut Saws under Learning Experiments, Tanzania

Dos Santos A. Silayo

Department of Forest Engineering, Faculty of Forestry and Nature Conservation, Sokoine University of Agriculture, Morogoro, Tanzania

Correspondence to: Dos Santos A. Silayo , Department of Forest Engineering, Faculty of Forestry and Nature Conservation, Sokoine University of Agriculture, Morogoro, Tanzania.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Timber harvesting in Tanzania still uses semi-mechanized and labour–intensive logging systems. Manual or semi-mechanised logging operations by using hand tools are more favoured due to cheap labour availability. These tools are operated by locally recruited crews characterized by low levels of skill and literacy. This study was designed to assess tree cutting crews using two man crosscut saws and develop productivity and production cost models in a learning by doing experiment. The experiments were designed in clear felling operations. Three experiments were set where each crew category was studied using time study and work sampling techniques that involved studying crews before training, after training and after the break at an interval of three months. Descriptive statistics and modelling was performed for each crews’ performance. Specific crew’s productivity and cost models have been developed reflecting necessary and unnecessary delay times. The results showed that there is an increase in production rate of the crews after training with a subsequent fall in production rates as the crews resumed cutting after the break. Results showed that there was an average of 40% production increase after training and about 23% production fall after the break for all crew categories. Further the production costs were relatively lower after training as compared to other experiments in the study. Generally, the unit cost of operations observed in the three experiments was mostly affected by labour costs. This is because labour cost accounted about 94% of the hourly costs. This means that since crosscut saw used two people, then any increase in labour charges will linearly affect the unit cost of production at a significant level. This study has demonstrated the importance of training tree cutting productivity and production costs. On the job training of the crews is therefore recommended despite their experience for improved productivity at reduced costs.

Keywords: Forest harvesting, Two man crosscut saw, Logging, Training, Tanzania

Cite this paper: Dos Santos A. Silayo , Modeling Productivity and Costs of Timber Harvesting in Plantation Forests Using Two Man Crosscut Saws under Learning Experiments, Tanzania, American Journal of Operational Research, Vol. 5 No. 2, 2015, pp. 29-38. doi: 10.5923/j.ajor.20150502.02.

Article Outline

1. Introduction

- Timber harvesting in plantation forests in Tanzania started early 1970’s. Logging and road building department of the Forestry Division in the Ministry of Land and Natural Resources carried out timber harvesting in these plantations using semi mechanised logging systems. Logs were sold to the customers at the landing sites [3]. Harvesting was mostly derived by volume with no apparent regard for efficiency and good working conditions of the crews. Beginning 1985 the country’s macro-economic policies changed towards a market economy where private sector started to play a big economic role through privatization. Wood industries were also privatized with the aim of bringing higher operations efficiency in production and lower costs [34]. However, when private companies took over, they adopted some equipments and logging techniques of the public regimes. This means they might have automatically retained the advantages and problems associated with the former regime. Today, timber harvesting in Tanzania still uses semi-mechanized and labour–intensive logging systems. “Manual or semi-mechanised logging operations by using hand tools are more favoured due to cheap labour availability” [20]; [43]. Tree cutting is done manually using two-man crosscut saws, axes or chainsaws. According to [46], traditional methods (basic technologies) are still being used in most developing countries including Tanzania, which in most cases give low productivity. For example in Tanzania log extraction in most forests is done using manual methods, animal power and tractors (crawler tractors, farm tractors and skidders). Manual skidding and forwarding, especially in the first and second thinning are also common in plantation forests. Loading and unloading is performed manually, semi-mechanized by means of front-end loaders. Truck-trailer, tractor-trailers of different sizes and skyline system perform secondary transportation [35]; [32]. The applied log transport systems are those explained by [1] which may be in form of short wood, log length and or tree length.However, after privatisation of some plantation forests in the Southern highlands of the country some companies have introduced heavy duty machines for logging [31. Such machines included feller bunchers which have an ability to sever a tree and move it to dump for which delimbing and toping is done by using chainsaws. Other machines included cable and grapple skidders which have the ability to skid full and or tree lengths. On the other hand, a substantial amount of timber is harvested in agroforestry farms, natural forests and from areas with poor accessibility [27]. Normally logs are either ‘pitsawn’ or sawn on ‘wooden platforms’ by two operators in these areas [28]. Therefore chainsaws and two man crosscut saws remains the major tool for tree cutting in plantations, woodlots and natural forests in Tanzania.These tools are operated by locally recruited crews [42]. Studies (eg. [20]; [44]; [33] have shown that these crews normally form part of the forest working groups which as for other groups in which do involve in road construction and maintenance, tree felling, log extraction and processing, is characterized by low levels of skill and literacy. Although private investors in forest industry recognize the importance of engaging professional staff for optimizing operations, they have made use of policy vacuums and availability of cheap labour to engage less and ill-skilled personnel in harvesting operations. This is due to the fact that about 75% of the Tanzanian population lives in rural areas [24]where most of them survive with low income under poor social infrastructures [20]; [44] ). Since most forests border these populations, workers with little knowledge of forest work can often be engaged at low wage rates. Therefore, workers are given in-service training and thus most learning takes place on site. [21] pointed out that in areas where no formal training is provided, workers learn through trial and error. Such learning may take a substantial number of labour-hours to produce ‘N’ units in a production run [10]. The slower the rate of learning, the greater the cost to the employer, as optimal production levels are not being attained [11]. [25] observed that new machine operators may increase costs of equipment maintenance for example as they may misuse them while increasing environmental hazards as well as threatening their own safety. Therefore this study was designed to measure crews’ performance in terms of production and costs focussing on experienced and inexperienced crews in three experiments. There study aimed at assessing crews before training after on-site-training and after the break on assumption that knowledge of crews depreciates on resuming operations after the break which is a common practise in timber harvesting in Tanzania.

2. Material and Methods

2.1. Description of the STUDY AREA

- This study was carried out at the Sokoine University of Agriculture Training Forest (SUATF), Olmotonyi, in Arumeru District, Arusha region, Tanzania. The forest lies between latitudes 3' 15º – 3' 18º south and longitudes 36' 41º – 36' 42º east. It is bordered by Meru forest plantation to the east and west, Arusha National Park to the north and Timbolo and Shiboro villages to the south. The forest covers about 840 hectares of plantation forests planted with soft and hardwood species and few patches of natural forests. SUATF is on the slopes of Mount Meru, at an altitude of between 1 740 to 2 320 m above sea level [2]. The seasonal climate includes a consistently dry period between June and October. Rainfall patterns vary considerably, but average annual precipitation is about 1200 mm. The mean annual temperatures range between 18°C in the morning and 23°C in the afternoon.

2.2. Experimental Design

- Study groupsThe study was conducted on clear cutting operations using two-man cross cut saws (Fig. 1). The crews were divided into two groups. The first group consisted of newly recruited individuals which were engaged during the study while the second group consisted of experienced operators. The education of all crews was primary level implying that they had complete class seven. Medical reports showed that all crew members were in good health as there was no one suffering from either chronic or communicable diseases that could affect their performance. Each group was first studied in situ (i.e before training) for up to three months, after which they were trained (provided with on site instructions) and studied again and then left to rest for the same period before they were re-engaged and studied again. This arrangement aimed at assessing the impact of production breaks on learning and forgetting behaviour of the crews. This was based on the fact that working experience accumulates as crews spend more time on the job with new skills. This in turn leads to increase in output due to learning and decrease of forgetting [50]; [46].

| Figure 1. Tree cutting using two man crosscut saw at SUA Training Forest, Arusha, Tanzania |

2.3. Training Plan

- The training plan was structured to allow for consistent learning focusing on hands-on skills based on the recommended tree cutting practices such as directional felling, proper limbing and bucking practices, appropriate ergonomic postures during tree cutting, proper use and maintenance of the cutting tools. The training aimed increasing workers competence1 in tree cutting. Accident prevention and safety precautions were also emphasized to reduce workplace accidents, risks and/or hazards. The methods of timber harvesting practises, safety and health training ranged from passive, information based techniques such as lectures to learner-centred performance-based techniques such as hands on demonstrations. The hypothesis was that greater knowledge acquisition that fits well working crews to work settings would occur through training, thereby improving productivity, working behaviours, safety performance and therefore reducing negative safety and health outcomes. On-site training/instructions method was adopted as it has proved to one of the most effective way of imparting crews with required skills following its wide application in the Scandinavia [22]. After the training sessions, field work and work studies were then performed concurrently. Tree cutting productivity and costs were then determined based on the time studies techniques.

2.4. Data Collection

- Productivity studies of tree cutting operations were performed on clear felling operations. Snap-back (zero-reset) time study methods were used to collect data on productive and delay times. This method provided immediate insight into the operation being studied as observed. Selected independent variables that might affect tree cutting productivity, costs and workers’ learning rates were measured and recorded concurrently during the time studies. The selected variables measured and recorded were; stump diameter and diameter at breast height (over bark), in centimetres, tree height, in meters, number of logs bucked, log lengths, in centimetres, number of trees cut per day, and terrain slope in percentages. Labour, equipment and machine costs (fixed and variable costs) were obtained from both primary and secondary sources. Equipment and machinery costs included: purchase price, depreciation, interest, taxes and insurance costs. Labour costs included direct wages and other indirect costs like incentives and fringe benefits.

2.5. Data Analysis

- Descriptive statistical analysis, regression analysis and economic (costs) analyses were performed. Descriptive statistics and regression models were developed to establish relationships between dependent and independent variables using MINITAB 15 Computer Software. The dependent variables were time for; felling (TFell), limbing (TLimb), measuring (TMeas), bucking (TBuck) and the total cutting (TCut) time (excluding delays) all recorded in minutes. The independent variables were; stump diameter (over-bark), (SDia in cm), stump basal area (over-bark) (SBA in cm2), diameter at breast height (over-bark) (Dbh in cm), total tree height (THgt in m), number of logs cut from an individual tree (NLogs), total log length (TLogL in m), log volume (over-bark) (LVol in m3), total log volume (over-bark), (TLvol in m3), total tree volume (over-bark) (TTvol in m3), necessary delay (ND) and unnecessary delay (UND) all recorded in minutes.

2.5.1. Delay Time Analysis

- Delay times are those time elements that are not related to effective working time. The delays were categorized as being necessary (or technical) and unnecessary (being personnel and or operational). The analysis of the delay times was based on the total observation of the individual element that contributes to such a delay. For example, instead of measuring the time used for moving separate from brushing, all these were recorded and analyzed under ‘preparation’ time component. The preparation time which forms part of the necessary delay has been analyzed separate in this study as it constitutes a reasonable portion of the necessary delay time and was easy to be recorded in the field.

2.5.2. Descriptive Time Study Statistics

- Descriptive statistics were performed based on crew category (inexperienced and experienced) and the experimental phase which included a study before training, after training and after the break. This section presents and discusses summary statistics for the dependent and independent variables.

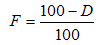

2.5.3. Production Rates Estimate

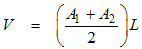

- Productivity and economic results were derived from the time and motion studies of the tree cutting operation. Multiple regression analysis was used to develop productive time models that can be used to estimate tree cutting time as a function of the selected independent variables. The models developed were then used to estimate production rates of the tree cutting operations. The Smalian’s formula (Eq. 1) was used in computing log volumes [9].

| (1) |

| (2) |

| (3) |

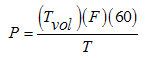

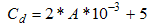

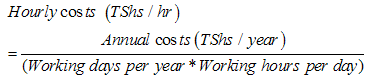

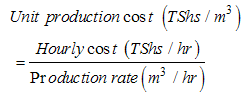

2.5.4. Estimation of Production Costs

- Production costs were determined by analysing both fixed and variable costs of the machines and labour. Labour costs were computed based on the [19] protocol. The scheduled working hours per day for the chainsaw crews were 6 which amount to 180 days per year. Machine costs were estimated based on the rule of thumb approach by [38], Eq. (4).

| (4) |

| (5) |

| (6) |

2.5.5. Multiple Regression Analysis

- In this study, multivariate and univariate (where appropriate) regression were used for modelling. Two different techniques were utilized to create a model for the time consumption in some cases. Firstly, a delay-free time consumption model was formed separately for each element of the work phase assuming that there were no delays which is of course impossible under natural conditions and secondly, time consumption models that excludes unnecessary delay times were formed separately for each element of the work phase on assumption that unnecessary delays could be avoided with training and proper supervisions. Therefore, regression equations have been developed for tree felling (notch cut and felling cut), limbing, measuring, bucking and total cutting times.

3. Results and Discussion

3.1. The Tree Volume Modelling

- In a volume equation, volume is predicted as a function of diameter at breast height (DBH), or DBH and height (h) and some other tree characteristics (xi) such as form quotient, or form point [30]. Therefore, a relationship between the tree diameters at breast height, tree height and the tree volume were developed for each experiment. Regression hypothesis for the relationship of Dbh, h, and xi to Tree Volume was developed. Eg. (7), Thus;

| (7) |

| (8) |

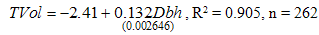

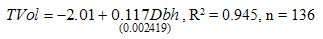

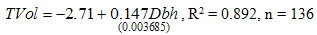

3.1.1. Tree Volume Models for the Experienced Crews

- Before training

| (9) |

| (10) |

| (11) |

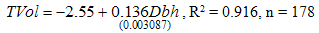

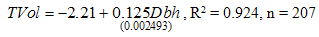

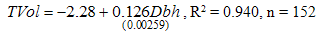

3.1.2. Tree Volume Models for the Inexperienced Crews

- Before training

| (12) |

| (13) |

| (14) |

3.2. Tree Cutting Production Rate Equations

- The total cutting time consumption and the tree volume estimate models were substituted in the general model of production rate (Equation 2) to generate production rate models. These models were developed first by considering the delay free models and secondly the necessary delays included. This assumes that unnecessary delays can be significantly reduced or eliminated by improved supervision and training of the operators. Therefore, the production rate models for cutting time and their respective values of ‘F’ (i.e. a fraction of the productive minutes per tree) are as follows;

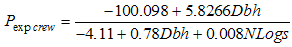

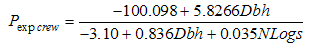

3.2.1. Production Rate Models for Experienced Crews

- The production rate equation of the experienced crews when studied before training in-situ with only effective time included;

| (15) |

| (16) |

| (17) |

| (18) |

| (19) |

| (20) |

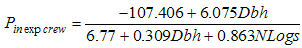

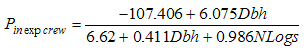

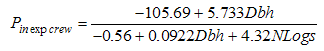

3.2.2. Production Rate Equations for the Inexperienced Crew s

- The production rate equation of inexperienced two-man crosscut saw crews when studied before training in-situ with only effective time included;

| (21) |

| (22) |

| (23) |

| (24) |

| (26) |

| (27) |

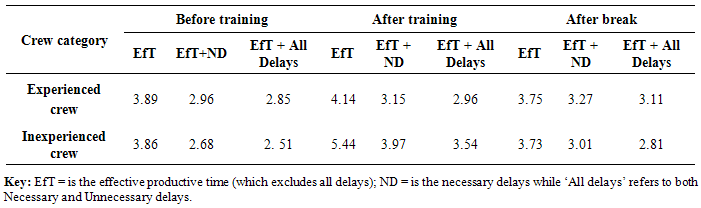

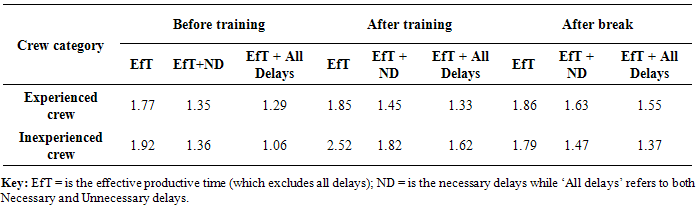

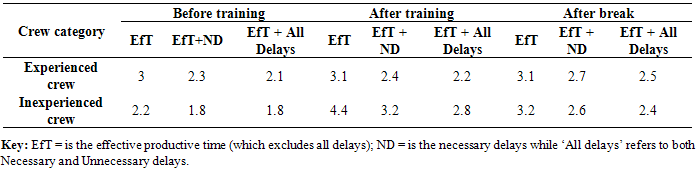

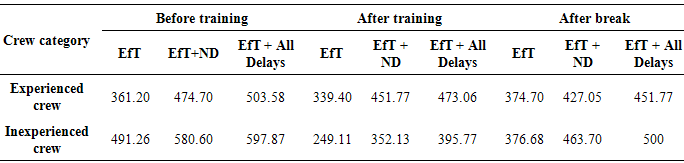

3.3. Tree Cutting Productivity

- Tree harvesting productivity was calculated on the basis of the number and volume (m3) of trees cut per hour. Production volume analysis was performed separately based on the logs produced as well as based on the whole tree volume. The production rates when the volume of whole trees and volume of produced logs is considered are shown in tables 1 and 2 respectively.

|

|

|

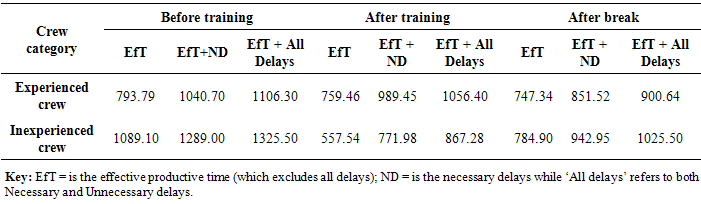

3.4. Tree Cutting Production Costs

- Assuming that all crews worked as described above, and the costs are estimated based on the 2011/12 price levels, the hourly costs would be TShs 1 405. The unit volume production costs for these crews are shown in Tables 4 and 5.The unit cost of cutting operations observed in the tree experiments was mostly affected by labour costs. This is because labour cost accounted about 94% of the hourly cost. A study by [46] found out that labour costs accounted for about 60% when using chainsaw in tree cutting.

|

|

3.5. Production Costs Modelling

- The general model for calculating the unit production costs can be expressed as follows;

| (28) |

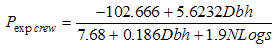

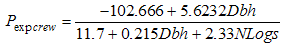

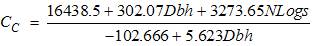

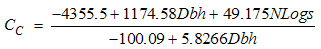

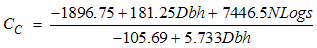

3.5.1. Production Unit Cost Equations for the Experienced Crews

- The unit production cost equation of the experienced crews when studied before training in-situ;

| (29) |

| (30) |

| (31) |

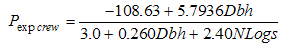

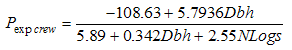

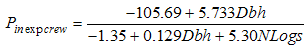

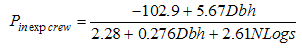

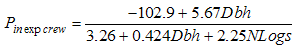

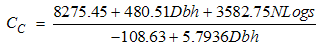

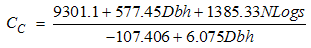

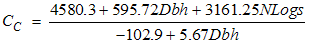

3.5.2. Production Unit Cost Equations for the Inexperienced Crews

- The unit production cost equation for the inexperienced crew when studied for the first time in-situ;

| (32) |

| (33) |

| (34) |

4. Conclusions and Recommendations

4.1. Conclusions

- The findings from this study have shown that there is undoubtful positive effect of onsite instructions to tree cutting crews using two man crosscut saws. This conclusion comes from the fact that there was an increased productivity at reduced costs when crews were provided with basic skill and knowledge on timber harvesting practices for experienced and inexperienced crews. Meanwhile, Job interruptions for a period up to three months can as well lead to decreased productivity and increased cost production costs which may be an indication of knowledge depreciation. Finally, this study has developed productivity and production costs models that are necessary for logging manager to plan for timber harvesting operations with different crew categories.

4.2. Recommendations

- All forest harvesting activities require the basic steps of engineering, techniques and equipment. As the harvesting difficulties increase, the importance of each step increases. This study has demonstrated the importance of training tree cutting productivity and production costs. On the job training of the crews is therefore recommended despite their experience. Further, training should be provided by professional technicians to avoid crews learning skills haphazardly from more experienced workers, who may not be using the best one. With the fact that job interruptions lead to knowledge depreciation, on-site instructions for crews are also recommended on resumption of operations for high productivity and improved crews’ safety.

ACKNOWLEDGEMENTS

- This paper has been produced with the financial assistance of the Norwegian Government through NORAD to the Programme for Agricultural and Natural Resources Transformation for Improved Livelihoods (PANTIL) at Sokoine University of Agriculture. The views expressed in this document are the sole responsibility of the author and do not necessarily represent the views of the institutions involved in this project or of NORAD.

Note

- 1. Competency comprises the specification of the knowledge and skills, and the application of such knowledge and skill. A competent person is one who can do a particular task under operational conditions, to the standard specified, without supervision.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML