-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Fluid Dynamics

p-ISSN: 2168-4707 e-ISSN: 2168-4715

2012; 2(5): 78-88

doi: 10.5923/j.ajfd.20120205.02

CFD Analysis for Turbulent Flow within and over a Permeable Bed

Nagia E. Elghanduri

School of Engineering, University of Aberdeen, UK, Fraser Noble Building, King’s College AB24 3UE

Correspondence to: Nagia E. Elghanduri , School of Engineering, University of Aberdeen, UK, Fraser Noble Building, King’s College AB24 3UE.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstact The main objective of this study is to improve our knowledge about the velocity profile and turbulence within and over a permeable bed. The study was using computation fluid dynamics (CFD) methodology to simulate the studied cases. It includes a detail analysis for two-dimensional fully developed turbulent flow over and through a permeable bed. Five different cases were simulated numerically. The analysis is set for the three flow zones (free stream, porous, and interface). The detailed two dimensional flow simulations were subsequently validated using previously published results, then it was specially averaged to overcome the heterogeneity of flow. The focus in this study is on the effect of porosity and free stream thickness on longitudinal and vertical velocities in different flow zones. On the basis of this study results, it is shown that the flow velocity within the porous zone increases with bed porosity, and decreases with increasing the water depth. It is also confirmed that the turbulence parameters (turbulent kinetic energy, turbulent dissipation rate, and turbulent kinetic energy production) penetrate practically throughout the whole porous layer to reach maximum values at the interface then decreases smoothly to minimum at the water surface.

Keywords: Permeable Bed, Porous Layer, Free Stream, Penetration Layer

Cite this paper: Nagia E. Elghanduri , "CFD Analysis for Turbulent Flow within and over a Permeable Bed", American Journal of Fluid Dynamics, Vol. 2 No. 5, 2012, pp. 78-88. doi: 10.5923/j.ajfd.20120205.02.

Article Outline

1. Introduction

- In general, a permeable bed has recently treated analogously to an impermeable bed. The velocity distribution, and flow resistance coefficients were derived irrespective of bed porosity. However, significant interaction processes occur between the flow above and through the porous zone which depends on the permeability of the surface. These interactions influence a non–zero velocity at the permeable zone, and turbulence exchange of mass and momentum between the two flow zones. The exchange process is responsible for additional shear stress near the boundary[1]. Nowadays, several studies gave a sight on the velocity distribution within, and close to the porous zone, especially within the interface zone. Such as[2] published that the time- average stream-wise velocity increased much more near the free surface than near the permeable bed. It was found experimentally that the velocity profile over the suction zone consists of two parts; an inner boundary layer where the shear stress changes rapidly, and a logarithmic law is applied for the zone above the first layer in which the flow is unaffected by the presence of suction[3]. The logarithmic zone at the free stream has been widely applied such as[4-7].It was found that there is a significant increase in the near bed velocity and a velocity reduction near the water surface, resulting in the formation of uniform velocity distribution[2].Although, the vertical velocity distribution is an important variable to be studied and analyzed as it gives a good indication about the fluid movement in the interface region, the previous studies focus on the longitudinal velocity as most of it deals with the free stream, where no vertical velocity exist.Fully developed turbulent flow through and over permeable bed is characterized by the momentum transfer occurring from the faster flow at the free stream and the slower flow in the porous zone. This phenomenon occurs at the interface zone, where a shear layer develops. It is developed with the secondary currents generated at the corner regions of the cross section, bed-generated turbulence, and free surface effects. These phenomena result in a very complicated flow field that studied by lots such as;[5] and[8- 10].

| (1) |

2. Governing Equation

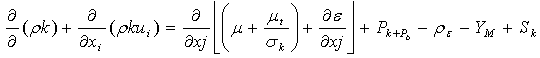

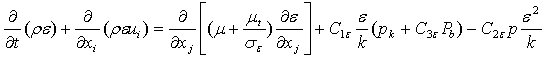

- In general, two equation models are widely used in present engineering calculations to solve Reynolds Averaged Navier Stokes (RANS) equation. It gives independent scales (eliminates the need for specifying the turbulence length scale) in calculating the turbulent viscosity (μt). The numerical solution for the 2-D model used in this study is K-epsilon. Within the K- epsilon model there are a three solution models available Standard, RNG, and Releasable models. The solution in this study is by two equation model using k-epsilon (k-) model which is widely used in literature. The two equations solved in K- epsilon model are the turbulent kinetic energy, and the turbulent dissipation rate:

| (2) |

| (3) |

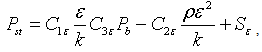

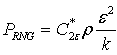

and Pst =0.0 at RNG model

and Pst =0.0 at RNG model  , for RNG model, and PRNG = 0.0 at standard model Coefficients k, , C1, and C2, are empirical constants. The turbulent viscosity (t) is[

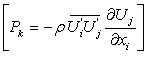

, for RNG model, and PRNG = 0.0 at standard model Coefficients k, , C1, and C2, are empirical constants. The turbulent viscosity (t) is[ ], and Pk represent the generation of turbulence kinetic energy due to the mean velocity gradients

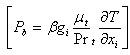

], and Pk represent the generation of turbulence kinetic energy due to the mean velocity gradients  , Pb represent the generation of turbulence due to buoyancy,

, Pb represent the generation of turbulence due to buoyancy,  , and eddy viscosity is computed by

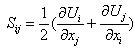

, and eddy viscosity is computed by  . It should be mentioned here that the strain rate (S) in both equations is

. It should be mentioned here that the strain rate (S) in both equations is , where, the strain rate tensor

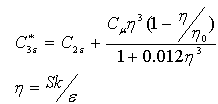

, where, the strain rate tensor  and the degree to which ε is affected by the buoyancy is determined by the constant C3 ε which equals

and the degree to which ε is affected by the buoyancy is determined by the constant C3 ε which equals  In the present study, the commercial CFD software Ansys- Fluent is used. In common with many other codes, Fluent solves the Navier Stokes equation numerically using the finite volume method on an unstructured grid. The Navier stokes equations consist of a continuity and three momentum equations, which are based on the conservation of mass and momentum respectively ([17]).

In the present study, the commercial CFD software Ansys- Fluent is used. In common with many other codes, Fluent solves the Navier Stokes equation numerically using the finite volume method on an unstructured grid. The Navier stokes equations consist of a continuity and three momentum equations, which are based on the conservation of mass and momentum respectively ([17]).3. The Simulated Cases

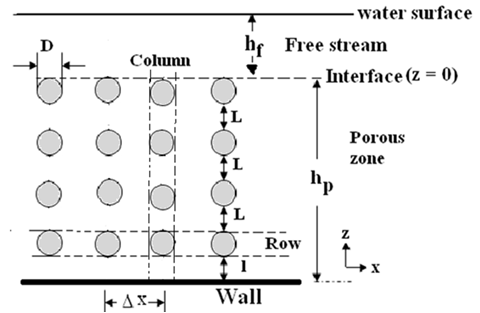

- The study was a numerical simulation for fully developed turbulent flow zone over and through permeable bed. The data for all simulated cases are defined in[18]. They carried out their experimental and numerical study for three different bed porosities. These cases involved turbulent flow over and within three and four layers of rods. These rods were fixed at different distances to enable to include the porosity effect on turbulence. Reference[18] computed the flow structure above and within the porous medium using a model based on the Reynolds – averaged Navier-Stokes equations. It was solved using Fluent software with the k-epsilon method. In their simulation, a periodic boundary condition was used. The periodic boundary conditions may do not accurate results within the porous zone as the flow passes around the rods from vortices the may be cut before it is complete and the flow pattern before and after the rod is not the same which is the basic in periodic boundary condition computation. In this study long flume is built for the studied cases. This enables us to reach fully developed turbulent flow in conditions as the real experiments.

| Figure 1. Columns of the arranged rods bundle and symbols for geometry |

3.1. Model Testing and Validation

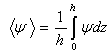

- In this study, the values of various flow parameters are kept the similar to that published[18] to assure correctness and consistency of the simulated results. The results simulated were tested for their validation[18]. Further, two simulated results from spars cases were tested with[16] who simulated these results using macroscopic technique to solve the (RANS) equations. Figure 2 shows a comparison between published and present data for normalized turbulent kinetic energy (TKE+) vs. normalized bed height for a mid-line between two column rods. From the figure, it can be concluded that the simulation is with reasonable results that is superior closer to experimental results than previous studies at the interface between the free stream and the porous zone.

|

4. Results and Discussion

- The work described here was undertaken to provide more detailed information about the velocity field and turbulence within the fully developed turbulent region. The data that exported from Fluent was irregular. Further, it was heterogeneous. To overcome these problems, a Matlab program was built for each case to convert the data to regular and to spatially averaged to overcome the flow heterogeneity. Spatial averaging was for conventional bed-parallel volumes (centre to centre column rod) for obtaining vertical properties of velocity components. The spatially averaged quantity of a flow variable ψ is defined as:

| (4) |

4.1. The Velocity within and Over the Permeable Bed

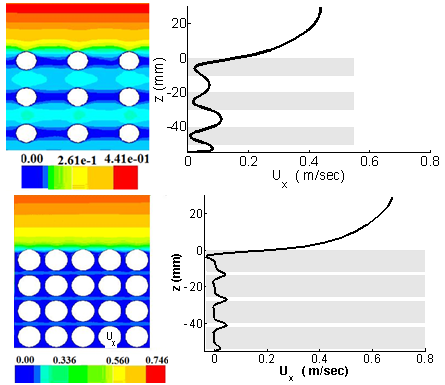

- The flow velocity through and over the porous zone is shown as contours at figure 3. This figure is for longitudinal velocity for two different porosity cases. From the figure, it could be noticed that the overall flow pattern is similar for both shown cases. The mean velocities show the expected boundary-layer profile in the free stream zone, and a much slower flow in the porous zone. A pipe-like velocity profile forms between each two successive rows of cylinders, with a faster and more developed flow in case of sparse cylinder packing, compared to the dense case. CFD provides details of the flow spatial structure between the cylinders, where the difference between the sparse and the dense packing is most pronounced. As expected bed porosity has a major influence on the flow velocities within the porous layer.

| Figure 2. Comparison Between Previously Published and Present Study for Normalized Turbulent Kinetic Energy Profile Above and Within Porous Medium(Left), and Normalized Velocity Distribution at The Free Stream(Right) for The Simulated Cases |

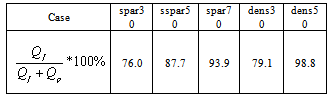

), where: Qf, and Qp are the volumetric flow rate within the free stream and the porous zone, respectively. The results are shown in Table 3. From the table it can be concluded that a large discharge difference exists between the porous and free stream zones, even when the area of flow is smaller than that at the porous zone. Further, as expected a comparison between the studied cases shows that the discharge difference between the free stream, and the porous zone, increases with the density of the rod packing. Furthermore, the larger is the free stream thickness, the larger is the discharge difference. This result is in agreement with experimental results of[21].

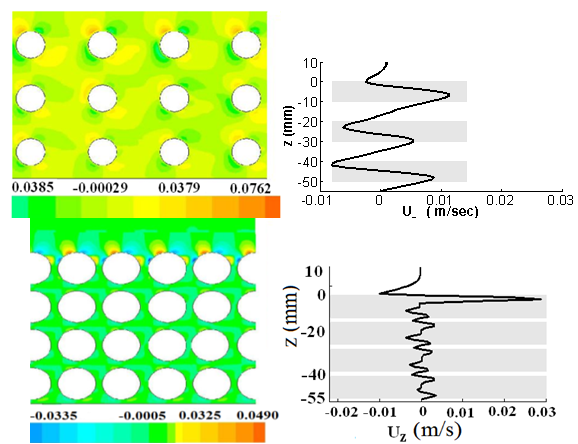

), where: Qf, and Qp are the volumetric flow rate within the free stream and the porous zone, respectively. The results are shown in Table 3. From the table it can be concluded that a large discharge difference exists between the porous and free stream zones, even when the area of flow is smaller than that at the porous zone. Further, as expected a comparison between the studied cases shows that the discharge difference between the free stream, and the porous zone, increases with the density of the rod packing. Furthermore, the larger is the free stream thickness, the larger is the discharge difference. This result is in agreement with experimental results of[21]. | Figure 3. The Longitudinal velocity distribution (m/s): Contours (Left) and the profile along the central line between two-rod columns (Right), for spar30 Case (Top) and dens30 Case (Bottom). Grey Areas on The Right Indicate The Position of The Rods |

|

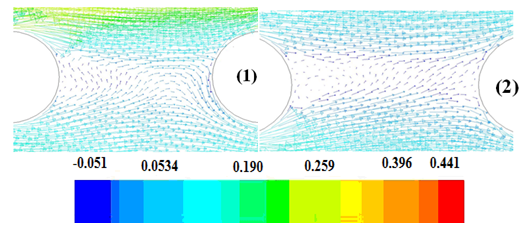

| Figure 4. The velocity vectors between two adjacent rods for spar30 (left), and dens30 (right) cases; rods are numbered top-down. Vectors are colour-coded based on Ux |

| Figure 5. The Velocity vectors between two adjacent rods for top rod (left), and second rod (Right) at dens30 ; vectors are colour-coded based on lateral velocity |

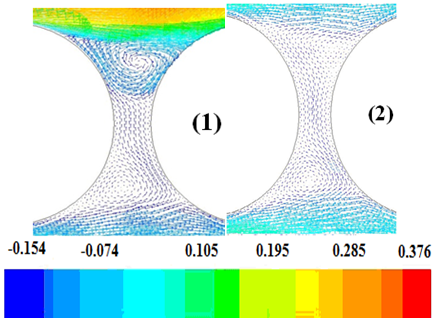

| Figure 6. Velocity vectors (m/s) in the free space between The rods; spar30 (Left), and dens30 (Right) cases; rods are numbered top-down. vectors are colour-coded based on lateral velocity |

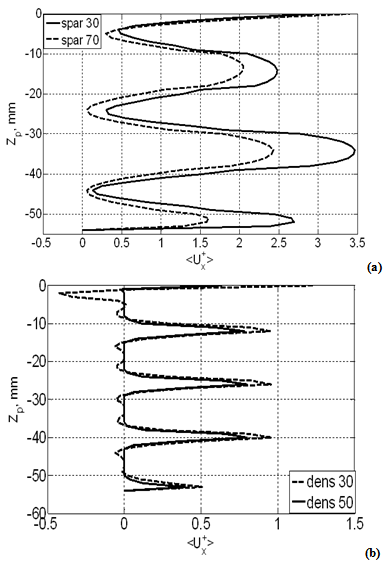

| Figure 7. Normalized longitudinal velocity within the porous zone Porosity effect on normalized longitudinal velocity for flow within porous zone; (a) for spars cases, and (b) dense cases |

| Figure 8. Free stream thickness effect on the longitudinal velocity within the porous zone; (a) for spars cases, and (b) dense cases |

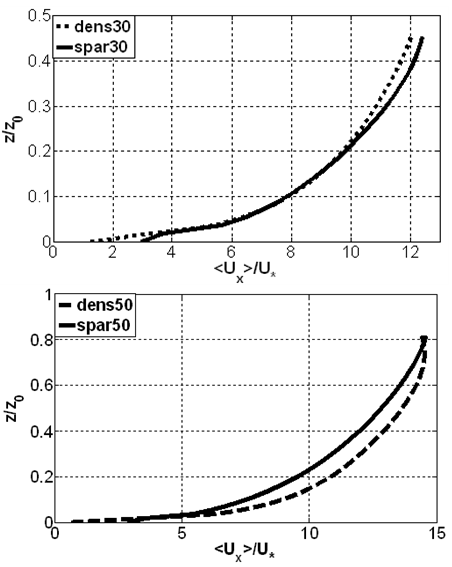

| Figure 9. Effect of bed porosity on the longitudinal velocity in the free stream zone |

| Figure 10. The bed-normal velocity distribution (m/s); contours (left) and the profile along the central line between two rod columns (right), for spar30 case (top) and dens30 case (bottom).Grey areas on the right indicate the position of the rods |

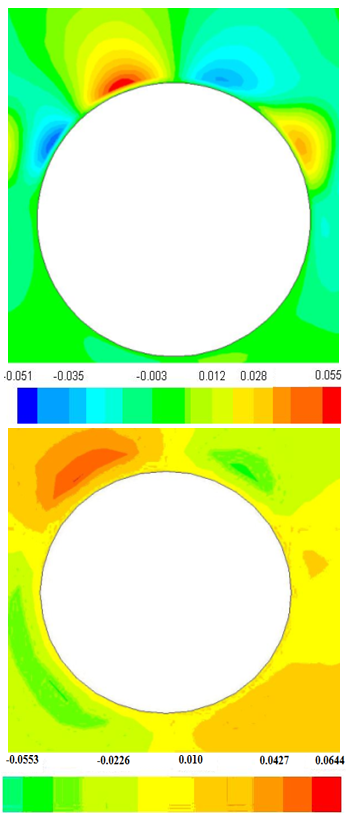

| Figure 11. The Vertical Velocity Contours Around a Top Rods; dens30 (UP) and spar30 (Bottom) Cases |

|

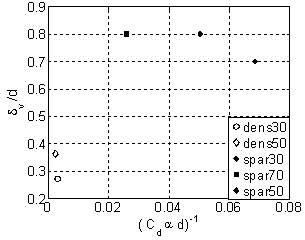

| Figure 12. Penetration thickness, versus (Cdαd)-1 |

4.2. Turbulence within and Over the Permeable Bed

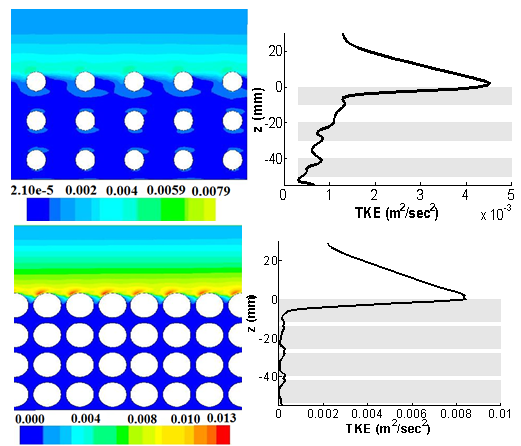

- Figure 13 shows the contour plots and vertical profiles of TKE for sparse and a dense case. For both cases, TKE has a clearly defined maximum close to the interface. This is due to the difference between velocities in the free stream and porous zone, which creates the most intense shearing at the interface. Within the free stream, TKE decreases with distance from the bed. Overall, the TKE pattern agrees with different published data such as;[16] and[18]Turbulence within the porous zone is heterogeneous and characterized with very small values of TKE. For the sparse case, TKE within the porous layer steadily increases towards the interface. However, the dense case has higher TKE values close to the interface where TKE reaches maximum. In this region, the TKE value for the dense case is nearly double that of the sparse case. This is probably due to the higher difference in velocity between the free stream, and the porous zone, which enhances shearing and hence also generation of turbulence.

| Figure 13. The turbulent kinetic energy distribution (m2/s2): contours (left) and the profile along the central line between two rod columns (right), for spar30 case (top) and dens30 case (bottom). Grey zones on the right indicate the positions of rods |

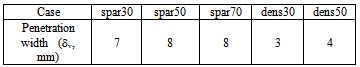

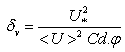

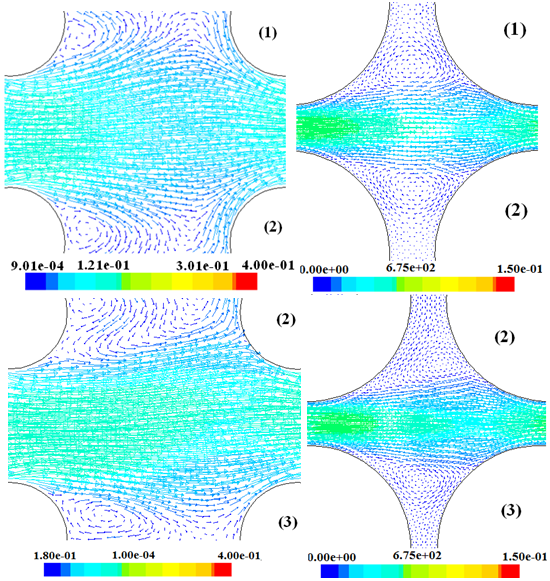

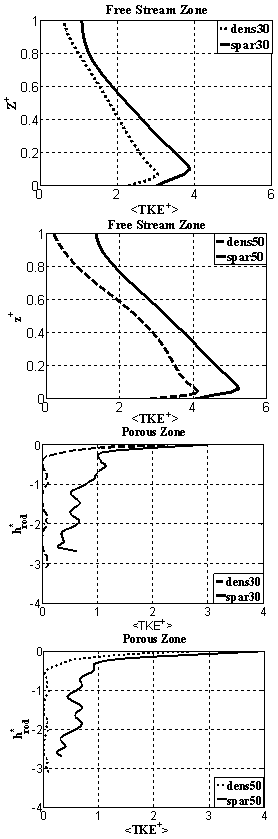

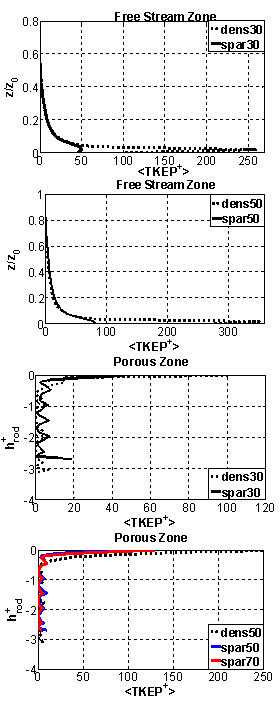

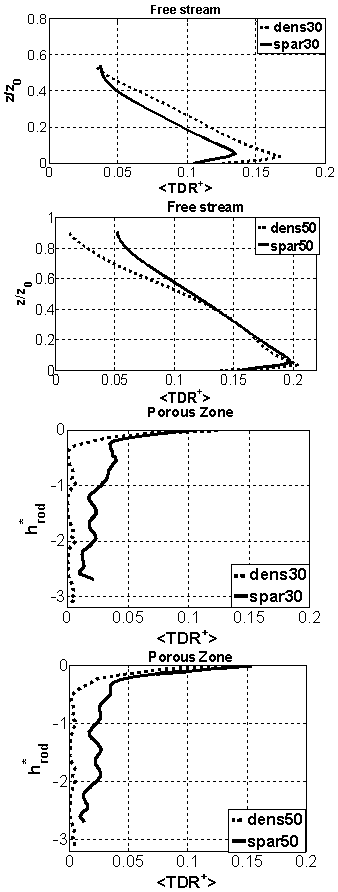

]; within the free stream (top), and within the porous zone (bottom) for both flow depths the sparse case has higher TKE in both free stream and porous zone compared with the dense case. Further, higher free stream thickness shows a higher TKE. Overall, the TKE profiles in the porous zone show a distinct difference between the sparse case, where turbulence penetrates vey deep into the bed and the dense case where does not go beyond the centre of the top rod.The turbulent energy production (TKEP) was normalized by dividing the spatially averaged TKEP with ρ.U*2 (Figure 15). From the figures it can be concluded that a larger TKEP rate in the dense case compared with the sparse. Further, the larger free stream thickness, have a larger TKEP.The turbulent dissipation rate (TDR) is the rate at which the turbulent energy is absorbed by breaking the eddies down into smaller until it is ultimately converted into heat by viscous forces. Figure 16 shows the normalized averaged turbulent dissipation rate over the free stream and the porous zone. From the figure, it can be concluded that TDR is lower when free stream thickness is higher, and the porosity effect is smaller than the effect of free stream thickness.

]; within the free stream (top), and within the porous zone (bottom) for both flow depths the sparse case has higher TKE in both free stream and porous zone compared with the dense case. Further, higher free stream thickness shows a higher TKE. Overall, the TKE profiles in the porous zone show a distinct difference between the sparse case, where turbulence penetrates vey deep into the bed and the dense case where does not go beyond the centre of the top rod.The turbulent energy production (TKEP) was normalized by dividing the spatially averaged TKEP with ρ.U*2 (Figure 15). From the figures it can be concluded that a larger TKEP rate in the dense case compared with the sparse. Further, the larger free stream thickness, have a larger TKEP.The turbulent dissipation rate (TDR) is the rate at which the turbulent energy is absorbed by breaking the eddies down into smaller until it is ultimately converted into heat by viscous forces. Figure 16 shows the normalized averaged turbulent dissipation rate over the free stream and the porous zone. From the figure, it can be concluded that TDR is lower when free stream thickness is higher, and the porosity effect is smaller than the effect of free stream thickness.  | Figure 14. Normalized spatially averaged turbulent kinetic energy distribution with normalized bed height at both free stream zone (Top), and porous zone. Bed normalized coordinate is (z/hf) |

| Figure 15. Normalized turbulent kinetic energy production distribution at both free stream zone (top), and porous zone (bottom) for different studied cases |

| Figure 16. Porosity effect on the turbulent dissipation rate in both free stream (Top) and porous (Bottom) regions |

5. Conclusions

- A detailed analysis was made to some flow variables to increase our understanding of turbulent flow through and over permeable bed. These variables were the vertical and longitudinal velocities, turbulent kinetic energy, turbulent dissipation rate, and the energy consumed by flow. The study covers free stream, porous and interface zones. Further, the porosity effect and the free stream thickness were also included in the simulation. The following results were gained from the analysis.• Mean velocities show the expected boundary-layer profile in the free stream zone, and a much slower flow in the porous zone. A pipe-like velocity profile forms between each two successive rows of cylinders. As expected bed porosity has a major influence on the flow velocities within the porous layer. • TKE in the free stream region have the expected shape with a maximum value close to the wall and the minimum close to the free surface. Within the porous layer there is a clear difference between the sparse and the dense arrangement: in the former case TKE penetrates practically throughout the whole porous layer, whereas in the latter case it penetrates only until the half of the top layer of cylinders. • TKE production and dissipation rate show very similar features. Turbulent shear stress in the free stream shows the expected approximately linear profile. Within the porous layer, the sparse case has a linear shear stress profile alternating between positive and negative values, typical for a pipe flow, whereas for the dense case the shear stress within the porous layer is practically zero.

ACKNOWLEDGEMENTS

- The writer gratefully acknowledge Dr Dubravaka Pokrajac for her writing comments.

References

| [1] | Iehisa Nezu, H. Nakagawa, “Turbulence in open channel flows, International Association for Hydraulic Research”, 3rd ed., A. A . Balkema, Netherlands, 1993 . |

| [2] | Xingwei Chen, Yee-Meng Chiew, “Velocity distribution of turbulent open-channel flow with bed suction, Journal of Hydraulic Engineering, Feb. pp. 140-148, 2004. |

| [3] | Alstair Maclean, “Open channel velocity profiles over a zone of rapid infiltration”, Journal of Hydraulic Research, vol. 29, No. 1, pp. 15-27. 1991. |

| [4] | Vladimir Nikora, Derek Goring, Ian McEwan, George Griffiths, “Stability averaged open-channel flow over rough bed”, Journal of Hydraulic Engineering, Feb., pp. 123-133, 2001. |

| [5] | Heidi Nepf, Marco Ghisalberti, “Flow transport in channels with submerged vegetation, Acta Geophysica, vol. 56, No. 3, pp. 753-777, 2008. |

| [6] | Constantino Manes, Dubravaka . Pokrajac, and Ian McEwan (2007), “Double-averaged open-channel flows with small relative submergence”, Journal of Hydraulic Engineering, August, pp. 896-904. |

| [7] | Hossein Afzalimehr, and Vijay Singh, ”Influence of Modeling on The Estimation of Velocity And Shear Velocity in Cobble-Bed Channels”, Journal of Hydrologic Engineering, Oct., pp.1126-1135, 2009. |

| [8] | Dimitris Sofialidis, Panayotis Prinos, “Numerical study of momentum exchange in compound open channel flow”, Journal of Hydraulic Engineering, Feb, pp. 152-165, 1999. |

| [9] | Brian White, Heidi Nepf, “Shear instability and coherent structures in shallow flow adjacent to a porous layer”, Journal of Fluid Mechanics, vol. 593, pp. 1-32, 2007 . |

| [10] | Nancy Steinberger, Midhat Hondzo, “Diffusional mass transfer at sediment-water interface”, Journal of Environmental Engineering, Feb., pp. 192 – 200, 1999 |

| [11] | Suga, K., and S. Nishiguchi, “Computation of turbulent flows over porous/fluid interfaces”, Fluid Dynamics Research, vol. 31, pp. 1-15, 2009. |

| [12] | Marco Ghisalbrti, “Obstructed shear flows: Similarities across systems and scales”, Journal of Fluid Mechanics, vol. 641, pp. 51-61, 2009. |

| [13] | Heidi Nepf, Marco Ghisalberti, Brian White, and E. Murphy, “Retention and dispersion associated with submerged aquatic canopies”, Water Resource Research, vol. 43, W04422, pp.1-10; DOI:10.1029/2006WR005362, 2007. |

| [14] | Ahmad Sana, Abdul-Razzaq Ghumman, Hitoshi Tanaka, “Modelling of a rough-wall boundary layer using two-equation turbulence models”, Journal of Hydraulic Engineering, Jan., No.1, pp. 60-65, 2009. |

| [15] | Panayotis Prinos, “Bed suction effect on structure of turbulent open channel flow”, Journal of Hydraulic Engineering, May, PP. 404-412, 1995. |

| [16] | H.C. Chan, M. Leu, C. Lai, M., and Yafi Jia, “Turbulent flow over a channel with fluid – saturated porous bed”, Journal of Hydraulic Engineering, June, pp. 610 – 617, 2007. |

| [17] | Hink Versteeg, Weeratunge Malasekera, “An introduction to computational fluid dynamics, the finite volume method”, 1st ed., Pearson Education Limited, UK, 1995. |

| [18] | Panayotis Prinos, Dimitrios Sofialdis, and Evangelos. Keramaris, “Turbulent flow over and within a porous bed”, Journal of Hydraulic Engineering, Sep., pp. 720 – 733, 2003. |

| [19] | ANSYS FLUENT, (2009), Documentation, Fluent user’s guide. |

| [20] | Dubravka Pokrajac, Constantino Manes, and Ian McEwan, “ Peculiar mean velocity profile within a porous bed of open channel”, Physics of Fluids, vol. 19, no.9, -098109-1-5, 2007 |

| [21] | Marco Ghisalberti, and Heidi Nepf, “Shallow flows over a permeable medium: The hydrodynamics of submerged aquatic canopies”, Transport Porous Med., 78 pp. 309 - 326. DOI 10.1007/s11242-00809305-x, 2009. |

| [22] | Heidi Nepf, Enrique Vivoni, “Flow structure in depth-limited vegetated flow”, Journal of Geophysical Research, vol. 105, pp. 547-557, 2000. |

| [23] | Brian White, Hiedi Nepf, “Shear instability and coherent structures in shallow flow adjacent to a porous layer”, Journal of Fluid Mechanics, vol. 593, pp. 1-32, 2007. |

| [24] | Dimitris Souliotis, Panayotis Prinos, “Macroscopic turbulence models and their application in turbulent vegetated flows”, Journal of Hydraulic Engineering, March, pp. 315-332, 2011. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML