-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Environmental Engineering

p-ISSN: 2166-4633 e-ISSN: 2166-465X

2014; 4(5): 106-116

doi:10.5923/j.ajee.20140405.04

Determination of Learning Curves and Forgetting Factors of Two-man Crosscut Saw Operators during Tree Cutting Operations in a ‘Learn by Doing’ Experiment

Dos Santos A. Silayo, George A. Migunga, Dunstan T. K. Shemwetta

Department of Forest Engineering, Faculty of Forestry and Nature Conservation, Sokoine University of Agriculture, Morogoro, Tanzania

Correspondence to: Dos Santos A. Silayo, Department of Forest Engineering, Faculty of Forestry and Nature Conservation, Sokoine University of Agriculture, Morogoro, Tanzania.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Integrating ecological concerns with the daily operations of logging crews has been an area of interest in ensuring for sustainable environmental management in forestry. Learning curves have been found to be a useful tool in scheduling harvesting operations for better performance in the sector. This study was conducted to establish learning curves and forgetting factors of two-man crosscut saw operators in tree harvesting operations in Tanzania. Experienced and inexperienced operators were studied before training, after training and after the break at an interval of three months during clear felling operations. The results for the learning rate were somewhat different between crew category and across experiments. For example, start-up operators had about 67% and 57% higher learning rate as compared to experience operator when studied for the first time and after training. Results on the forgetting function showed some levels of knowledge depreciation for both crews as could be reflected by their productivity levels. For example the experienced crew had a forgetting factor of 9.4% while the start-up crew had 19% forgetting factor. Therefore, training is imperative for the logging crews to realise high performance at reduced environmental damage such as forest soils disturbances and increased logging residues that may arise from improper logging practises.

Keywords: Learning curve, Forgetting factor, Crosscut saw, Forest harvesting, Tanzania

Cite this paper: Dos Santos A. Silayo, George A. Migunga, Dunstan T. K. Shemwetta, Determination of Learning Curves and Forgetting Factors of Two-man Crosscut Saw Operators during Tree Cutting Operations in a ‘Learn by Doing’ Experiment, American Journal of Environmental Engineering, Vol. 4 No. 5, 2014, pp. 106-116. doi: 10.5923/j.ajee.20140405.04.

Article Outline

1. Introduction

1.1. The Learning Curve Concept

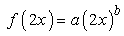

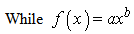

- Past experience indicates that individuals learn by experience and their performance gets better and better at the job by carrying out the tasks more and more [47]; [34]. Therefore, learning curve is a graphical representation of the relationship between time and the produced units in a production run [2]. Some studies have described the phenomenon as what they have referred to as an “experience curve”, which includes all manufacturing costs rather than only labour cost [6]. The [24] argues that “learning by doing” concept would have been more accurately described as “learning by producing” curves.The learning curve model operationalizes experience as an explanatory variable using a cumulative measure of production or use [31]. The “learning curve theory” by [47] resulted in a mathematical model (equation 1):

| (1) |

= the time required by a worker or crew to produce the Nth unit in a series (e.g., to plant the Nth seedling);

= the time required by a worker or crew to produce the Nth unit in a series (e.g., to plant the Nth seedling); estimate of the time required to produce the first unit in the series (thus, α is an estimator of Y0);

estimate of the time required to produce the first unit in the series (thus, α is an estimator of Y0); unit number

unit number = a constant that measures the rate (Learning rate) at which the time required to produce a single unit changes relative to the cumulative number of units produced.However, several studies have criticized the learning curve model, especially in its more general form as the experience curve. [9] surveyed 108 learning curve studies and showed a wide variation in learning rates leading them to question the explanatory power of experience. [1] explored this variation further and proposed four alternative hypotheses for the observed technical improvements: economies of scale, knowledge spillovers, and two opposing factors, organizational forgetting and employee turnover. Despite such critiques, the application of the learning curve model has persisted without major modifications as a basis for predicting technical change, informing public policy, and guiding firm strategy [31]. Since their development LCs have been applied in many non-airframe industries including petroleum refining, machine tools, clerical operations, electrical manufacturing [30]; energy technology industry [8]; Environmental management [15, 20] construction industry and forestry [16]; [10, 12]. In the fields of environmental engineering for example, LCs have been used in many aspects including waste management in cities [14, 28]. Studies have shown that the nature of Municipal Solid Wastes (MSW) management has been quite dynamic. Different countries used not only different philosophies, but also different models to put certain common philosophies into practice. MSW as a commodity was demonstrating very eloquently for the first time that there were limits to this satisfaction, and that they were being exceeded. This was a new and unexpected situation for traditional engineering science. However, according to [14] through learning curves common approaches are being applied including use of landfills [35, 29, 7]. In the construction industry where many repetitive construction field operations exhibit a learning curve as for the forestry sector, LCs have been used to determine the activity time, cost and the cycle number [26].However, according to [18] research in forestry especially on harvesting operations has not progressed to a point where specific learning curves are suggested for the highly variable, complex, repetitive tasks. In that context the forestry sector has had few applications of learning curves or experience curves [10]. For example [13] noted that logging productivity can be expected to improve over time for workers being trained to cut trees, although the publication does not tell how the improvement could be estimated. At the same time environmental impacts can be minimised if the crews know how best to manage the equipment for logging in forest environments. A study by [37] established the effect of on-job training and job interruptions on harvesting productivity and found that a newly recruited machine operator would require about three months to attain the production level of an experienced operator. [21, 19] provided an evidence of increasing productivity through professional training to logging crew on cable logging operations. The authors found out that after crews had received one full week of professional training the average productivity increased from about 18 to 23.7 tons per productive machine hour. The main factors were a reduction in carriage out and in times, as well as increased average turn volume. A study by [12] provided an unusual opportunity to measure learning rates for chainsaw felling in Tanzania where a new learning curve model was suggested for complex operations in forestry. However, according to [11] (there were some indications that a basic assumption-that the working plateau of the crews had been reached prior to the beginning of the study-was violated. But also the developed model could not be tested numerically due to incapacity to analyze non-linear equations [12]. This called for a study which will make use of the advancement in computer technology and a number of possible software’s to address these limitations and make LCs useful in forest operations management in Tanzania.Of recent, with the increasing demand for reducing greenhouse gas emissions from forests, environmental management has been the subject of a growing number of studies that have shown the complexity and challenges involved in integrating ecological concerns with the daily operations of companies. The control of environmental impacts is now viewed as the responsibility of all employees, who are called on to integrate these issues into their daily activities. According to [4] this integration logic requires the harnessing of wide-ranging knowledge as well as the learning of new, less polluting practices. Some companies have taken their employees’ learning and daily commitment and turned them into the main thrust of their environmental policy. Although the knowledge normally associated with environmental management is primarily formal and explicit in nature, organizational learning may as well benefit forestry industry if the learning curve of the expected logging crews is known or can be determined. For example introduction of clean technologies or the learning of new work methods, environmental management focuses above all on technical and objective know-how. This predominance of explicit knowledge over human and implicit aspects according to [40] is partly related to the very nature of environmental issues, which require technical and often highly specialised competencies. Machine operators in forests need to learn new methods to perfect their operations and reduce environmental damages such oil and lubricant management, soil erosion control and reduced logging residues.According to [39] about 70% at wood being logged from forests is wasted owing to poor harvesting practices. Having big portions of residues may justify for more clearing of forest to meet the wood demand in expense of the unnecessary wastes leading to numerous environmental consequences. In Tanzania as for many tropical countries logging wastes are a result of poor work methods, felling and bucking techniques which result in the splitting and braking of field trees. A considerable amount of valuable wood is lost when large trees are felled across obstacles on the ground such as hollows, ridges, logs or rocks. Again poor cross cutting techniques can result in wood waste. For instance when trees are under tension they will easily split if cross cutting starts on the side which is under tension [46]. Also wood residue may result due to the workers. Studies show that the low skill of worker contributes to part of the 35–40% of the logging waste. While labour skills may have significant contribution to optimum logging productivity, crews in most plantations are normally engaged without professional training.

= a constant that measures the rate (Learning rate) at which the time required to produce a single unit changes relative to the cumulative number of units produced.However, several studies have criticized the learning curve model, especially in its more general form as the experience curve. [9] surveyed 108 learning curve studies and showed a wide variation in learning rates leading them to question the explanatory power of experience. [1] explored this variation further and proposed four alternative hypotheses for the observed technical improvements: economies of scale, knowledge spillovers, and two opposing factors, organizational forgetting and employee turnover. Despite such critiques, the application of the learning curve model has persisted without major modifications as a basis for predicting technical change, informing public policy, and guiding firm strategy [31]. Since their development LCs have been applied in many non-airframe industries including petroleum refining, machine tools, clerical operations, electrical manufacturing [30]; energy technology industry [8]; Environmental management [15, 20] construction industry and forestry [16]; [10, 12]. In the fields of environmental engineering for example, LCs have been used in many aspects including waste management in cities [14, 28]. Studies have shown that the nature of Municipal Solid Wastes (MSW) management has been quite dynamic. Different countries used not only different philosophies, but also different models to put certain common philosophies into practice. MSW as a commodity was demonstrating very eloquently for the first time that there were limits to this satisfaction, and that they were being exceeded. This was a new and unexpected situation for traditional engineering science. However, according to [14] through learning curves common approaches are being applied including use of landfills [35, 29, 7]. In the construction industry where many repetitive construction field operations exhibit a learning curve as for the forestry sector, LCs have been used to determine the activity time, cost and the cycle number [26].However, according to [18] research in forestry especially on harvesting operations has not progressed to a point where specific learning curves are suggested for the highly variable, complex, repetitive tasks. In that context the forestry sector has had few applications of learning curves or experience curves [10]. For example [13] noted that logging productivity can be expected to improve over time for workers being trained to cut trees, although the publication does not tell how the improvement could be estimated. At the same time environmental impacts can be minimised if the crews know how best to manage the equipment for logging in forest environments. A study by [37] established the effect of on-job training and job interruptions on harvesting productivity and found that a newly recruited machine operator would require about three months to attain the production level of an experienced operator. [21, 19] provided an evidence of increasing productivity through professional training to logging crew on cable logging operations. The authors found out that after crews had received one full week of professional training the average productivity increased from about 18 to 23.7 tons per productive machine hour. The main factors were a reduction in carriage out and in times, as well as increased average turn volume. A study by [12] provided an unusual opportunity to measure learning rates for chainsaw felling in Tanzania where a new learning curve model was suggested for complex operations in forestry. However, according to [11] (there were some indications that a basic assumption-that the working plateau of the crews had been reached prior to the beginning of the study-was violated. But also the developed model could not be tested numerically due to incapacity to analyze non-linear equations [12]. This called for a study which will make use of the advancement in computer technology and a number of possible software’s to address these limitations and make LCs useful in forest operations management in Tanzania.Of recent, with the increasing demand for reducing greenhouse gas emissions from forests, environmental management has been the subject of a growing number of studies that have shown the complexity and challenges involved in integrating ecological concerns with the daily operations of companies. The control of environmental impacts is now viewed as the responsibility of all employees, who are called on to integrate these issues into their daily activities. According to [4] this integration logic requires the harnessing of wide-ranging knowledge as well as the learning of new, less polluting practices. Some companies have taken their employees’ learning and daily commitment and turned them into the main thrust of their environmental policy. Although the knowledge normally associated with environmental management is primarily formal and explicit in nature, organizational learning may as well benefit forestry industry if the learning curve of the expected logging crews is known or can be determined. For example introduction of clean technologies or the learning of new work methods, environmental management focuses above all on technical and objective know-how. This predominance of explicit knowledge over human and implicit aspects according to [40] is partly related to the very nature of environmental issues, which require technical and often highly specialised competencies. Machine operators in forests need to learn new methods to perfect their operations and reduce environmental damages such oil and lubricant management, soil erosion control and reduced logging residues.According to [39] about 70% at wood being logged from forests is wasted owing to poor harvesting practices. Having big portions of residues may justify for more clearing of forest to meet the wood demand in expense of the unnecessary wastes leading to numerous environmental consequences. In Tanzania as for many tropical countries logging wastes are a result of poor work methods, felling and bucking techniques which result in the splitting and braking of field trees. A considerable amount of valuable wood is lost when large trees are felled across obstacles on the ground such as hollows, ridges, logs or rocks. Again poor cross cutting techniques can result in wood waste. For instance when trees are under tension they will easily split if cross cutting starts on the side which is under tension [46]. Also wood residue may result due to the workers. Studies show that the low skill of worker contributes to part of the 35–40% of the logging waste. While labour skills may have significant contribution to optimum logging productivity, crews in most plantations are normally engaged without professional training.1.2. The Forgetting Phenomenon

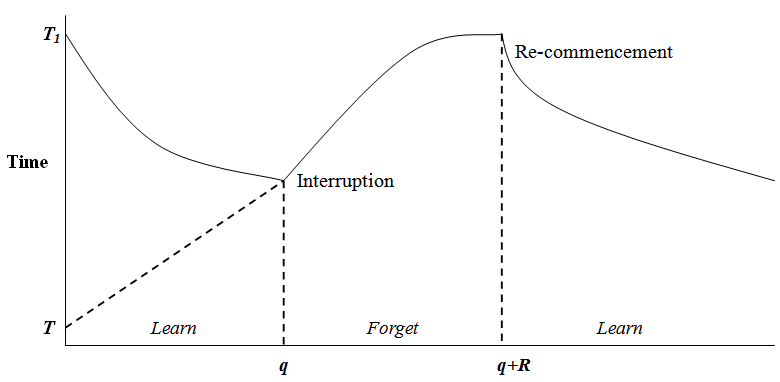

- The issue of forgetting has attracted the attention of psychologists for sometime. Just as learning increases with experience, forgetting appears to increase as a function of break from task performance. Learning is defined as the process of acquiring knowledge, abilities or values through the study or experience. On the other hand, forgetting represents the intensity of the memory [33]. Interruptions in production and use can cause a “forgetting by not doing” effect. Researchers in the area of memory decay for example [23, 41], differentiated between short term and long term memory decay. Short term memory decay occurs if the information stored is not retrieved within 30 seconds or so it will totally be forgotten. On the other hand, long-term memory (LTM) is memory that can last as little as a few days or as long as decades. It differs structurally and functionally from working memory or short-term memory, which ostensibly stores items for only around 18 seconds [32]. Long term memory is more applicable to forgetting in an organizational environment. [42] suggested that the residual memory of the participants after a break is a function of the length of the break and performance time immediately before the break took place. Therefore, forgetting is a function of the amount learned and the length of interruption [27]. [5] developed a learning-forgetting-learning model (Equation 2) in which forgetting is modelled by a curve similar to the learning curve. Their forgetting curve is also assumed to be of an exponential form.

| (2) |

= the time for the xth unit of lost experience of the forgetting curve, X = the amount of output that would have been accumulated if interruption did not occur,

= the time for the xth unit of lost experience of the forgetting curve, X = the amount of output that would have been accumulated if interruption did not occur, = the equivalent time for the first unit of the forgetting curve, andf = is the forgetting slope[43] proposed a similar approach, assuming that the same learning curve may be used to model both learning and forgetting. However, [3] articulates that a measure of the forgetting rate is uncorrelated to that of the learning rate. He challenges that forgetting is a “retrogression” along the original learning curve. Traditionally, this learn-forget-learn relationship is illustrated in figure 1 [25]. Whereby ‘R’ is the number of units that would have been produced in time assuming that there had been no break in the production process.

= the equivalent time for the first unit of the forgetting curve, andf = is the forgetting slope[43] proposed a similar approach, assuming that the same learning curve may be used to model both learning and forgetting. However, [3] articulates that a measure of the forgetting rate is uncorrelated to that of the learning rate. He challenges that forgetting is a “retrogression” along the original learning curve. Traditionally, this learn-forget-learn relationship is illustrated in figure 1 [25]. Whereby ‘R’ is the number of units that would have been produced in time assuming that there had been no break in the production process. | Figure 1. The decrease and the increase in labour due to the learning forgetting effect |

2. Material and Methods

2.1. Description of the Study Area

- This study was carried out at the Sokoine University of Agriculture Training Forest, (SUATF) Olmotonyi, in Arusha region, Tanzania which is part of the Meru Plantaiton forests. It lies between latitudes 3' 15º – 3' 18º south and longitudes 36' 41º – 36' 42º East. The main tree species grown include Cupressus lusitanica, Pinus patula, Eucalyptus sp., Grevillea robusta and Acacia sp. SUATF is on the slopes of Mount Meru, at between 1740 to 2320 m above sea level. The seasonal climate includes a consistently dry period between June and October. Rainfall patterns vary considerably, but average annual precipitation is about 1200 mm. The mean annual temperatures range between 18°C in the morning to 23°C in the afternoon. During this study, logging was carried out using common tools used in other forest plantations in Tanzania. Tree cutting was done by using two man crosscut saws. Skidding was done manually, by semi-mechanised methods using farm tractors as well as by using oxen while hauling was performed using farm tractors fitted with trailers.

2.2. Experimental Design

2.2.1. Study Groups

- The crews were divided into two groups. The first consisted of newly recruited operators (start-up crews) which were engaged during the study and the second group consisted of experienced operators (crews with experience in tree cutting). Each group was first studied in situ for up to three months, then trained and studied after which they break and studied again for the same period of time.

2.2.2. Start-up Crews

- Crews in this category were made up of individuals without prior experience in tree cutting operations. Two-man raker toothed saw were used for cutting. The crews involved aged between 38 and 42 years old. They had previously worked in the forest as casual labourers in different capacities including tree planting, log delimbing, skidding, loading and road maintenance for over four years.

2.2.3. Experienced Crews

- Crews in this category comprised individuals who had previously been engaged in tree cutting operations using the same tools for at least one year. This crew had worked in the same capacity for over 12 years. The members of this group aged between 41 and 45 years old and have been working as casual labourers and had never received any formal training pertaining tree cutting to their activities apart from on-the-job training.

2.3. Training Plan

- The training programme focused on hands-on skills based on the recommended tree cutting practices such as directional felling, proper limbing and bucking practices, appropriate ergonomic postures during tree cutting, proper use and maintenance of cutting tools and chainsaws. Accident prevention and safety precautions were also emphasized to reduce workplace accidents and risk hazards. The methods for safety and health training ranged from passive, information based techniques (e.g., lectures) to learner-centred performance-based techniques (e.g., hands on demonstrations), hypothesising that greater knowledge acquisition and more transfer of training to work setting will occur (thereby improving behaviours safety performance and reducing negative safety and health outcomes). Training incorporated specific group requirements. Swahili language was used for training the crews. After the training sessions, field work and work studies were then performed concurrently. Tree cutting productivity and costs were then determined based on the time studies techniques.

2.4. Data Collection

- Productivity studies of tree cutting operations were performed on clear felling operations. Snap-back (zero-reset) time study methods were used to collect data on productive and delay times. This method provided immediate insight into the operation being studied as observed. Selected independent variables that might affect tree cutting productivity, costs and workers’ learning rates were measured and recorded concurrently during the time studies. The selected variables measured and recorded were; stump diameter and diameter at breast height (over bark), in centimetres, tree height, in meters, number of logs bucked, log lengths, in centimetres, number of trees cut per day, and terrain slope in percentages.

2.5. Data Analysis

- Data were analyzed to establish logging production rates, costs, and learning curves. Data analysis was carried out using MINITAB 15 Computer Software, Microsoft excel spreadsheet and SPSS (Statistical Package for the Social Sciences) programs after obtaining independent, dependent and control variables.

2.5.1. Development of Learning Curves

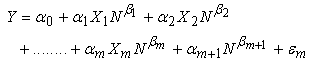

- Number of trees harvested was used as a measure of unit of production as there was no great variability in tree sizes. To account for the many variables that influence productivity in forest operations and yet simultaneously consider the effect of cumulative production on productivity, the proposed non-linear formulation (Equation 3) which is intrinsically nonlinear by [12, 11] was used.

| (3) |

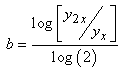

2.5.2. Modelling Learning Behaviour

- The learning behaviour for this system was considered to follow the general model as expressed in equation 1. But also the measure of ‘learning’ ‘b’ could be estimated by hand using selected data as the unit number doubled. Thus;

| (4) |

| (5) |

Therefore

Therefore | (6) |

2.5.3. Computing the Forgetting Factors

- The forgetting analysis was done on the basis that there are periods of time when the task is not done and that knowledge tends to depreciate. Therefore, the forgetting factor ‘f’ was computed from [5] learn-forget-learn model (Equation 2) on the assumption that no total forgetting had occurred and that the break length was constant as maintained in the three months periods.

2.5.4. Predictive Capability of the Models and or Predictors

- In generating the models each model and the predictors of the dependent variable were tested for significance. The first approach was to test all the possible predictor variables to the dependent variable for each sub operation per experiment for each crew. Multicollinearity was tested using Variance Inflationary Factor (VIF) to ensure that variable that are highly correlated not all of them get included in the models.

3. Results and Discussion

3.1. The Learning Curves

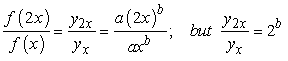

3.1.1. The Learning Curves of the Experienced Operators

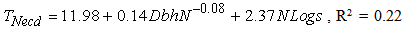

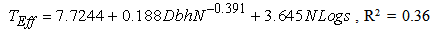

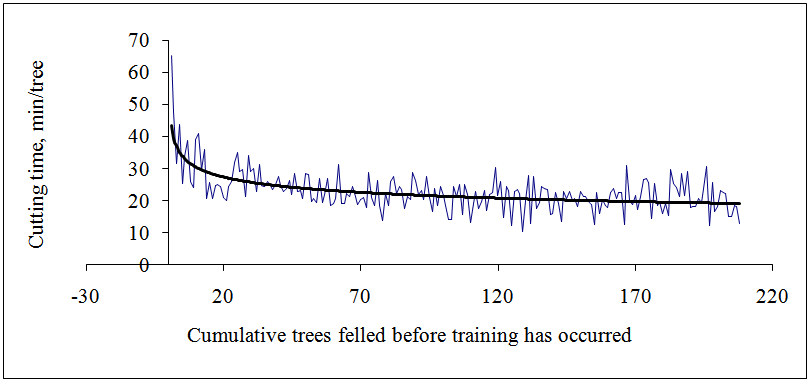

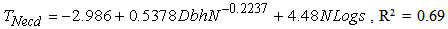

- LCs before trainingThe learning index of the experienced crosscut saw crews during their first study was found to be -0.08 (Equation 7) which gives a learning rate of about 6%. A learning curve of this crew for this experiment is shown in figure 2.

| Figure 2. A learning curve of the experienced crosscut saw crew when studied before training |

| (7) |

| (8) |

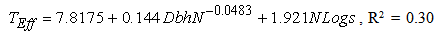

| Figure 3. A learning curve of the experienced crosscut saw crews when studied after training has occurred |

| (9) |

| (10) |

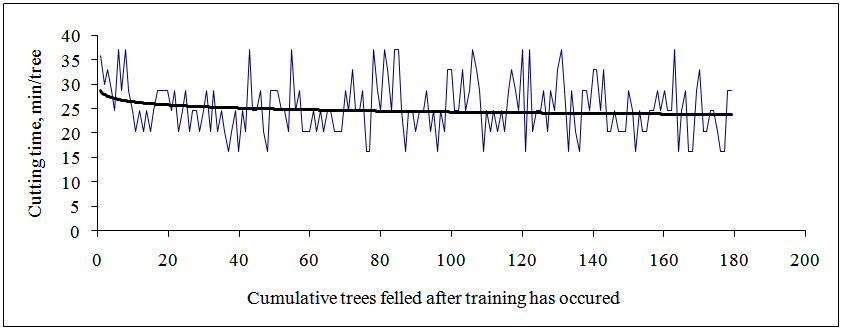

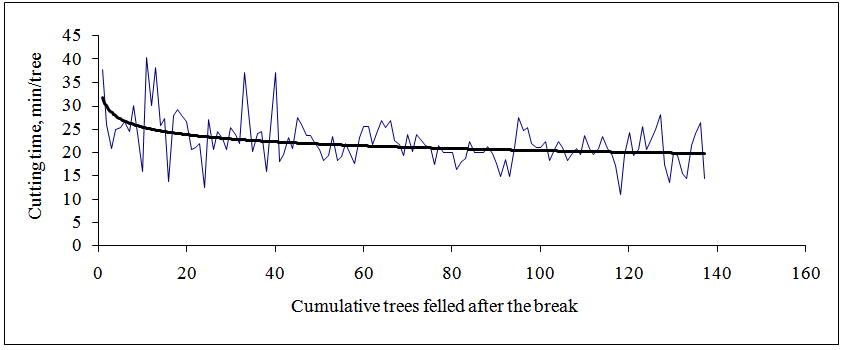

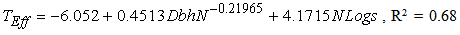

| Figure 4. A learning curve of the experienced crosscut saw crews when studied after the break |

| (11) |

| (12) |

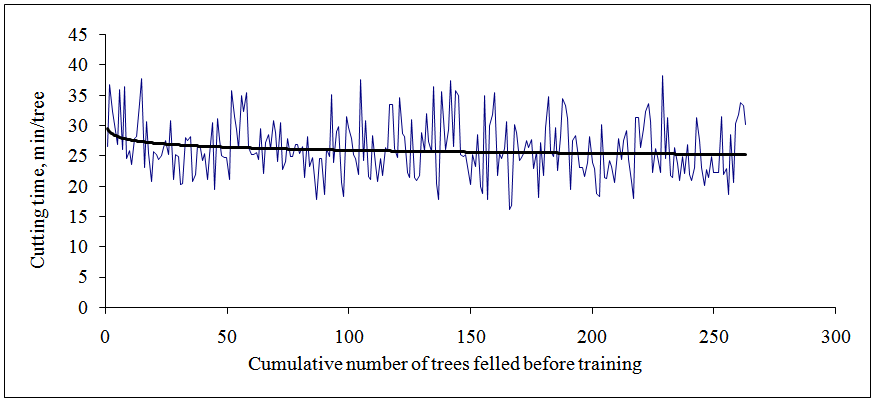

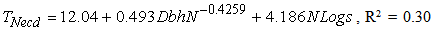

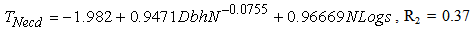

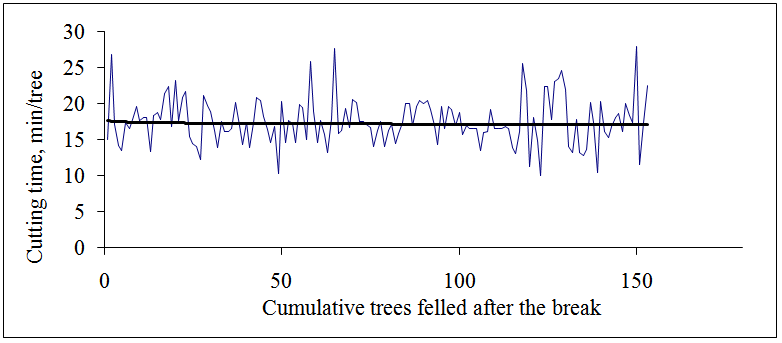

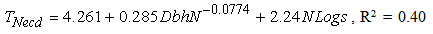

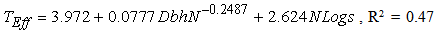

3.1.2. The Learning Curves of the Start-up Operators

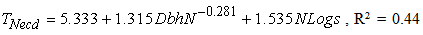

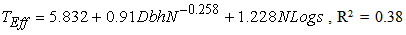

- Equation 13 shows a learning index of -0.281 corresponding to a learning rate of 18% observed before training for the start-up crosscut saw crews. A learning curve plotted from the cutting times estimated by the same equation is shown in figure 5.

| Figure 5. A learning curve of the Start-up crosscut saw crews when studied before training |

| (13) |

| (14) |

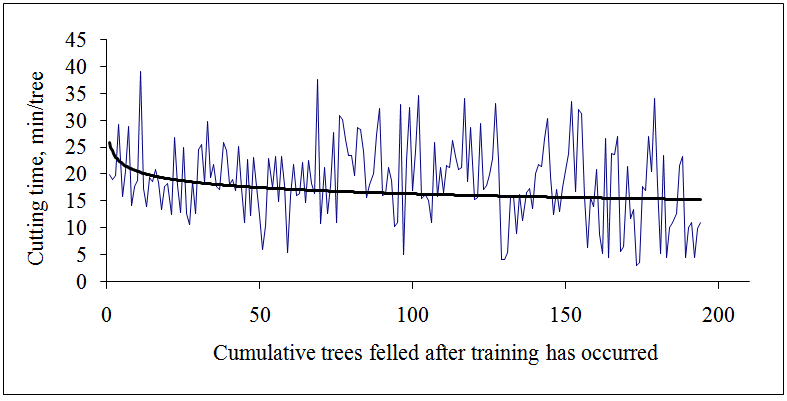

| Figure 6. A learning curve of the start-up crosscut saw crews when studied after the training |

| (15) |

| (16) |

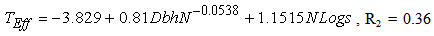

| Figure 7. A learning curve of the Start-up crosscut saw crews when studied after the break |

| (17) |

| (18) |

3.2. The Forgetting Factors

- The forgetting function was determined for each crew category. Results show that both crews showed some level of knowledge depreciation as could be reflected by their productivity levels. For example the experienced crew had a forgetting factor of 9.4% while the start-up crew had 19% forgetting factor. The learning curves after the break showed relatively steeper slopes at the beginning followed with a working plateau indicating that crews could attain some levels of their knowledge after some practice. [5] argues that the learning-forgetting curve is affected in the following two ways. Firstly, the output is quickly reduced, but it is gradually stabilized. Lastly, the speed and proportion of forgetting decreases if the task finishes before an interruption. These observations imply that crews must be training even for a short periods before resuming operations although scheduling of short trainings on site even if there are no job interruptions could also maintain productivity levels by increasing the learning rates. This is because more recent studies argue that forgetting occurs even under conditions of continuous production [45].Generally, the forgetting factor levels observed in this study are relatively lower as compared to finding from other industries which have observed an average of 25% forgetting factor. This is probably due to the nature of the training that was provided and or the length of the break. It is not known whether three months break which was taken to reflect the average forest operation interruptions in Tanzanian condition is the optimum time to measure the maximum knowledge retention by forest workers. But also forgetting levels can be a function of other factors other than the length of the interruption. For example according to [27] the curve of forgetting also depends on the quantity of things learned and the interruptions between them. Regardless of the shape of the curve, there is a proportion of forgetting which starts when workers stop doing the task learned before. Furthermore, the speed with which something is forgotten depends on different factors like the difficulty of the subject, its representation or physiological factors.

4. Conclusions

- The learning curves and forgetting functions of the tree cutting crosscut saw operators in forest plantations have been established. These facts are important tools in panning for forest harvesting operations for ensuring high performance and environmental sustainability. The general observation showed that start up crews showed a steeper curve on commencement of the operations. The higher rate observed for the start-up operators may imply that experienced operators may have reached a working plateau which requires re-tooling measures. Therefore training is imperative for the operators if the sector is to realise; high production rate, low operating costs and reduced environmental damage such disturbances of the forest soils and reduced logging residues that may arise from improper practises of the working crews. Observations on the forgetting factors imply that crews must be training even for a short periods before resuming operations. Meanwhile scheduling of short trainings on site even if there are no job interruptions could also maintain productivity levels by increasing the learning rates for sustainable forestry. As learning, and particularly learning at work, becomes essential, forest workers must be subjected into a continuous assessment because the needs for current work and needs for learning can be contradictory. With the growing global interest reducing greenhouse gas emissions from forest ecosystems the need to observe environmental standards cannot be over-emphasised. Therefore environmental protection initiatives such as introduction of environmentally friendly forest harvesting technologies would require regular establishment of learning curves as necessary decision tool for logging and environmental managers in scheduling forest activities.

ACKNOWLEDGEMENTS

- This paper has been produced with the financial assistance of the Norwegian Government through NORAD to the PANTIL Programme at Sokoine University of Agriculture. The views expressed in this document are the sole responsibility of the authors and do not necessarily represent the views of the institutions involved.

Note

- 1. Wright's original model was based on the cumulative average time (i.e., the total time required to produce the first N items, divided by N). Later Crawford (1944) suggested that the unit model specified in the equation would be more reasonable for certain types of production processes. This later model seems generally more applicable to forest operations than Wright's cumulative-average model [10].

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML