Nabendu Sen 1, Biman Kanti Nath 2, Sumit Saha 1

1Department of Mathematics, Assam University, Silchar, India

2Department of Mathematics, N.C College, Badarpur, India

Correspondence to: Nabendu Sen , Department of Mathematics, Assam University, Silchar, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

In traditional inventory models, parameters are considered to be constants. But in reality, the system parameters cannot be considered as constants. In this paper, a production Inventory model with deterioration is developed to determine optimal inventory policy in fuzzy environment. It is assumed that some of the parameters of the model are fuzzy number due to their impreciseness. An effort is given to study the effect of different defuzzification techniques on the optimal value of the variable and associated cost function. An algorithm is proposed to solve the developed model and coded in MATLAB. To validate optimal policy derived, numerical examples along with graphical representations of the results are presented. Finally sensitivity analysis has been carried out.

Keywords:

Fuzzy Production, Fuzzy Demand, Deterioration, Defuzzification, Optimal Inventory Policy

Cite this paper: Nabendu Sen , Biman Kanti Nath , Sumit Saha , A Fuzzy Inventory Model for Deteriorating Items Based on Different Defuzzification Techniques, American Journal of Mathematics and Statistics, Vol. 6 No. 3, 2016, pp. 128-137. doi: 10.5923/j.ajms.20160603.07.

1. Introduction

The deterioration plays an important role in the study of inventory control. Several researchers developed inventory models with deterioration in precise and imprecise environment. Some of the researchers considered demand rate, deterioration, production rate etc. as constants and others considered those parameters as fuzzy in nature. Jaggi et al. [1] developed fuzzy inventory model with deterioration where demand was taken as time-varying. Nagar and Surana [5] developed fuzzy inventory model for deteriorating items with fluctuating demand. Nezhad et al. [4] developed periodic and continuous review model by taking fuzzy set up cost, holding cost and shortage cost. Jain et al. [3] gave a fuzzy generic algorithmic approach for inventory model for deteriorating items with back orders under fuzzy inflation and discounting over random planning horizon. Kumar and Rajput [6] developed a fuzzy inventory model for deteriorating items with time dependent demand and partial backlogging where demand rate, deterioration rate and backlogging rate were considered triangular fuzzy numbers. Roy et al. [8] developed inventory model for seasonal deteriorating item with linearly displayed stock dependent demand in imprecise environment under inflation and time value of money. Saha and Chakra borty [11] developed inventory model with time dependent demand and deterioration with shortages. Recently Jaggi et al. [2] developed inventory model for optimal replenishment policy under inflationary condition. In the field of fuzzy inventory modeling for deteriorating items, the work of Roy [9], Rong et al. [10], Panda et al. [7] are worth mentioning. All the above mentioned work discussed inventory models for deteriorating items in fuzzy environment and defuzzification were done by various methods.In present paper, a production inventory model for deteriorating item is discussed. The rate of deterioration along with other parameters is taken as triangular fuzzy numbers. For defuzzification, we have used signed distance method, centroid method and graded mean integration method separately. To the best of authors’ knowledge, this type of defuzzification approach at a time has not done in literature in order to see the effect on the optimal results.

2. Preliminaries on Fuzzy Numbers and Defuzzification Methods

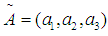

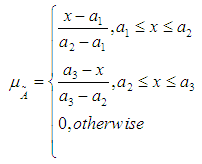

It is always better to discuss decision making problems in fuzzy sense. The use of fuzzy number is better than the probabilistic approach as mentioned by Zadeh [12, 13].Fuzzy Number: A fuzzy number is a fuzzy set which is both convex and normal.A fuzzy number

with

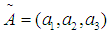

with  is triangular if its membership function is defined as

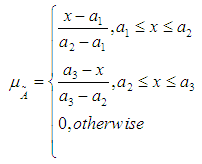

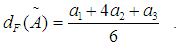

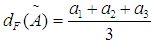

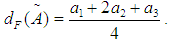

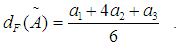

is triangular if its membership function is defined as  In the same manner, trapezoidal fuzzy number, parabolic fuzzy number, pentagonal fuzzy number, hexagonal fuzzy numbers etc. can be defined. There are number of methods available for defuzzification of fuzzy numbers. The mostly used methods for defuzzification are graded mean integration method, centroid method and signed distance method. Graded mean integration representation of triangular fuzzy number is defined as

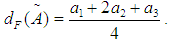

In the same manner, trapezoidal fuzzy number, parabolic fuzzy number, pentagonal fuzzy number, hexagonal fuzzy numbers etc. can be defined. There are number of methods available for defuzzification of fuzzy numbers. The mostly used methods for defuzzification are graded mean integration method, centroid method and signed distance method. Graded mean integration representation of triangular fuzzy number is defined as The centroid method for triangular fuzzy number is

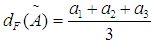

The centroid method for triangular fuzzy number is  and signed distanced method for triangular fuzzy number is defined as

and signed distanced method for triangular fuzzy number is defined as

3. Assumptions

I. The inventory system involves production of single item.II. Lead time is zero and shortages are not allowed.III. The set-up cost, deterioration rate, holding cost are fuzzy.IV. The production rate, demand rate are fuzzy.V. Replenishment is instantaneous.

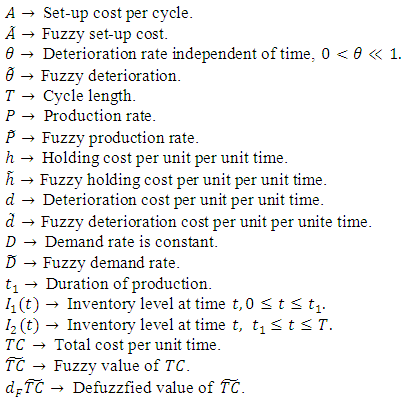

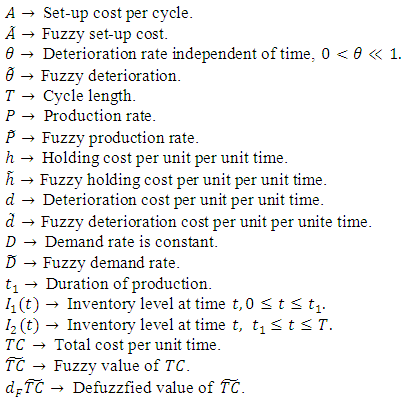

4. Notations

5. The Proposed Model

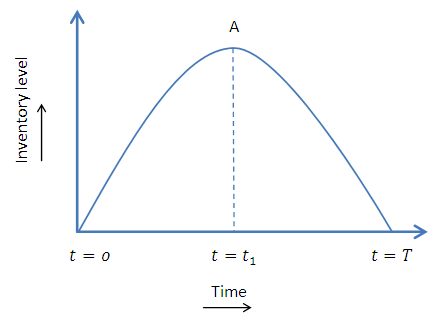

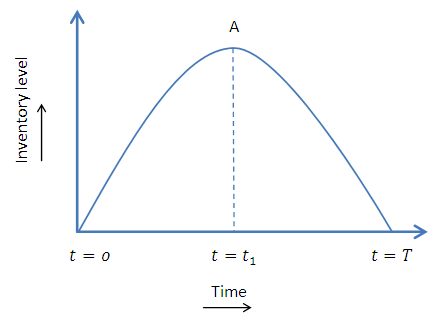

The objective of this work is to formulate and solve production inventory model considering the aforesaid assumptions.At  the inventory level is zero. It increases in the time period

the inventory level is zero. It increases in the time period  due to production at the constant rate

due to production at the constant rate  After that inventory level decreases and reaches to zero at

After that inventory level decreases and reaches to zero at  This depletion is due to demand and deterioration of the item. This situation is represented in fig 1.

This depletion is due to demand and deterioration of the item. This situation is represented in fig 1. | Figure 1. |

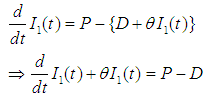

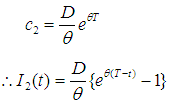

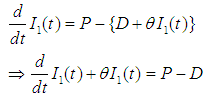

For  The differential equation governing the situation is

The differential equation governing the situation is  | (5.1) |

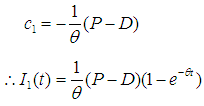

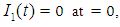

which is linear. Therefore the solution is given by Using the condition that

Using the condition that  we get

we get | (5.2) |

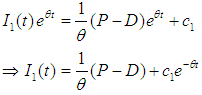

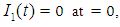

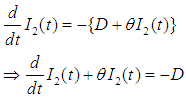

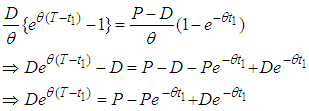

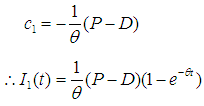

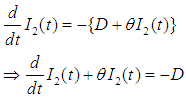

For  the differential equation governing the situation is

the differential equation governing the situation is | (5.3) |

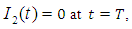

Which is linear and therefore, the solution is given byUsing the condition that  we get

we get | (5.4) |

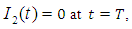

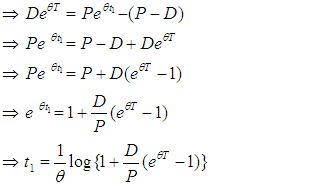

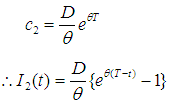

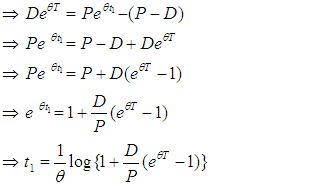

Now we find  by using

by using

| (5.5) |

| (5.6) |

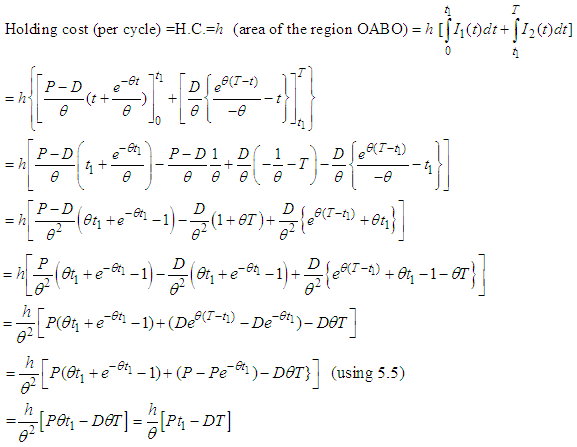

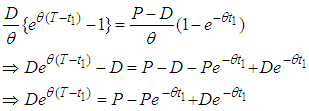

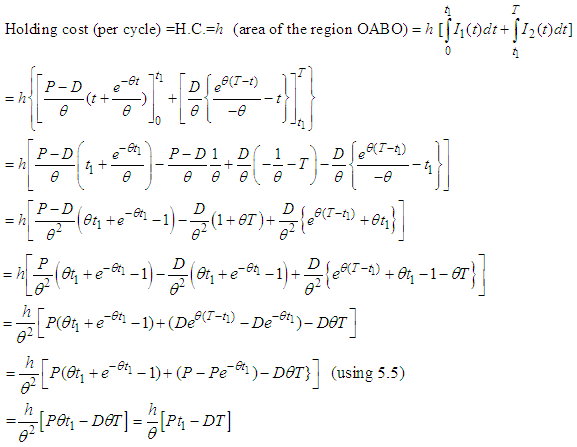

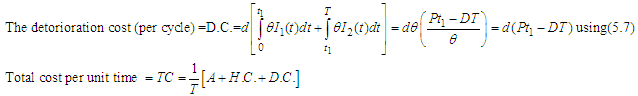

Now we find different inventory costs namely 1. Holding cost per cycle2. Deterioration cost per cycle3. Total cost per unit time | (5.7) |

| (5.8) |

| (5.9) |

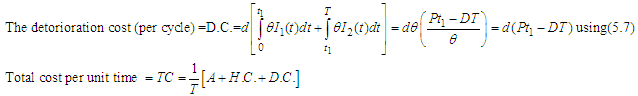

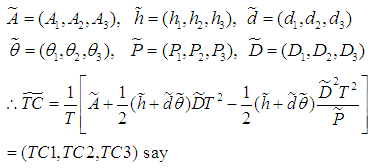

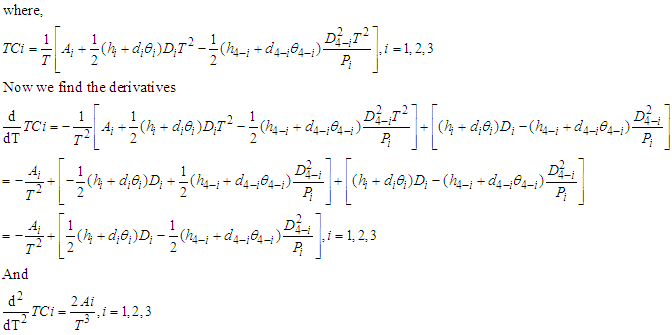

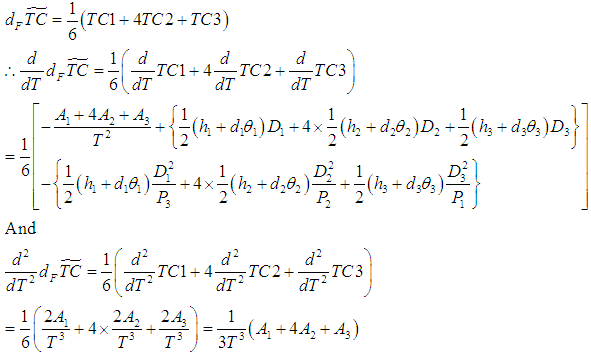

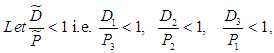

6. Fuzzy Model

Due to uncertainty in the environment, it is not always possible to define certain parameters with certainty for which we fuzzify some parameters. Here we fuzzify the parameters  We consider triangular fuzzy numbers

We consider triangular fuzzy numbers

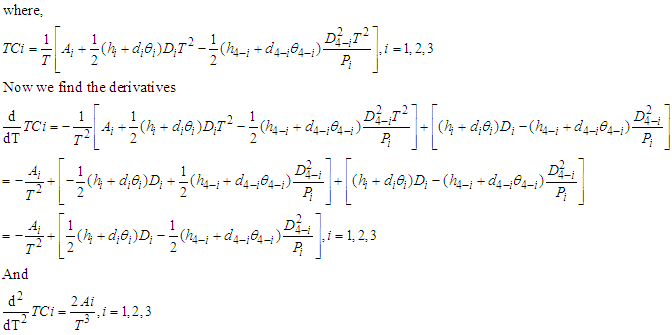

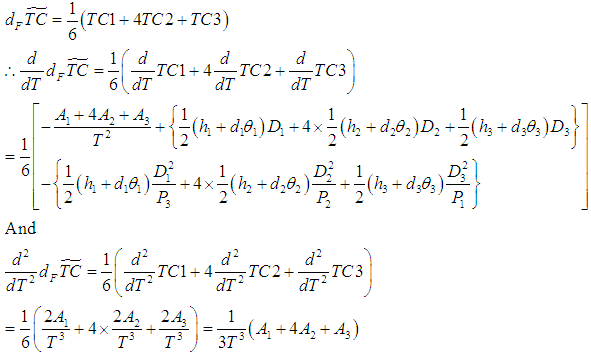

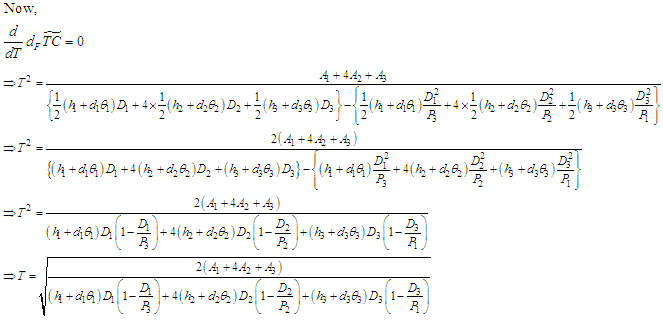

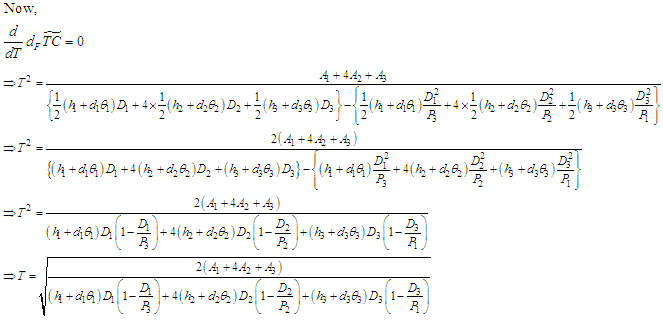

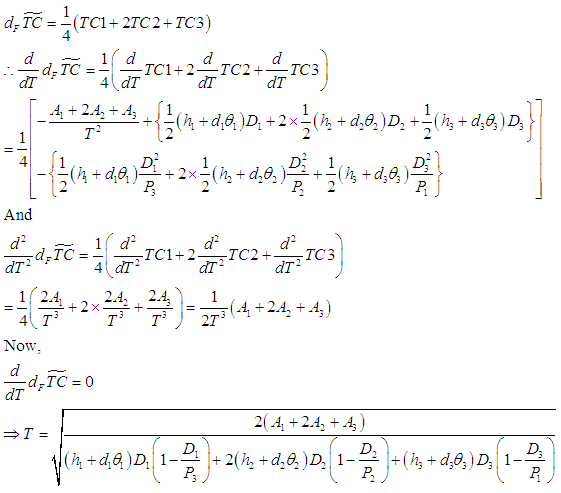

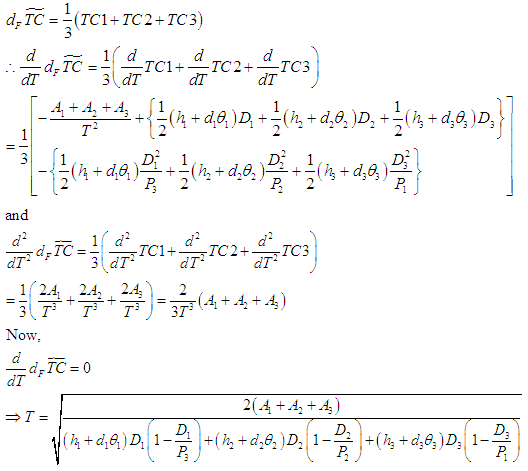

Now we find the defuzzified value of

Now we find the defuzzified value of  by 1. Graded mean integration method2. Signed distance method3. Centroid methodBy Graded Mean Integration MethodThe defuzzified value is:

by 1. Graded mean integration method2. Signed distance method3. Centroid methodBy Graded Mean Integration MethodThe defuzzified value is:

By Signed Distance MethodThe defuzzified value is:

By Signed Distance MethodThe defuzzified value is: By Centroid MethodThe defuzzified value is:

By Centroid MethodThe defuzzified value is:

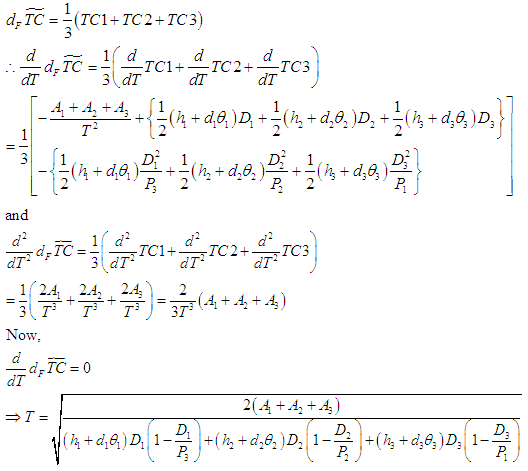

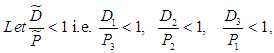

then in each case,

then in each case,  exists and clearly for this value of

exists and clearly for this value of  we see that

we see that so that defuzzified value of total cost per unit time i.e.

so that defuzzified value of total cost per unit time i.e.  is minimum. And the minimum value is obtained by putting the value

is minimum. And the minimum value is obtained by putting the value  in

in  for the respective cases.

for the respective cases.

7. Solution Procedure

To solve the proposed model, an algorithm is developed and coded in MATLAB. The proposed algorithm is as below.Algorithm:

8. Results and Discussion

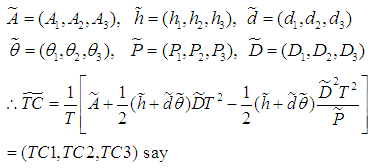

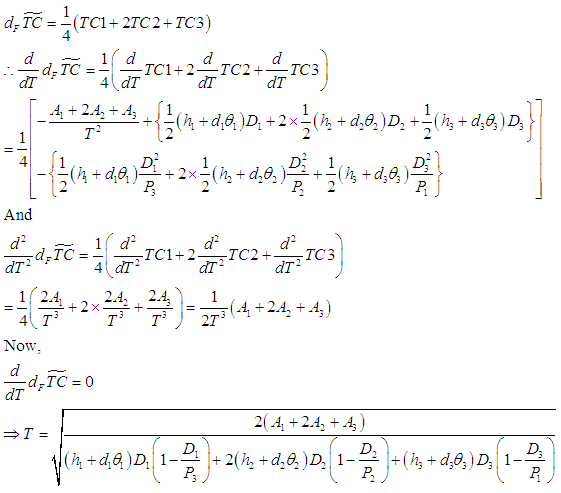

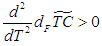

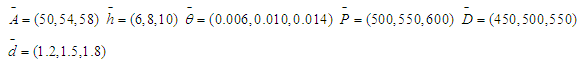

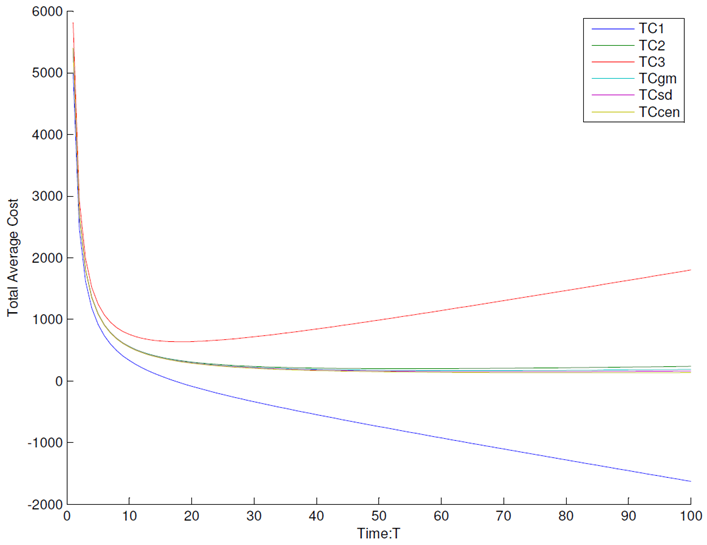

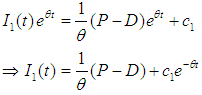

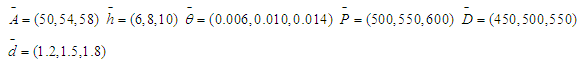

The following numerical values of the parameters in appropriate units are considered to analyze the model numerically and graphically, The output of the model using MATLAB software under different defuzzification methods are given below TCgm=168.7322, T=0.6400; TCsd=151.7654, T=0.7100 and TCcen=132.6469, T=0.8100.From the above results indicate that total cost is minimum with corresponding value of T when centroid method of defuzzification is used. On the other hand T is minimum with corresponding total cost when graded mean integration value is used. The cost functions are plotted against T in the following figure.

The output of the model using MATLAB software under different defuzzification methods are given below TCgm=168.7322, T=0.6400; TCsd=151.7654, T=0.7100 and TCcen=132.6469, T=0.8100.From the above results indicate that total cost is minimum with corresponding value of T when centroid method of defuzzification is used. On the other hand T is minimum with corresponding total cost when graded mean integration value is used. The cost functions are plotted against T in the following figure. | Figure 2. Representation of Cost against Time under Different Defuzzification Methods |

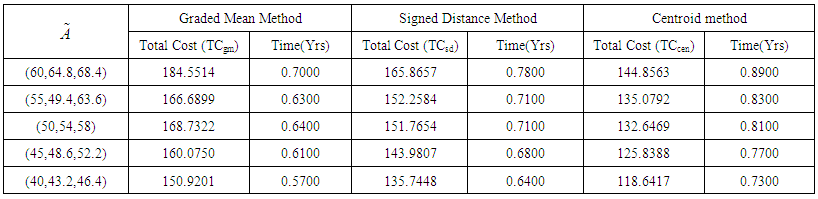

9. Sensitivity Analysis

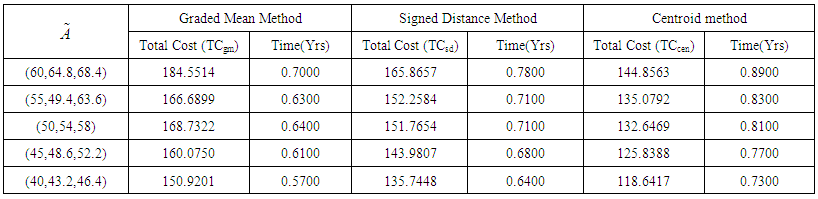

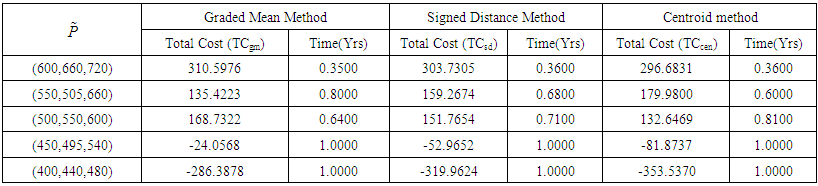

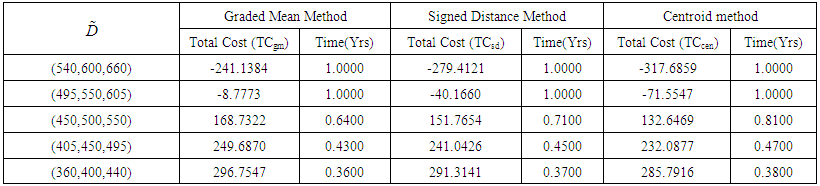

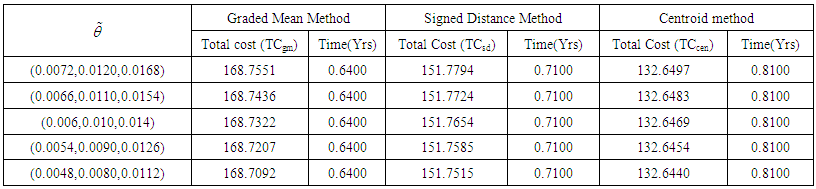

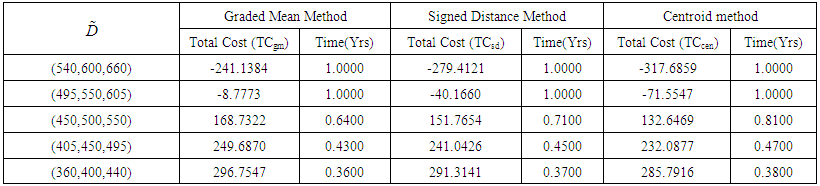

Sensitivity analysis is performed to study the effect on optimal values due to changes in different inventory parameters. The sensitivity analysis of the parameters has been discussed in table (1-6). | Table 1. Sensitivity on  |

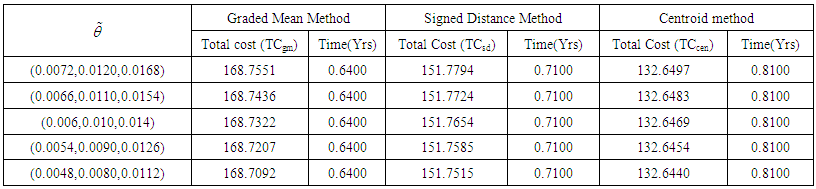

| Table 2. Sensitivity on  |

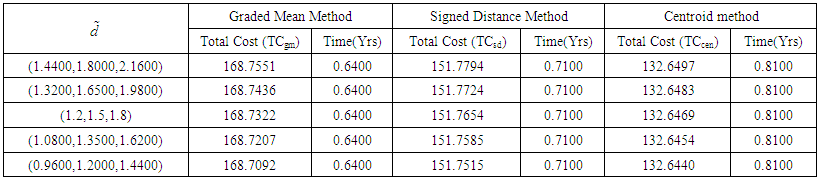

| Table 3. Sensitivity on  |

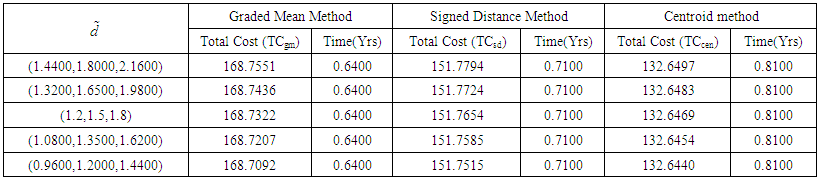

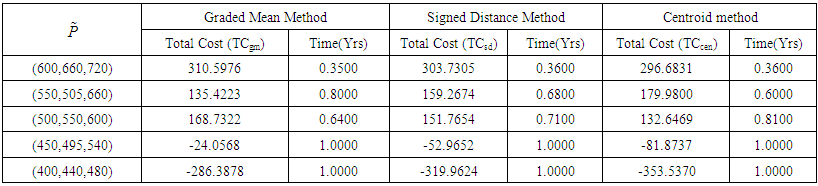

| Table 4. Sensitivity on  |

| Table 5. Sensitivity on  |

| Table 6. Sensitivity on  |

The optimal values change significantly with change (+10%,-10%) in in table (1-4). Table (5&6) show some absurd values. On the basis of the sensitivity analysis, the following are noted 1. When fuzzy set up cost is decreased, TCgm and T are decreased.2. First increased value of fuzzy set up cost show the best optimal value in TCgm where as TCsd and TCcen are increased.3. When fuzzy deterioration is increased, Cycle length remains same. Similar scenario appears when it is decreased.4. When fuzzy production rate is decreased, cycle length increase and total cost moves towards negative.5. When fuzzy demand rate is increased, total cost decreases.

in table (1-4). Table (5&6) show some absurd values. On the basis of the sensitivity analysis, the following are noted 1. When fuzzy set up cost is decreased, TCgm and T are decreased.2. First increased value of fuzzy set up cost show the best optimal value in TCgm where as TCsd and TCcen are increased.3. When fuzzy deterioration is increased, Cycle length remains same. Similar scenario appears when it is decreased.4. When fuzzy production rate is decreased, cycle length increase and total cost moves towards negative.5. When fuzzy demand rate is increased, total cost decreases.

10. Conclusions

In real life situation, nothing can be predicted with certainty in production system. This type of uncertainty cannot be handled with probabilistic approach alone. The use of fuzzy set theory is of great importance to handle uncertainty in industrial problems. Thus, the study of production inventory model in fuzzy environment helps the manufacturer to run the production process without any interruption. The proposed fuzzy inventory model extends the model of literature with key parameters as fuzzy numbers. In this model, the production of deteriorating items has thrown light to understand the uncertainty clearly and then to make appropriate decision for optimality. The graphical representations also allow us to understand the scenario clearly. The developed model may be further extended by taking shortage, different types of demand, perishable items.

ACKNOWLEDGMENTS

The authors wish to express their thanks to Department of Mathematics, Assam University, Silchar for software MATLAB support and also acknowledge the support of UGC-SAP, Mathematics (F.5105/DRS/2011(SAP-I)) provided by University Grant Commission, New Delhi to Department of Mathematics, Assam University. The first author would like to Professor Chandra K. Jaggi, Department of Operational Research, University of Delhi, Delhi-110007, India for his encouragement.

References

| [1] | Jaggi, C.K., Pareek ,S and Sharma, A., (2012) Fuzzy Inventory Model for Deteriorating Items with Time –Varying Demand and Shortages, American Journal of Operations Research, 2(6), 81-92. |

| [2] | Jaggi, C.K., Pareek, S., Khanna, A and Nidhi (2016) Optimal Replenishment Policy for Fuzzy Inventory Model with Deteriorating Items and Allowable Shortages Under Inflationary Conditions. Yugoslav Journal of Operations Research. DOI.10.2298/YJOR150202002Y. |

| [3] | Jain, D.K., Das, B and Roy, T.K (2013) A Fuzzy Generic Algorithm Approach for Inventory Model for Deteriorating Items with Back Orders Under Fuzzy Inflation and Discounting Over Random Planning Horizon. Advances in Operations Research, 2013, 1-15. |

| [4] | Nezhad, S.S, Nahavandi, S.M and Nazemi, J (2011) Periodic and Continuous Inventory Models in the Presence of Fuzzy Costs. International Journal of Industrial Engineering Computations, 2, 167-178. |

| [5] | Nagar and Surana (2015) Fuzzy Inventory Model for Deteriorating Items with Fluctuating Demand Using Inventory Parameters as Pentagonal Fuzzy Numbers. Journal of Computer and Mathematical Sciences. 6(2), 55-66. |

| [6] | Kumar, S and Rajput, U.S (2015) Fuzzy Inventory Model for Deteriorating Items with Time Dependent Demand and Parial Backlogging. Applied Mathematics, 6,496-509. |

| [7] | Panda, D., Rong, M and Maiti, M (2014) Fuzzy Mixture Two Warehouse Inventory Model Involving Fuzzy Random Variable lead Time Demand and Fuzzy Total Demand. Central European Journal of Operations Research, 22, 187-209. |

| [8] | Roy, A., Maitti, M.K., Kar, S and Maitti, M (2009) An Inventory Model for a Deteriorating Item with Displayed Stock Dependent Demand Under Fuzzy Inflation and Time Discounting over a random Planning Horizon.Applied Mathematical Modelling, 33, 744-759. |

| [9] | Roy, A(2015) Fuzzy Inventory Model for Deteriorating Items with Price Dependent Demand .International Journal of Management Science and Engineering Management, 10(4), 237-241. |

| [10] | Rong, M., Mahapatra, N.K and Maiti, M (2008) A Two Warehouse Inventory Model for Deteriorating Item with Partially/Fully Backlogged Shortage and Fuzzy Lead Time. European Journal of Operations Research, 189,59-75. |

| [11] | Saha, S and Chakraborty, T (2012) .Fuzzy EOQ Model with Time Dependent Demand and Deterioration withShortages. IOSR, Journal of Mathematics, 2, 46-54. |

| [12] | Zadeh, L. A (1965) Fuzzy Sets. Information and Control, 8, 338-353. |

| [13] | Zadeh, L. A (1973) Outline of a New Approach to the Analysis of Complex Systems and Decission Processes. IEEE Transactions on Systems, Man and Cybernatics, 3, 28-44. |

with

with  is triangular if its membership function is defined as

is triangular if its membership function is defined as  In the same manner, trapezoidal fuzzy number, parabolic fuzzy number, pentagonal fuzzy number, hexagonal fuzzy numbers etc. can be defined. There are number of methods available for defuzzification of fuzzy numbers. The mostly used methods for defuzzification are graded mean integration method, centroid method and signed distance method. Graded mean integration representation of triangular fuzzy number is defined as

In the same manner, trapezoidal fuzzy number, parabolic fuzzy number, pentagonal fuzzy number, hexagonal fuzzy numbers etc. can be defined. There are number of methods available for defuzzification of fuzzy numbers. The mostly used methods for defuzzification are graded mean integration method, centroid method and signed distance method. Graded mean integration representation of triangular fuzzy number is defined as The centroid method for triangular fuzzy number is

The centroid method for triangular fuzzy number is  and signed distanced method for triangular fuzzy number is defined as

and signed distanced method for triangular fuzzy number is defined as

the inventory level is zero. It increases in the time period

the inventory level is zero. It increases in the time period  due to production at the constant rate

due to production at the constant rate  After that inventory level decreases and reaches to zero at

After that inventory level decreases and reaches to zero at  This depletion is due to demand and deterioration of the item. This situation is represented in fig 1.

This depletion is due to demand and deterioration of the item. This situation is represented in fig 1.

The differential equation governing the situation is

The differential equation governing the situation is

Using the condition that

Using the condition that  we get

we get

the differential equation governing the situation is

the differential equation governing the situation is

we get

we get

by using

by using

We consider triangular fuzzy numbers

We consider triangular fuzzy numbers

Now we find the defuzzified value of

Now we find the defuzzified value of  by 1. Graded mean integration method2. Signed distance method3. Centroid methodBy Graded Mean Integration MethodThe defuzzified value is:

by 1. Graded mean integration method2. Signed distance method3. Centroid methodBy Graded Mean Integration MethodThe defuzzified value is:

By Signed Distance MethodThe defuzzified value is:

By Signed Distance MethodThe defuzzified value is: By Centroid MethodThe defuzzified value is:

By Centroid MethodThe defuzzified value is:

then in each case,

then in each case,  exists and clearly for this value of

exists and clearly for this value of  we see that

we see that so that defuzzified value of total cost per unit time i.e.

so that defuzzified value of total cost per unit time i.e.  is minimum. And the minimum value is obtained by putting the value

is minimum. And the minimum value is obtained by putting the value  in

in  for the respective cases.

for the respective cases.

The output of the model using MATLAB software under different defuzzification methods are given below TCgm=168.7322, T=0.6400; TCsd=151.7654, T=0.7100 and TCcen=132.6469, T=0.8100.From the above results indicate that total cost is minimum with corresponding value of T when centroid method of defuzzification is used. On the other hand T is minimum with corresponding total cost when graded mean integration value is used. The cost functions are plotted against T in the following figure.

The output of the model using MATLAB software under different defuzzification methods are given below TCgm=168.7322, T=0.6400; TCsd=151.7654, T=0.7100 and TCcen=132.6469, T=0.8100.From the above results indicate that total cost is minimum with corresponding value of T when centroid method of defuzzification is used. On the other hand T is minimum with corresponding total cost when graded mean integration value is used. The cost functions are plotted against T in the following figure.

in table (1-4). Table (5&6) show some absurd values. On the basis of the sensitivity analysis, the following are noted 1. When fuzzy set up cost is decreased, TCgm and T are decreased.2. First increased value of fuzzy set up cost show the best optimal value in TCgm where as TCsd and TCcen are increased.3. When fuzzy deterioration is increased, Cycle length remains same. Similar scenario appears when it is decreased.4. When fuzzy production rate is decreased, cycle length increase and total cost moves towards negative.5. When fuzzy demand rate is increased, total cost decreases.

in table (1-4). Table (5&6) show some absurd values. On the basis of the sensitivity analysis, the following are noted 1. When fuzzy set up cost is decreased, TCgm and T are decreased.2. First increased value of fuzzy set up cost show the best optimal value in TCgm where as TCsd and TCcen are increased.3. When fuzzy deterioration is increased, Cycle length remains same. Similar scenario appears when it is decreased.4. When fuzzy production rate is decreased, cycle length increase and total cost moves towards negative.5. When fuzzy demand rate is increased, total cost decreases. Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML