-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Fluid Dynamics

p-ISSN: 2168-4707 e-ISSN: 2168-4715

2019; 9(2): 35-43

doi:10.5923/j.ajfd.20190902.01

Unsteady MHD Free Convective Chemically Reacting Flow over a Heated Vertical Plate with Heat Source, Thermal Radiation and Oscillating Wall Temperature, Concentration and Suction Effects

Ighoroje W. A. Okuyade1, Tega Okor2

1School of Applied Sciences, Federal Polytechnic of Oil and Gas, Bonny Island, Nigeria

2Department of Mathematics, University of Benin, Benin City, Nigeria

Correspondence to: Ighoroje W. A. Okuyade, School of Applied Sciences, Federal Polytechnic of Oil and Gas, Bonny Island, Nigeria.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

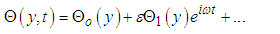

The problem of transient MHD free convective chemically reacting fluid flow past a hot vertical porous plate with the attendant effects of thermal radiation, heat source and varying wall temperature, concentration and suction is investigated. The governing non-linear and coupled partial differential equations are non-dimensionalized, and linearized using the oscillating perturbation series expansion solutions. The resulting equations are solved and the expressions for the temperature, concentration, velocity, Nusselt number, Sherwood number and force on the plate wall are obtained. The flow characteristics are quantified and presented graphically. The results, amidst others, show that increase in the Hartmann number increases the velocity and skin friction; increase in the convection force increases the velocity and skin friction. Furthermore, it is seen that increase in the Raleigh number increases the temperature, velocity and skin friction but decreases the rate of heat transfer; increase in the heat source parameter increases the temperature, velocity and skin friction but decreases the rate of heat transfer; increase in the chemical reaction rate increases the concentration, Sherwood number, and velocity and skin friction. These results are bench-marked with the results in some existing literatures and they are in agreement.

Keywords: Chemical reaction, Free convection, Heat source, Oscillating boundaries, Thermal radiation

Cite this paper: Ighoroje W. A. Okuyade, Tega Okor, Unsteady MHD Free Convective Chemically Reacting Flow over a Heated Vertical Plate with Heat Source, Thermal Radiation and Oscillating Wall Temperature, Concentration and Suction Effects, American Journal of Fluid Dynamics, Vol. 9 No. 2, 2019, pp. 35-43. doi: 10.5923/j.ajfd.20190902.01.

1. Introduction

- Convective flows involving MHD chemical reactions over porous plates have relevance in, amongst others, engineering, power generating systems and geophysics.In many natural and engineering processes, there are different levels of interactions which influence the flow variables. Some are highly interactive, some moderately or low, and others non-interactive. In the highly interactive flow cases, the simultaneous heat and mass transfer effects exist, and they are seen as thermo-diffusion and diffusion-thermo effects. A number of research works involving the different levels of interactions exist. In some the effects of magnetic field are played down, and in others they are considered. With the magnetic field neglected, for the highly interactive flow over vertical plates, [1,2] studied natural convective heat and mass transfer effects on the unsteady flow with cross-diffusive effects over an accelerating semi-infinite vertical porous plate; [3] considered the mixed convective flow with double diffusive effects over a vertical wavy plate; Also, for the moderate or less interactive flow over vertical plates but with the magnetic field effects neglected, [4] studied the unsteady natural convective flow over a porous plate in the presence of time-dependent temperature, concentration and suction; [5] investigated the transient mixed convective flow over a porous vertical plate in the presence of periodic suction; [6] considered the radiation effects in a mixed convective flow over an isothermal vertical porous plate; [7] studied the unsteady mixed convective flow over a vertical porous plate with heat and mass transfer, periodic suction and oscillatory free stream effects.Magnetic field plays very important roles in the dynamics of fluids. Upon this, a great number of researches have been carried out in this domain of study. For the highly interactive flow, [8] examined the viscous effects on a steady MHD free convective flow through a vertical porous plate; [9,10] investigated the effects of simultaneous heat and mass transfer, thermal radiation and Hall currents on the unsteady free convective flow over a vertical porous plate; [11] studied the effects of chemical reaction, convection, thermal radiation, cross-diffusion and magnetic field on the transient flow over a porous vertical plate. With the effects of magnetic field in view, for the moderate or less interactive flow, [12-22] studied the free convective flow over porous plates in the presence of suction, thermal radiation, chemical reaction rate and viscous dissipation. Importantly, for a partial in-depth review of literature, [23] studied the unsteady natural convective flow over a porous vertical plate using numerical approach, and noticed that the velocity is increased by the convective currents and Darcy number but is decreased by the magnetic field parameter, Prandtl and Schmidt numbers. [24] investigated the effect of chemical reaction rate in a transient free convective flow over a vertical plate in the presence of oscillating temperature and variable suction, and found that the magnetic field parameter increases the skin friction; the PrandtL number decreases the velocity, temperature, skin friction and Nusett number; the Schmidt number decreases the velocity, concentration, skin friction and Sherwood number; the convective currents increase the skin friction; chemical reaction rate decreases the velocity. [25] examined the unsteady mixed convective flow over a porous plate using similarity transformation and a numerical approach, and saw that the velocity is increased by the convective currents but it is decreased by the suction and magnetic field parameters; the heat source source/sink parameter increases the temperature and skin friction. Gundagani et al., [23] studied the MHD free convective flow past a vertical porous plate using the finite element numerical approach. In their work, the effects of heat source, thermal radiation and chemical reaction were neglected. Upon this, we are motivated to improve on the same model by investigating amongst others, the effects of the afore-mentioned parameters using the oscillating perturbation series solutions analysis. This paper is organized as follows: section 2 is the methodology, and section 3 is the conclusion.

2. Methodology

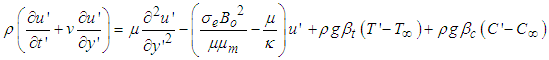

- The unsteady MHD natural convective chemically reacting flow over a vertical porous plate with heat source, thermal radiation, oscillating wall temperature, concentration and suction effects is considered. We assumed the y’ – axis is along the plate;

is the edge of the plate, and is taken to be the origin; the

is the edge of the plate, and is taken to be the origin; the  -axis is normal to the plate; the flow region is between

-axis is normal to the plate; the flow region is between  and

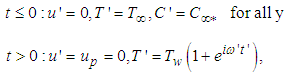

and  ; the fluid is viscous, incompressible, Newtonian, optically transparent, magnetically susceptible (due to the influence of the Earth or applied magnetic field) and non-highly chemically interactive; the plate is porous, heated, coated with some chemical substance, and vertically accelerating; the flow is naturally convective; the pressure is along the x-axis and is equal to the hydrostatic pressure such that

; the fluid is viscous, incompressible, Newtonian, optically transparent, magnetically susceptible (due to the influence of the Earth or applied magnetic field) and non-highly chemically interactive; the plate is porous, heated, coated with some chemical substance, and vertically accelerating; the flow is naturally convective; the pressure is along the x-axis and is equal to the hydrostatic pressure such that  ; the wall temperature and concentration and suction are oscillating. The hotness of the plate creates room for radiation and promotes heat exchange in the fluid system. The porous nature of the plate allows the fluid to permeate it; the chemical substance on the plate, which is of a higher concentration than that of the fluid is to enhance chemical reaction and suction. The magnetic field is constant and normal to the plate. Upon the one-dimensional mathematical theory for transient flows, the only independent variables are

; the wall temperature and concentration and suction are oscillating. The hotness of the plate creates room for radiation and promotes heat exchange in the fluid system. The porous nature of the plate allows the fluid to permeate it; the chemical substance on the plate, which is of a higher concentration than that of the fluid is to enhance chemical reaction and suction. The magnetic field is constant and normal to the plate. Upon the one-dimensional mathematical theory for transient flows, the only independent variables are  and

and  . If

. If  are the velocity components in the

are the velocity components in the  coordinates of the Cartesian system, where

coordinates of the Cartesian system, where  is the axial velocity and

is the axial velocity and  is the normal velocity and suction,

is the normal velocity and suction,  and

and  are the fluid temperature and concentration (quantity of material being transported), respectively; T∞ and C∞ are the fluid temperature and concentration at equilibrium;

are the fluid temperature and concentration (quantity of material being transported), respectively; T∞ and C∞ are the fluid temperature and concentration at equilibrium;  and

and  are the temperature and concentration at which the plate is maintained. Now, under the Boussinesq approximations, the governing flow equations are:

are the temperature and concentration at which the plate is maintained. Now, under the Boussinesq approximations, the governing flow equations are: | (1) |

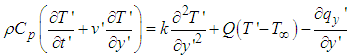

| (2) |

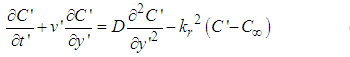

| (3) |

| (4) |

| (5) |

| (6) |

| (7) |

and

and  are the volumetric expansion coefficient for temperature and concentration respectively;

are the volumetric expansion coefficient for temperature and concentration respectively;  is the fluid density;

is the fluid density;  is the plate velocity;

is the plate velocity;  is the viscosity of the fluid;

is the viscosity of the fluid;  is the magnetic permeability of the fluid; g the gravitational field vector acting in the reverse direction of the flow;

is the magnetic permeability of the fluid; g the gravitational field vector acting in the reverse direction of the flow;  is the permittivity of the porous medium;

is the permittivity of the porous medium;  is the uniform magnetic field strength, σe is the electrical conductivity of the fluid;

is the uniform magnetic field strength, σe is the electrical conductivity of the fluid;  is the thermal conductivity of the fluid; Cp is the specific heat capacity at constant pressure; D is the diffusion coefficient;

is the thermal conductivity of the fluid; Cp is the specific heat capacity at constant pressure; D is the diffusion coefficient;  is the chemical reaction term;

is the chemical reaction term;  is the frequency of oscillation;

is the frequency of oscillation;  is the heat source/sink;

is the heat source/sink;  is the radiative heat flux;

is the radiative heat flux;  is the optical depth of penetration,

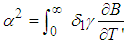

is the optical depth of penetration,  is the Botzman constant,Radiative heat transfer has great influence on high temperature regime and is comparable with convective heat transfer. The analysis of radiation is based the optically thin or thick limits. For an optically thin medium with low density and

is the Botzman constant,Radiative heat transfer has great influence on high temperature regime and is comparable with convective heat transfer. The analysis of radiation is based the optically thin or thick limits. For an optically thin medium with low density and  , the radiative heat flux is given in equation (3) can be expressed in the spirit of [26]; as seen in [27] as

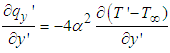

, the radiative heat flux is given in equation (3) can be expressed in the spirit of [26]; as seen in [27] as  | (8) |

and

and  is the radiation absorption coefficient,

is the radiation absorption coefficient,  is the frequency of the radiation, B is the Planck’s function. Now, by equation (8), equation (3) becomes

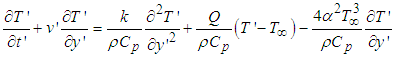

is the frequency of the radiation, B is the Planck’s function. Now, by equation (8), equation (3) becomes | (9) |

| (10) |

a small perturbation parameter,

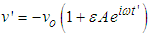

a small perturbation parameter,  is the uniform suction, A is a position constant,

is the uniform suction, A is a position constant,  (see [24], [27]). The negative sign in the suction means that the suction is towards the plate. And, by equation (1), suction is not a function of

(see [24], [27]). The negative sign in the suction means that the suction is towards the plate. And, by equation (1), suction is not a function of  but

but  .We introduce the following dimensionless quantities:

.We introduce the following dimensionless quantities: | (11) |

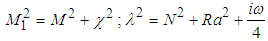

is the Hartmann number,

is the Hartmann number,  is the heat source parameter,

is the heat source parameter,  is the porosity parameter, Gr is the Grashof number due to temperature gradient, Gc is the Grashof number due concentration gradient, Pr is the Prandtl number, Sc is the Schmdt number, Ra2 is the Raleigh number,

is the porosity parameter, Gr is the Grashof number due to temperature gradient, Gc is the Grashof number due concentration gradient, Pr is the Prandtl number, Sc is the Schmdt number, Ra2 is the Raleigh number, is dimensionless temperature,

is dimensionless temperature,  is the dimensionless concentration,

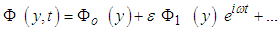

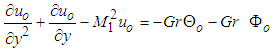

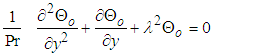

is the dimensionless concentration,  is the frequency of oscillation, into the governing equations.By equations (10) and (11), equations (2), (4), (9), (6) and (7) become

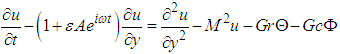

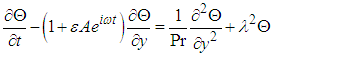

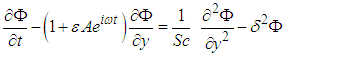

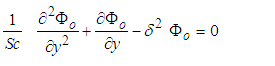

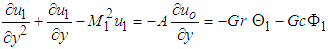

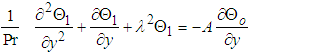

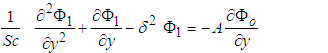

is the frequency of oscillation, into the governing equations.By equations (10) and (11), equations (2), (4), (9), (6) and (7) become | (12) |

| (13) |

| (14) |

| (15) |

| (16) |

| (17) |

| (18) |

| (19) |

| (20) |

| (21) |

| (22) |

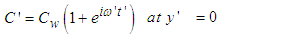

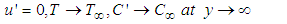

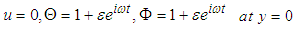

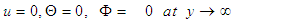

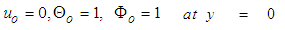

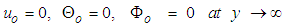

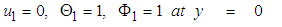

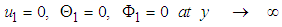

with the boundary conditions:

with the boundary conditions: | (23) |

| (24) |

| (25) |

| (26) |

| (27) |

| (28) |

| (29) |

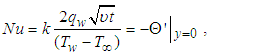

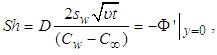

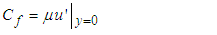

mass transfer rate

mass transfer rate  and skin friction as

and skin friction as | (30) |

| (31) |

| (32) |

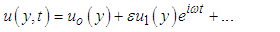

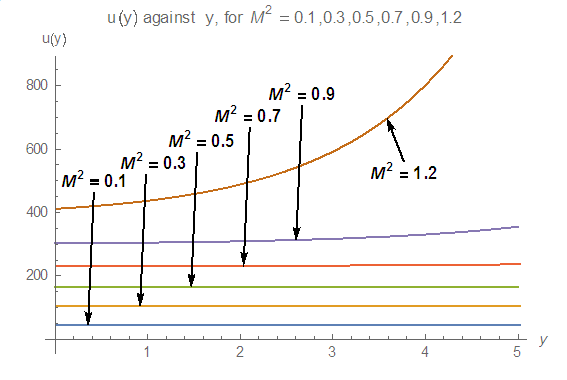

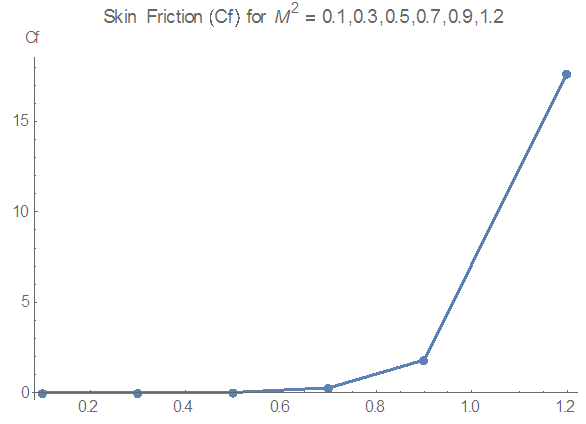

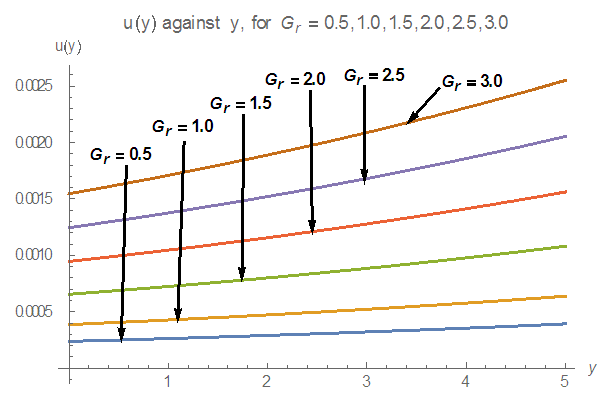

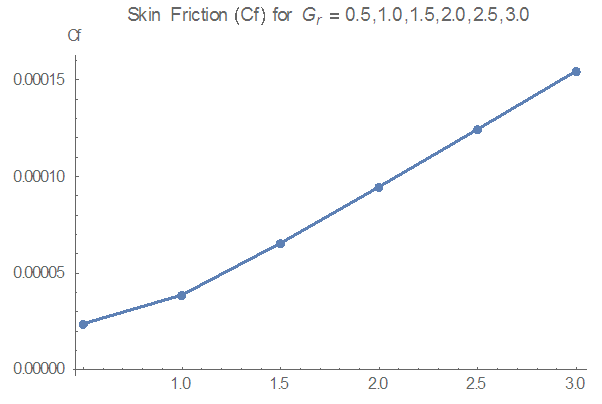

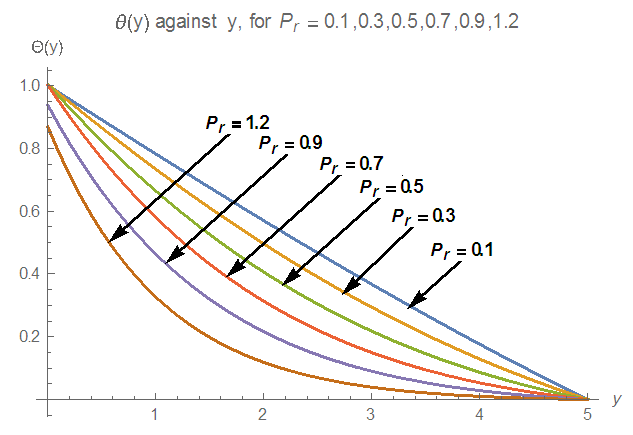

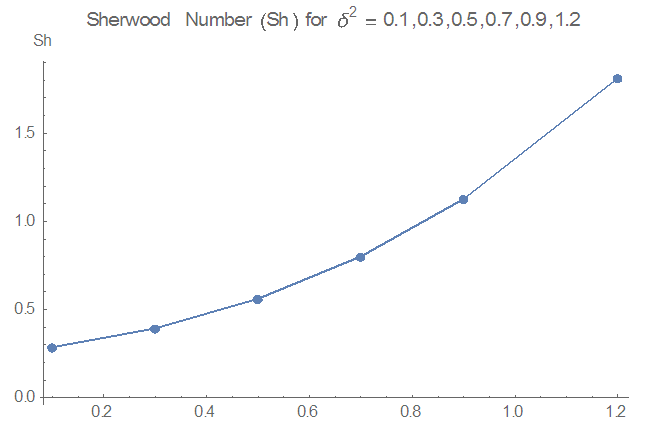

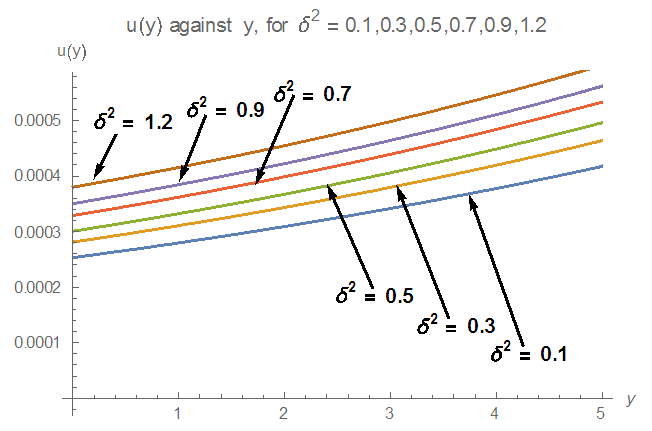

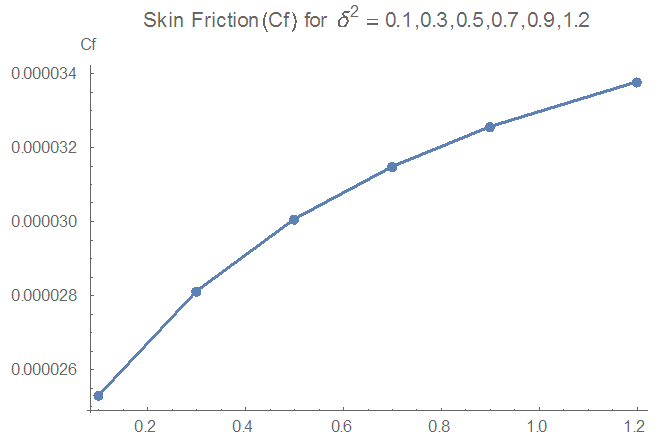

We investigate the unsteady MHD natural convective flow over a vertical porous plate under the influence of Hartmann, Grashof, Prandtl and Schmidt numbers, heat source parameter, thermal radiation and chemical reaction rate, and the results are shown graphically in Figure 1 – Figure 20. The results are obtained using Mathematica 11.0 computational software. For constant value of

We investigate the unsteady MHD natural convective flow over a vertical porous plate under the influence of Hartmann, Grashof, Prandtl and Schmidt numbers, heat source parameter, thermal radiation and chemical reaction rate, and the results are shown graphically in Figure 1 – Figure 20. The results are obtained using Mathematica 11.0 computational software. For constant value of  and varied values of

and varied values of  = 0.1, 0.3, 0.5, 0.7, 0.9, 1.2; Gr= 0.5, 1.0, 1.5, 2.0, 2.5, 3.0; Pr = 0.1, 0.3, 0.5, 0.7, 0.9, 1.2; Sc = 0.1, 0.3, 0.5, 0.7, 0.9, 1.2; Ra2= 0.1, 0.3, 0.5, 0.7, 0.9, 1.2;

= 0.1, 0.3, 0.5, 0.7, 0.9, 1.2; Gr= 0.5, 1.0, 1.5, 2.0, 2.5, 3.0; Pr = 0.1, 0.3, 0.5, 0.7, 0.9, 1.2; Sc = 0.1, 0.3, 0.5, 0.7, 0.9, 1.2; Ra2= 0.1, 0.3, 0.5, 0.7, 0.9, 1.2;  = 0.1, 0.3, 0.5, 0.7, 0.9, 1.;,

= 0.1, 0.3, 0.5, 0.7, 0.9, 1.;,  = 0.1, 0.3, 0.5, 0.7, 0.9, 1.2, we obtained the

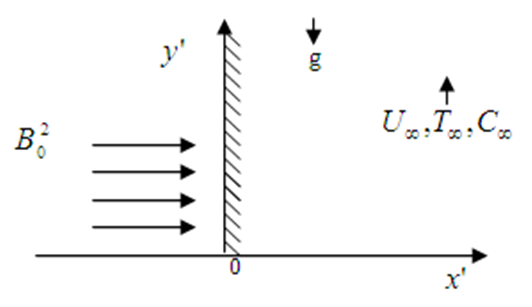

= 0.1, 0.3, 0.5, 0.7, 0.9, 1.2, we obtained the | Figure 1. A schematic model of a moving vertical plate in a flowing fluid |

| Figure 2. Velocity (u(y))-Hartmann Number (M2) Profiles |

| Figure 3. Skin friction (Cf)-Hartmann Number (M2) Profile |

| Figure 4. Velocity (u(y))-Grashof Number (Gr) Profile |

| Figure 5. Skin Friction (Cf)-Grashof Number (Gr) Profile |

| Figure 6. Temperature  -Prandtl Number (Pr) Profiles -Prandtl Number (Pr) Profiles |

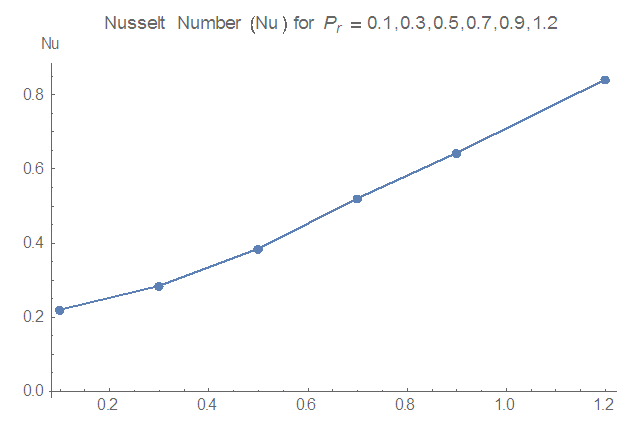

| Figure 7. Nusselt Number (Nu)-Prandtl Number (Pr) Profile |

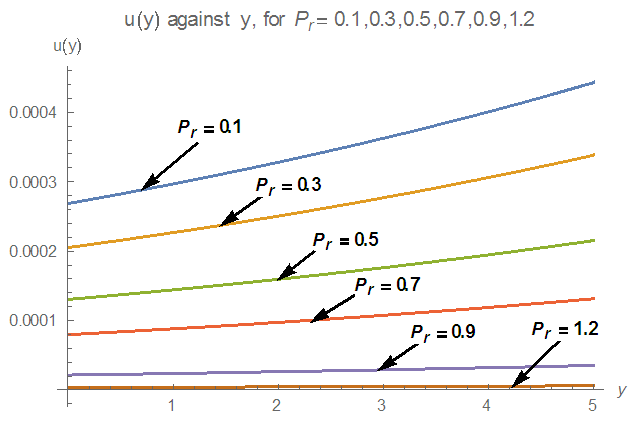

| Figure 8. Velocity (u(y))-Prandtl Number (Pr) Profiles |

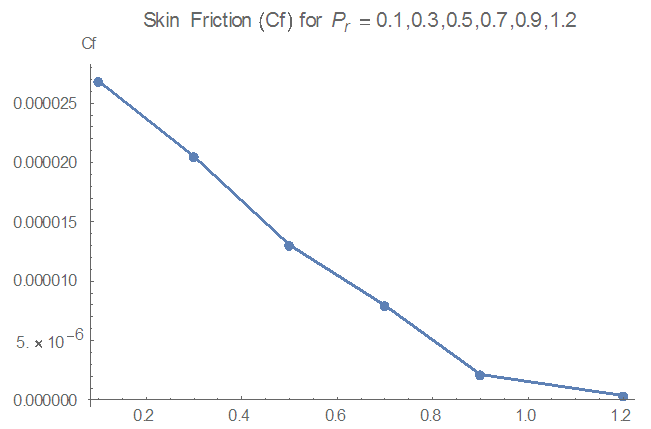

| Figure 9. Skin Friction (Cf)-Prandtl Number Profile |

but decreases in the region

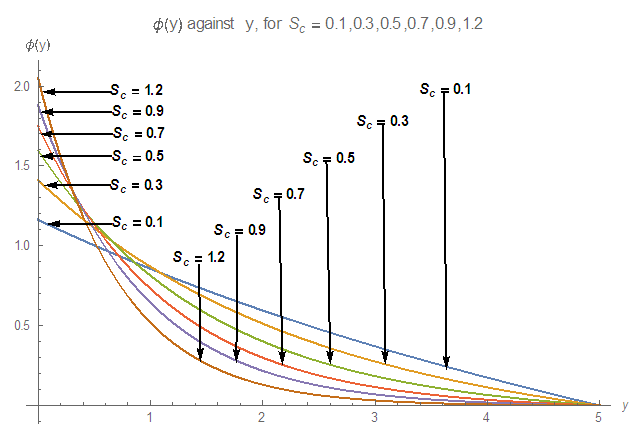

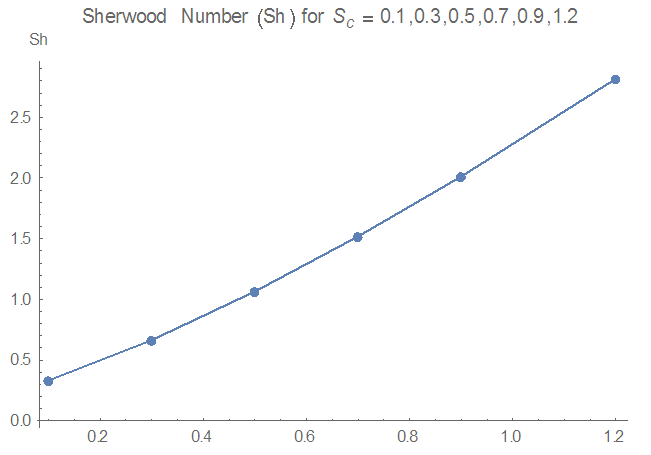

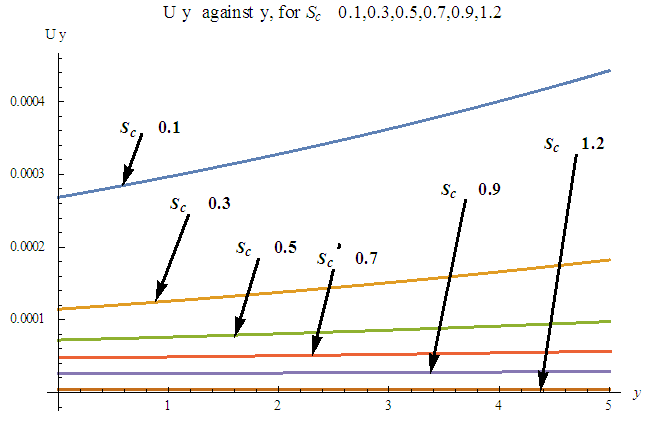

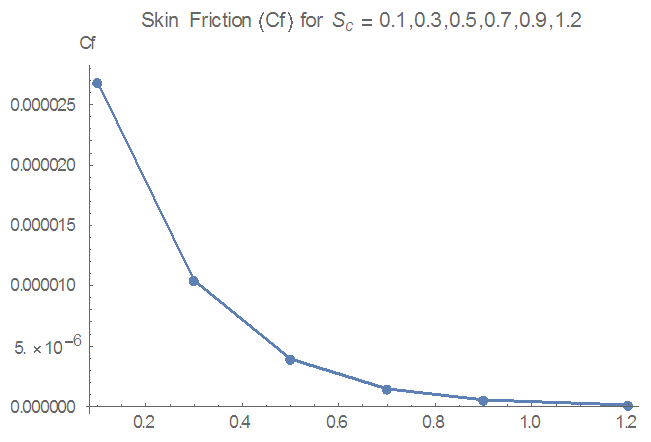

but decreases in the region  as the Schmidt number increases. The concentration profiles are twisted at y=0.5. Additionally, Figure 11 shows that the Sherwood number increases as the Schmidt number increases. Similarly Figure 12 shows that the velocity decreases as the Schmidt number increases. This may partly be due to the decrease in the concentration, velocity being a function of concentration. This result agrees with [24]. More so, Figure 13 depicts that the skin friction decreases as the Schmidt number increases. This may be due to the decrease in the velocity. This result agrees with [24].

as the Schmidt number increases. The concentration profiles are twisted at y=0.5. Additionally, Figure 11 shows that the Sherwood number increases as the Schmidt number increases. Similarly Figure 12 shows that the velocity decreases as the Schmidt number increases. This may partly be due to the decrease in the concentration, velocity being a function of concentration. This result agrees with [24]. More so, Figure 13 depicts that the skin friction decreases as the Schmidt number increases. This may be due to the decrease in the velocity. This result agrees with [24]. | Figure 10. Concentration  -Schmidt Number (Sc) Profiles -Schmidt Number (Sc) Profiles |

| Figure 11. Sherwood Number (Sh)-Schmidt Number (Sc) Profile |

| Figure 12. Velocity (u(y))-Schmidt Number (Sc) Profiles |

| Figure 13. Skin Friction (Cf)-Schmidt Number (Sc) Profile |

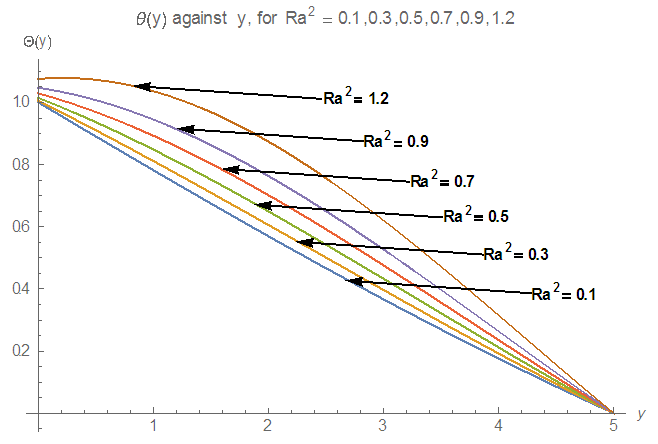

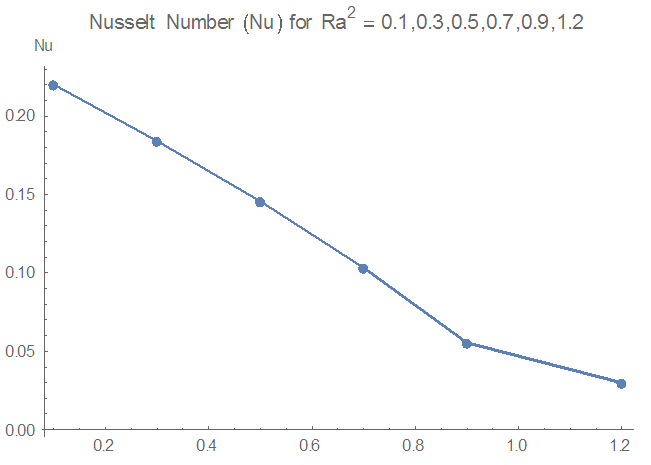

| Figure 14. Temperature  -Raleigh Number (Ra2) Profiles -Raleigh Number (Ra2) Profiles |

| Figure 15. Nusselt Number (Nu)-Raleigh Number (Ra2) Profile |

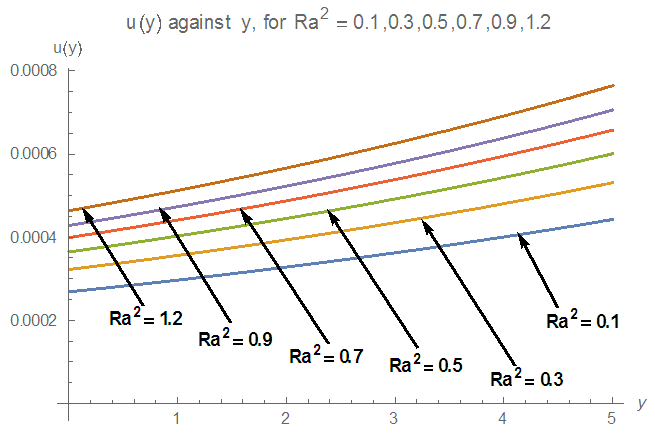

| Figure 16. Velocity (u(y))-Raleigh Number (Ra2) Profile |

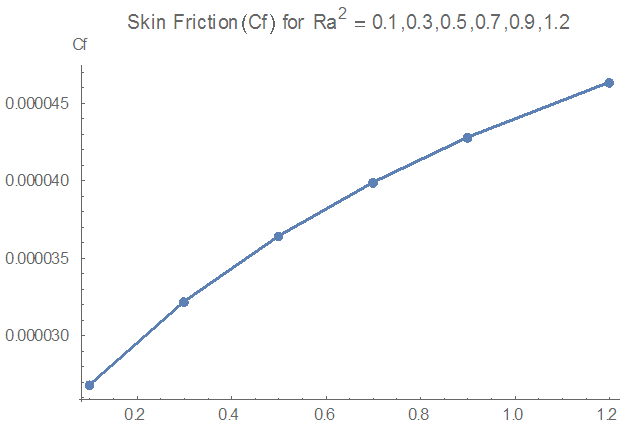

| Figure 17. Skin Friction (Cf)-Raleigh Number (Ra2) Profile |

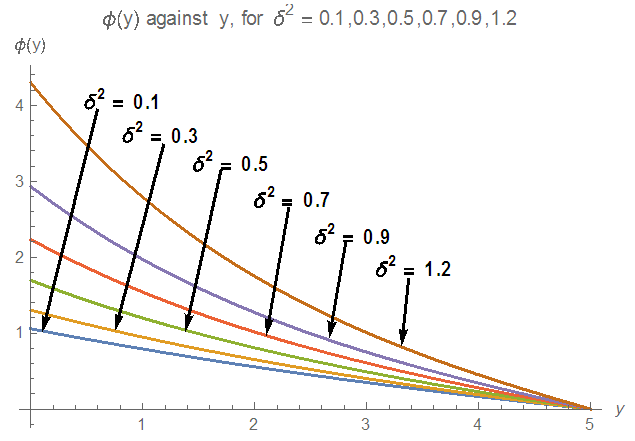

| Figure 18. Concentration  -Chemical Reaction rate -Chemical Reaction rate  Profile Profile |

| Figure 19. Sherwood Number-Chemical Reaction  Profile Profile |

| Figure 20. Velocity (u(y))-Chemical Reaction rate  Profiles Profiles |

| Figure 21. Skin Friction (Cf)-Chemical Reaction  Profile Profile |

3. Conclusions

- The roles of magnetic field, convection, Prandtl number, Schmidt number, Raleigh number, heat source and chemical reaction rate parameters in an unsteady viscous, incompressible, Newtonian flow past a vertically accelerating porous plate are considered. The equations governing the problem are simplified using the oscillating perturbation series expansion solutions. The evolving equations are solved and computed using the Mathematica 11.0 computational software. The results show that increase in:• Hartmann number increases the velocity and skin friction; • Grashof number increases the velocity and skin friction;• Prandtl number decreases the temperature, velocity and skin friction but increases the Nusselt number, • Schmidt number decreases the velocity and skin friction but increases the rate of mass transfer;• Raleigh number increases the temperature, velocity and skin friction but decreases the rate of heat transfer;• the heat source parameter increases the temperature, velocity and skin friction but decreases the rate of heat transfer.• the chemical reaction rate increases the concentration, Sherwood number, velocity and skin friction.. These results are benchmarked with some existing reports in literature, and are in good agreement.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML