-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Fluid Dynamics

p-ISSN: 2168-4707 e-ISSN: 2168-4715

2018; 8(4): 112-115

doi:10.5923/j.ajfd.20180804.02

Application an Euler–Euler Multiphase-Flow Model for Simulation Flow in a Centrifugal Separator Machine

Ashkan Shokrian1, Hossein Mobli2, Abbas Akbarnia3, Ali Jafari4, Hossein Mousazade5, Baoshan Zhu6

1PhD Students, Bio System Engineering, College of Agriculture & Natural Resources, University of Tehran, Karaj, Iran

2Professor of College of Agriculture & Natural Resources, University of Tehran, Tehran, Iran

3Associated Professor of Iranian Research Organization for Science and Technology, Karaj, Iran

4Professor of College of Agriculture & Natural Resources, University of Tehran, Karaj, Iran

5Associated Professor of College of Agriculture & Natural Resources, University of Tehran, Karaj, Iran

6Associated Professor of Department of Energy and Power Engineering, Tsinghua University, Beijing, China

Correspondence to: Hossein Mobli, Professor of College of Agriculture & Natural Resources, University of Tehran, Tehran, Iran.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

A computational fluid dynamics (CFD) simulation of solid–liquid–liquid three-phase flow was carried out on for the multiphase complex fluid flow motion in a centrifugal separate machine (Tricanter). An Euler–Euler, multiphase-flow model was used for the three-phase flow simulation. This centrifugal device is designed for separated three – phase flow, two- phase liquid (water and olive oil) and one phase solid materials (olive pomace). Results from the three-dimensional CFD include velocity and pressure distribution for solid phase flow. The simulations indicate that the velocity of solid material in near the surface bawl is maximum value but velocity in near the outer surface scroll is zero then causes the suspended solids to settle, and accumulate at the scroll wall. Also the pressure at the middle of the tricanter was lower than atmospheric pressure.

Keywords: Centrifugal separate three phase machine (Tricanter), Computational Fluid Dynamics (CFD), Euler–Euler multiphase-flow model, Olive oil

Cite this paper: Ashkan Shokrian, Hossein Mobli, Abbas Akbarnia, Ali Jafari, Hossein Mousazade, Baoshan Zhu, Application an Euler–Euler Multiphase-Flow Model for Simulation Flow in a Centrifugal Separator Machine, American Journal of Fluid Dynamics, Vol. 8 No. 4, 2018, pp. 112-115. doi: 10.5923/j.ajfd.20180804.02.

Article Outline

1. Introduction

- The decanter centrifuge has become a major processing tool in a wide range of liquid/solid separation applications. The versatility of tricanter centrifuges has led to their widespread use in industrial applications [1]. Olive oil is the most widely used fat in the diet of Mediterranean countries, thanks especially to its healthy properties, unique aroma and long shelf life, and due to its natural antioxidant content, which make it different from other vegetable oils [2]. Today, centrifugation system is mainly used for olive oil production; The three-phase system is a continuous process dating at 1970e1980, which has three exits for oil, water, and solids [3].Evolution of the oil extraction process has led to the replacement of traditional discontinuous lines, using the pressure system extraction, with continuous ones, using centrifugal extraction. In particular, the horizontal centrifuge with a screw conveyor (i.e. tricanter) is widely used in olive oil extraction, especially if large amounts of olives have to be processed in a short time [4-5]. However, olive oil extraction by centrifuge is dramatically affected by changes in the rheological characteristics of the olive paste in relation to water content, fruit variety, maturity level and seasonal temperature variations [6].Due to different rheological characteristics the non-Newtonian fluids cannot be described by a single constitutive equation. Therefore, several constitutive equations are presented in the literature via three main categories namely the differential, the rate and integral types [7].The resulting ordinary differential equation is then solved analytically using the homotopy analysis method and numerically by shooting method to show the accuracy of the analytical solution [8].The exact solution for the velocity and the temperature fields are derived in the form of an incomplete Gamma function [9].In the recent year’s computational fluid dynamics (CFD) has been advanced and widely used for the prediction of flow fields for multiphase flow [10]. The simulations were conducted with the CFD software Fluent 15.0 from ANSYS, Canonsburg, USA. For the simulation an Euler-Euler approach is applied. Even if the phase interface cannot be resolved with this technique it incorporates a momentum equation for each phase.

2. Materials and Methods

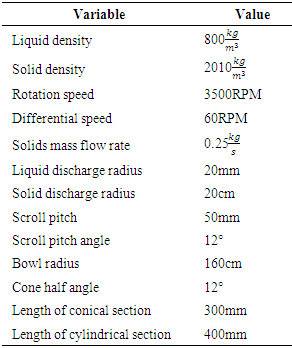

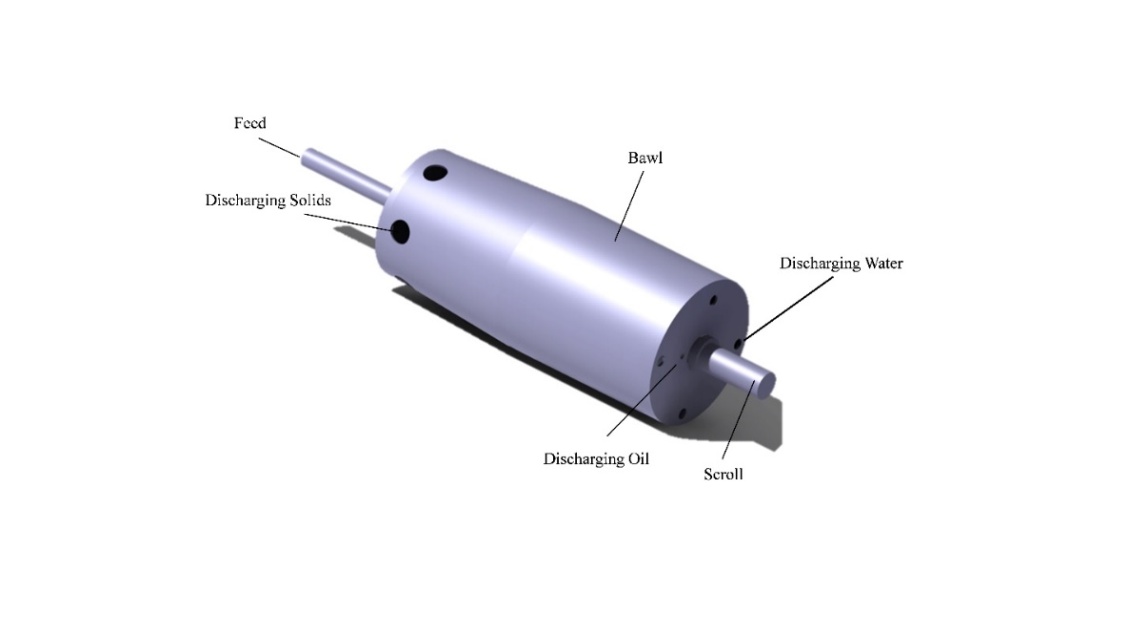

- Centrifugal horizontal machine (Tricanter) has become a major processing tool in a wide range of liquid/solid separation applications. Although a complicated piece of machinery, the tricanter centrifuge embodies a simple principle, that of the screw conveyor [11].The tricanter centrifuge is, in principle, a relatively simple device, though far from simple to manufacture, being a rotating drum with a screw conveyor in it; clarified liquid decants out of one end while dewatered solids are scrolled out of the other. The prime virtue of the tricanter is its ability to remove quite high levels of suspended solids from a liquid, with a reasonably low level of retained liquids in the separated solids.A schematic of a tricanter centrifuge is shown in Fig. 1, with an example of dimensions and operating parameters for a typical application listed in Table 1.

| Figure 1. Schematic of a tricanter centrifuge |

|

2.1. Basic Theories

- In the centrifuge, it is the liquid that moves round in a circle, and the particles in suspension are free to move relative to the liquid. Thus, relative to the liquid, the suspended particles experience an acceleration,

radially outwards.Thus, the gravitational force, F, on a particle of mass m, is the product of its mass and acceleration, where:

radially outwards.Thus, the gravitational force, F, on a particle of mass m, is the product of its mass and acceleration, where: | (1) |

2.2. Methodology

- Flow governing equations in terms of Navier-Stokes equations are solved. Multiphase simulation flow inside the tricanter machine is resolved by The Eulerian-Eulerian method. We used ANSYS CFD software package for simulation of fluid motion in the centrifugal tricanter. The CFD simulation allow us to predict the performance of a tricanter machine [12]. In the recent year’s (CFD) has been advanced and widely used for the prediction of multiphase flows. for simulation of a three-phase separator in industrial scale with ANSYS CFD Their grid contained about 8.5 million elements butstill the element size was around 5 cm [12]. Simulation model for three phase centrifuge machine (gas – liquid- liquid) can be used Eulerian-Eulerian model. The behaviour of multiphase flows can be modelled using the general Eulerian multi-fluid balance equations. It may correspond to distinct physical materials (e.g. gas, liquid and solid particles) which can be split into different groups (e.g. water and several groups of different particles diameter); different thermodynamic phases of the same component (e.g. liquid and its vapour) or physical components, where some of which may be split into different groups [13].

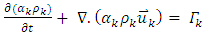

2.3. Eulerian-Eulerian Method

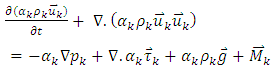

- The Eulerian-Eulerian multiphase model, the governing equations of continuity and the momentum conservation for the ‘kth’ phase are given by the following equations [14]:

| (2) |

| (3) |

is computed at each cell.

is computed at each cell.  describes the mass transfer between phases and is assumed to be zero in this work because mass transfer is not considered.

describes the mass transfer between phases and is assumed to be zero in this work because mass transfer is not considered.  Is the stress tensor of the ‘kth’ phase, including the viscous stress tensor and Reynolds stress tensor.

Is the stress tensor of the ‘kth’ phase, including the viscous stress tensor and Reynolds stress tensor.  describes the interfacial forces acting on the ‘kth’ phase due to the presence of the other phases, including the effects of drag, lift, and virtual mass forces.

describes the interfacial forces acting on the ‘kth’ phase due to the presence of the other phases, including the effects of drag, lift, and virtual mass forces.2.4. Turbulence Models Description

- The standard

model is a model based on model transport equations for the turbulence kinetic energy (k) and its dissipation rate

model is a model based on model transport equations for the turbulence kinetic energy (k) and its dissipation rate  The model transport equation for k is derived from the exact equation, while the model transport equation for

The model transport equation for k is derived from the exact equation, while the model transport equation for  was obtained using physical reasoning and bears little resemblance to its mathematically exact counterpart.The turbulence kinetic energy, k and its rate of dissipation,

was obtained using physical reasoning and bears little resemblance to its mathematically exact counterpart.The turbulence kinetic energy, k and its rate of dissipation,  are obtained from the following transport equations [14]:

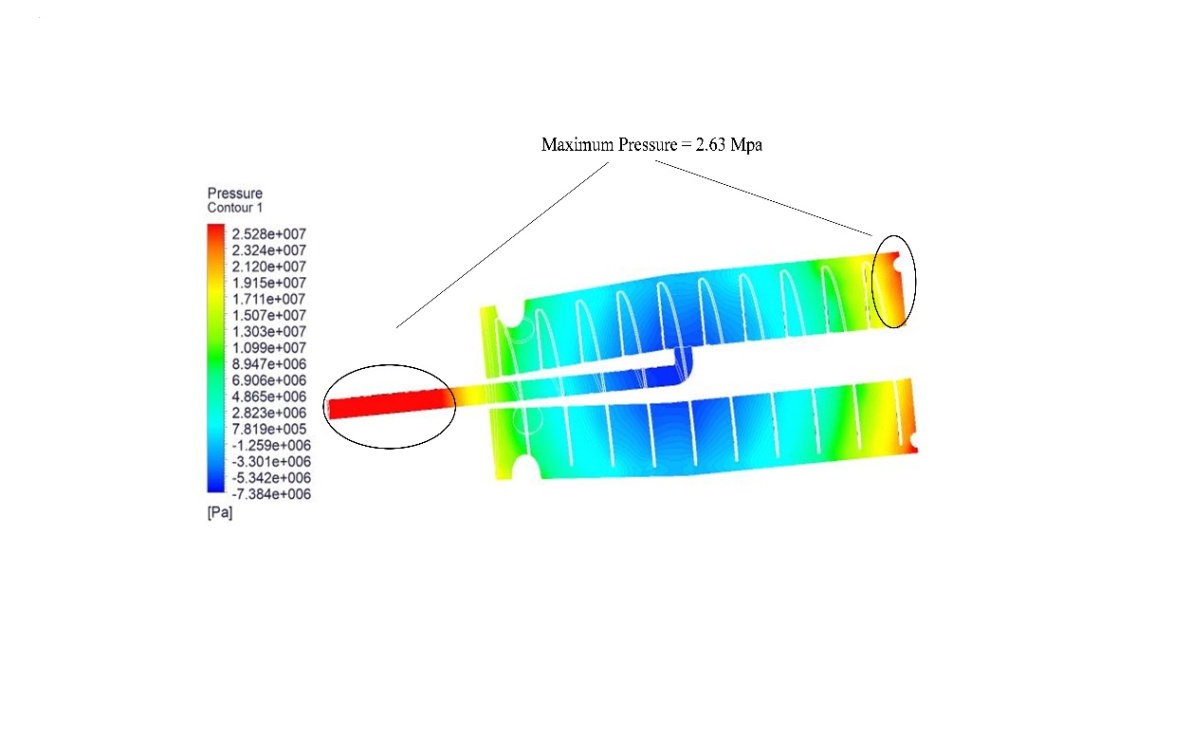

are obtained from the following transport equations [14]: | (4) |

represents velocity component in corresponding direction,

represents velocity component in corresponding direction,  represents component of rate deformation

represents component of rate deformation  represents viscosity and ρ is density of fluid.

represents viscosity and ρ is density of fluid.2.5. Olive Samples

- This study included olive oil samples produced from olives (Fashemi) of the Manjil cultivar, which is considered as the most prized Iran olive variety for oil production, originating from the area of Gilan province, Iran. This variety grows well on mountain slopes and produces small fruit; the high ratio of skin to flesh giving the oil its coveted aromatic qualities. Olive fruits grown in an organic farm in Manjil, were picked by hand during February 2014. The maturity of olive fruits was confirmed by their color: 70% were green and 30% brown. Olives’ average diameter was 12.8mm and their average weight was 0.78 g. Overall, 200 kg of olive fruits were collected. Olives were processed within 24 h, by the following procedure: (i) leaf removal from olive lots; (ii) washing of olives with water; (iii) milling of drupes by disk crusher; (iv) malaxation of the paste in a single-stage malaxation machine at 25

for 15 min.

for 15 min.3. Results and Discussion

3.1. Solid Velocity

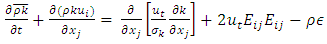

- The contour velocity vectors profiles of solid materials inside tricanter machine are displayed in figure 2. It can be seen from figure 2 that the velocity of solid material in near the surface bawl is maximum value (72.30

) but velocity in near the outer scroll is zero then causes the suspended solids to settle, and accumulate at the scroll wall. Secondary upward axial flow is observed in the center region of the separator, while the bulk of the axial flow moves downward with a swirl in the outlets at the front and rear machine. The figure shows a very strong flow near the outlets.

) but velocity in near the outer scroll is zero then causes the suspended solids to settle, and accumulate at the scroll wall. Secondary upward axial flow is observed in the center region of the separator, while the bulk of the axial flow moves downward with a swirl in the outlets at the front and rear machine. The figure shows a very strong flow near the outlets. | Figure 2. Solid materials velocity counter |

3.2. Pressure

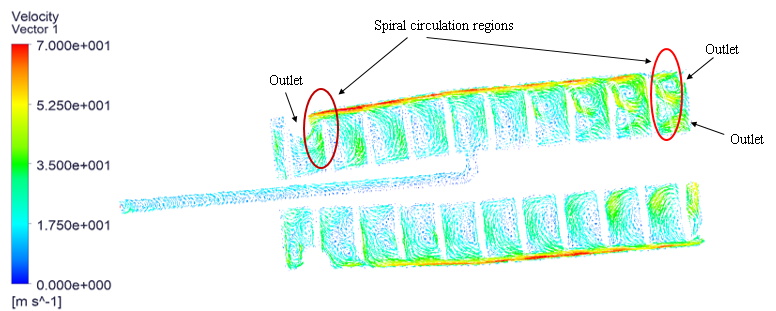

- The highest pressure occurs at the front and rear of the separator is also decreased the flow velocity at the entrance. It was noticed that the pressure at the middle of the tricanter was lower than atmospheric pressure and ideally lower than the inflow inlet for the tricanter to have optimum efficiency (Figure 3).

| Figure 3. Pressure contour inside the tricanter machine |

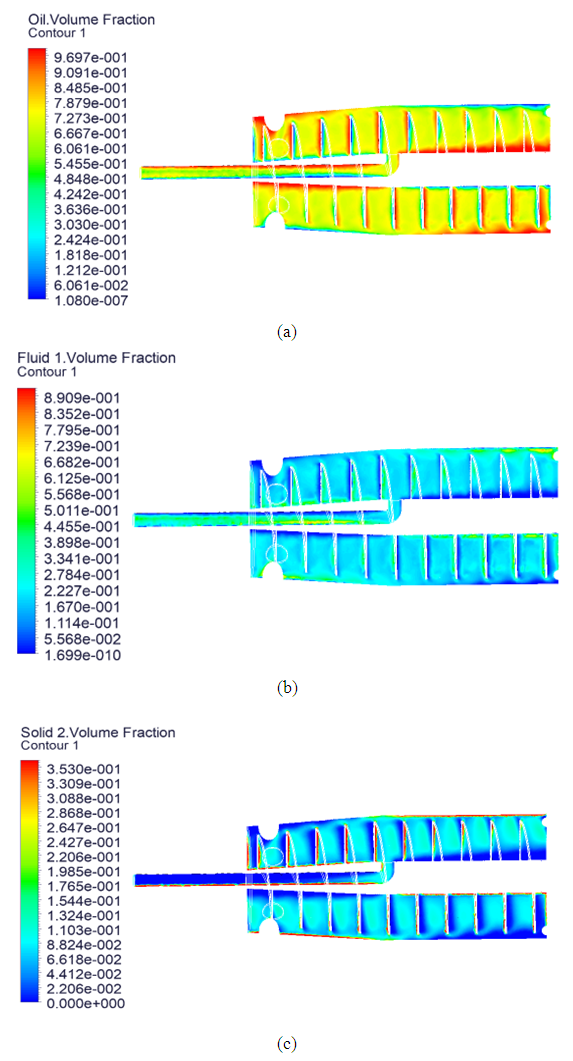

3.3. Volume Fraction

- Figure 4a show biggest oil concentration is near the scroll, and this is due to lower oil density than the density of oil and solid materials. Also, the water concentration is zero or almost zero close to centrifugal rotor (scroll) body.It is possible to see in figure 4b, that water concentration is almost zero or zero exactly where the water concentration is the biggest (Figure 4a). This shows that the separation of the mixture starts around the centrifugal rotor.Figure 4c shows solid materials that the suspended solids to settle, and accumulate at the bawl wall that’s because the solid density is higher than the density of water and oil.

| Figure 4. Volume fraction contour: Oil (a), Water (b), Solid materials (c) |

4. Conclusions

- A slurry of liquid and suspended solids is fed along the centerline to some fixed position within the bowl, and is accelerated outwards to join the pond of liquid held on the bowl wall by the centrifugal force. This same force then causes the suspended solids to settle, and accumulate at the bowl wall. In this paper, the flow inside tricanter simulated by Computational Fluid Dynamics (CFD) technique. The CFD simulation of solid− liquid− liquid three-phase flow was by using an Euler − Euler, multiphase flow model.Results from the three-dimensional CFD include velocity and pressure distribution for solid phase flow. The simulations indicate that the velocity of solid material in near the surface bawl is maximum value but velocity in near the outer surface scroll is zero then causes the suspended solids to settle, and accumulate at the scroll wall. Also the pressure at the middle of the tricanter was lower than atmospheric pressure and ideally lower than the inflow inlet for the tricanter to have optimum efficiency.Inside the tricanter centrifuge the separation of water, oil and solid parts are performed efficiently. At the outlet it is possible to see, that on the water outlet comes out water, on the oil outlet comes out oil and on the solid particles outlet come out solid particles, mainly.

ACKNOWLEDGEMENTS

- The authors would like to thank the Iranian national science foundation (INSF) and Iranian Research Organization for Science and Technology for funding and supporting this project.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML