-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Environmental Engineering

p-ISSN: 2166-4633 e-ISSN: 2166-465X

2019; 9(2): 31-35

doi:10.5923/j.ajee.20190902.02

Eco-friendly Manufacturing Process of Casein Fiber with It’s Sustainable Features & Comfortable Uses

Nishat Tasnim

M.Sc (On Going) in Yarn Engineering, (BUTEX), B.Sc in Textile Engineering (KUET), Tejgaon, Dhaka, Bangladesh

Correspondence to: Nishat Tasnim, M.Sc (On Going) in Yarn Engineering, (BUTEX), B.Sc in Textile Engineering (KUET), Tejgaon, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In this modern era with the improvement in technology, people can realize that they can only survive, if ournature survives. So scientists are trying their best to cooperate with our mother like environment by reducing the amount of waste product. Again people are very conscious about different diseases even if while dressing themselves up. From all these thoughts he casein or milk fiber is discovered which may help both the human being & the nature. From the huge amount of discarded milk, a special type of fabric can be produced which is silky, smooth, very desirable for high fashion, appealing to high end consumers who are not only interested in ecology but also the economic & social responsibility supporting the fashionable collections. This article is all about the manufacturing process of casein fiber, it’s special features & comfortable uses. Again there are some techniques of producing casein fiber which are beyond any kind of harm to the environment. With the interest in & the use of this textile fiber growing, supply is challenged to meet the demand. So this article is very well suited with the modernization of the textile sector. It is an overview of the casein fiber & garments which also includes it’s drawbacks & the points which require further improvement. This article will help the researchers to reach the casein fiebr at a very remarkable stage of use as textile garments.

Keywords: Sustainability, Eco friendly, Qmilk, Drawbacks etc.

Cite this paper: Nishat Tasnim, Eco-friendly Manufacturing Process of Casein Fiber with It’s Sustainable Features & Comfortable Uses, American Journal of Environmental Engineering, Vol. 9 No. 2, 2019, pp. 31-35. doi: 10.5923/j.ajee.20190902.02.

Article Outline

1. Introduction

- Textile is the major part of the basic human needs. Environmental impacts occur at every stage of the life cycle of a product. Natural fibers are at the stage of heart of an eco-fashion movement that seeks to create garments that are sustainable at every stage of their life cycle, from production to disposal. But all natural fibers are not eco-friendly fibers. Again man made fibers can also be eco-friendly fibers. In the present era of environmental consciousness more and more materials are emerging worldwide, efficient utilization of plant species and utilizing the smaller particles and fibers obtained from various eco-friendly materials. Either a sustainable produced textile or one which is created by reuse of a waste product is preferred. One possibility to create fibers from waste is using waste milk for casein fiber production. Apparently it takes about 100 pounds of skim milk to make 3 pounds of milk fiber. This fiber contains 18 types of amino acids extracts that helps in the nourishments of the skin and makes it healthier. Casein is obtained by the acid treatment of skimmed milk. Milk protein fiber is a blend of nature science & technology that has benefits of natural as well as synthetic fiber. Milk fiber was invented in 1930s in both Italy and America to compete the wool and was called milk casein. A new generation of innovative fiber and a kind of synthetic fiber made of milk casein through bioengineering method with biological health care function and natural and long lasting antibacterial effects, which has got valid certification for international ecological textile certification, Oeko-tex standard-100. Authentication approved it in April, 2004. There are also some different brands for the same fiber manufactured from milk casein known as Aralac, Lanatil and Merinova. Firstly casein fibers are produced with formaldehyde, the process needed a lot of water and the production could not be made profitable, a problem which is not yet solved. Over the last years new methods were found to produce these fibers in a more eco-friendly manner and a new process without using formaldehyde is developed.

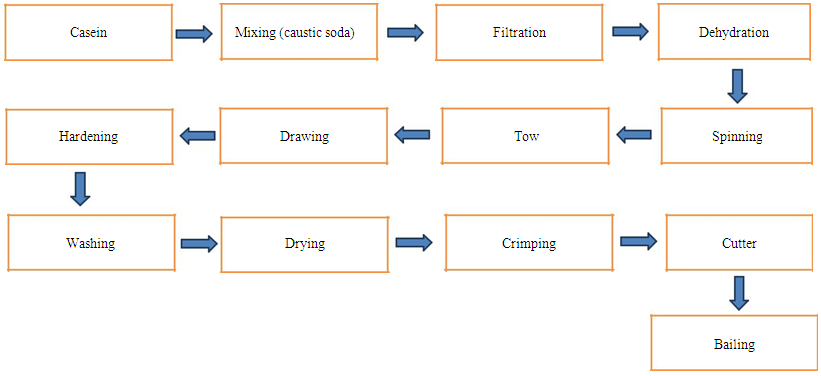

2. Materials & Methods of Casein Fiber Manufacturing

- The conversion of the casein of skim milk into textile fiber is not a process that can be carried out on the farm. The casein must be made by a controlled procedure possible only in a dairy plant or a plant making casein exclusively. The conversion of casein into fiber requires the knowledge and experience of textile engineers and equipment similar to that of plants producing viscose rayon.Sour milk is taken as a raw material that is otherwise wasted and unmarketable. Then it is processed naturally until it becomes the most basic protein in the milk- a protein called casein.The casein is dissolved in water that contains about 2% by weight of alkali to make a viscous solution with 20 to 25% protein. The solution is allowed to ripen until it reaches a suitable viscosity and is then filtered and dehydrated.The spinning solution is wet spun by extrusion through spinnerets into a coagulating bath containing sulphuric acid (2 parts), formaldehyde (5 parts), glucose (20 parts) and water (100 parts). The jets of solution coagulate into filaments in a manner similar to the coagulation of viscose filaments.The next process is very critical as the fiber has to be treated chemically to harden it. The process is commonly described as hardening, in that it minimized the softening effects of water. Treatment with formaldehyde forms the basis of many hardening techniques.In the plant scale bunches of filaments are collected together into a tow as they leave the coagulating bath and are then steeped in formaldehyde solution.The filaments are subjected to drawing at this stage. After treatment, the tow is washed and dried, crimped mechanically and then cut into staple fiber. Otherwise tow to top convertor makes tops for blending with wool.

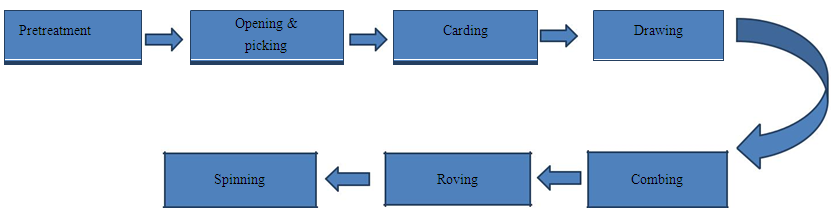

3. Fiber to Fabric Formation

- Pre-treatment: The mass specific resistance of milk protein fiber is larger, so the pre-treatment before scutching is more important.Opening and picking: Opening is very important in order to loosen the fibers and cleaning is done to remove the trashes present in the fibers. Raw fibers with compressed mass must be removed from bales. With good uniformity and less impurity, the milk protein fiber is bulky and it is easy to open.Carding: The objective of the process is to further open and clean the remaining impurities in the fibers delivered from the opening and picking line. It must be detangled and straightened.Combing: the main object of this process are the reduction in short fiber content, removal of trash and neps. Production of more straight, parallel and uniform sliver.

| Figure 1. Flowchart of Milk Casein Fiber Production |

| Figure 2. Process flowchart of producing fabric from casein fiber |

4. Wet Processing

- Desizing: Enzyme products may be used, preferably at pH 4.0 to 6.0, if water soluble sizes have been used, desizing is not necessary.Scouring: Synthetic detergents should be used preferably under acidic condition.Bleaching: Casein fiber is generally white and bleaching is not usually necessary. If required a mild perborate or peroxide bleach should be used under controlled condition. Casein fibers retain maximum strength and minimum swelling under weakly acidic condition. If alkaline processing is used, it must be followed by careful washing and acidification with acetic acid.Dyeing: in general, casein can be dyed with dyestuffs used for wool. Acid, basic, direct and disperse dyes are used where good washing fastness is not a prime essential.Drying: After dyeing, loose stocks and yarns may be centrifugally hydro-extracted before being dried in conventional plant.Printing: Casein blend fabrics can be printed very effectively. Fabrics containing casein may be printed by block, roller, surface roller and modified paper printer methods.

5. Finishing

- Singeing: If singeing is needed, a light treatment with a slow burner will be sufficient.Crease Resistant Finish: The crease resistant finishing agents have more choices and the environmental finishing with good crease resist effect should be selected.Softening: During dyeing and after crease resistant treatment fiber feels hard in high temperature and tension, in order to make fabric full and soft, softening is needed and softening with a suitable softening agent is an effective method.Carbonising: Casein will withstand carbonising treatment when carried out with the minimum strength of sulphuric acid necessary for the effective removal of vegetable matter. Then the material should be well rinsed and adjusted to pH 4 with sodium carbonate.

6. Eco-friendly Technique for Producing Casein Fiber

- The process used to produce milk fiber is not environmentally friendly because it uses too many chemicals including some carcinogenic chemical like formaldehyde. So the new type of milk fiber is invented which uses a 100% natural and renewable resources, which is called Qmilk. Here only two litres of water and 80 deg calcius temperature is only needed. It is made of 100% organic polymer without plasticizers, solvents and chemical cross-linkers, it is home compostable and break down free of residues within a few months on the environment. The manufacture of this organic fabris, which involves heating powdered casein and adding ingredients like zinc and beeswax, is environmentally friendly. The casein is extracted from dried milk powder and then heated up in a type of meat-mincing machine with other natural ingredients. The fibers come out in strands and is then spun into yarn on a spinning machine. Qmilk fills a gap in the market that might unwittingly turn a blind eye to sustainable option.This process is considered as an eco-friendly process of producing casein fiber because there is no use of formaldehyde in the processing of casein fiber. It ensures a particular level of cost efficiency and ensures a minimum of CO2 emissions.

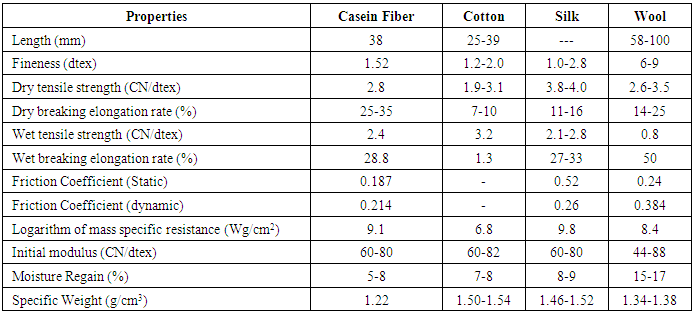

7. Physical Properties Comparison

8. Chemical Properties

- Effects of Acids: Casein is stable to aids of moderate strength under normal conditions.Effects of Alkalis: Casein is sensitive to alkali.Effects of Organic Solvants: Dry cleaning solvents do not cause dmage.Insects: Casein fiber is not attacked by moth grubs to the same degree as wool.Micro-Organisms: Casein fibers are attavked by mildews, particularly when moist.Electrical Properties: Dielctric strength of casein fibers is low.

9. Special Characteristics

- Hydrating: It’s the only existing fiber to hydrate and nourish the wearer’s skin, thanks to the milk amino acid present in the fiber itself.Antibacterial activity: It’s naturally antibacterial. In particular, it has antibacterial effects against Escherichia coli and staphylococcus aureus. The fiber, in fact, does not allow multiplication of bacteria inside, leaving a feeling of freshness for the duration of the wear.Absorbs moisture: It easily absorbs moisture and it’s therefore particularly suitable for making underwear, sportswear home textiles, but also technical fabrics.Natural protection against UV radiations: Tests carried out by manufacturer have shown that milk fiber is a natural screen against UV radiations.Dermatologically Tested: It’s dermatologically tested for compatibility with the skin and body. For its construction are used only natural and renewable raw materials and it’s therefore free of optical brighteners components that can create an environmental risk.Compostable: It’s completely biodegradable, providing a positive contribution to the environment not only during the production cycle but also throughout the entire life cycle.

10. Sustainability of Casein Fiber

- The dairy industry is looking for ways to address the problem of sustainability by diversifying their business model. Milk waste offers unique opportunities to develop a local textile and apparel industry. Casein fiber textile products made from milk waste offer new business opportunities for the dairy industry to compete in green markets. By using waste, overall negative environmental impact producing both fabric and milk is reduced.Moreover the garments produced from casein fibers, are biodegradable. So there is no chance of affecting the environment in a badly manner. If the use of formaldehyde in the manufacturing process can be restricted, the casein fabric garments are one of the best product for ou skin purpose.As the people in today’s world are very much conscious about carcinogenic garment items, they are quite interested in using casein fabric & garments. So by inventing some cheap process of manufacturing casein fiber can reduce the price of the garments made from casein fiber & also can enhance the use of those items in a rapid way.

11. Comfortable Uses as Apparel

- • Children’s garments• Intimate garments• T-shirts• Sweaters• Women’s garments• Sports wear• Eye mask• Socks & hats• Home textiles• Automobile industry• Medical technology• Thermal insulated seat covers• Hygenic diaphragms

12. Drawbacks of Casein Fiber/ Fabric

- • The main drawback is the higher expense of producing casein fiber.• It is not hard and it has low durability.• It gets wrinkles very easily after washing and needs to be ironed every time.• The use of formaldehyde to make the fiber stiff, as the formaldehyde is carcinogenic.• The coagulation bath is contagious for our environment if it is not be handled in a safe way.

13. Conclusions

- Being the optimal combination of nature and hi-tech, milk fiber is more accommodated to the need of people’s modern lifestyle. So far clothing made from milk is expensive so it has a limited market. However a handful of companies are experimenting with the fabric. Milk fabrics are so skin friendly that it itself makes us feel better. To educate designers about these revolutionary materials, the future fashion initiative offers a textiles research team. Advances in science are also helping to fill the green wardrobe of tomorrow. Sweaters are knit from spun milk protein. These textiles are where the future innovations are going to lie. It’s taking fashion to a whole new level where it never really existed before, where it’s not just about looking good. It’s about feeling good, too. The milk protein fiber is a fresh product as a superior green, healthy and comfortable fiber, which will certainly become popular goods in the market.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML