-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Fluid Dynamics

p-ISSN: 2168-4707 e-ISSN: 2168-4715

2012; 2(5): 71-77

doi: 10.5923/j.ajfd.20120205.01

Comparative Study of Indion-860 and Indion GS-400 Anion Exchange Resins by Application of 131I and 82 Br as a Tracer Isotopes

Pravin U. Singare

Department of Chemistry, Bhavan’s College, Munshi Nagar, Andheri (West) , 400 058, Mumbai

Correspondence to: Pravin U. Singare , Department of Chemistry, Bhavan’s College, Munshi Nagar, Andheri (West) , 400 058, Mumbai.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The present investigation deals with the application of radioactive tracer isotopes 131I and 82Br for the performance assessment of two widely used industrial grade ion exchange resins Indion-860 and Indion GS-400. The study reveals that for both the resins, iodide ion-isotopic exchange reaction take place at the faster rate as compared to bromide exchange reaction. Also for both the resins the amount of ions exchanged increases with increase in ionic concentration and decreases with rise in temperature. The above resins were characterized based on kinetics of ion-isotopic exchange reactions. It was observed that the values of specific reaction rate, initial rate of exchange and distribution coefficient values calculated for Indion GS-400 was higher than that calculated for Indion-860 under identical experimental conditions, indicating the superior performance of Indion GS-400 over Indion-860.

Keywords: Tracer Application, Radioactive Isotopes, Ion-isotopic Exchange Reactions, Reaction Kinetics, Specific Reaction Rate, Distribution Coefficient, Indion GS-400, Indion-860

Cite this paper: Pravin U. Singare , "Comparative Study of Indion-860 and Indion GS-400 Anion Exchange Resins by Application of 131I and 82 Br as a Tracer Isotopes", American Journal of Fluid Dynamics, Vol. 2 No. 5, 2012, pp. 71-77. doi: 10.5923/j.ajfd.20120205.01.

Article Outline

1. Introduction

- Radioactive tracers were first applied to industrial problem solving around the middle of the last century. Since then their use has increased steadily so that, at present, radiotracer techniques are used extensively throughout the world for troubleshooting and process optimization in industry. The economic benefits that may be derived from the use of this technology are great, a fact that is recognized by the governments of developing countries. Though radioisotopes have been applied to the solution of problems in industry for over 50 years, research and development of the technology continues unabated. There are two main reasons for the continuing interest. Firstly, it is industry driven. Because of their unique properties, radioactive isotopes can be used to obtain information about plants and processes that cannot be obtained in any other way. Often, the information is obtained with the plant on-stream and without disrupting the process in any way. This can lead to substantial economic benefits, from shutdown avoidance to process optimization. Secondly, the methodology is derived from many fields of science and technology including radioisotope production, radiation detection, data acquisition, treatment and analysis, and mathematical modeling. The radioisotopes have proved as a tool to study many problems in chemical, biological and medicinal fields. Radiotracers have helped in identification of leaks in buried pipelines and dams. Process parameters such as mixing efficiency, residence time, flow rate, material inventory and silt movement in harbours are studied using radioisotopes[1]. The efficiency of several devices in a wastewater treatment plant (primary and secondary clarifiers, aeration tank) is also investigated by means of radiotracers[2].The fundamental principle in radiochemical investigations is that the chemical properties of a radioisotope of an element are almost the same as those of the other stable/radioactive isotopes of the element. When radioisotope is present in a chemical form identical to that of the bulk of the element in a chemical process, then any reaction the element undergoes can be directly traced by monitoring the radioisotope. Radiochemical work involves two main steps first is the sampling of chemical species to be studied and second is quantitative determination of the radiation emitted by the radioisotope in the sample[1]. In radiotracer study, a short lived radioisotope in a physico-chemical form similar to that of the process material is used to trace the material under study. The radioisotopes in suitable physical and chemical forms are introduced in systems under study. By monitoring the radioactivity both continuously or after sampling (depending on the nature of study), the movement, adsorption, retention etc. of the tracer and in turn, of the bulk matter under investigation, can be followed. The tracer concentration recorded at various locations also helps to draw information about the dynamic behavior of the system under study. The radioisotopes preferred for such studies are gamma emitters having half-life compatible with the duration of studies. The strength of radioactivity used varies depending on the nature of application. Applications of radiotracers in chemical research cover the studies of reaction mechanism, kinetics, exchange processes and analytical applications such as radiometric titrations, solubility product estimation, isotope dilution analysis and autoradiography.Considering the above wide use of radioactive isotopes in various industrial and technical applications, in the present investigation, they are applied to assess the performance of industrial grade anion exchange resins Indion-860 and Indion GS-400 under different operational parameters like temperature and ionic concentrations. It is expected that the tracer technique used here can also be used for characterization of other organic ion exchange resins which are synthesized for their specific technical applications[3-7]. The present technique can also be extended further to standardize the operational parameters so as to bring about the most efficient performance of those resins in their specific industrial applications.

2. Experimental

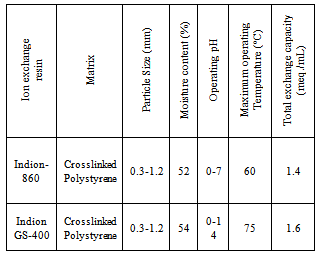

2.1. Conditioning of Ion Exchange Resins

|

2.2. Radioactive Tracer Isotopes

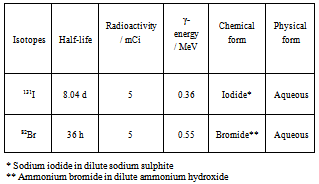

- The radioisotope 131I and 82Br used in the present experimental work was obtained from Board of Radiation and Isotope Technology (BRIT), Mumbai. Details regarding the isotopes used in the present experimental work are given in Table 2.

|

2.3. Study on Kinetics of Iodide Ion-isotopic Exchange Reaction

- In a stoppered bottle 250 mL (V) of 0.001 M iodide ion solution was labeled with diluted 131I radioactive solution using a micro syringe, such that 1.0 mL of labeled solution has a radioactivity of around 15,000 cpm (counts per minute) when measured with γ -ray spectrometer having NaI (Tl) scintillation detector. Since only about 50–100 μL of the radioactive iodide ion solution was required for labeling the solution, its concentration will remain unchanged, which was further confirmed by potentiometer titration against AgNO3 solution. The above labeled solution of known initial activity (Ai) was kept in a thermostat adjusted to 30.0℃. The swelled and conditioned dry ion exchange resins in iodide form weighing exactly 1.000 g (m) were transferred quickly into this labeled solution which was vigorously stirred by using mechanical stirrer and the activity in cpm of 1.0 mL of solution was measured. The solution was transferred back to the same bottle containing labeled solution after measuring activity. The iodide ion-isotopic exchange reaction can be represented as:

| (1) |

2.4. Study on Kinetics of Bromide Ion-isotopic Exchange Reaction

- The experiment was also performed to study the kinetics of bromide ion- isotopic exchange reaction by equilibrating 1.000 g of ion exchange resin in bromide form with labeled bromide ion solution in the same concentration and temperature range as above. The labeling of bromide ion solution was done by using 82Br as a radioactive tracer isotope for which the same procedure as explained above was followed. The bromide ion-isotopic exchange reaction can be represented as:

| (2) |

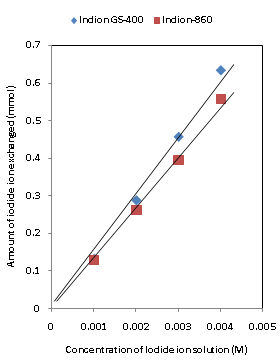

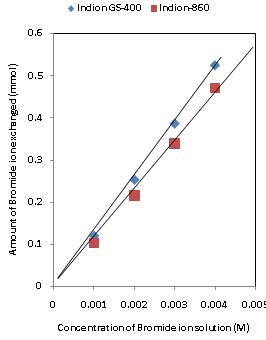

| Figure 2. Variation in Percentage Ions Exchanged with Concentration of Labeled Ionic Solution Amount of ion exchange resin = 1.000 g, Volume of labeled ionic solution = 250 mL, Temperature = 30.0℃ |

|

3. Results and Discussion

3.1. Comparative Study of Ion-isotopic Exchange Reactions

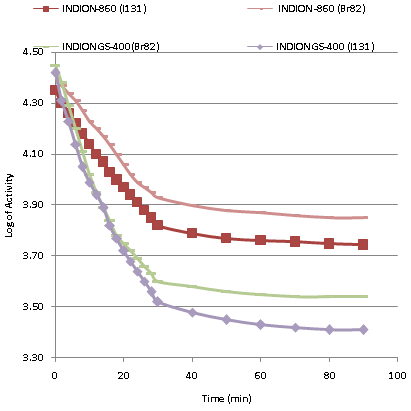

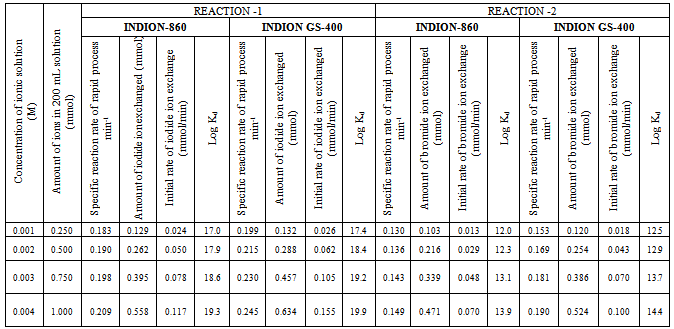

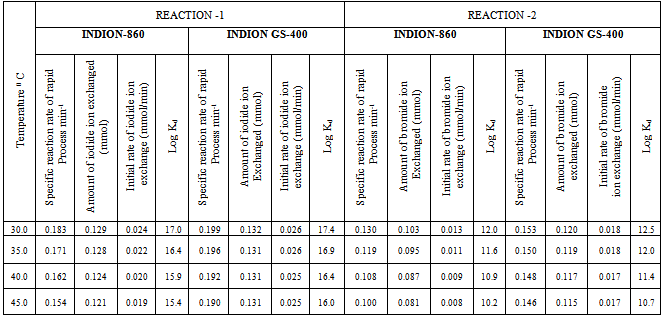

- In the present investigation it was observed that due to the rapid ion-isotopic exchange reaction taking place, the activity of solution decreases rapidly initially, then due to the slow exchange the activity of the solution decreases slowly and finally remains nearly constant. Preliminary studies show that the above exchange reactions are of first order [15, 16]. Therefore logarithm of activity when plotted against time gives a composite curve in which the activity initially decreases sharply and thereafter very slowly giving nearly straight line (Figure 1), evidently rapid and slow ion-isotopic exchange reactions were occurring simultaneously[9-14]. Now the straight line was extrapolated back to zero time. The extrapolated portion represents the contribution of slow process to the total activity which now includes rapid process also. The activity due to slow process was subtracted from the total activity at various time intervals. The difference gives the activity due to rapid process only. From the activity exchanged due to rapid process at various time intervals, the specific reaction rates (k) of rapid ion-isotopic exchange reaction were calculated. The amount of iodide / bromide ions exchanged (mmol) on the resin were obtained from the initial and final activity of solution and the amount of exchangeable ions in 250 mL of solution. From the amount of ions exchanged on the resin (mmol) and the specific reaction rates (min-1), the initial rate of ion exchanged (mmol/min) was calculated.Because of larger solvated size of bromide ions (310 pm) as compared to that of iodide ions (300 pm), it was observed that the exchange of bromide ions occurs at the slower rate than that of iodide ions[17]. Hence under identical experimental conditions, the values of specific reaction rate (min-1), amount of ion exchanged (mmol) and initial rate of ion exchange (mmol/min) are calculated to be lower for bromide ion-isotopic exchange reaction than that for iodide ion-isotopic exchange reaction as summarized in Tables 3 and 4. For both bromide and iodide ion-isotopic exchange reactions, under identical experimental conditions, the values of specific reaction rate increases with increase in concentration of ionic solution from 0.001M to 0.004M (Table 3). However, with rise in temperature from 30.0℃ to 45.0℃, the specific reaction rate was observed to decrease (Table 4). From the results, it appears that iodide ions exchange at the faster rate as compared to that of bromide ions which was related to the extent of solvation (Tables 3 and 4).From the knowledge of Ai, Af, volume of the exchangeable ionic solution (V) and mass of ion exchange resin (m), the Kd value was calculated by the equation

| (3) |

3.2. Comparative Study of Anion Exchange Resins

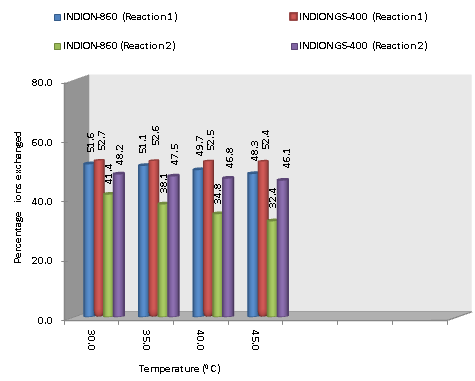

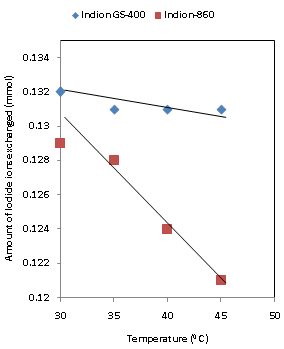

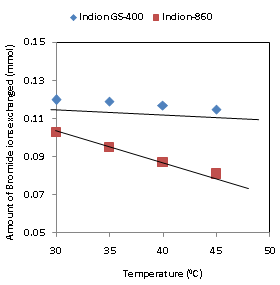

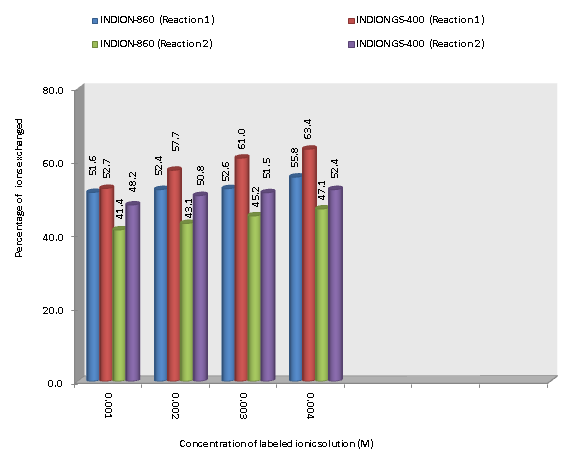

- From the Table 3, it is observed that for iodide ion-isotopic exchange reaction by using Indion GS-400 resin, the values of specific reaction rate (min-1), amount of iodide ion exchanged (mmol), initial rate of iodide ion exchange (mmol/min) and log Kd were 0.199, 0.132, 0.026 and 17.4 respectively, which was higher than 0.183, 0.129, 0.024 and 17.0 respectively as that obtained by using Indion-860 resins under identical experimental conditions of 30.0℃, 1.000 g of ion exchange resins and 0.001 M labeled iodide ion solution. The identical trend was observed for the two resins during bromide ion-isotopic exchange reaction.From Table 3, it is observed that using Indion GS-400 resins, at a constant temperature of 30.0℃, as the concentration of labeled iodide ion solution increases 0.001 M to 0.004 M, the percentage of iodide ions exchanged increases from 52.7 % to 63.4 %. While using Indion-860 resins under identical experimental conditions the percentage of iodide ions exchanged increases from 51.6 % to 55.8 %. Similarly in case of bromide ion-isotopic exchange reaction, the percentage of bromide ions exchanged increases from 48.2 % to 52.4 % using Indion GS-400 resin, while for Indion-860 resin it increases from 41.4 % to 47.1 %. The effect of ionic concentration on percentage of ions exchanged is graphically represented in Figure 2.From Table 4, it is observed that using Indion GS-400 resins, for 0.001 M labeled iodide ion solution, as the temperature increases 30.0℃to 45.0℃, the percentage of iodide ions exchanged decreases from 52.7 % to 52.4 %. While using Indion-860 resins under identical experimental conditions the percentage of iodide ions exchanged decreases from 51.6 % to 48.3 %. Similarly in case of bromide ion-isotopic exchange reaction, the percentage of bromide ions exchanged decreases from 48.2 % to 46.1% using Indion GS-400 resin, while for Indion-860 resin it decreases from 41.4 % to 32.4 %. The effect of temperature on percentage of ions exchanged is graphically represented in Figure 3.The overall results indicate that under identical experimental conditions, as compared to Indion-860 resins, Indion GS-400 resins shows higher percentage of ions exchanged. Thus Indion GS-400 resins show superior performance than Indion-860 resins.

3.3. Statistical Correlations

- The results of present investigation show a strong positive linear co-relationship between amount of ions exchanged and concentration of ionic solution (Figures 4, 5). In case of iodide ion-isotopic exchange using Indion GS-400 and Indion-860 resins, the values of correlation coefficient (r) were found to be 0.9996 and 0.9987 respectively, while for bromide ion-isotopic exchange the respective values of r were calculated as 1.0000 and 0.9994.There also exist a negative co-relationship between amount of ions exchanged and temperature of exchanging medium (Figures 6, 7). For Indion GS-400 during iodide isotopic exchange reaction somewhat poor correlationship was observed having value of (r) -0.7746, however for Indion-860 resins, excellent correlationship exist having (r) value of -0.9778. Similarly in case of bromide ion-isotopic exchange the (r) values calculated for Indion GS-400 and Indion-860 were -0.9898 and -0.9978 respectively.

4. Conclusions

- The experimental work carried out in the present investigation will help to standardize the operational process parameters so as to improve the performance of selected ion exchange resins. The radioactive tracer technique used here can also be applied for characterization of different nuclear as well as non-nuclear grade ion exchange resins.

ACKNOWLEDGEMENTS

- The author is thankful to Professor Dr. R.S. Lokhande for his valuable help and support in carrying out theexperimental work in Radiochemistry Laboratory of Department of Chemistry, University of Mumbai, Vidyanagari, Mumbai -58.The authors are extremely thankful to SAP Productions for developing and maintaining the manuscript template.

References

| [1] | Sood, D.D., Reddy, A.V.R., and Ramamoorthy, N., 2004, Applications of Radioisotopes In Physico-Chemical Investigations, in Fundamentals of Radiochemistry, Indian Association of Nuclear Chemists and Allied Scientists (IANCAS), 253-263. |

| [2] | Radiotracer Applications in Industry- A Guidebook, 2004, Safety Reports Series No. 423, International Atomic Energy Agency (IAEA) Vienna. |

| [3] | Zhu, L., Liu, Y., and Chen, J., 2009, Synthesis of N-Methylimidazolium Functionalized Strongly Basic Anion Exchange Resins for Adsorption of Cr(VI)., Ind. Eng. Chem. Res., 48(7), 3261–3267. |

| [4] | Korshak, V.V., Rogozhin, S.V., Davankov, V.A., and Vyrbanov, S.G., 1966, Synthesis of optically active ion exchange resins., Russian Chemical Bulletin, 15(3), 510-512. |

| [5] | Yergozhin, Ye.Ye., Abdrakhmanova, I.K., and Menligaziyev, Ye.Zh., 1981, Synthesis and investigation of the properties of organosilicon anion-exchange resins., Polymer Science U.S.S.R., 23(11), 2671-2678. |

| [6] | Sugii, A., Ogawa,N., Nozaki, Y., and Haratake, M., 1988, Preparation of macroreticular anion-exchange resins having spacers and an evaluation of these resins in the synthesis of sulfones., Reactive Polymers, Ion Exchangers, Sorbents, 8(1), 3-6. |

| [7] | Zaidi, S.A.R., and Shah, G.B., 2000, Synthesis of strongly basic anion exchange resins based on glycidyl methacrylate-ethylene glycol dimethacrylate copolymer. Effect of amount and nature of diluent, and the degree of crosslinkage on the resins properties., Macromolecular chemistry and physics, 201(18), 2760-2764. |

| [8] | Sood, D.D., 1998, Proc. Int. Conf. on Applications of Radioisotopes and Radiation in Industrial Development, ed. Sood, D.D., Reddy, A.V.R., Iyer, S.R.K., Gangadharan, S., and Singh, G., (B.A.R.C., India) 35–53. |

| [9] | Lokhande, R.S., Singare, P.U., and Kolte, A.R., 2010, Application of Radioactive Tracer Technique for Characterization of Strongly Basic Anion Exchange Resins Duolite A 101D and Duolite A 102D., Radiochemistry, 52(1), 81–86. |

| [10] | Singare,P.U., and Lokhande, R.S., 2009, Behaviour of Radioactive Iodide and Bromide ions from Aqueous Solution on Ion Exchange Resins Amberlite IRA-400., Natural Science, 1(1),191-194. |

| [11] | Lokhande, R.S., Singare, P.U., and Parab, S.A., 2008, Application of Radioactive Tracer Technique to Study the Kinetics of Iodide Ion- Isotopic Exchange Reaction using Strongly Basic Anion Exchange Resin Duolite A-116., Radiochemistry 50(6), 642-644. |

| [12] | Lokhande, R.S., Singare, P.U., and Patil, V.V., 2008, Application of Radioactive Tracer Technique to Study the Kinetics and Mechanism of Reversible Ion- Isotopic Exchange Reaction using Strongly Basic Anion Exchange Resin Indion -850., Radiochemistry, 50(6), 638-641. |

| [13] | Lokhande, R.S., Singare, P.U., and Dole, M.H., 2007, Application of Radiotracer Technique to Study the Ion Isotope Exchange Reactions Using a Strongly Basic Anion-Exchange Resin Duolite A-113., Radiochemistry, 49(5), 519-522. |

| [14] | Lokhande, R.S., Singare, P.U., and Karthikeyan, P., 2007, The Kinetics and Mechanism of Bromide Ion Isotope Exchange Reaction in Strongly Basic Anion-Exchange Resin Duolite A-162 Determined by the Radioactive Tracer Technique., Russ. J. Physical Chemistry A, 81(11), 1768–1773. |

| [15] | Lokhande, R.S., and Singare, P.U., 2003, Study of reversible ion-isotopic self diffusion reaction using 82 Br as a radioactive tracer isotope., Asian J. Chem., 15(1), 33-37. |

| [16] | Lokhande, R.S., and Singare, P.U., 2005, Study on kinetics of self diffusion reaction by application of 82 Br as a radioactive tracer isotope., Asian J. Chem., 17(1), 125-128. |

| [17] | Shannon, R.D., 1976, Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides., Acta Crystallographica, A32, 751-767. |

| [18] | Heumann, K.G., and Baier, K., 1982, Chloride distribution coefficient on strongly basic anion-exchange resin: Dependence on co-ion in alkali fluoride solutions., Chromatographia, 15(11), 701-703. |

| [19] | Adachi, S., Mizuno, T., and Matsuno, R., 1995, Concentration dependence of the distribution coefficient of maltooligosaccharides on a cation-exchange resin., J. Chromatography A, 708(2), 177-183. |

| [20] | Shuji, A., Takcshi, M., and Ryuichi, M., 1996, Temperature dependence of the distribution coefficient of maltooligosaccharides on cation-exchange resin in Na+ form., Bioscience, Biotechnology, and Biochemistry, 60(2), 338-340. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML