-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Medicine and Medical Sciences

p-ISSN: 2165-901X e-ISSN: 2165-9036

2024; 14(4): 1007-1011

doi:10.5923/j.ajmms.20241404.42

Received: Mar. 17, 2024; Accepted: Apr. 15, 2024; Published: Apr. 18, 2024

Hygienic Assessment of Workplaces of Main Professions of Hydraulic Structures of Urta-Chirchik HPP

Mirayubova Shakhnoza Rakhmatilla Kizi, Hamrakulova Muqaddashon Askarovna

Scientific Research Institute of Sanitation, Hygiene and Occupational Diseases of the Ministry of Health, Tashkent, Republic of Uzbekistan

Copyright © 2024 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Microclimatic conditions when working inside a dam are one of the factors to which the largest number of reservoir workers are exposed to harmful and dangerous effects [3,6]. The hygienic characteristics of the technological process of a hydraulic structure (Urta-Chirchik hydroelectric power station (HPP)) revealed the specifics of working conditions [7]. The most significant production factors for occupational risk that influence the formation of working conditions at reservoirs are such factors of the production environment as unfavorable microclimate in the workplace [8]. It has been established that the work of workers in the main professions in terms of factors of the working environment, classes of working conditions and the degree of hazard, operating three reservoirs, belongs to the hazardous class 3.4 [1,5].

Keywords: Working conditions, Hydraulic structures, Factors, Occupational risk, Main professions, Job assessment

Cite this paper: Mirayubova Shakhnoza Rakhmatilla Kizi, Hamrakulova Muqaddashon Askarovna, Hygienic Assessment of Workplaces of Main Professions of Hydraulic Structures of Urta-Chirchik HPP, American Journal of Medicine and Medical Sciences, Vol. 14 No. 4, 2024, pp. 1007-1011. doi: 10.5923/j.ajmms.20241404.42.

Article Outline

1. Introduction

- Hydraulic structures are reservoirs for the detention, accumulation and storage of water, which is later used to meet the needs of the water sector [4]. Up to 5 thousand people work at these reservoirs. The labor of workers has direct national economic significance in providing water to irrigated agricultural lands and indirectly in providing electricity to the republic [2].However, the issues of labor protection and health status of reservoir workers today remain open, since these problems are not covered in the world and domestic literature [11,12]. There is no normative and methodological documentation on the issues of occupational hygiene and health protection of reservoir workers, covering information support for issues of monitoring working conditions and prevention of the health status of workers of hydraulic technical structures, which require their decision [14]. Specific working conditions are characterized by a lack of natural light, work in tunnels, underground without access to outside air [9]. Due to production needs, workers are forced to move horizontally and vertically over long distances [13]. If it is impossible to use lifting and transport equipment, they have to lift and move heavy loads manually and are under constant threat to their lives and the population of the nearby area [10].

2. Target Research

- To study the working conditions of workers of hydraulic structures of the Urta-Chirchik hydroelectric power station and determine the hazard class of production factors in the workplace.

3. Research Methods

- The objects of the study were the working conditions of workers employed at the hydraulic structures of the Urta-Chirchik hydroelectric power station.The work used sanitary-hygienic and statistical research methods.To consider the possibility of the impact of working conditions factors on the worker’s body, it was necessary to quantify the actual parameters of the factor in the workplace, determine the class of working conditions depending on the parameters of the factor and the presence of joint influence with other production factors. Then it was necessary to determine the level of occupational risk depending on the class of working conditions.To characterize working conditions, the following were studied: microclimate (temperature, relative humidity, air speed), noise, lighting, severity and intensity of the labor process.Meteorological conditions were measured in accordance with SanPiN No. 0324-16 “Sanitary and hygienic standards for the microclimate of industrial premises”. Temperature and relative air humidity were measured using an Assmann aspiration psychrometer; air movement - with a cup anemometer. In the dynamics of the working day, measurements of the illumination of each workplace were carried out.Noise measurements were carried out with a type 2 VShV – 003M sound level meter. Noise levels were measured according to methodological guidelines. The assessment of noise levels was carried out according to SanPiN No. 0325-16 “Sanitary standards for permissible noise levels in workplaces” [26].The severity of labor was studied in accordance with the “Methodological recommendations for assessing the severity of the labor process during workplace certification” [14]. The intensity of the labor process was studied in accordance with the “Methodological recommendations for assessing the intensity of the labor process during workplace certification” [15].The determination of the class of working conditions was carried out in accordance with SanPiN No. 0141-03 “Hygienic classification of working conditions according to indicators of harmfulness and danger of factors in the working environment, severity and intensity of the labor process” [5].The assessment of occupational risk when exposed to physical and chemical factors of the production environment in the workplace was carried out in accordance with the general scheme for assessing occupational risk and was based on an assessment of the class of working conditions by factors of the production environment and the labor process by class and degree of harmfulness and danger. The work uses methodological approaches to assessing working conditions through the risk of occupational diseases depending on the type of factors, the availability of information about the levels, time and mode of its prevalence, which are reflected in scientific and methodological documents.The severity of labor was studied in accordance with the “Methodological recommendations for assessing the severity of the labor process during workplace certification” [21]. The intensity of the labor process was studied in accordance with SanPiN No. 0141-03 “Hygienic classification of working conditions according to indicators of harmfulness and danger of factors in the working environment, severity and intensity of the labor process” [22].To characterize working conditions, the following were studied: microclimate (air temperature, relative humidity, air speed), noise, vibration, illumination” [2,3,10,17,24,36,37].Meteorological conditions were measured in accordance with SanPiN No. 0324-16 “Sanitary and hygienic standards for the microclimate of industrial premises” [34]. Temperature and relative air humidity were measured using an Assmann aspiration psychrometer; air movement - cup and vane anemometers.Noise and vibration measurements were carried out with a type 2 VShV – 003 2M sound level meter. Noise levels were assessed according to SanPiN No. 0325-16 [36] And vibration levels - SanPiN No. 0326-16 [37].Air sampling at workplaces was carried out in accordance with SanPiN No. 0327-16 “Requirements for organizing measurements of hazardous and harmful production factors during hygienic conformity assessment.” The determination of harmful gases - carbon oxide, nitrogen oxides, hydrogen sulfide was carried out using portable gas analyzers of the "PAG-3" and "ELAN" series.

4. Research Results

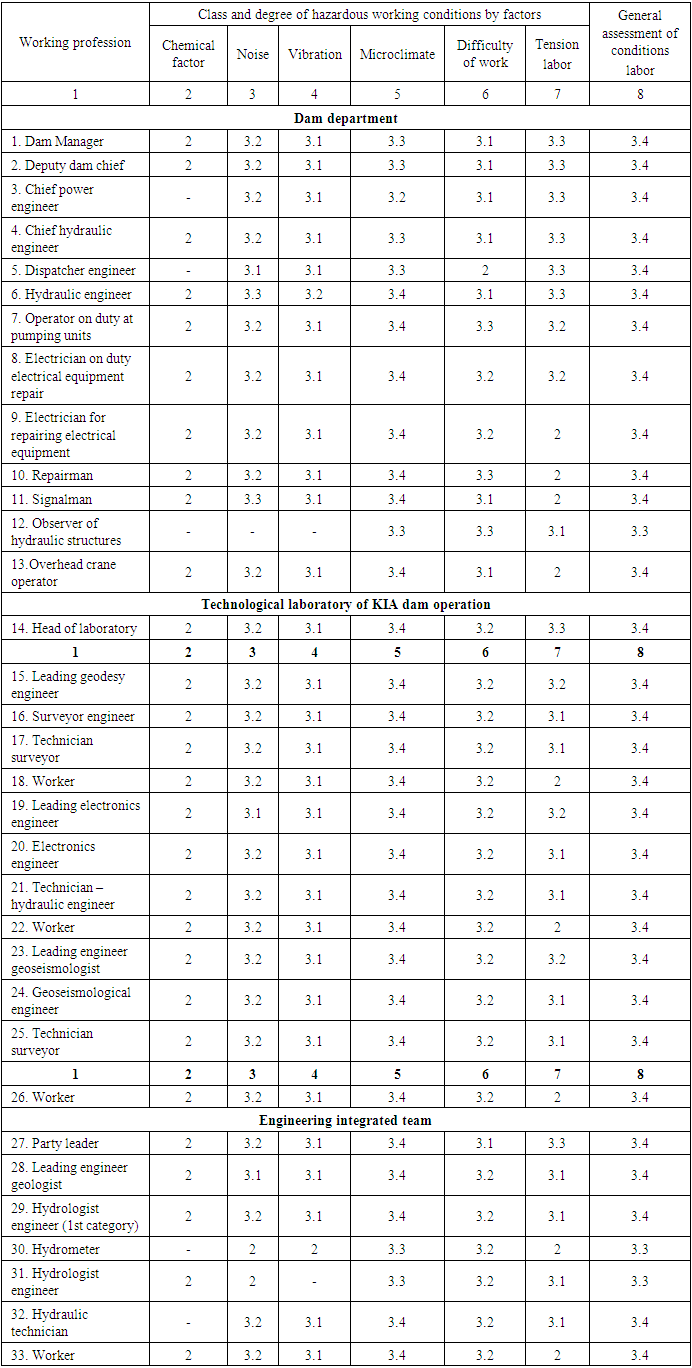

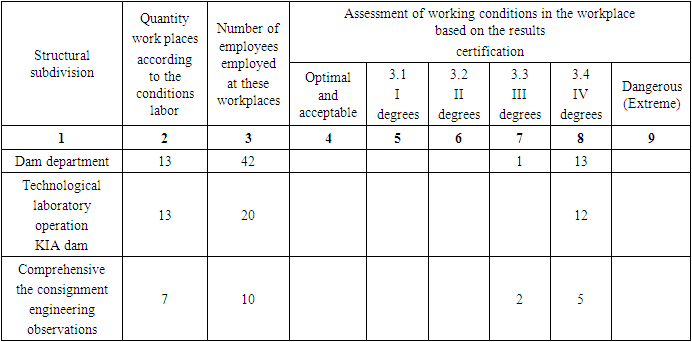

- The hygienic characteristics of the technological process of hydraulic structures of the Urta-Chirchik hydroelectric power station revealed the specifics of working conditions. The most significant production factors for occupational risk that influence the formation of working conditions at reservoirs are such factors of the production environment as unfavorable microclimate in the workplace, lack of natural and low artificial light, noise, vibration, levels that exceed permissible values. Due to production needs, workers are forced to move horizontally and vertically over long distances. When lifting and transport equipment is not available, workers must lift and move heavy loads manually.During a hygienic assessment of industrial lighting, it was found that illumination levels at workplaces do not meet hygienic standards [4]. This is due to the fact that at all workplaces located in the body of the dam, in adits and tunnels, there is no natural lighting, and artificial lighting is low on average 3-4 lux, which in terms of harmfulness and danger of industrial environmental factors belongs to class 3.2 [4].Climatic conditions are formed under the influence of its geographical location. A characteristic feature of the climate of Uzbekistan is long, hot summers and rather cold winters with large fluctuations in air temperature both throughout the year and throughout the day, low mobility, very dry air and intense radiation. The location of the hydraulic structures of the Urta-Chirchik hydroelectric power station, according to the characteristics of the climatic regions, also belongs to the IV degree.Due to the specific design of the dam, workers are exposed to a cooling microclimate during the cold and warm periods of the year. The air temperature in the body of the dam in the warm and cold periods of the year is the same (10-12°C), which corresponds to class 3, degree 4 according to SanPiN SanPiN No. 0141-03 [4]. When the gates are opened, the drainage pumping station is constantly operating, water passes through the collectors, through the joints of sections, the concrete of the body and base of the dam, through water outlet structures, pressure conduits, which are located throughout the body of the dam, the relative humidity at work places reaches 97-100% of the value. High air humidity is formed from several sources. In the first place there is the proximity of the reservoir bowl, the water of which seeps through the concrete walls, then in the dam tunnel there are various structures with an open water surface, when water is released for the operation of a nearby hydroelectric power station. As a result, the relative humidity in the body of the dam, in the tunnel and at various levels of the dam is determined at a level of up to 100%, which is why the working conditions in terms of relative humidity belong to class 3, degree 4. In addition, the movement of water through all structures leads to an increase in air speed to 3 - 4 m/s.Microclimatic conditions when working inside the dam are one of the factors to which the largest number of reservoir workers are exposed to harmful and dangerous effects.During the growing season (from April to October), workers are exposed to noise exceeding permissible levels by 18 dBA (class 3.2) and vibration exceeding permissible levels by 6 dB (class 3.1), taking into account the exposure time of less than 80% of the working time.When emissions from an emergency diesel power plant spread, working conditions are characterized by the content of carbon monoxide in the air of the working area at a level not exceeding the maximum permissible concentration (class 2). The integrated assessment of working conditions based on the totality of the existing unfavorable factors in the working environment at the hydraulic structures corresponds to class 3.4, which poses a risk to the health of workers.A study of the severity of the labor process showed that a number of production operations related to the maintenance of equipment and devices require the use of heavy manual work, staying in an uncomfortable fixed working position (class 3, degree 2) for more than 50% of the working time, moving vertically from one mark to another up and down up to 230m, horizontally extend up to 10 км (3rd class, 1st degree).Labor intensity is characterized by intellectual, sensory and emotional stress, which corresponds to class 3, degree 2.Hygienic studies were carried out on the workers of the technological laboratory for the operation of control and measuring equipment (KIA) by studying the chemical and physical factors of the production environment, identifying the influence of work activity on the severity and intensity of the labor process.The leading unfavorable factor in the working environment at the workplaces of seismologists located in the body of the dam is the unfavorable microclimate, which primarily depends on the specific design of the dam. The operating factors of the production environment when working in the dam body include noise and vibration, the quantitative characteristics of which at the main workplaces correspond to class 3, degree 1-2. Seismologists' work inside a dam is stressful and requires heavy manual handling. Seismology Group carries out seismometric work to control and operate the KIA installed in the body of the dam, below ground level, at all levels of 1st, 2nd tiers and galleries. The group’s employees spend 80% of their working time monitoring the operation of the instrument, and if necessary, remove them and repair them in the laboratory.The team's job is to monitor foundation deformations and general movements of elements of the dam sections. A total of 1356 static devices are used. Hydrological studies are carried out in water pipelines, where sensors are installed to determine the abrasion of metal and concrete in 16, 21 sections, 56 sensors in total. Observations of vertical displacements are made by leveling the high-altitude side marks and triaxial gap gauges installed in the service gallery at levels 803.0; 817.0; cement loss and on the lower edge.Seismology Group carries out seismometric work to control and operate the KIA installed in the body of the dam, below ground level, at all levels of 1st, 2nd tiers and galleries. The group’s employees spend 80% of their working time monitoring the operation of the instrument, and if necessary, remove them and repair them in the laboratory.All members of the seismological group, being in the body of the dam, are exposed to the same unfavorable production factors: physical (microclimate, noise, vibration), illumination, severity and intensity of the labor process.The general assessment of the working conditions of the specialists of the group of seismologists is 3rd class 4th degree in terms of microclimate.Due to the specific design of the dam, the relative humidity of the air reaches 100%, the speed of air movement due to the release of water from the reservoir reaches 5 m/s, and the air temperature during the warm and cold periods of the year remains at the same level of 11-14°C.All members of the seismological group, being in the body of the dam, are exposed to the same unfavorable production factors: physical (microclimate, noise, vibration), illumination, severity and intensity of the labor process.The work consists of monitoring the operation of the reservoir, forecasting the flow of water into the reservoir; control of groundwater levels, technical operation of observation wells, hydrometric posts; equipment maintenance and repair, well stability.The leading unfavorable factor in the working environment at the workplaces of specialists located in the body of the dam is the unfavorable microclimate, which primarily depends on the specific design of the dam. The operating factors of the production environment when working in the dam body include noise and vibration, the quantitative characteristics of which at the main workplaces correspond to class 3, degree 1-2. Seismologists' work inside a dam is stressful and involves heavy manual work.An assessment of the state of working conditions at each workplace, of workers engaged in harmful and dangerous work, made it possible to establish that 22.3% of workplaces in the enterprise are in the zone from acceptable (2nd class) to harmful 3rd class, 1st and 2nd degree working conditions. The remaining workplaces are classified as harmful and dangerous working conditions, which at the studied hydraulic structure amounted to 77.7% with conditions 10 or more times exceeding the maximum permissible level of working environment factors (class 3.3, 3.4). Tables 1 and 2 present the main results of the certification carried out according to the degree of harmfulness and danger.

|

|

5. Conclusions

- It has been established that the work of workers in the main professions, in terms of factors of the working environment, classes of working conditions and the degree of harmfulness of the operating hydraulic structures of the Urta-Chirchik hydroelectric power station, belongs to the hazardous class 3.4.; workers of pumping stations - to class 3.2 and 3.3. Working conditions for divers of technical work - class 3.4.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML