Acha Chigozie Kelechi , Nduaguibe Ugochukwu Joe

Department of Statistics, Michael Okpara University of Agriculture, Umudike, Abia State, Nigeria

Correspondence to: Acha Chigozie Kelechi , Department of Statistics, Michael Okpara University of Agriculture, Umudike, Abia State, Nigeria.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

The passion to carry out this research work was ignited by the alarming rate of unemployment in the Nigerian society which mostly result from quest for white-collar jobs among youths and failure of existing industries. The objective of this study is to encourage youths to go into entrepreneurship by helping existing entrepreneurs to maximize their profit and/or minimize their cost irrespective of the constraints militating against them. Both primary and secondary data were collected from the DUNA HOLDINGS PLC ABA. Observation and interview methods were used to source primary data. TORA Optimization system, window version 2.00 was used in maximization and minimization analyses. Maximization analysis suggested that a maximum profit of N3083.7 will be made per day if zero unit of DUNA soft, 2392 unit of DUNA pack and 5211 units of DUNA strip are produced per day. The result of minimization analysis shows that a minimum cost of N66661.14 will be incurred per day if zero unit of DUNA pack, 4784 unit of DUNA soft and 38368 units of DUNA strip are produced per day. It was concluded that the company is neither maximizing profit nor minimizingcost and as such may liquidate in the long run. Recommendations on production combination that will maximize profit and those that will minimize cost were given to the company. It was also recommended that government should organize programs that will educate entrepreneurs on applications of operations research techniques in their production to prevent failure of industries and attract more youths into entrepreneurship so that unemployment will be eradicated.

Keywords:

Constrain, Liquidation, Unemployment, Slack Variable, Dummy, Entrepreneur

Cite this paper:

Acha Chigozie Kelechi , Nduaguibe Ugochukwu Joe , "Entrepreneurial Success and Operations Research Techniques", American Journal of Operational Research, Vol. 2 No. 5, 2012, pp. 45-50. doi: 10.5923/j.ajor.20120205.01.

1. Introduction

Over the years, unemployment has been a problem in Nigeria. This results from the quest for white collar jobs among youths and the failure of businesses mostly infant ones. The failure of infant industries discourages youths that would have loved to become entrepreneurs and possibly employers of labour. Various research reports have shown that these liquidations result from wrong production techniques and this forms the basis of this research work. This study focuses on DUNA HOLDINGS PLC ABA.The main objective of this research work is to help entrepreneurs maximize their profit and/or minimize their cost since it is rare for a company that maximizes its profit and/or minimizes its cost to fail. This forms the basis of this study titled “optimization of entrepreneurship through operations research techniques”.[1], laid emphasis on theimportanceof knowing themaximizationor optimum point of production. There are many factors that can constrain production maximization of profit and minimization of cost but this study concentrates on time and machine constraints. Furthermore, there are several methods of carrying out maximization and minimization analysis in linear programming, for example, simplex method and revised method for maximization analysis and the big M artificial variable technique for minimization analysis. Here, this research work uses software called “TORA Optimization system, version 2.00”.

1.1. Hypotheses

The company claims that they are maximizing their profit and minimizing their cost. This forms two different hypotheses that are to be tested or verified by this research work. The hypotheses are:(a) Ho: Daily profit = Zmax (The company is maximizing their profit)H1: Daily profit≠ Zmax (The Company is not maximizing their profit) (b) Ho: Daily cost = Zmin (The company is minimizing their cost)H1: Daily cost≠ Zmin (The Company is not minimizing their cost)

2. Literature Review

2.1. Review of Works on Entrepreneurship

The word “entrepreneurship” originated from a French word “entreprendre” which means “undertaker”. The name is as a result of the fact that the entreprendre undertakes the risk of the enterprise.[2]laissez-faire capitalism popularized entrepreneurship.[3] was the first to define entrepreneurship and according to him, it means buying goods and services at a known price with an intension of disposing them in near future at an unknown price and bearing the inherent risk.[4] used entrepreneurship to mean a function that involves bringing together of the factors of production (land, labour and capital) with the provision of management and bearing the associated risk of the venture.[5] argued that entrepreneurship involves running a business whether small or large scale in agriculture, manufacturing, distribution, processing and services.[6] identified three types of entrepreneurship as pure entrepreneur, franchise entrepreneur and others. [7]supported the classification by Hutt but went further to classify the third type (others) into eight classes which include: solo self-employed individuals, team builders, independent innovators pattern multipliers, economy of large scale exploiters, capital aggregators, acquirers and buy sell activity persons. According to him, the solo self-employed refers to owner managers of enterprises. This owner manager may employ few workers to help him perform the job. DUNA HOLDINGS PLC which is the case study of this research work is a typical example of solo self-employed.[8] in his classic book “the achieving society” identified eight characteristics of an entrepreneur as; desire for responsibility, preference for moderate risk, confidence in personal success, desire for immediate feedback, high level of energy and drive to work hard, future orientation, skilled in organization and achievement oriented. According to him, any entrepreneur that possesses these characteristics will surely achieve his/her entrepreneurial goals.[8] argues that the first step to entrepreneurship is what he called SWOT analysis which means analysis of strengths, weaknesses, opportunities and threats of the system in which the entrepreneur exists. He further identified four basic components that will help in entrepreneurship as man, machine, method and money[the 4M’s]. He goes further to say that though the 4m’s are very important but “method” is more important than others.[10] in his article “today’s manager” identified crude methods of cost reduction in business as; downsizing, which simply means reducing the number of workers in the company, restructuring and reduction of customer service level. According to him, downsizing is not a good method of cost reduction as it leads to the layoff of good employees leaving the business with “deadwood” staff who are expected to do twice as much work as before. He went further to say that restructuring includes; closing of obsolete plants or branches, administrative overhauls, selling of non-core operations and improving internal processes. Reducing customer service, according to him, is not also a good method of reducing cost because a neglected customer will no doubt become an ex-customer as he or she will simply go to the company’s competitors who will be glad to service their needs at the company’s expense. Moreover, customer satisfaction helps to establish long-term relationships as the customer may network other clients and refer them to your business which not only gives you a source of continuous business but also a viable route to new business opportunities which saves your company money that might be spent on advertising. However, in institute of management trade magazine/journal business identified cutting corners in production or service methods as one of the rampant but bad ways of reducing cost. In fact, some business owners feel that by using cheaper materials and workers and by playing with quality they can cut cost and save money. Although that cost may be cut at short run but often the product or service standards suffer and if this results in such low quality products that repairs and rework are required, this will add to cost and obviously is not a good thing. Customers will become unhappy with the low quality and may eventually move to another supplier and the business will suffer from both a loss of business and reputation. He rather suggested that the business should look to methods that allow it to produce its services at the same level with lesser costs. This means reducing wastage to help reduce cost. He further suggested that the effective ways of reducing cost include; training the workers and using some form of total quality management tools.

2.2. Review of Works on Operations Research, Optimization and Linear Programming

Operations research, or Operational Research in British usage, is a discipline that deals with the application of advanced analytical methods to help make better decisions. This implies that operations research as the application of scientific methods, tools and techniques to problems involving operations of systems so as to provide those in control of the system with optimum solution of the problem, see http://en.wikipedia.org/wiki/Operations_researchOperations research[11].[12] defined operations research to be a scientific method of providing executive department with a quantitative basis for decisions regarding the operations under their control.[13] identified the scope for application of operations research to include; industry, defence, planning, agriculture and public utilities. They went further to say that the application of operations research in industry can be seen in the field of production, blending, product mix, inventory control, demand forecast, sales and purchase, transportation, repair and maintenance. This research work is interested in the application of operations research in industry specifically in the field of production.[14] in their classical book “problems in operations research: principles and solutions” recorded that operations research techniques have been successfully applied in problems involving linear programming, inventory control, dynamic programming, queuing theory, decision theory, network techniques, etc. This study focuses on the application of operations research in linear programming.[15] in his book “linear programming and games theory” stated the characteristics of operations research to include: system orientation, use of interdisciplinary teams, application of scientific methods, uncovering of new problems, improvement in the quality of decisions, etc. This research work wants to utilize operations research techniques in improving the quality of decisions of entrepreneurs. The fact of optimizing means making the best of anything or a mathematical technique for finding a maximum or minimum value of a function of several variables subject to a set of constraints, as linear programming or systems analysis, see http://dictionary.reference.com/browse/optimization[16].[17] explained optimization to mean “getting the best possible result out of something”. He went further to say that optimization may be constrained or unconstrained. He also stated that whether constrained or unconstrained, it will be either linear or nonlinear programming. This research work focuses on constrained linear programming.[17] stated that a linear programming model must satisfy five basic properties namely: proportionality, additivity, continuity, certainty and finite choices. The researchers ensured that this study satisfied these properties.

2.3. Historical Background of Duna Holdings Plc

DUNA HOLDINGS PLC was established in the year 2000. It is owned and managed by Mr. Damian Uche Nathan Agomuo. The name DUNA was coined with his initials. The company started with only a single machine (2.500QM) and was only producing a small white bag which was called DUNA soft. The owner (entrepreneur) was working alone then, he had no assistance and no worker. He produced, supplied, and organized the business alone. In 2003, he bought another machine called 6.00QJ. Then another product was introduced which is also a poly bag but black and bigger than the former and also with a handle and he named it DUNA pack. The work became so tedious for him, so in 2004 he employed two people who carry out the production processes while he focused on supply, record keeping and management of the business. In 2007 he bought another machine which is also another brand (9.00QC) and also introduced another brand of poly bag which is bigger than the previous ones and is yellow in colour with black strips and he called it DUNA STRIP. In 2009, he employed another worker to make work easier. Since then, he has been in the business and has been able to run the business effectively.

3. Methodology

3.1. Method of Data Collection

Both primary and secondary data are collected for this research work from DUNA HOLDINGS PLC ABA. Observation and interview methods are used to source primary data. The machines were observed and the time it takes to produce each of the three products in each of the machines was recorded. The observation process was repeated ten times in ten different days to find out if daily temperature affects the rate at which the machines work but the same result was obtained each time which shows that the working rate of the machines is not affected by change in temperature. The entrepreneur was interviewed and during the interview he released some secondary data which include: the profit per unit of each of the products, the number of hours the machine can work nonstop, the profit made per day and the cost incurred per day.

3.2. Data Presentation

Data collected from DUNA HOLDINGS PLC; the firm manufactures three (3) products namely; Duna soft, Duna Pack and Duna strip. Production starts from 7.00am and closed at 6.00pm. The firm makes use of 3 machines namely 2.500QM, 6.00QJ and 9.00QC. Each machine can produce the three (3) products, cost per unit of each of the product are ; Duna soft 30k i.e. N 0.3; Duna pack 50k i.e. N 0.5 and Duna Strip 17Ok i.e. N 1.70. The selling prices for the products are: Duna Soft N40 per 100 – 40k per Unit; Duna Pack N70 per 100 --- 70k per unit; Duna Strip N220 per 100 --- N2.20 per unit. From the data on cost price and selling price, the profit is as follows: Duna soft 10k per unit i.e. N 0.1; Duan pack 20k per unit i.e. N 0.2; Duna strip 50k per unit i.e. N 0.5.| Table 1. The time in seconds required to manufacture a unit |

| | Machine | Duna soft | Duna pack | Duna strip | | 2.500QM | 2 | 3 | 4 | | 6.00QS | 3 | 2 | 6 | | 9.00QC | 5 | 4 | 3 |

|

|

The time in seconds required to manufacture a unit of each of the products in each machine is given in table 1.2.500QM can work for not more than 8 hours nonstop; 6.00QS can work for not more than 10hours non-stop; 9.00QC can work not more than 7 hours nonstop. The company makes daily profit of N2350 and the company hours daily cost of N84500.

3.3. Formation of Linear Programming Problem (LPP)

The general model for an LPP to be optimized; Subject to;

Subject to;  Where Xj is the jth decision variable, Cj is the jth coefficient of the decision variable and aij is the ijth coefficient of the constraints. Let DUNASOFT=X1, DUNAPACK=X2 and DUNASTRIP=X3 which are the decision variables and let Z be the objective function. Converting time to seconds then;The LPP for maximization becomes Max Z= 0.1x1 + 0.2X2 + 0.3X3S.t 2X1 + 3X2 + 4X3 ≤288003X1 + 2X2 + 6X3 ≤360005X1 + 4X2 + 3X3 ≤25200X1 + X2 + X3 ≤43200 X1,X2,X3 ≥ 0The LPP for the minimization problem becomes:MmZ = 0.3x, + 0.5x2 + 1.7x3S.t2x1 + 3x2 + 4x3≥ 288003x1 + 2x2 + 6x3≥ 360005x1 + 4x2 + 3x3≥ 25200X1, X2, X3≥ 0

Where Xj is the jth decision variable, Cj is the jth coefficient of the decision variable and aij is the ijth coefficient of the constraints. Let DUNASOFT=X1, DUNAPACK=X2 and DUNASTRIP=X3 which are the decision variables and let Z be the objective function. Converting time to seconds then;The LPP for maximization becomes Max Z= 0.1x1 + 0.2X2 + 0.3X3S.t 2X1 + 3X2 + 4X3 ≤288003X1 + 2X2 + 6X3 ≤360005X1 + 4X2 + 3X3 ≤25200X1 + X2 + X3 ≤43200 X1,X2,X3 ≥ 0The LPP for the minimization problem becomes:MmZ = 0.3x, + 0.5x2 + 1.7x3S.t2x1 + 3x2 + 4x3≥ 288003x1 + 2x2 + 6x3≥ 360005x1 + 4x2 + 3x3≥ 25200X1, X2, X3≥ 0

4. Data Analysis

This chapter deals with maximization and minimization analysis, using TORA Optimization system, windows version 2.00 software.

4.1. Maximization Analysis

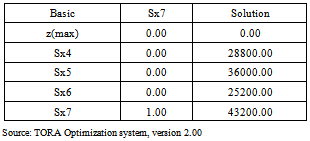

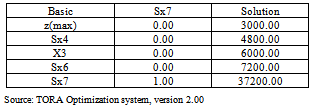

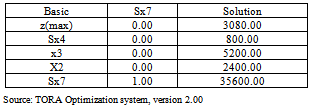

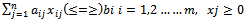

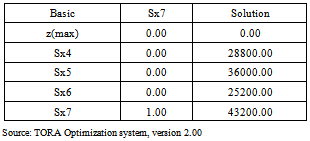

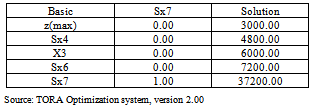

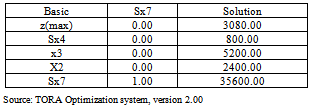

Max Z = 0.1X1 + 0.2X2 + 0.5X3S.t2X1 + 3X2 + 4X3 ≤ 288003X1 + 2X2 +6X3 ≤ 360005X1 + 4X2 +3X3 ≤ 25200X1 + X2 +X3 ≤ 43200X1, X2, X3≥ 0Now converting the problem to standard form givesMax Z = 0.1X1 + 0.2X2 + 0.5X3 + 0Sx4 + 0Sx5 + 0Sx6 + 0Sx7S.t2X1 + 3X2 + 4X3 + Sx4 = 288003X1 + 2X2 + 6X3 + Sx5 = 360005X1 + 4X2 + 3X3 + Sx6 = 25200X1 + X2 + X3 + Sx7 = 43200X1, X2, X3, Sx4, Sx5, Sx6, Sx7, ≥ 0Where, Sx4, Sx5, Sx6, and Sx7 are slack variables. There co-efficient in the objective function is zero because they are idol resources and contribute nothing to the objective function. To obtain the initial basic feasible solution (IBFS), we set X1 = X2 = X3 = 0Hence from first constraint, Sx4= 28800From 2nd constraint Sx5= 36000From 3rd constraint, Sx6 = 25200From 4th constraint Sx7 = 43200From objective function, Zmax = 0Iteration results using TORA Optimization system, version 2.00 for maximization.Since all the elements in Cj- Zj row are negative and zeros, an optimal solution has been reached. The solution is X2 = 2400.00, X3 = 5200.00, Sx4 = 800.00, Sx7 = 35600.00 and Zmax = 3080.00.Table 2. Iteration 1

|

| |

|

Table 3. Iteration 2

|

| |

|

Table4. Iteration 3

|

| |

|

Table 5. Iteration 4

|

| |

|

4.2. Minimization Analysis

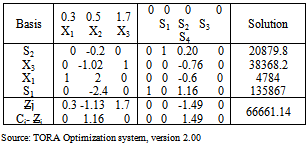

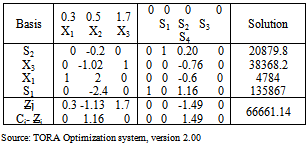

The minimization problem isMin Z = 0.3X1 + 0.5X2 + 1.7X3S.t2X1 + 3X2 + 4X3 ≥ 28003X1 + 2X2 + 6X3 ≥ 360005X1 + 4X2 + 3X3 ≥ 25200X1 + X2 +X3 + ≥ 43200X1, X2, X3, ≥ 0Now converting to standard form gives:Min Z = 0.3X1 + 0.5X2 + 1.7X3 + 0S1 + 0S2 + 0S3 + 0S4S.t2X1 + 3X2 + 4X3 – S1 = 288003X1 + 2X2 + 6X3 – S2 = 360005X1 + 4X2 + 3X3 – S3 = 25200X1 + X2 + X3 – S4 = 43200X1, X2, X3, ≥ 0, S1, S2, S3, S4 ≤ 0. Since S1, S2, S3 and S4 do not satisfy the non-negativity condition, there is no initial basic feasible solution (IBFS). In order to obtain IBFS, the big M artificial variable technique is employed. We now have:Min Z = 0.3X1 + 0.5X2 + 1.7X3 + 0S1 + 0S2 +0S3 + 0S4 +MA1 + MA2 +MA3 + MA4S.t2X1 + 3X2 + 4X3 – S1 + A1 = 288003X1 + 2X2 + 6X3 – S2 + A2 = 360005X1 + 4X2 + 3X3 – S3 + A3 = 25200X1 + X2 +X3 – S4 + A4 = 43200X1, X2, X3, S1, S2, S3, S4, A1, A2, A3, A4 ≥ 0Hence the IBFS becomes: A1 =28800, A2 = 36000, A3 = 25200, A4 = 43200. Appling the TORA Optimization system, version 2.00, it was obvious, that at 6th iteration (below) an optimal solution has been reached hence S2 = 20879.8, X3 = 38368.2, X1 = 4784, S1 = 135867. Also, all the elements in Cj- Zj row are positive and Zeros confirming the fact that the optimal solution have been reached.

5. Summary, Conclusions and Recommendations

5.1. Summary

This study’s findings are summarized separately with respect to maximization analysis and minimization analysis which is the basic idea of the research work.

5.1.1. Summary on Maximization Analysis

From the maximization analysis using simplex method, it is observed that an optimal solution was reach when, X1= 0, X2=2392, X3= 5210, and Zmax =3083.7. No cognizance will be taken about S1 and S4 (the slacks) since they are fictitious products yielding zero profit and incurring zero cost hence the solution to the maximization problem depend only on the decision variables X1 X2 X3 which represent DUNA products. Similarly, the maximization analysis using revised method confirms the result obtained using simplex method because the optimal solution was reached also at X1= 0, X2=2392, X3 =5210.6 and Zmax= 3083.7. S1and S4 also being slack and fictitious. Now since X1, X2 and X3 represent DUNA soft, DUNA pack and DUNA strip respectively and cannot occur in decimal fraction, their values will be rounded up to the nearest whole number so that X= 0, X2=2392 and X35211.

5.1.2. Summary on Minimization Analysis

From the minimization analysis, it is observed that the optimal solution was reached when X1=4784, X2 = 0, X3=38368.2 and Zmin=66661.14. Here also S2 and S4 (surplus) are free products that incurs zero cost and yield zero profit so are not taken cognizance of. The artificial variables disappeared at the end of the analysis as expected so the solution of the minimization analysis depends only on the decision variables X1, X2 and X3 = (DUNA PRODUCTS). Similarly X1, X2 and X3 should be rounded up to the nearest whole number since no fraction product can be produce so their value in the minimization problem becomes X1 = 4784, X2 = 0 and X3 = 38386.

5.2. Conclusions

Conclusions on Maximization AnalysisSince in both methods applied in maximization analysis, Zmax=3083.7>Daily profit=2350, it suffices the rejection of Ho and the conclusion that the company is not maximizing its profit. Now for the company to maximize its daily profit, it should produce 2392 units of DUNA pack, 5211 units of DUNA strip per day and stop the production of DUNA soft. When this is done, a daily profit of N3083.7 will be made and this is the maximum profit the company can make with the influence of the constraints it operates in.Conclusions on Minimization AnalysisSince Zmin=N6666.14 Daily cost= N84500, it suffices the rejection of Ho and the conclusion that the company is not minimizing their daily cost. For the company to minimize their daily cost, they should stop the production of DUNA pack and produce 4784 units of DUNA soft and 38368 units of DUNA strip per day. When this is done, they will incur a cost of N6666.14 per day and it represents the minimum cost they can incur in the influence of the constraints they operate upon.

5.3. Recommendations

a)The company should stop the production of DUNA soft and produce 2392 units of DUNA pack and 5211 units of DUNA strip per day if they really want to maximize their profit as that will increase their daily profit from N2350 to N3083.7 which represents a profit increase of N733.7 daily.b) If the company wants to minimize its cost, it should stop the production of DUNA pack; produce 4784 units of DUNA soft and 38368 units of DUNA strip per day. When this is done, it will incur a cost of N66661.14 as against N84500 which will reduce their cost by N17838.86c) Other entrepreneurs should adopt operations research techniques in their production in order to be maximizing their profit and/or minimizing their cost to prevent business failure.d) Government should sensitize entrepreneurs through seminars on the benefits of applying operations research techniques. This will help stem the tide of business failures. The success of existing businesses will encourage youths into entrepreneurship, reduce unemployment and increase gross domestic product.e) Future researchers should apply operations research in other life endeavours and fields of study.

References

| [1] | Acha, C.K. Comparative Analysis of Quadratic and Cubic Models on Egg Production. Animal Production Research Advances, vol.7, no.2, pp.110-115, 2011. |

| [2] | Smith, A.C. Laissez-faire Capitalism: New York: Jackul Printing Press, 1776. |

| [3] | Cantellion, R. Entrepreneurial Concepts. Sidney: Danward limited, 1792. |

| [4] | Baptist, J.P. Entrepreneurship.JHilson Publishers London, 1803. |

| [5] | Siropolis, N.C.Small Scale Entrepreneurship: London: Stevepub Limited, 1977. |

| [6] | Hutt, C.O. Entrepreneurship and Management. New York: Jackub Printing Press, 1988. |

| [7] | Drucker, P. F. (1983). Concept of the corporation. New Brunswick, N.J., U.S.A.: Transaction Publishers |

| [8] | Lelland, M.C.C. The Achieving Society Rockey. New York: J Press, 1961. |

| [9] | Nwobi, A.C. Economic and Social Statistics. Enugu, Nigeria: Eldemak publishers, 2007. |

| [10] | Ravindran, R. Share Buyback Craze-experience of Malaysia, International Business Colloquium, Malaysia, University Putra,2008. |

| [11] | On-line Available: http://en.wikipedia.org/wiki/Operations_ research Operations research accessed on 10th June, 2012. |

| [12] | Morse, P and Kimbell D. Principles of Operations Research. Sidney: Leroy and company Limited, 1958. |

| [13] | Gupta, P.K and Hira, D.S.Operations Research. New Delhi: S. Chand Limited, 1979. |

| [14] | Gupta, P.K. and Hira, D.S. Problems in Operations Research: Principles and Solution. New Delhi: S. Chand Limited, 2006. |

| [15] | Gupta, P.K. Linear Programming and Theory of Games. New Delhi: S. Chand Limited, 1987. |

| [16] | On-line: http://dictionary.reference.com/browse/optimization accessed on 10th June, 2012. |

| [17] | Taha, H.A. Operations Research: An Introduction, Prentice Hall; 9th edition, 2011. |

Subject to;

Subject to;  Where Xj is the jth decision variable, Cj is the jth coefficient of the decision variable and aij is the ijth coefficient of the constraints. Let DUNASOFT=X1, DUNAPACK=X2 and DUNASTRIP=X3 which are the decision variables and let Z be the objective function. Converting time to seconds then;The LPP for maximization becomes Max Z= 0.1x1 + 0.2X2 + 0.3X3S.t 2X1 + 3X2 + 4X3 ≤288003X1 + 2X2 + 6X3 ≤360005X1 + 4X2 + 3X3 ≤25200X1 + X2 + X3 ≤43200 X1,X2,X3 ≥ 0The LPP for the minimization problem becomes:MmZ = 0.3x, + 0.5x2 + 1.7x3S.t2x1 + 3x2 + 4x3≥ 288003x1 + 2x2 + 6x3≥ 360005x1 + 4x2 + 3x3≥ 25200X1, X2, X3≥ 0

Where Xj is the jth decision variable, Cj is the jth coefficient of the decision variable and aij is the ijth coefficient of the constraints. Let DUNASOFT=X1, DUNAPACK=X2 and DUNASTRIP=X3 which are the decision variables and let Z be the objective function. Converting time to seconds then;The LPP for maximization becomes Max Z= 0.1x1 + 0.2X2 + 0.3X3S.t 2X1 + 3X2 + 4X3 ≤288003X1 + 2X2 + 6X3 ≤360005X1 + 4X2 + 3X3 ≤25200X1 + X2 + X3 ≤43200 X1,X2,X3 ≥ 0The LPP for the minimization problem becomes:MmZ = 0.3x, + 0.5x2 + 1.7x3S.t2x1 + 3x2 + 4x3≥ 288003x1 + 2x2 + 6x3≥ 360005x1 + 4x2 + 3x3≥ 25200X1, X2, X3≥ 0 Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML