-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Medicine and Medical Sciences

p-ISSN: 2165-901X e-ISSN: 2165-9036

2024; 14(5): 1355-1358

doi:10.5923/j.ajmms.20241405.44

Received: Apr. 22, 2024; Accepted: May 16, 2024; Published: May 21, 2024

Hygienic Characterization of the Chemical Factor in Mechanical Engineering Enterprises

U. А. Xadjayeva1, A. B. Iskandarov2, G. T. Iskandarova1, N. R. Samigova1

1Tashkent Medical Academy, Uzbekistan

2Central Asian Medical University, Uzbekistan

Copyright © 2024 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

All factors of the working environment, as well as the organization of work, which directly or indirectly may cause impairment of the health or performance of persons working in these conditions. To identify harmful factors, it is necessary to study working conditions and environmental parameters in production premises and directly in the work area, comparing them with accepted hygienic standards. The results of the analysis of air pollution of the main working areas show that a high concentration of the chemical factor was observed to be generated during the work process of the electric gas welding as well as the test drive. The reason for the high chemical factor in this enterprise under research is the installation of a non-rational ventilation system in workplaces and workshops, as well as the lack of rational use of the local intake system, low ventilation efficiency.

Keywords: Machinery enterprises, Working conditions, Chemical factor

Cite this paper: U. А. Xadjayeva, A. B. Iskandarov, G. T. Iskandarova, N. R. Samigova, Hygienic Characterization of the Chemical Factor in Mechanical Engineering Enterprises, American Journal of Medicine and Medical Sciences, Vol. 14 No. 5, 2024, pp. 1355-1358. doi: 10.5923/j.ajmms.20241405.44.

1. Introduction

- The who's global strategy aimed at protecting workers 'health is aimed at protecting workers' health in the workplace, maintaining and strengthening workers ' ability to work in enterprises and organizations, organizing working conditions in accordance with health and safety requirements, taking measures to improve the health of employees in the workplace [2,6,7,12]. All factors of the working environment, as well as the organization of work, which directly or indirectly may cause impairment of the health or performance of persons working in these conditions. To identify harmful factors, it is necessary to study working conditions and environmental parameters in production premises and directly in the work area, comparing them with accepted hygienic standards [1,4,13].The most important technical significance for characterizing the state of the air environment in workshops is its contamination with vapors of aromatic hydrocarbons and organic solvents. Workplaces are constantly exposed to highly concentrated vapors of organic solvents in various combinations, and in some workplaces also pigments, the effects of which are multidirectional and have not been sufficiently studied. It is known that the concentrations of organic solvent vapors in the air are often [3,8,11,15,16]. Another study found that 68.2% of esa machinery industry workers were exposed to lubricating and cooling fluids, 24.3% chemicals, 14.4% heavy metals, 14.4% high temperature, 66.2% noise, and 40.1% local vibration. According to the analysis of the authors in it, the health of workers in the mechanical engineering industry is most influenced by chemical factors, causing negative changes in the respiratory organs. Next, the central nervous system and reproductive system are affected by this factor [5,9,10,14].

2. Results

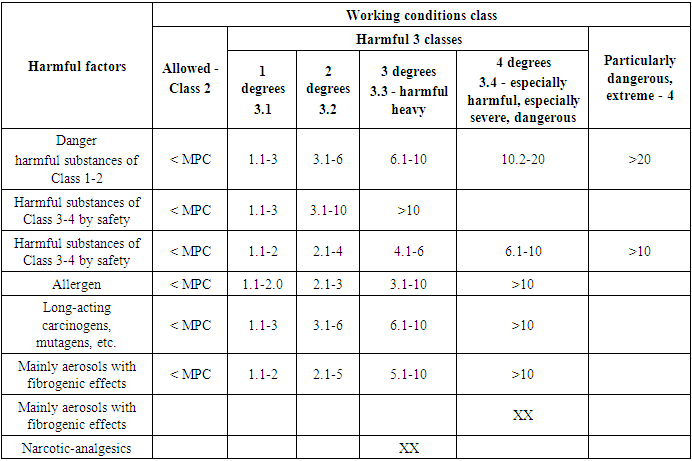

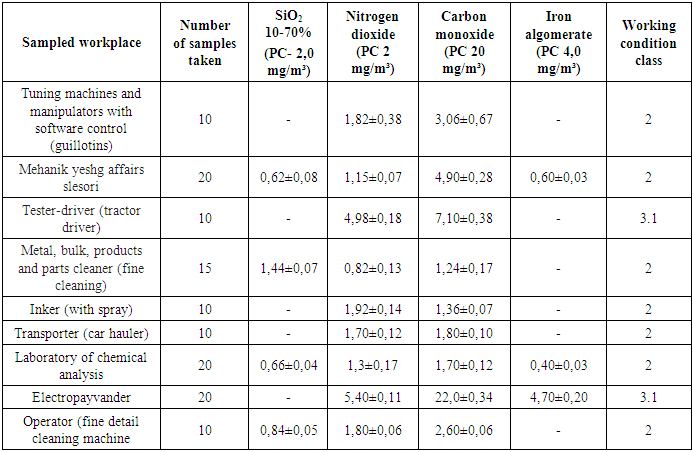

- The purpose of the study: To study the leading chemical factor of working conditions from harmful factors and give hygienic assessment at the Enterprise “Tashkent mechanical plant” in the field of mechanical engineering industry.Research method. The concentration of chemical factors on plots where harmful factors are formed in the air of workplaces was determined using the express method through “Identification of harmful and dangerous factors in laboratory tests for assessing working conditions” (2013) and an analysis was carried out according to the state standard “General sanitary and hygienic requirements for the air in the working area” No. 12.1.005-88. In the production environment, the assessment of working conditions on harmful substances with two or more multidirectional effects at the same time in the composition was carried out as follows (Sanitary Rules and Regulations No. 0141-03).Thus, during the operation of technological equipment in the production shops of a machine-building enterprise, there is a more difficult and intense nature of production operations, closer contact of workers with chemical factors of the production environment, etc. In this regard, there was a need to study working conditions in modern machine-building production. In the conditions of production, there are many harmful factors that affect the chemical composition of the air in the rooms. Ensuring the cleanliness of the working space air to create its optimal conditions in the mechanical engineering industry is one of the main problems of the present time. During the research carried out, when the production activity was organized, it was determined that as a result of the technological process in the main workplaces of the enterprise, various harmful factors were emitted, from which the chemical factor was considered as the leading factor.The main place of work of the tester - driver at the machine-building production enterprise contains nitrous oxide from chemical factors, these workers are dangerous for the respiratory system and have corrosive properties. The high concentration of nitrous oxide when analysed using samples from workplace air is 4.98±0.18 mg/m3, which should be 2 mg/m3 concentration of nitric oxide under state standard 12.1.005-88 “General sanitary hygienic requirements for workplace air” (Table 1).

|

|

3. Discussions

- Thus, the chemical factor of the production environment can play a certain negative role, aggravating the effect of an already existing set of harmful production factors. The reasons for the high air pollution in the working area at this enterprise are the irrational ventilation system and the lack of local exhaust ventilation to combat the resulting chemical aerosols. We can see that the harmful chemical factor norms in the air of the working environment “General sanitary hygienic requirements for the air of workplaces” less than the permissible amount of state standard 12.1.005-88-i.e. fully comply with the requirements of this standard.Mechanical engineering as an industry requires a well-functioning ventilation system. Workshops require a rational ventilation system, represented by a general supply and exhaust system with mechanical drive. The influx of clean air and the exhaust of air with chemical vapors are carried out by fans connected to the air duct system.

4. Conclusions

- When organizing technological processes, it is necessary to give preference to automated, continuous and hermetic processes and equipment. Maximum isolation of technological processes accompanied by the formation of industrial hazards should be provided. Technological and auxiliary equipment that generate increased levels of noise and vibration must be installed on separate foundations. Technological processes, equipment, raw materials used, materials and other factors must ensure the production of high-quality products that are safe for the health of consumers.The results of the analysis of the air pollution of the main working areas show that a high concentration of the chemical factor was observed to be formed during the work process of the electrogazpayvander as well as the test drive. The reason for the high chemical factor in this enterprise under research is the installation of a non-rational ventilation system in workplaces and workshops, as well as the lack of rational use of the local taker system, low ventilation efficiency.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML