-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Environmental Engineering

p-ISSN: 2166-4633 e-ISSN: 2166-465X

2015; 5(4): 79-89

doi:10.5923/j.ajee.20150504.01

Production of Biogas from Perennial and Biennial Crop Wastes: Peach Palm and Banana’s Wastes as Alternative Biomass in Energy Generation and Environmental Susteinability

Patrick Ozovehe Samuel

Department of Biological Sciences, Federal University of Technology, Minna, Nigeria

Correspondence to: Patrick Ozovehe Samuel, Department of Biological Sciences, Federal University of Technology, Minna, Nigeria.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

There is growing global concern about the future of non-renewable biomass in form of fossil fuel and its attendant consequences on the environment as evident in global warming. There is also, ever growing demand for energy and the need for environmental susteinability. Renewable energy sources from agricultural wastes especially those from biennial and perennial crop can be employed in the generation of biogas that will not only be environmentally friendly but also capable of solving the challenges of competition of biofuel with food crops. This review focuses on the possibility of using biomass from banana and peach palm’s wastes for biogas production with twin advantages of clean energy and environment. Biomethantion is one of the major processes of conversion of wastes to biogas in digesters via anaerobic digestion in the presence of micro-organisms in optimal environmental conditions in terms of temperature and pH. It is well known that fossil fuel is finite no matter the deposits or reserves the world can boast of today. Biomass on the other hand, is abundant, renewable and available world-wide. If this energy source is tapped into effectively with concerted efforts from all and sundry, the economies of the developing world in particular and the whole world in general will be better for it.

Keywords: Biogas, Biomethanation, Biomass, Banana’s wastes, Peach Palm’s wastes, Anaerobic Digestion, Environmental Susteinability

Cite this paper: Patrick Ozovehe Samuel, Production of Biogas from Perennial and Biennial Crop Wastes: Peach Palm and Banana’s Wastes as Alternative Biomass in Energy Generation and Environmental Susteinability, American Journal of Environmental Engineering, Vol. 5 No. 4, 2015, pp. 79-89. doi: 10.5923/j.ajee.20150504.01.

Article Outline

1. Introduction

- The menace of environmental pollution and the urgent need for alternate energy free of its attendant green-house gases and effects due to anthropogenic influences on the natural ecosystems are on the increase globally. As human population increases globally so is a consequent increase in generation of pollutants and wastes that calls for desirable measures that will not only mitigate the effects of the wastes but also provide alternatives that will put such wastes in check and convert where possible, to veritable energy sources for the benefit of human race. New technologies are being developed globally on daily basis in turning the huge biomass of wastes to biogas, and these technologies involve multidisciplinary approaches. Biomass is a promising eco-friendly alternative source of renewable energy in the context of current energy scenarios. Current global energy supply is to a large extent based on fossil fuels (oil, natural gas, coal), of which the reserves are finite. Given the growing world population, the increasing energy consumption per capita and the evidence of global warming, the necessity for long-term alternative energy sources is obvious and inevitable. For instance, methane (CH4) gas is a greenhouse gas that remains in the atmosphere for considerable length of time [17]. It was also reported by Ayodele and Emmanuel [4] that methane gas is more effective in trapping heat than carbon dioxide (CO2). Methane was first recognized as having practical and commercial value in the 1890s in England, where a specially designed septic tank was used to generate the gas for the purpose of lighting streets. For these twin crises of fossil fuel depletion and environmental degradation, energy planning and technology improvement have become an important public agenda of most developed and developing countries. Because of this, the European Commission has decided that in 2020 20% of the energy used should be derived from renewable source [8]. Biomass is recognized as a renewable resource for energy production and is abundantly available around the world [36]. Biomass utilization in mainstream energy uses is receiving great attention due to environmental considerations and the increasing demands of energy worldwide [40]. Biomass can be converted to bio-fuel via different thermal, biological and physical processes. Development of renewable energy sources would seem sensible if it is linked with environmental sustainability criteria to ensure that they efficiently contribute to overall net public good. With virtually all of the biofuels currently produced in the United States sourced from either soybeans or corn, there is significant interest in developing a diverse array of biomass feed stocks that will not compete for food resources, hence the consideration of waste products of farms and other means. Biomass refers to the diverse materials obtained from plants and animals, which can be used as raw materials for the creation of useful energy in various forms and for diverse purposes [54]. Biomass includes a broad variety of raw materials such as wood, agricultural crops, byproducts of wood processing, agricultural and forestry industry products, manure and the organic fraction of waste streams. Variety of crops both wild and domestic such as switchgrass, big bluestem, wheat grass, sycamore, sweet gum, cottonwood, reed canary grass in Finland, willow grass and hemp in Sweeden, poplar in Spain and Italy, sorghum, barley, maize, wheat and Brassica crops, sugar beet, leys, maize, cereals, potato and hemp have been used as biomass for biogas production all over the world. Also, Patrick et al. [35] observed that the major biomass world-wide is Jatropha plant which is currently generating interest in every economy of the world. The utilization of food wastes has the potential to provide new revenue streams to crop producers and food processors while creating new sources of clean renewable energy and chemicals. Unused crops and food processing wastes represent additional sources of renewable biomass that do not directly compete with food production. Also, the use of wastes from banana and peach palm plantations amongst other biennial and perennial plants can serve as a lucrative and worthwhile venture in energy generation and production from wastes biomass. The current literature is inundated with biogas production from corn, soybean and other common annual crops which may raise some crucial debate on its competitiveness with food production for man and other animals. Shift to the use of biennial and perennial crops especially their wastes can ameliorate this. This review draws attention to the possibility of producing high quality biogas from banana and palm heart wastes biomass so as to advance the frontiers of knowledge in biogas technology bearing in mind its environmental sustainability. Energy (and other resources) recovery from these wastes therefore has the potential of greatly altering the situation - turning an environmental liability into a socioeconomic and poverty alleviation asset [53].

2. Biogas and Bio-methane

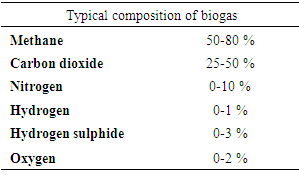

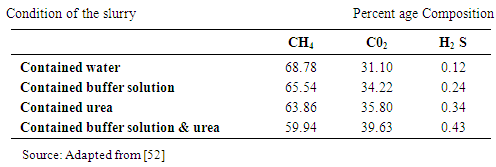

- Biogas is generated when bacteria degrade biological material in the absence of oxygen, in a process known as anaerobic digestion. Biogas is a renewable fuel. It is a mixture of methane (about 65%), carbon dioxide (CO2), and impurities of hydrogen sulfide (H2S), CO2 and water (Table 1). Technology is commercially available to remove H2S, CO2 and water contaminants present in the biogas and landfill gas through processing to produce high-purity natural gas (RNG or biomethane) suitable for vehicles. When biogas is produced from biological material it is called bio-methane. After removal of contaminants, biomethane is the same as natural gas, and can be used as a transport fuel in the form of Liquid Natural Gas (LNG) or Compressed Natural Gas (CNG). Anaerobic Digestion (AD) technology is well established, hence biogas is often categorized as a 'first generation' biofuel. Bio-gas is widely used as a transport fuel in many European countries, notably Italy, which boasts of 650,000 gas powered vehicles. Sweden is a world leader in upgrading and use of biomethane for transport, and has many 'biogas vehicles', including private cars, buses, and even a biogas train and a biogas powered touring car team [18]. Germany is leading the field (biogas production) with almost 3, 900 biogas plants in operation in 2009, the majority using enlisted crops. Renewable natural gas (RNG) provides a clean, easily controlled source of renewable energy from organic waste materials, replacing fossil natural gas with a sustainable carbon neutral fuel option. Anaerobic digestion is the most commonly employed and technologically mature method; requiring only a low-oxygen environment for the naturally occurring breakdown of organic matter by bacteria.

|

3. Biomethanation

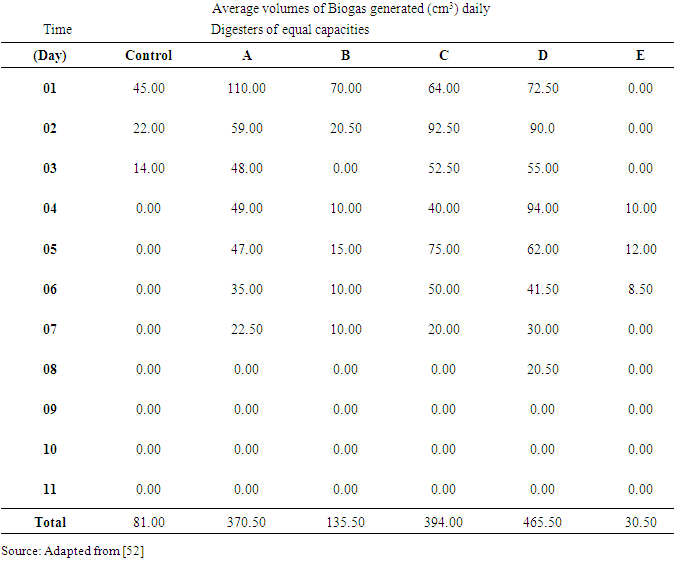

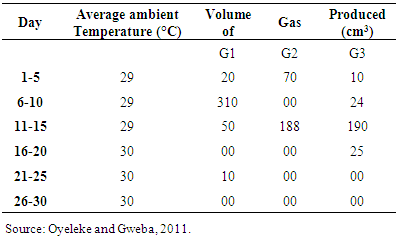

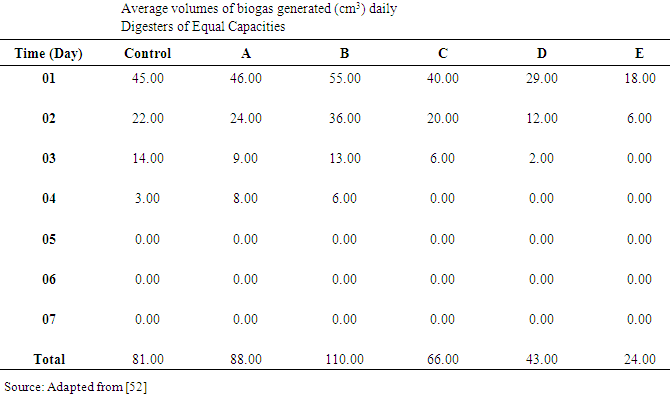

- Biomethanation is a process by which organic material is microbiologically converted under anaerobic conditions to biogas. Three main physiological groups of microorganisms are involved_fermenting bacteria, organic acid oxidizing bacteria, and methanogenic archaea. Microorganisms degrade organic matter via cascades of biochemical conversions to methane and carbon dioxide. Energy has a major economical and political role as an important resource traded worldwide. Biomethanation technology (BT) may be perceived as a potential alternative as it not only provides renewable source of energy but also utilizes recycling potential of degradable organic portion of solid waste generated by numerous activities in the country. BT is the anaerobic digestion of biodegradable organic waste in an enclosed space under controlled conditions of temperature, moisture, pH, etc (Table). It is a human engineered decomposing system wherein depending on the waste characteristics; the waste mass undergoes decomposition anaerobically thereby generating biogas comprising mainly methane and carbon dioxide. Microbes are nature's ultimate garbage disposal, devouring the dead, decomposing an inert material that litters Earth's surface. This is their specialty. Microorganisms are so good at it, such that humans have taken an increasing interest in coercing them to clean up our environmental messes. This approach is termed bioremediation, and it involves using microorganisms and other organisms that are naturally contaminants- or pollutants-philic. Genetically altered organisms have also been used to degrade environmental toxins. Scientists are designing or deploying microbes to purge sites of contaminants such as PCBs, oil, radioactive waste, gasoline and mercury, and new bioremediation research appears regularly on daily basis. Cellulose recycling in nature is in the order of 1015 kg per year [6]. This number is so high that we could make enough fuel ethanol to supply 100 times the energy requirements of the entire world in a rampant development scenario projection for 2035 [30]. Perennial and biennial crops are made up chiefly of cellulosic materials which can generarte high amount of energy. This is an area that has not been fully explored. For instance, Table 2 below shows the quantities of biogás produced from various farm waste in which banana leaves (control) produced 81cm3 volume of biogas. The table gives the comparison of biogas generation of banana leaves and Maize cob, Maize stalk, Water hyacinth, Elephant grass and Cow dung. The results shows that with the exception of the digester E in which Cow dung without yeast was used, all the other digesters (i.e A, B, C and D) in which Maize cob, Maize stalk, water hyacinth and elephant grass, were respectively used generated more biogas than the control digester in which banana leaves used, in spite of the fact that all the digesters were of equal slurry concentration.

|

|

|

4. Biogas and Biofuel

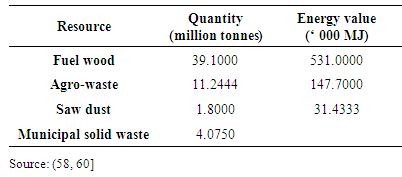

- Biogas is only one of many types of biofuels which include solid, liquid or gaseous fuels from biomass. Biofuels include fuels derived from biomass conversion, as well as solid biomass, liquid fuels and various biogases [15]. Any combustible fuel derived from recent (non-fossil) living matter (biomass) may be considered a biofuel, including ethanol derived from plant products, biodiesel from plant or animal oils as well as biogas from biomass. All biofuels are produced from sources which are renewable and are included as a subset of renewable energy sources that also include energy produced from solar, hydro, tidal, wind, and geothermal sources. Biogas, like natural gas, has a low volumetric energy density compared to the liquid biofuels, ethanol and biodiesel. However, biogas may be purified to a natural gas equivalent fuel for pipeline injection and further compressed for use as a transportation fuel. Methane, the principal component in biogas, has four times the volumetric energy density of hydrogen (H2) and is suitable for use in many types of fuel cell generators. Fuel yields depend on photosynthetic efficiency (less than 3% of solar energy is captured in even high yield crops), the efficiency of the conversion process, and the energy used in the production and conversion process (a significant cost for ethanol production). On a per acre basis, biogas production is far more efficient in capturing the energy found in energy crops. While the convenience and energy density of liquid fuels is an admirable target, if maximizing energy recovery from biomass and wastes is targeted, biogas production is the best choice. In addition, where ethanol and biodiesel production is used, biogas production from their waste products can improve the energy balance of the overall conversion process. Biofuels offer the advantage of coming from large, mainly under-utilized biomass resources that are sustainable and renewable in a closed carbon cycle that reduces environmental input [43]. Biofuels apply to solid, liquid or gaseous fuel produced from biological materials (biomass) which can be used for the generation of power, heat or fuel for motive power [59, 55, 56, 57]. In 2005, research revealed that bio-energy reserves/potential of Nigeria stood at: Fuel wood 13071,464 hectares, animal waste, 61 million tons per year, crop residues, 83 million tonnes [55]. It well known that Nigeria is the largest producer of cassava in the world and has the largest capacity for oil palm plantation which serves as a great source for biodiesel [1]. Table 5 shows the estimated biomass quantities in Nigeria. This stands the country in a good stead in turning these huge biomasses into valuable products that can enhance generation of income for both government and her citizens.

|

|

|

5. Biomethanation and Composting Processes

- Composting has been the age-long process applied by farmers in the production of manure as means of fertilization of arable land for food production. In today’s world, the reduced organic and inorganic compounds produced by anaerobic microbial processes serve as carbon and energy reservoirs for photosynthetically fixed energy. Biogas and manure are the end products obtained from biomethanation and composting produces manure as the only product. Thus, comparatively biomethanation could be considered as better option for its compactness, cleaner operation and better product range (i.e. both gas as energy source and processed solid waste as manure). Composting is the aerobic decomposition of organic materials by microorganisms under controlled conditions. Biogas technology has become therefore interesting as a way to improve the energy release from agricultural residues, save plant nutrients, and improve health conditions and quality of life in the villages [41].

6. Biogas Production Technology

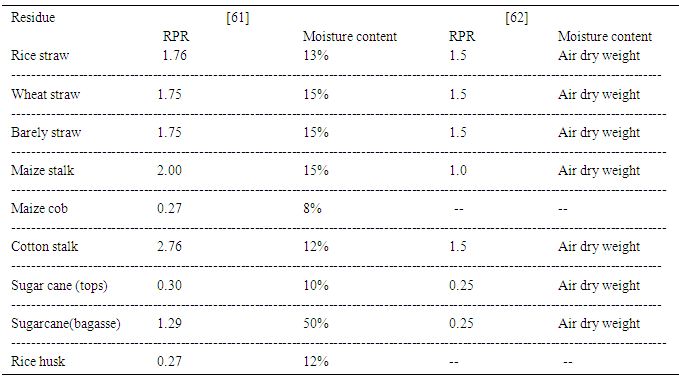

- Agricultural biogas plants typically consist of a number of low digesters built either from concrete or metal. They are often topped by a twin-skinned gas storage bag, giving them a characteristic appearance. Majority of the biogas is produced from the first digestion tank with a lower gas yield being attained in the secondary digestate storage tank. The common technology for biogas production is the digestion of feedstock in specially designed digesters. These digesters must be strong enough to withstand the buildup of pressure and must provide anaerobic conditions for the bacteria needed in the digestion process. Today, there are many different technologies and digester types available. Generally, the size of biogas plants can vary from a small household system to large commercial plants of several thousand cubic meters. Digester size also influences logistics and vice versa. Therefore, they are often built near the source of the feedstock.The water content of substrate influences the design and type of digester. One of the most common classifications regarding the water content of the substrate is wet digestion (which is fed with dry mass contents lower than 15% and into dry digestion which is fed with dry mass content between 20 and 40%). Wet digestion is usually applied to manure and sewage sludge whereas dry digestion is often applied to the fermentation of energy crops. The removal of H2S from the biogas is achieved by air dosage into the digester gas phase. Water vapour is removed by means of a water tap. Furthermore, digesters can be classified by the number of process steps. Single-stage and two-stage digesters are the most common technologies today. Single-stage digesters are characterized by no special separation of different process steps (hydrolysis, acidification, methanisation). All process steps are conducted in one single digester. Digesters can also be classified according to the filling procedure and filling interval. Co-digestion refers to the simultaneous anaerobic digestion of multiple organic wastes in one digester. Co-digestion is used to increase methane production from low-yielding or difficult- to- digest feed stocks. The co-digestion of manure, residuals of food processing and energy crops in continuous stirred reactor systems is an effective and reliable way for the production of biogas.The presence of too much NH3 or H2S can inhibit the production of methane. Wastes from fruits, vegetables, and grains contain large amounts of primary metabolites of lipids, proteins, and carbohydrates and a broad range of high-value bioactive compounds of phenolics, terpenoids, and alkaloids. Extraction techniques have been widely investigated to obtain valuable natural compounds from plant-based processing wastes. Wet plant-based food processing wastes, which are rich in sugars, vitamins, and minerals, have been used to produce fuel alcohols, organic acids, biodegradable polymers, enzymes, antioxidants, and vitamins in biological processes. Both high and low levels of nitrogen can inhibit the biogas process. The substrate composition not only has an influence on the process performance but also affect the composition of the produced biogas [7]. For instance, Table 8 depicts the various moisture contents of the feed stocks used in the biogas production process that can guarantee success in biogas production.

|

|

|

6.1. Other Benefits Accruing from Biogas Production

- Anaerobic digestion (AD) can be used to provide renewable energy from most organic material. AD produces 2 outputs_energy in the form of biogas and digestate as source of organic fertilizer. Crop based AD for energy can provides employment, increase diversity through the use of a wide range of crops, produces fuel which is clean, environmentally friendly and has multiple uses.Agricultural biogas plants typically generate returns via the sale of electricity alone, this means that the gas engine is of particular importance for the success of the plant. In large farms where there is biogas plant the farmer can have dual advantages of the proper waste management as well as reducing the energy cost of the operations of the farm.

7. The Peach Palm (Bactris gasipaes) and Banana (Musa spp.)

- The peach palm, Bactris gasipaes is an important tropical perennial agricultural crop cultivated for the fruits and heart of palm or 'palmito'_the unexpanded leaves above the meristems. The peach palm (Bactris gasipaes Kunth, Arecacea) is a widely domesticated palm in the Neotropics, and is considered to have an Amazonian origin [11]. The fruits are a main component of subsistence diets in lowland humid regions, while the heart of palm has a considerable commercial value [12, 13] particularly in Brazil, Ecuador and Costa Rica where cultivation is almost totally devoted to the extraction of palmito [9]. The fruit has a high nutritional value, and is an important component of subsistence farming in resource-poor communities in lowland humid regions.Banana is the second largest produced fruit after citrus, contributing about 16% of the world’s total fruit production [20]. India is the largest producer of banana contributing 27% of world’s banana production. Edible banana are either derived solely from Musa accuminata or are a hybrid between two wild diploid species, Musa accuminata Colla and M. balbisiana Colla. Common species grown worldwide include M. sapientum, M. paradisiacal, M. cavendishii (is the desert species_ very sweet and less starchy).

8. Discussions

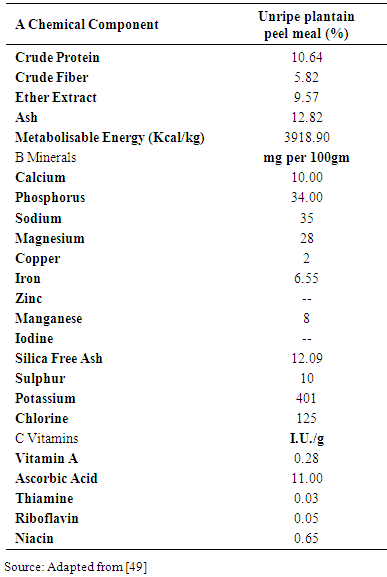

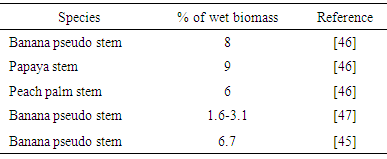

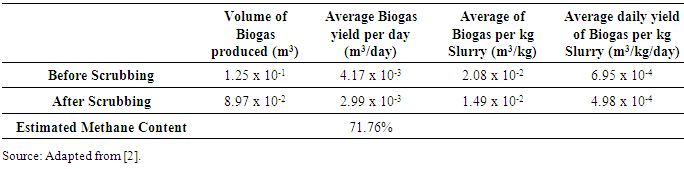

- Given that wastes constitute large chunk of anthropogenic activities and the need for alternate energy source that is not only sustainable but also capable of replacing the fossil fuel which is finite and non-renewable the need for exploitation of other crops apart from those routinely used in biogas production can no longer be taken with levity. In addition, Current estimated oil reserve in Nigeria is 35.9 billion barrels with daily production capacity of 2.4 million barrels of crude oil. The 35.9 billion barrels of oil reserve will be depleted by 30-35 years period [1]. There is currently a movement towards reduced use of fuels from fossil origin; thus, fuel production from renewable biomass is becoming increasingly acceptable [39]. Biomass means agriculturally produced raw materials which are available on renewable or recurring basis. It includes tree crops, plant fibres, cellulose based materials, industrial wastes and other biodegradable parts of municipal solid waste [29]. The production of biogas from palm heart’s and banana wastes biomass separately and then, combined in varying proportions and, or percentages in a completely randomized block design can indicate the importance of perennial and biennial crop plants in generating high quality biogas since the energies were accumulated over the years from solar energy. For instance, the biennial crop, Sugar beet and its tops can give 450m3 of methane/ton VS [7]. Although much work has not been done in this direction, it is also believed that the superiority of peach palm and other perennial crops in terms of biogas production may be better than those that can be gotten from biennial and annual crops’ wastes. Use of fibers from peach-palm has also become increasingly popular in recent years and is not only limited to biogas production. Several producers of natural fiber based products currently use palm-fibres in production of parquet, panels and furniture [21, 34]. The best energy crops are durable, their dry matter yields are high and constant and their production costs are low. A perennial growth habit, low agrochemical requirements, effective conversion of solar energy to biomass and ease of conversion back to useful energy guarantee that energy efficiency of production is high and environmental impacts are low [19] since the methane and energy content of the gas generated usually varies and is dependent on the physical and chemical properties of the substrate used [10]. For instance, Alfa et al. [2] demonstrated that Biogas could be produced from Cymbopogon citratus in quantity and quality comparative with others in literature.It is also believed that the mixture of palm heart’s waste and banana’s waste biomass can produce the highest volume of biogas (that is, the mixture of banana’s wastes and palm heart’s waste in a ratio of 3:2 might be the best option). This can be effectively tested by grouping the experimental units into blocks such that variability within each block is minimized and variability among blocks is maximized. According to Mophapaltra et al. [28], the core of the banana pseudo-stem is rich in polysaccharides with traces of other elements, and has very low content of lignin. Also, the high content of holocellulose and low content of lignin make the banana pseudo-stem bark, an ideal material for application in pulping and papermaking [25]. This feature can also be exploited in terms of biogas production. Perennial crops require less maintenance and fewer inputs than do annual row crops, so they are cheaper and more sustainable to produce. Perennial energy crops need considerably less fertilizer, pesticide, herbicide, and fungicide than annual row crops. Perennial and biennial crops are known to be made up of high content of cellulose. These cellulosic materials can give large volume of biogas when the proper anaerobic digestion process is employed. In line with this thought, Larson [24] projects that future advanced cellulosic processes from perennial crops could bring reductions of 80–90 percent and higher in green house gases. Hoogwijk et al. [22] indicated that the bio- fuel production potential around 2050 could lie between about 70 and 300EJ fuel production capacity depending strongly on the development scenario.Anaerobic digestion of energy crops through biomethanation requires in most cases prolonged hydraulic residence times from several weeks to months (for a period of 75 to 90 days for example). Nevertheless, if sustainability criteria are followed [14], the use of energy crops will reduce GHG emissions by replacing fossil fuels at least to some extent. EEA Technical Report [16] estimates the environmentally compatible overall bioenergy potential from agriculture in Europe in 2030 of up to 6 EJ. Africa and Nigeria in particular can key into the use of perennial crops so as not to be left out when the fossil fuels are depleted. Since this can lead to reduction of the amounts of emitted CO2 by replacement of fossil fuels with biogas in vehicles and for production of electricity and heating [5]. Given the growing world population, increasing energy demand per capital and global warming, the need for a long term alternative energy supply is clear and inevitable.

9. Conclusions and Recommendations

- Biomethanation can serve as a valuable process in biogás production from wastes from biennial and perennial crops thereby solving environmental problems as well as generating energy for both domestic and commercial use.The main drawback from this analysis is that any banana and peach palm biogas plant will need government support, whether through tax exemptions, subsidizing or reduced subsidies on petrol, in order to provide a substantial financial return on investment.In Brazil and the United States, large corporations dominate the bioenergy industry, but farmer cooperatives play a useful role in linking these large firms to independent growers [31]. This a good way to start and association of interested farmers (Cooperative) could serve as a means of assessing large capital from relevant organizations. Banana and peach palm wastes like other perennial and biennial crops should be considered as economic resources that can be turned into valuable products in progressing towards a permanent solution to waste disposal problems and generation of renewable energy. Feasible methods with optimal environmental conditions such as pH and temperature will have to be found and employed to solve the environmental problems to assure susteinability. These environmental conditions have to be factored into the design of the digesters.The biogas process and biomethane production is also advantageous as it mediate the recirculation of nutrient from waste products to arable fields as residues from the whole process can be used as fertilizer.Despite this potential, bioenergy must be viewed not as the single replacement for oil, but as one element in a wider portfolio of renewable sources of energy_ as part of the whole solution to energy and environmental crises. Deliberate efforts should be made by the government in terms of massive capital investment, training of man-power in the field of biofuel or biodiesel development, granting tax holidays to would-be investors _ companies and individuals, amongst many other things; and that if adequate policy frame-work is put in place and necessary political will is expressed and applied to the development and production of biodiesel in the country the economy would be better for it [35]. Same could also be applied to biogás production from peach palm and banana’s wastes amongst others.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML