Kobilova G. A.

Bukhara State Medical Institute, Bukhara, Uzbekistan

Correspondence to: Kobilova G. A., Bukhara State Medical Institute, Bukhara, Uzbekistan.

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

This article proposes sanitary and hygienic indicators and health status of workers in the silk-winding production Bukhara Brilliant Silk and ways to improve the health of workers in this production. To study the sanitary and hygienic indicators and health status of workers in the silk-winding production Bukhara Brilliant Silk and the influence of harmful factors on the health of workers in this production.

Keywords:

Silk-winding production, Humidity, Illumination, Medical examination, Health groups

Cite this paper: Kobilova G. A., Sanitary and Hygienic Indicators of Working Conditions and Health Indicators of Workers in Silk-Winding Production, American Journal of Medicine and Medical Sciences, Vol. 10 No. 11, 2020, pp. 842-847. doi: 10.5923/j.ajmms.20201011.03.

1. Introduction

Sericulture in Uzbekistan is one of the most ancient branches of agriculture. It provides textile raw materials - silk thread, which is highly valued due to the special qualities that determine the trends of the use of silk in everyday life and technology. Uzbekistan, producing about 67% of cocoons harvested in the country, ranks fourth in world production after China, India and Japan. At present, the transition from market relations is underway, the forms of production in agriculture are being improved, including in sericulture. In the silk industry of the country, large-scale structural transformations were carried out aimed at further deepening economic reforms, creating favorable conditions for attracting foreign investment, creating new and modernizing existing industries, increasing the volume and expanding the range of finished products that are in demand and competitive in the world market.One of the main tasks of medicine is to protect the health of workers working with harmful factors, to reduce diseases leading to temporary loss or long-term disability. Health protection of workers - in terms of its significance and solutions, is the most important social and hygienic problem. This is mainly of socio-economic importance, because on the basis of healthy and capable workers, the working capacity of society increases. Occupational diseases develop under the influence of harmful factors that form among experienced workers in the most flourishing, actively working age.Primary and periodic medical examinations are carried out on the basis of order No. 200 of July 10, 2012 of the Ministry of Health of the Republic of Uzbekistan. Responsibility for the quality of their conduct, early detection of occupational diseases, lies with the head of the relevant enterprise. Study of sanitary and hygienic indicators and health status of workers in the silk-winding production "Bukhara Brilliant Silk" and the influence of harmful factors on the health of workers in this production.

2. Materials and Research Methods

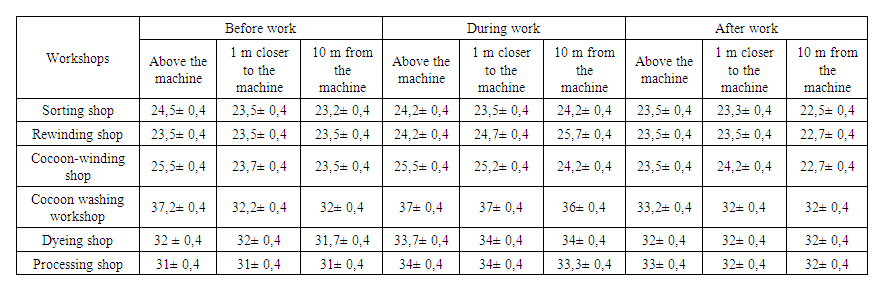

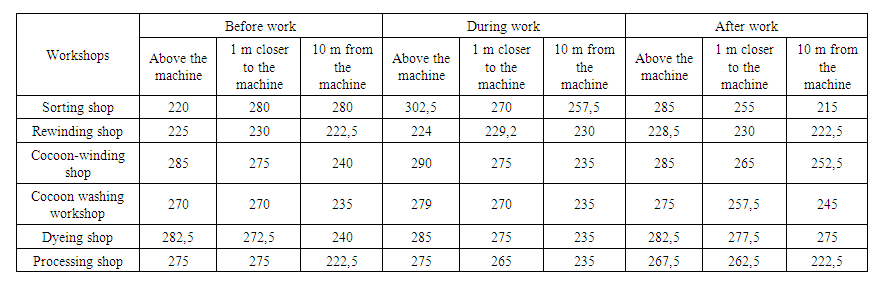

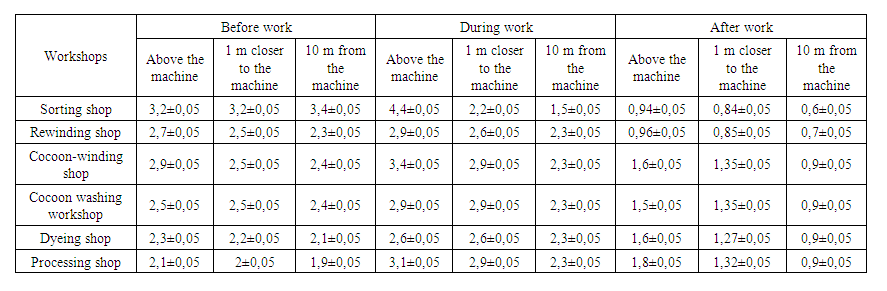

The methodological basis of the study is a materialistic approach to the study of the problem, as well as Decrees of the President of the Republic of Uzbekistan, government decrees on improving material interest and material incentives, as well as other provisions and instructions on economic issues of sericulture development.For the study of sanitary and hygienic indicators, sanitary and hygienic studies were used and, as a result, the following indicators were obtained. | Table 1. Indicators of temperature data of shops in silk-winding production "Bukhara Brilliant Silk" |

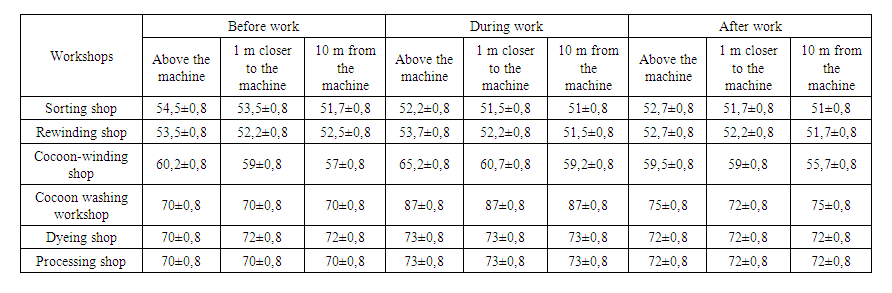

On the basis of SanPin 0324-16 “Sanitary and hygienic standards for the microclimate of industrial premises”, the air temperature of workplaces was measured in the warm season above the machine, 1 m closer to the machine and 10 m from the machine. According to the measurement results, the following data were obtained: in the sorting shop before work, during work and after work, the temperature in the production premises ranged from 22.5 to 24.5°C, since the optimal temperature of these premises according to SanPin 0324-16 is allowed 22-24°C, and in permanent workplaces, the upper limit is permissible up to 29°C. In the rewinding shop, these data ranged from 24.2 to 25.7°C. In the cocoon-winding shop, the room temperature ranged from 22.7 to 25.5°C. In the shop for washing cocoons, in the dyeing shop and in the processing shops, the room temperature in permanent workplaces is from 31 to 37, 2°C. The greatest increase in the temperature of workplaces was observed in the cocoon washing shop from 36 to 37°C. | Table 2. Indicators of moisture content of these workshops in silk-winding production in Bukhara Brilliant Silk |

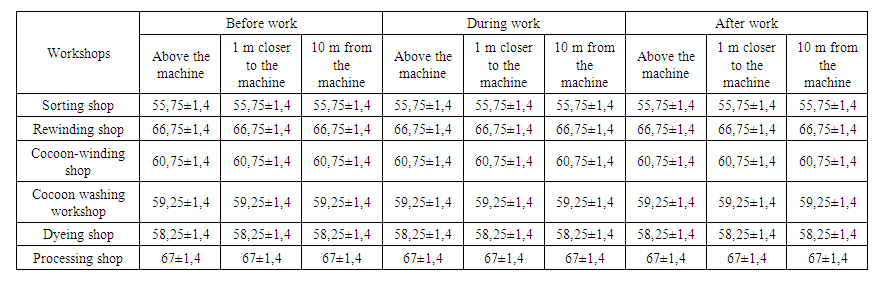

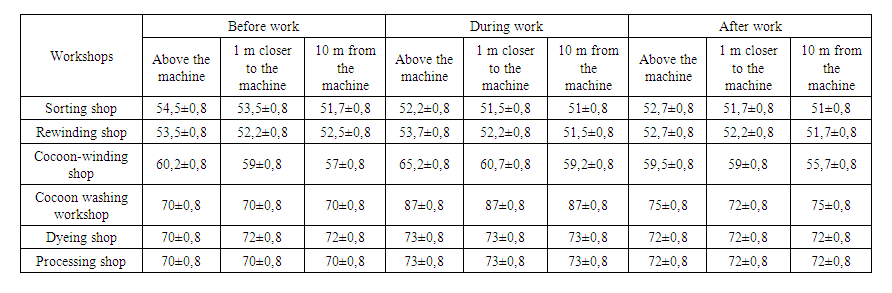

On the basis of SanPin 0324-16 “Sanitary and hygienic standards for the microclimate of industrial premises”, measurements of the relative humidity of the air of workplaces in the warm season were made above the machine, 1 m closer to the machine and 10 m from the machine. According to the measurement results, the following data were obtained: in the sorting shop before work, during work and after work, the temperature in the production premises ranged from 51 to 54.5%, since the optimal humidity of these premises according to SanPin 0324-16 is allowed 40-60%, and in permanent workplaces, the upper limit is acceptable up to 45%. In the rewinding shop, these figures ranged from 51.7 to 53.7%. In the cocoon-winding shop, the humidity of the premises ranged from 55.7 to 65.2%, the highest humidity was observed during the work on the machine-65.2%. In the cocoon washing shop, these data reached from 70 to 87%, which was observed all periods of work, in the dyeing shop and in processing shops, the humidity of the premises in permanent workplaces is from 70 to 73%, which shows an increase in air humidity during all periods of work. | Table 3. Dust content of these workshops in silk-winding production in "Bukhara Brilliant Silk" |

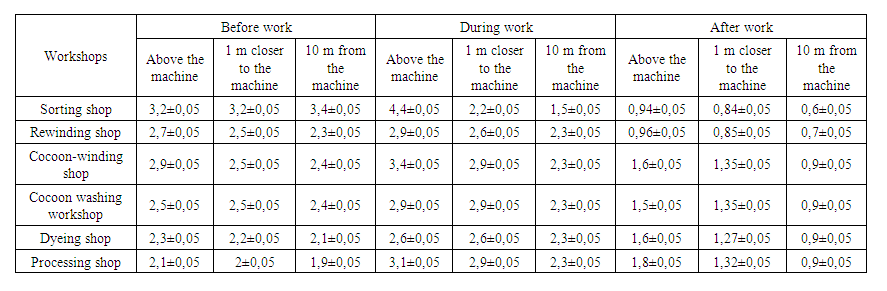

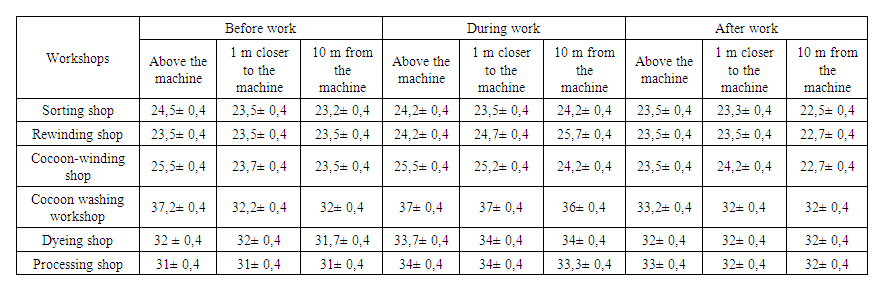

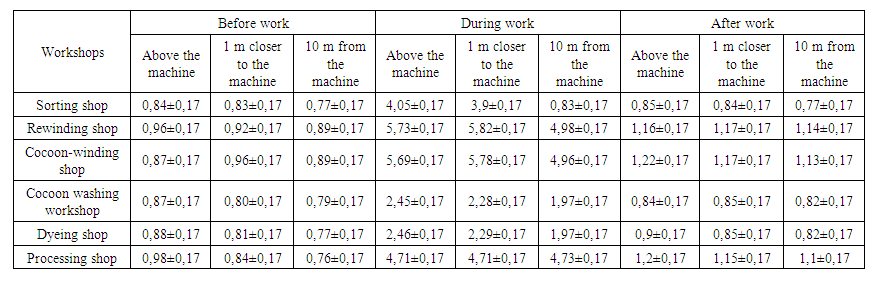

On the basis of SanPin 12.1.005-88, measurements of the dust content of the air of workplaces in the warm season were made above the machine, 1 m closer to the machine and 10 m from the machine. According to the measurement results, the following data were obtained: in the sorting shop before work, during work and after work, the dust content in the production premises ranged from 0.6 to 4.4 mg / m3, since the maximum permissible concentration of dust content in these premises according to SanPin 12.1.005-88 is allowed up to 6 mg / m3. In the rewinding shop, these data ranged from 0.7 to 2.9 mg / m3. In the cocoon-winding shop, the dust content of the premises ranged from 0.9 to 3.4 mg / m3. In the shop for washing cocoons, dust content in the working room was observed from 0.9 to 2.9 mg / m3. In the dyeing shop, these data ranged from 0.9 to 2.6 mg / m3. In the processing shop, the dust content in the premises ranged from 0.9 to 3.1 mg / m3. | Table 4. Indicators of gas pollution of these workshops in silk-winding production in "Bukhara Brilliant Silk" |

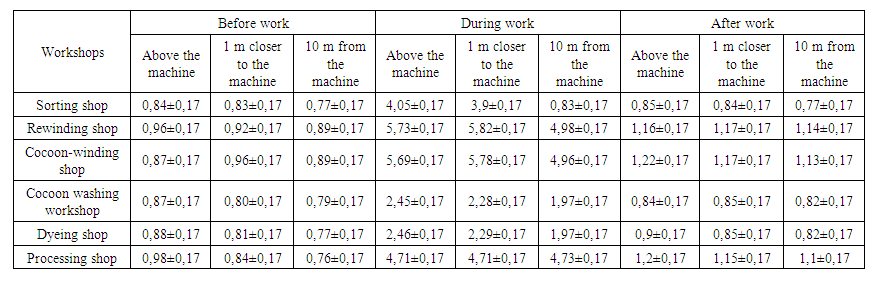

On the basis of SanPin 12.1.005-88, measurements were made of the air pollution of workplaces in the warm season above the machine, 1 m closer to the machine and 10 m from the machine. According to the measurement results, the following data were obtained: in the sorting shop before work, during work and after work, the dust content in the production premises ranged from 0.77 to 4.05 mg / m3, since the MPC of the gas content of these premises according to SanPin 12.1.005-88 is allowed up to 20 mg / m3. In the rewinding shop, these data ranged from 0.89 to 5.82 mg / m3. In the cocoon-winding shop, the gas content of the premises ranged from 0.87 to 5.78 mg / m3. In the shop for washing cocoons, gas pollution in the working room was observed from 0.79 to 2.45 mg / m3. In the dye shop, these data ranged from 0.77 to 2.46 mg / m3. In the processing shop, the gas content of the premises ranged from 0.76 to 4.73 mg / m3. | Table 5. Indicators of illumination of these workshops in silk-winding production in "Bukhara Brilliant Silk" |

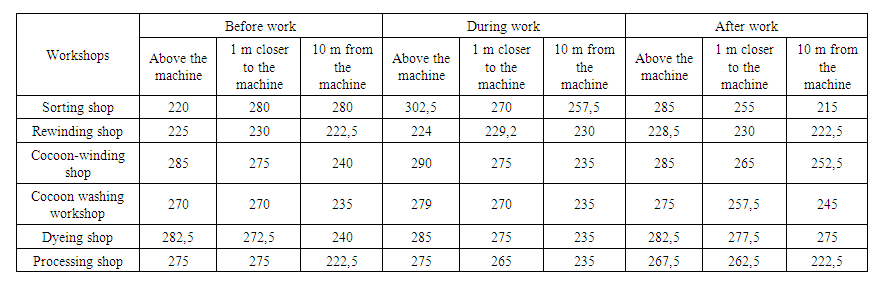

On the basis of SanPin 2.01.05 "Natural and artificial lighting", measurements were made of the illumination of workplaces in the warm season above the machine, 1 m closer to the machine and 10 m from the machine. According to the measurement results, the following data were obtained: in the sorting shop before work, during work and after work, the illumination in the production premises ranged from 215 to 302.5 lux, since the optimal illumination of these premises according to SanPin 2.01.05 is 200 lux. In the rewinding shop, these figures ranged from 222.5 to 230 lux. In the cocoon-winding shop, the illumination of the premises ranged from 240 to 290 lux, In the cocoon washing shop, these data reached from 235 to 279 lux, in the dyeing shop, the illumination ranged from 240 to 285 lux, and in the processing shops, the illumination of premises in the workplaces from 222.5 to 275 lux ... | Table 6. Noise indicators of these workshops in silk-winding production in "Bukhara Brilliant Silk" |

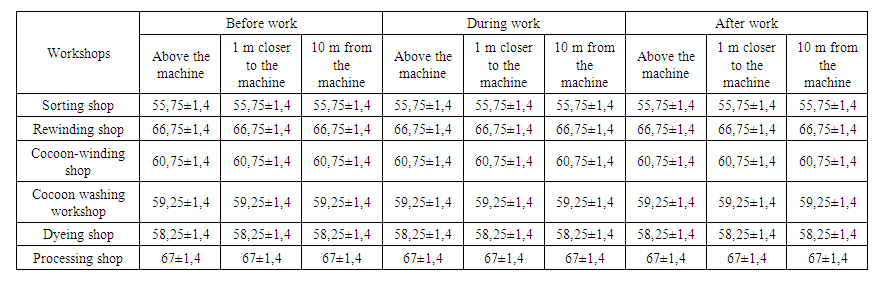

On the basis of SanPin 0325-16 “Sanitary Standards for Permissible Noise Levels at Workplaces”, the noise of workplaces was measured in the warm season above the machine, 1 m closer to the machine and 10 m from the machine. According to the measurement results, the following data were obtained: in the sorting shop before work, during work and after work, the noise in industrial premises is reached up to 55.7 dB, since up to 80 dB is allowed at permanent workplaces in industrial premises on the territory of enterprises according to SanPin 0324516. In the rewinding shop, these data are achieved up to 66.7 dB. In the cocoon-winding shop, these data are reached up to 60.7 dB; in the cocoon washing shop, these data are reached up to 59.25 dB, in the dyeing shop, these data are reached up to 58.2 dB in the processing shop, these data are reached up to 67 dB.The method of continuous observation was applied by passing a periodic medical examination on the basis of order No. 200 paragraph 4.8. Based on this point, the workers of this production 1 time in 2 years had to undergo a periodic medical examination. According to the plan, only 200 employees were subject to medical examination, of which 150 were women, only 198 employees underwent medical examination, which is 99%, 148 of women underwent medical examination, which is 98.6%. On the basis of Order No. 200, those subject to periodic medical examination had to be examined by four specialists - as a therapist, ophthalmologist, dermatovenerologist and torinolaryngologist. Also, these workers had to undergo an X-ray examination and data of the leukocyte blood count. It is known that doctors working in territorial medical and prophylactic institutions are not doctors for occupational pathologies, they are mainly general practitioners. Therefore, during periodic medical examinations, many disadvantages are allowed, that is, the specialists participating in these medical examinations cannot correctly assess the sanitary and hygienic condition of the workplace. As a result, they cannot deeply analyze the developing occupational diseases in the body and determine the risk factors leading to these diseases. Also, laboratory and instrumental studies are not widely used during medical examinations. Based on the above, as an innovative development, the passage of workers of this enterprise through an ultrasound examination of internal organs was applied to the study. The narrow specialists of the above-listed specialists from the Bukhara Medical Institute on the basis of an agreement drawn up between the institute and the silk-winding production, as well as the medical personnel of this enterprise, the head of the occupational health department of the regional TsGSEN, the local committee of this enterprise and a representative of this enterprise participated in the periodic medical examination. The temporary disability of workers in this production was also studied. Disability should be understood as a condition caused by illness, injury, its consequences or other reasons, when it is impossible to perform professional work in whole or in part, for a limited time or permanently. Temporary disability is the state of the human body caused by illness, injury and other reasons in which functional disorders are accompanied by the impossibility of performing professional work in normal working conditions for a certain period of time, i.e. they are reversible. Establishing the fact of temporary disability is a medical action, since it is aimed at eliminating adverse factors and means the beginning of treatment. In determining the ability to work, both medical and social criteria must be considered. Medical criteria include a timely complete clinical diagnosis, taking into account the severity of morphological changes, the severity and nature of the disease, the presence of decompensation and its stage, complications, determination of the clinical near and long-term prognosis. Social criteria reflect everything that is associated with the patient's professional activity: the characteristics of the prevailing stress (physical or neuropsychic), the organization, frequency and rhythm of work, the load on individual organs and systems, the presence of unfavorable working conditions and occupational hazards. Establishing the fact of incapacity for work is of great legal importance, since it guarantees the citizen the appropriate rights: in case of temporary disability, to be released from work and receive benefits at the expense of compulsory state social insurance, and in case of disability, to retire at the expense of the pension fund of the Republic of Uzbekistan. Cases of temporary disability of workers of this enterprise for 2019 were studied and the following data were obtained: 55 cases of temporary disability were revealed in 2019. These cases of temporary disability were based on the following diagnoses:Acute gastritis-1 case1. Vegetovascular dystonia-3 cases2. Chronic duodenitis-1 case3. Acute pharyngitis-5 cases, of which 1 case of inpatient treatment4. Acute calculous cholecystitis-1 case of inpatient treatment5. Acute respiratory viral infections-8 cases6. Psoriasis-1 case7. Acute bronchitis-3 cases, of which 1 case of inpatient treatment8. Acute rhinosinusitis-1 case9. Follicular tonsillitis-1 case10. Fibroadenoma of the left breast-1 case11. Burn-2 cases12. Chronic cholecystitis-1 case13. Periostitis-3 cases14. Acute nasopharyngitis-3 cases15. Angiospastic cephalalgia-1 case16. Sinusitis-1 case17. Phlegmon-1 case18. Osteochondrosis-1 case19. Severe preeclampsia, urgent labor - 1 case, inpatient treatment20. Myositis-1 case21. Ischemic heart disease, angina pectoris-1 case22. Hypertension-2 cases23. Chronic cerebral arachnoiditis-3 cases24. Fracture of the left foot-2 cases, 1 of them inpatient treatment25. Fracture of the clavicle-1 case-inpatient treatment26. Risk of abortion-1 case27. Pyelonephritis-1 case28. Mixed type neurocirculatory dystonia-1 case29. Maternity leave before and after childbirth -4 cases

3. Research Results

Of the examined 198 employees, no persons with suspicion of occupational intoxication or occupational diseases were identified. According to the results of medical examinations, all workers of the silk-winding production are divided into 3 health groups:Group 1 - Healthy. Workers with no health complaints. Also, no chronic diseases were identified, and when examining the functions of organs and systems are normal. On examination, they were 54 employees, which was 27.27%Group 2 - practically healthy. Examination of such workers does not reveal acute and chronic diseases, but there are changes in the organs and systems. This group of workers had a long history of work. They accounted for 129 employees - 65.15%Group 3 - in whom the initial stage of disease was detected or workers with chronic diseases - 15 employees - 7.5%According to X-ray studies, 6 cases of bronchitis were revealed, which is 3%, 1 case of chronic bronchitis - 0.5%. A therapeutic examination revealed mixed neurocirculatory dystonia in 9 workers, which is 4.5%, hypertension of the 1st degree in 13 workers - 6.5%, hypertension of the 2nd degree in 5 workers - 2.5%. Examination by an ophthalmologist presented the following data: chronic dacryocystitis in 2 workers - 1%, allergic conjunctivitis in 6 workers - 3%, refractive errors in 5 workers - 3%, myopia in 1 workers - 0.5%, accommodation spasm in 2 workers -1%. The dermatovenerologist found seborrheic dermatitis in 1 worker, which is 0.5%, psoriasis in 1 worker, which is 0.6%. According to the examination of the otorhinolaryngologist, the following data were obtained: acute laryngitis in 6 workers - 3%, frontitis in 1 worker - 0.6%, curvature of the nasal septum in 2 workers - 1%.At the end of the periodic medical examination, an act was filled out from Appendix No. 8 on the basis of Order No. 200 of July 10, 2012.Based on the results of studying the sanitary and hygienic data of working conditions, it was revealed that the highest temperature of workplaces was observed in the dyeing shop at 31-37.2 degrees, when the permissible temperature at permanent workplaces should be up to 29 degrees. An increase in humidity was observed in such shops as rewinding - 51.53.7%, cocoon-reeling 55.7-65.2%, in the shop for washing cocoons 70-87%, in the processing shop 70-73%, since the humidity in permanent workplaces up to 45% is allowed, and the optimal humidity of these premises according to SanPin 0324-16 is allowed 40-60%. It is recommended to draw up a comprehensive plan of measures to reduce temperature and humidity at permanent workplaces, to improve working conditions. According to the data of temporary disability and periodic medical examination in the above mentioned groups with chronic diseases during the period of compensation and decompensation, it is recommended to receive outpatient and inpatient treatment, to carry out a comprehensive series of preventive measures.

References

| [1] | Alimov S.M., Alimova M.A. Occupational hygiene issues in silkworm processing production // Young scientist. - 2017. - No. 50. - pp. 114-116. - URL https://moluch.ru/archive/184/47220/. |

| [2] | Resolution of the President No. 3472 of January 12, 2018 "On measures to organize the activities of the Uzbekipaksanoat Association" of March 29, 2018. |

| [3] | Sanitary norms and rules for enterprises of sericulture and silk-processing industry of the Republic of Uzbekistan 16. 12. 2002. |

| [4] | Slavinskaya N.V., G.Z. Ibragimova, A.B. Iskandarov, M.A.Kamalova Actual problems of labor hygiene of women in modern ditch production // Zhurn. theor. and clinics. medicine. - 2012. - No. 4. - P. 61–63. - Res. uzb., eng. - Bibliography. |

| [5] | Slavinskaya NV, GZ Ibragimova, MA Kamalova [et al.] Dynamics of the psychoemotional state of women working at the ditch production // Zhurn. theor. and a wedge. medicine. - 2013. - No. 5. - P. 67–69. - Res. uzb., eng. - Bibliography: 8 titles. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML