Nguyen Van Than1, 2, Sheng-Shung Cheng2, Yu-Min Tien2

1Department of Food Biotechnology, College of Food Industry Da Nang, Vietnam

2Department of Environmental Engineering, National Cheng Kung University, Taiwan

Correspondence to: Nguyen Van Than, Department of Food Biotechnology, College of Food Industry Da Nang, Vietnam.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Abstract

Biochemical methane potential (BMP) was evaluated for biogas production with different substrate and different seeding sources. Biological solid state fermentation (SSF) on organic waste was done in our Lab. With the purpose to evaluate an efficiency of SSF biodegradation processes about jar tests of farm waste and biological pretreatment of Napier grass mixed kitchen waste. In this study, a soluble leachate from aerobic SSF processes and a liquid substrate from biodegradation farm waste (anaerobic SSF) were investigated for biogas production. A difference of COD concentration and seeding sources were conducted. Our results revealed that, with a substrate from kitchen waste achieved highest CH4 production. Efficiency of biodegradation was demonstrated by biogas production rate, removal efficiency of chemical oxygen demand (COD). It was found that the highest soluble COD removal was 86%. In the experimental studies, two different seeding sources were used and compared through biogas fermentation.

Keywords:

Biochemical methane, CH4 production, Soluble leachate

Cite this paper: Nguyen Van Than, Sheng-Shung Cheng, Yu-Min Tien, Biochemical Methane Production Potential of Soluble Leachate from Biological Solid State Fermentation with Batch Jar Tests, American Journal of Environmental Engineering, Vol. 4 No. 6, 2014, pp. 169-175. doi: 10.5923/j.ajee.20140406.05.

1. Introduction

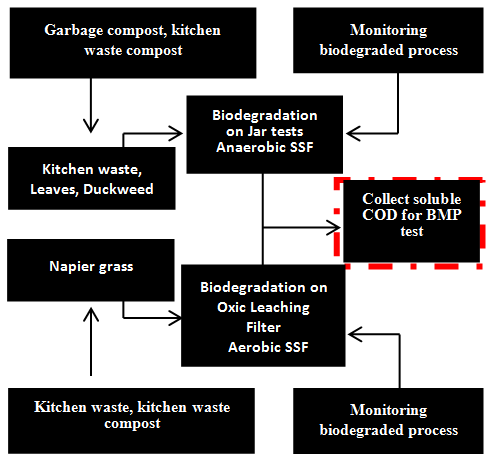

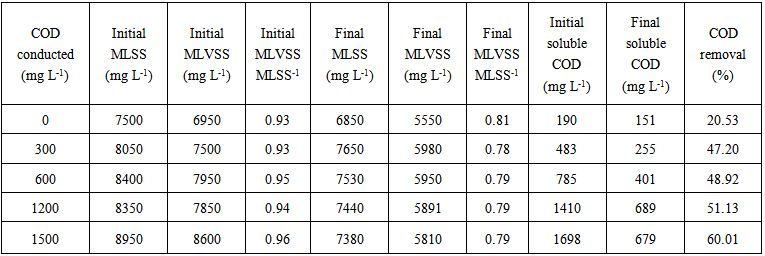

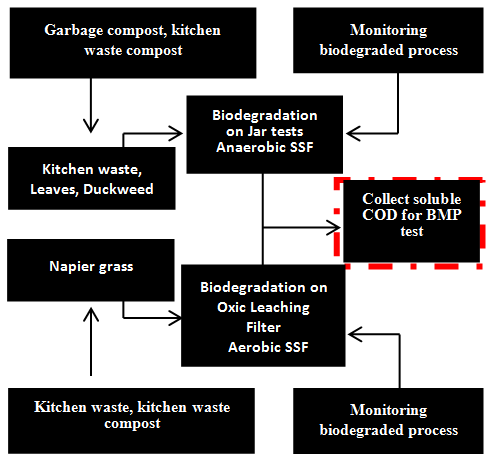

To our knowledge, anaerobic biogas fermentation is anaerobic degradation processes of organic material to methane and carbon dioxides production. The biochemical reaction divided to four groups: hydrolysis, acidogenesis, acetogenesis and methanogenesis. Batstone et al. showed a model of anaerobic process with six steps conducted substrate to final methane biogas production. First, it is sugar and amino acid production from hydrolysis stages. In this step, a soluble substrate can be directly converted to methane production by acidogenesis methanogenesis processes. In addition, a long chain fatly acids (LCFAs) from hydrolysis stage of compound fats converted into the hydrogen production by acetogenesis processes. Brief of principal from complex particulate waste and inactive biomass would be transferred into the methane and carbon dioxides including [1]. In anaerobic digester processes, a reaction of anaerobic fermentation is complex and has many relationships with other factors, such as a temperature, pH, organic loading, hydraulic retention time (HRT), gas concentration. A total COD input is the most important through anaerobic processes, as a consideration fraction of the input COD may be non-biodegradable. A gas liquid exchanges gas transfer rapid or medium occurs in fermentation processes. A liquid-solid transformation, this reaction is important in system with precipitation and solubilisation of ions. Therefore, when we control and set point of pH values almost need to consider about the physical chemical sate in anaerobic reactor [1]. In our research, a substrate from aerobic SSF and anaerobic SSF was collected and used as food for biochemical methane potential processes (Figure 1). This study aimed to evaluate the substrate on biodegradation processes for biogas production. Therefore, BMP test was conducted on the substrate from SSF processes. | Figure 1. Overall for the conductive experiment BMP test |

2. Materials and Methods

2.1. Substrates from Biological Pretreatment Processes

Our aim is to identify and evaluate a biogas production of substrates from SSF biodegradation processes with different seeding sources. Seeding inoculation collected from activated sludge of food processing plant and the sludge was from anaerobic kitchen-waste. In this case, there are three important indicators need to be considered through BMP test, which are food, microbes, and bioreactor. First substrate is collected from anaerobic SSF in batch jar tests. Food for this BMP test was a leachate from Jar tests and from oxic leaching filter (OxLF) with same dry weight. 70g samples from each Jar were collected and diluted in the water (1:5), after that only a soluble COD was collected. Second substrate is collected from aerobic SSF with aerobic leaching filter bioreactor. Food for this BMP test was leachate from aerobic SSF with soluble COD in different concentration at 300, 600, 1200 and 1500 mg L-1. Microbes were an activated sludge and collected from different seeding sources. In our experiments, soluble COD in both final anaerobic and aerobic SSF processes was conducted. A reactor of BMP test was conducted in serum bottle at thermophilic temperature and was kept at 55℃.

2.2. Biochemical Methane Potential Test (BMP)

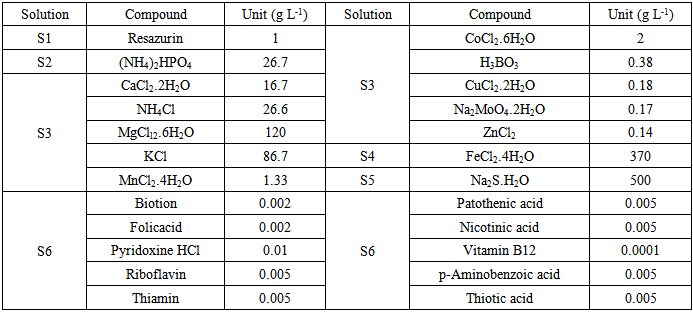

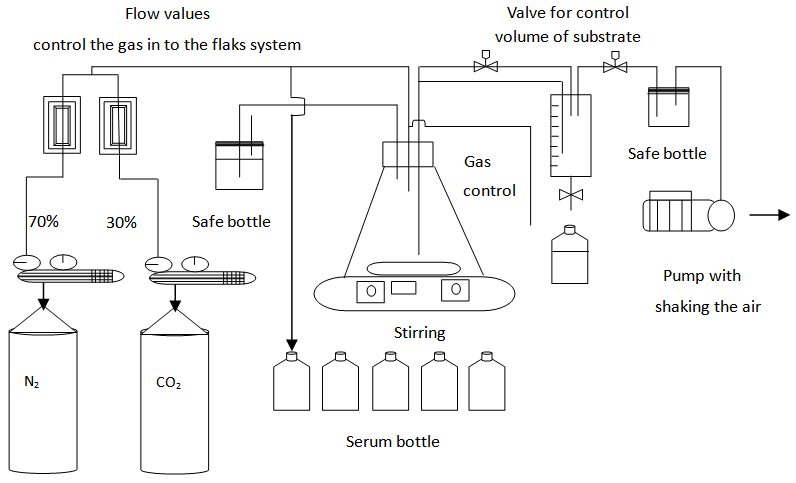

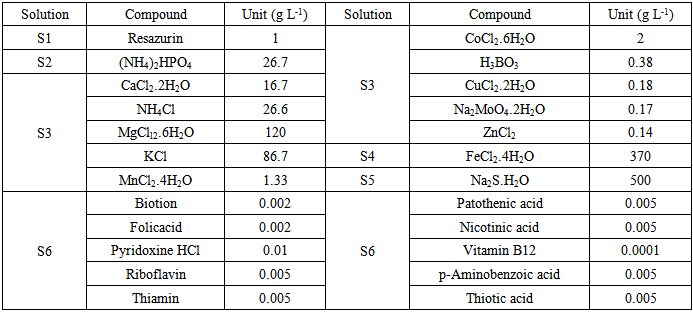

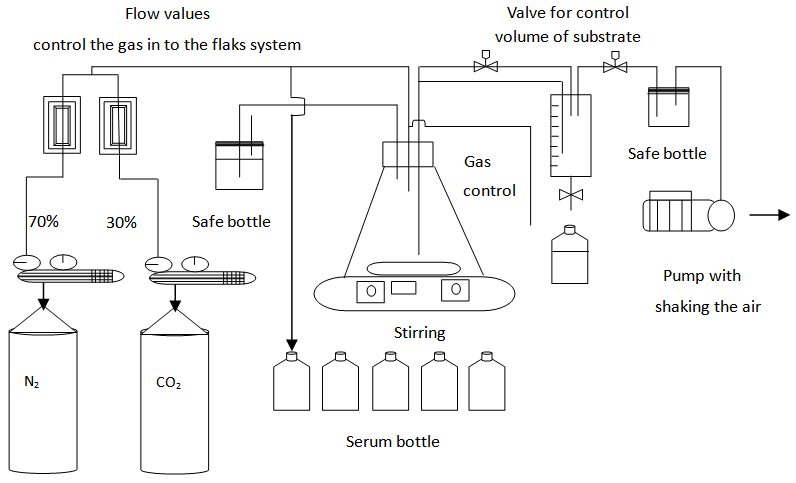

Procedure of BMP test was done according to Owen et al (1979). We were designed the experiment step by step was followed the procedure below [1, 2]. a) Soluble COD from anaerobic and aerobic SSF prepared, fixed at the concentration for BMP test.b)The medium for our experiment was prepared and showed in Table 1, and according to Owen et al [2]. The medium Resazurim S1 is added to detect oxygen contamination (pink when oxidized), and sodium sulfide S5 is added to provide a reducing environment.c) Substrate solution and a bottle were prepared. Solution and nutrient were prepared following the steps above:• Add 1.9 L of deionized water to 2 L volumetric flask.• Add 1.8 mL S1 medium, 5.4 mL S2 medium, and 27 mL S3 medium.• Boiling solution for 15 minutes while flushing with N2 gas at around 1L minute-1.• Cool to room temperature (but keep a flushing with N2 gas).• Add18 mL S6 medium, 1.8 mL S4 medium and 1.8 mL S5 medium.• A gas composition about 30% CO2 and 70% N2 mixture and continue flushing about 1 L in minute-1 were adjusted. Then 8.40 gram NaHCO3 as powder was added. After that bubble 30% CO2 and 70% N2 gas mixture were controlled and managed pH value stabilities about 7.In Figure 2 and in Table 1 show the assay transfer inoculate and substrate into serum bottles under anaerobic and equilibrate condition. Gas volume sampling and removal during incubation is performed with glass syringes (5-50 mL depend on gas volume). | Figure 2. Anaerobic transportation system conducted for BMP test |

Table 1. The medium composition of BMP test

|

| |

|

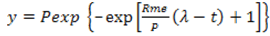

The most important during the BMP test is we need to consider and make sure the CO2 and N2 gas bubble into the flaks and serum bottles to make sure an anaerobic condition without oxygen. In addition, a pH values was adjusted before do BMP test. During the time take sample for monitoring biogas production, glass syringes cleaned to make sure the water level steady in a bottle. After that value of biogas was obtained stable and at balance condition. An anaerobic transportation system processes is shown in Figure 2.Biogas production was calculated by the Gompertz equation and showed the composition of biogas such as: H2, CH4, and CO2 [3]. The equation 1 showed below: | (1) |

Where: y = Accumulative biogas production (mL). P = Potential biogas production (mL). time (hours). R me = Maximum producing rate (mL h-1).

time (hours). R me = Maximum producing rate (mL h-1).

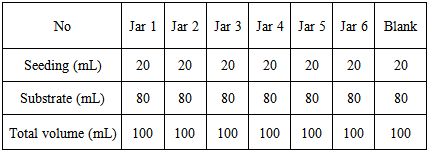

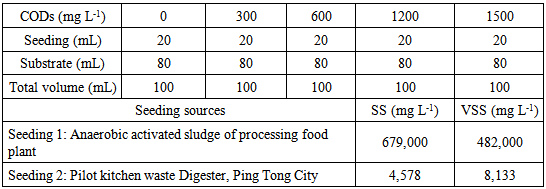

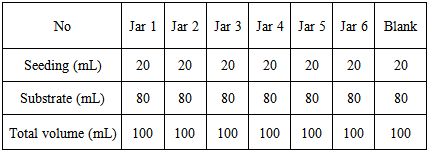

2.3. Experimental Designs for BMP Test Substrate from Difference of Biological Processes with two Seeding Sources

In this study, a substrate from oxic leaching filter and batch jar test were collected and realized in different COD concentrations at 0, 300, 600, 1200, 1500 mg L-1. We used different seeding sources. Seeding 1 was collected from anaerobic activated sludge of processing food plant. Seeding 2 was collected from pilot kitchen waste digester in Ping Tong City, Taiwan. The SS and VSS values were measured and presented in Table 2 and in Table 3.Table 2. Experimental design for BMP test with substrate form Jar tests

|

| |

|

Table 3. Experimental design for BMP test with substrate form OxLF bioreactor

|

| |

|

3. Results and Discussions

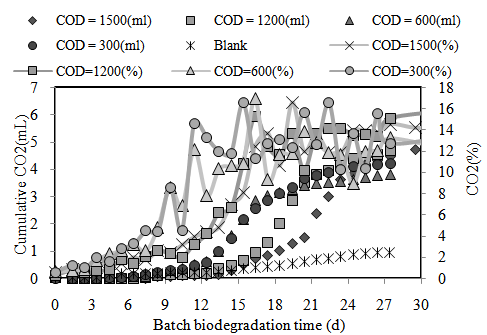

3.1. BMP Test with a Substrate from Jar 5 and Jar 6 of Biodegradation Jar Tests

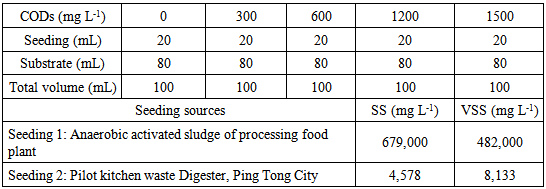

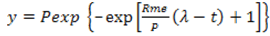

An anaerobic digestion for biogas production has been applied for several organic wastes. It was operated and recovered a bioenergy from waste, which consists mainly of CH4 and CO2 [4-8]. The result illustrate that a substrate was easy for methane fermentation after biodegradation. After 60 hours fermentation percentage of CH4 was achieved at highest value, the percentage of CH4 maintain during biogas fermentation was more than 70% (Figure 3). | Figure 3. Methane production in jar 5 and Jar 6 tests |

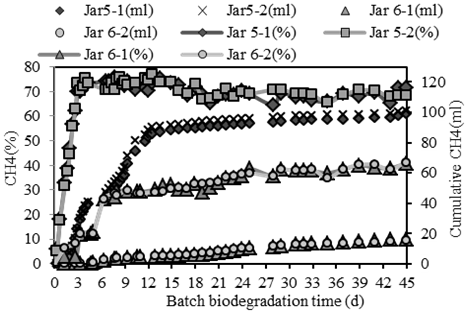

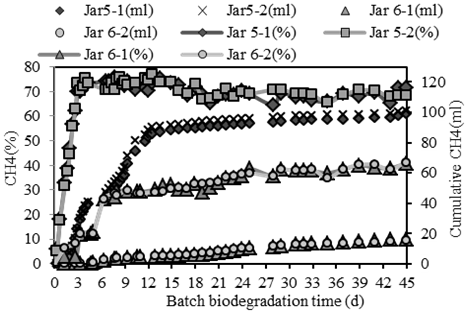

In addition, the CO2 production in this BMP test was also high value around 25-30%. It means that during biogas fermentation, a hydrolysis also convert a substrate into simple compound and CO2 production. A comparison between two jars, jar 5 was achieved methane and carbon dioxides higher than jar 6. It means that in jar contained kitchen waste was suitable and obtained higher biogas production. Figure 3 shows the percentage of CH4 of jar 5 which was steady more than 70%, in jar 6 was 45%.In other hand, the percentage of CO2 also was quite different between jar 5 and jar 6. In jar 6 the value of percentages of CO2 was about 28-32%, in jar 5 was about 10-20% (Figure 4). We concluded that a substrate of jar 5 after biodegrading processes was much achieved ability for biogas production. | Figure 4. Carbon dioxides production in jar 5 and Jar 6 tests |

3.2. BMP Test with a Substrate from Jar 1 to Jar 4 of Biodegradation Processes

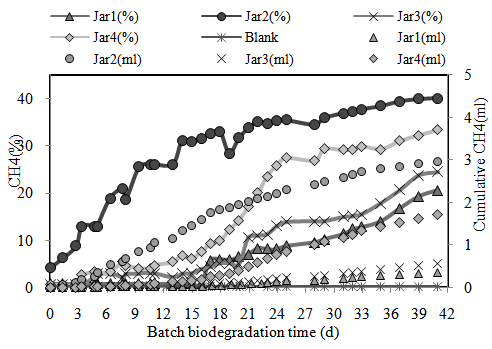

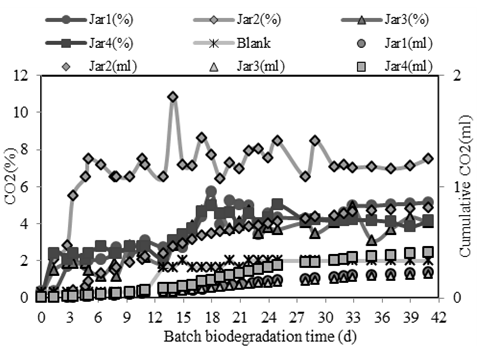

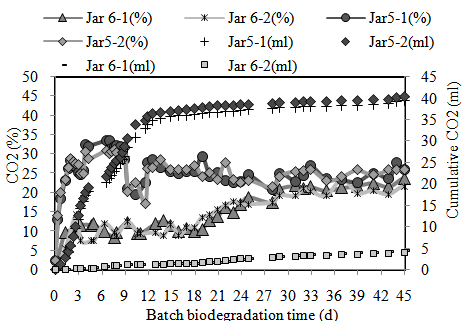

Biological pretreatment investigated for cellulose substrate of Agro-Industrial residues, organic waste. Then it was used for biogas fermentation with different conduction and various efficiencies of biogas production [9-12].Experimental results showed that there is beneficial effect at different substrates using for CH4 production between each jar (Figure 5). Jar 2 and jar 4 contained leave, duckweed and seeding where were obtained percentage CH4 production higher than jar 1 and jar 3. However, percentage and volume of CH4 in the jar 2 was highest value about 40%, 3 mL day-1, respectively. In samples mixed kitchen waste with a substrate enhanced biodegradation processes and anaerobic biogas production.  | Figure 5. Methane productions from jar 1 to Jar 4 tests |

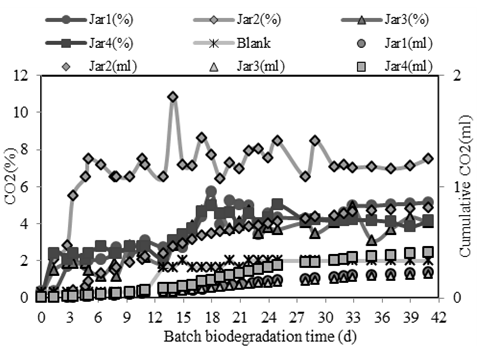

As seen from Figure 6, the CO2 production was different between each jar. In jar 2, a percentage and volume of CO2 were highest value, but a value was smaller than jar 5 and jar 6. | Figure 6. Carbon dioxides production from jar 1 to Jar 4 tests |

Comparable results for biogas production, from jar 1 to jar 4 achieved the biogas lower than jar 5 and jar 6. Therefore, biogas production revealed that a substrate contained kitchen waste after biodegradation was suitable for anaerobic biogas fermentation.

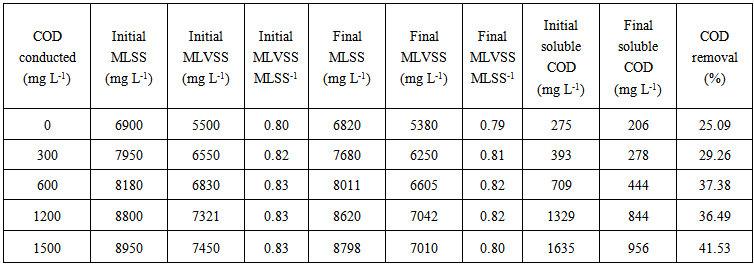

3.3. BMP Test of a Substrate from Biological Pretreatment in OxLF with Seeding 1

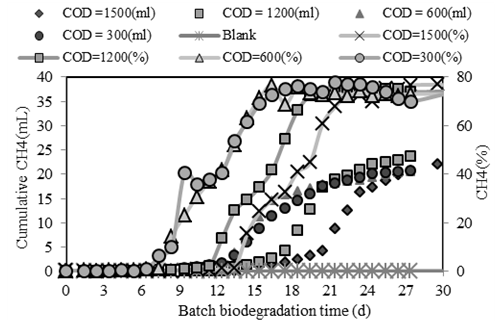

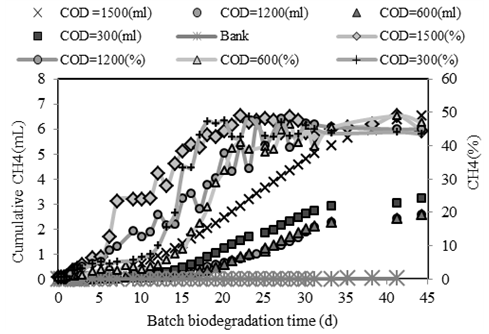

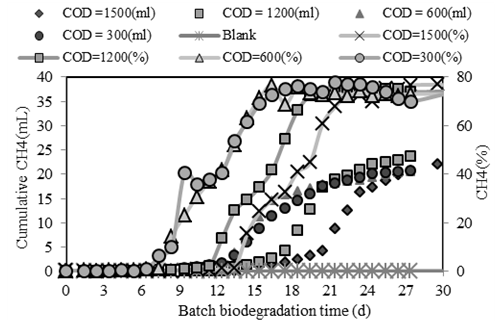

In our BMP test, a COD value of leachate from aerobic biological pretreatment processes in differences of COD concentrations was conducted. Sludge from food proceeding wastewater was used as a seeding source, like as an inoculum for fermentation methane production.As can be seen the results of Figure 7 and Figure 8 revealed that a lag phase took long time for biogas production, which was more than 5 days. Almost of biogas production was achieved until 7 days fermentation processes. A percentage of CH4 obtained 40%-50% in each sample. | Figure 7. CH4 production in different COD concentrations and seeding 1 |

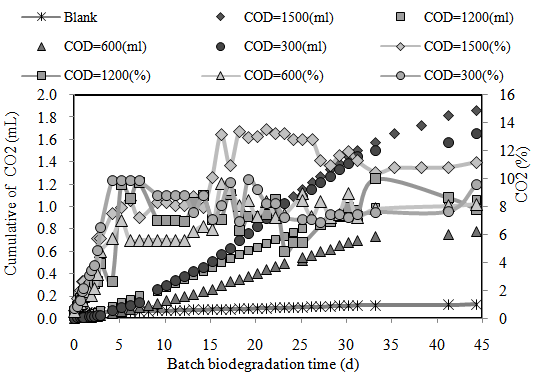

| Figure 8. CO2 production with different COD concentrations and seeding 1 |

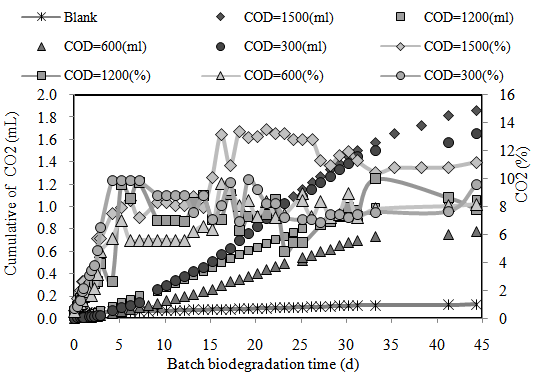

Our research showed that a CO2 production was similar between different soluble COD concentrations. Results showed that after 5 days percentage of CO2 achieved 8-10%, volume of CO2 was 1.6-1.8 mL day-1. Otherwise, the volume of biogas production was increased lowly until 12 days fermentation. It means that, in this BMP test we need to check and maintain a process in long time for good results.

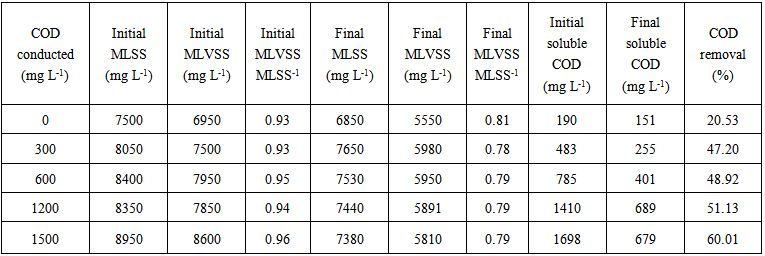

3.4. BMP Test of Substrate from Biological Pretreatment in OxLF with Seeding 2

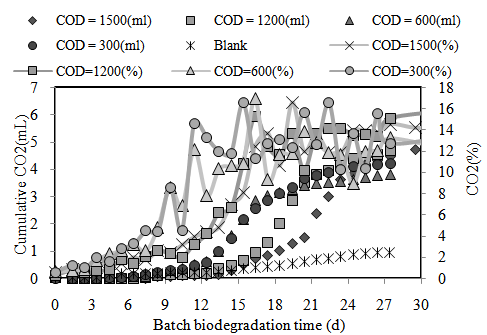

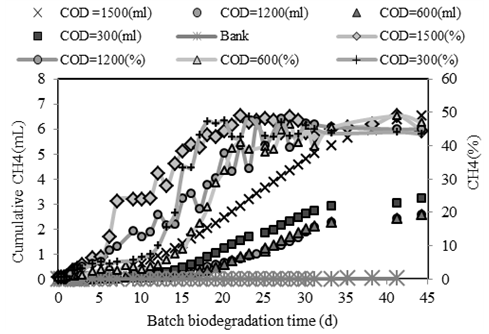

The different between two seeding sources is given in our study. Seeding 2 was used for this BMP test, which was collected from anaerobic kitchen waste digester. Figure 9 provided that cumulative and a percentage of CH4 obtained with variable value when different soluble COD concentrations were used. | Figure 9. CH4 production in different COD concentrations and seeding 2 |

In addition, the results illustrate that in the differences of soluble COD concentrations took variable time for a first stage of anaerobic fermentation. A percentage of CH4 in different soluble COD concentration was similar value about 75-78%. Other remark of biogas production at different seeding sources was achieved various value. CH4 production during anaerobic digestion between seeding 1 and seeding 2 were noticed and compared. In seeding 2, which was a seeding from anaerobic digester kitchen waste, where the substrate was similar with our substrate. Therefore, cumulative and percentage of CH4 was produced higher than the seeding 1, cumulative of CH4 was about 20-25 mL day-1. Meanwhile cumulative of CH4 from seeding 1 was obtained low value, 2 mL day-1.The aim of this experiment is to evaluate biogas production in different seeding sources. Figure 10 shows a CO2 production in different soluble COD concentration were no more various values. Moreover, the percentage of CO2 after two weeks was maintained at steady value around 12-16%. | Figure 10. CO2 production in different COD concentrations and seeding 2 |

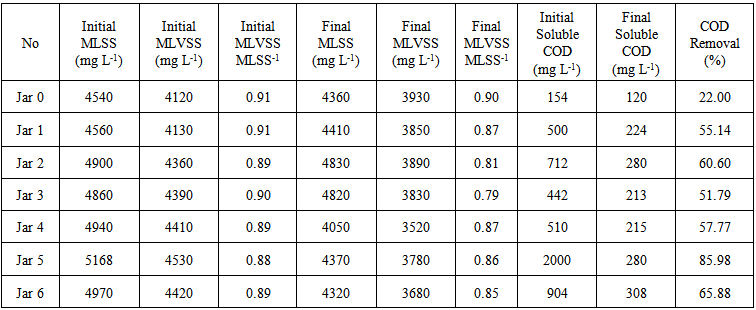

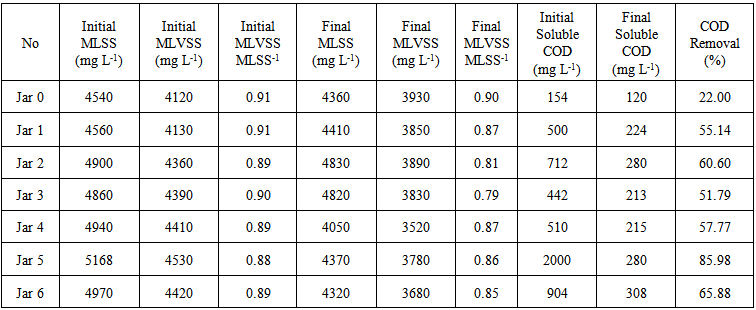

The cumulative of CO2 also took about two weeks for biogas fermentation and achieved at 4-5 mL CO2 day-1. It is seen that in our research the BMP test is taken long time for microorganisms consumed a substrate and converted it into biogas production. A characteristic of the important parameters during BMP test was showed in Table 1, Table 2 and Table 3. The percentage of CODs removal of each jar tests was different (Table 4). The highest value of soluble COD removal was 85%, in jar 5; in Jar 6 was about 65% and in jar 2 was 60%. In jar 1, jar 3 and jar 4 obtained similar values of COD removal around 50%. Therefore, it is concluded that an efficiency of biodegradation of each jar test is significant effect of biogas production and COD removal. This findings may confirm that the kitchen waste and kitchen waste composting were enhanced for biological processes and anaerobic fermentation processes. | Table 4. Characteristics of SS, VSS, COD initial and final during BMP test of substrate from biodegradation Jar tests |

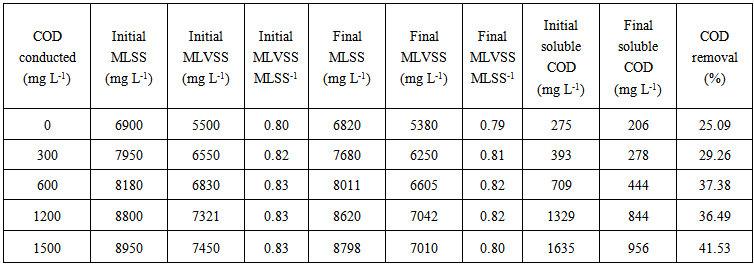

On the other hand, a difference of substrate concentrations were achieved various values of biogas conversion. The CODs removal was also different. A higher COD concentration was obtained higher efficiency of CODs removal. During BMP test, COD removal of seeding 1 and seeding 2 were different. In seeding 2 obtained higher CODs removal than in seeding 1 around 60% and 40%, respectively. This can satisfactorily illuminate that in seeding 2, which was collected from anaerobic kitchen waste mixed Napier grass, where the substrate was similar as substrate of our experiment. Therefore, the substrate was easy performed and achieved with high efficiency of CODs removal (Table 5 and Table 6).  | Table 5. Characteristics of SS, VSS, COD initial and final during BMP test of substrates from OxLF bioreactor with seeding 1 |

| Table 6. Characteristics of SS, VSS, COD initial and final during BMP test of substrates from OxLF bioreactor with seeding 2 |

4. Conclusions

This study shows that the substrate from SSF processes was suitable for biogas production. With a jar contained kitchen waste through anaerobic also aerobic SSF processes almost achieved higher biogas production than other jar did not add kitchen-waste. The highest soluble COD removal of jar 5 was 86%.Moreover, the study demonstrates that in the jar contained kitchen waste compost showed a soluble COD removal was also high about 66%. Therefore, kitchen-waste was an important role in aerobic biodegradation processes also anaerobic biogas production. In difference of seeding sources achieved various CODs removal value and biogas production. Among two seeding, seeding from anaerobic kitchen waste digester was much more suitable for biogas production than seeding from sludge of food processing plant.

ACKNOWLEDGEMENTS

We are grateful to National Science Council in Taiwan, for its financial support to our research (NSC 100-2627-M-006-002, NSC 100-2627-M-006-003).

References

| [1] | D. J. Batstone, J. Keller, I. Angelidaki, S. V. Kalyuzhnyi, S. G. Pavlostathis, A. Rozzi, et al., "The IWA Anaerobic Digestion Model No 1 (ADM1)," Water Science and Technology, vol. 45, pp. 65-73, 2002. |

| [2] | W. F. Owen, D. C. Stuckey, J. B. Healy Jr, L. Y. Young, and P. L. McCarty, "Bioassay for monitoring biochemical methane potential and anaerobic toxicity," Water Research, vol. 13, pp. 485-492, 1979. |

| [3] | M. H. Zwietering, I. Jongenburger, F. M. Rombouts, and K. van 't Riet, "Modeling of the bacterial growth curve," Appl Environ Microbiol, vol. 56, pp. 1875-81, Jun 1990. |

| [4] | H. Uellendahl and B. K. Ahring, "Anaerobic digestion as final step of a cellulosic ethanol biorefinery: Biogas production from fermentation effluent in a UASB reactor-pilot-scale results," Biotechnol Bioeng, vol. 107, pp. 59-64, Sep 1 2010. |

| [5] | B. H. Gilroyed, T. Reuter, A. Chu, X. Hao, W. Xu, and T. A. McAllister, "Anaerobic digestion of specified risk materials with cattle manure for biogas production," Bioresour Technol, vol. 101, pp. 5780-5, Aug 2010. |

| [6] | Y. Lin, D. Wang, and L. Wang, "Biological pretreatment enhances biogas production in the anaerobic digestion of pulp and paper sludge," Waste Manag Res, vol. 28, pp. 800-10, Sep 2010. |

| [7] | Y. Zheng, Z. Pan, R. Zhang, H. M. El-Mashad, J. Pan, and B. M. Jenkins, "Anaerobic digestion of saline creeping wild ryegrass for biogas production and pretreatment of particleboard material," Bioresour Technol, vol. 100, pp. 1582-8, Feb 2009. |

| [8] | R. Samson and A. Leduy, "Biogas production from anaerobic digestion of Spirulina maxima algal biomass," Biotechnol Bioeng, vol. 24, pp. 1919-24, Aug 1982. |

| [9] | P. Nigam, N. Gupta, and A. Anthwal, "Pre-treatment of Agro-Industrial Residues," in Biotechnology for Agro-Industrial Residues Utilisation, P. Nigam and A. Pandey, Eds., ed: Springer Netherlands, 2009, pp. 13-33. |

| [10] | W. Zhong, Z. Zhang, Y. Luo, S. Sun, W. Qiao, and M. Xiao, "Effect of biological pretreatments in enhancing corn straw biogas production," Bioresource Technology, vol. 102, pp. 11177-11182, 2011. |

| [11] | A. Pandey, C. R. Soccol, P. Nigam, and V. T. Soccol, "Biotechnological potential of agro-industrial residues. I: sugarcane bagasse," Bioresource technology, vol. 74, pp. 69-80, 2000. |

| [12] | J. Perez, J. Munoz-Dorado, T. de la Rubia, and J. Martinez, "Biodegradation and biological treatments of cellulose, hemicellulose and lignin: an overview," Int Microbiol, vol. 5, pp. 53-63, Jun 2002. |

time (hours). R me = Maximum producing rate (mL h-1).

time (hours). R me = Maximum producing rate (mL h-1).

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML