-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Environmental Engineering

p-ISSN: 2166-4633 e-ISSN: 2166-465X

2013; 3(6): 267-272

doi:10.5923/j.ajee.20130306.01

Roadmap for Development of Waste-to Energy Facility in Saudi Arabia

Omar K. M. Ouda1, Huseyin M. Cekirge2

1Department of Civil Engineering, Prince Mohamed Bin Fahd University, Al Khobar, KSA

2Department of Mechanical Engineering, Prince Mohamed Bin Fahd University, Al Khobar, KSA

Correspondence to: Omar K. M. Ouda, Department of Civil Engineering, Prince Mohamed Bin Fahd University, Al Khobar, KSA.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The Kingdom of Saudi Arabia (KSA) has experienced through rapid population, urbanization, and social-economic growth over the last four decades. KSA population increased from about 7 million in 197 0to more than 27 in 2010. This situation resulted in a massive increase in Municipal Solid Waste (MSA) generation. Currently, KSA generates 14 million tons of MSW annually with an average 1.4 kg/capita/day. The Kingdom is proposing most impressive plan towards renewable energy utilization on the planet including large scale Waste-to-Energy (WTE) facilities. This research presents roadmap for development of WTE facility in Saudi Arabia and reviews the potential benefits to Saudi economy and environment. The roadmap facility successful development and operation of a WTE facility in Saudi Arabia and includes detailed description of all needed steps towards this goal. A WTE facility will have substantial positive impacts on Saudi economy characterized by new energy sources, jobs and training opportunity, and land saving. The environmental benefits include reduction of global warming gas emission and leachate production, land saving, air quality improvement, and soil and groundwater protection.

Keywords: Saudi Arabia, Waste-to-Energy, Municipal Solid Waste, Renewable Energy

Cite this paper: Omar K. M. Ouda, Huseyin M. Cekirge, Roadmap for Development of Waste-to Energy Facility in Saudi Arabia, American Journal of Environmental Engineering, Vol. 3 No. 6, 2013, pp. 267-272. doi: 10.5923/j.ajee.20130306.01.

Article Outline

1. Introduction

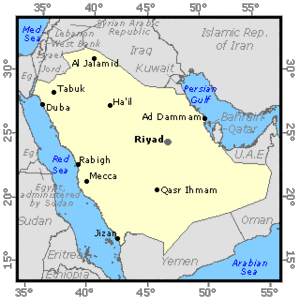

- The Kingdom of Saudi Arabia (KSA) lies between 16o 22’ and 32o 14’ North Latitudes and 34o 29’ and 55o 40’ East Longitudes as shown in Figure 1. KSA population increased from 7 millions to 27 millions in the last 40 years with annual population growth rate of 3.4%[1-5]. There are seven major cities in the KSA with a population of one million or more: Riyadh, the capital, with 5.2 million, Jeddah with 3.4 million, the Dammam area with 2.0 million, Makka with 1.7 million, Madinah with 1.2 million, Al-Hassa with 1.1 million, and Al-Taif with 1.0 million[1-3]. These cities are potential hosts for the WTE projects. KSA is currently the largest crude oil producer in the world and holds the largest reserve. The country has been going through massive industrial and construction development during the last four decades. The development comes with substantial growth of standards of living, immigration from rural to urban areas and international migrant workers; and resulted in rapid growth of municipal solid waste (MSW) generation[5-7].Municipalities are responsible for MSW management in KSA[8]. The low cost of landfills makes large MSW recycling program implementation unachievable at the time being[7]. The only large scale recycling system currently exists is the trash sorters collection of metals and cardboards from garbage containers[7]. Initiatives for MSW recycling are in place in the Eastern Province of KSA. The results of these initiatives are not documented. KSA currently generates 14 million tonnes of MSW per year with an average of 1.4 kg/capita/day[7,9]. The landfill requirement is about 2.8 million m2 per year[7]. The MSW wastes of KSA include 37% organic materials, 28.5% paper, 5.2% plastics, 8.3% mineral, 4.6% glass, 8% wood, 6.4% textile, and 2% others[2,9]. The huge MSW annual quantity and its high energy contents show significant potential for WTE facilities in KSA. In this direction, KSA is proposing the most impressive plan towards renewable energy utilization on the planet that includes WTE facilities. The two decades plan includes Hybrid Feed-in-Tariff program and productions of up to fifty four thousand Megawatt (MW) from renewable energy. The first round of bidding will take place in 2013 includes 200 MW of Geothermal and WTE facilities[10]. In this paper, we present roadmap for development of WTE facility in Saudi Arabia and an evaluation methodology for the potential benefits to Saudi economical development and environment.

| Figure 1. Saudi Arabia Map.[5] |

2. WTE Technology

- The most widely used and proven WTE is the process of producing energy in the form of heat and/or electricity from waste sources combustion[11-14]. There are a number of developed and emerging technologies that are able to produce energy from waste without direct combustion. These Technologies produce combustible fuels. Typical combustible fuel includes methanol, ethanol, synthetic fuels, and methane[13]. Many of these technologies have potential to produce more electric power from the same amount of fuel than would be possible by direct combustion if the cost processing is not considered[12,15, 16]. This is mainly due to the separation of corrosive components (ash) from the converted fuel, thereby, allowing higher combustion temperatures in boilers, gas turbines, internal combustion engines, fuel cells[17]. WTE technologies can be classified as thermal and non-thermal. Thermal technology includes incineration, gasification, thermal de-polymerization, pyrolysis, and plasma arc gasification[17]. Incineration recovers energy in the form of electricity, district heating, steam, district cooling or any combination. Gasification produces combustible gas, hydrogen, synthetic fuels. Thermal de-polymerization generate synthetic crude oil, which can be further refined. Pyrolysis produces combustible tar/bio-oil and chars. Plasma arc gasification or plasma gasification process produces rich syngas including hydrogen and carbon monoxide usable for fuel cells or generating electricity to drive the plasma arcs. Non-thermal technology includes anaerobic digestion and fermentation process. Anaerobic digestion produces biogas rich in methane. Fermentation process generates products such as ethanol, lactic acid, and hydrogen[12,13]. The primary and most widely used WTE technology in the world are incineration and gasification. Over 600 WTE facilities are in place worldwide which combust about 130 million tonnes of MSW, producing electricity and stream for district heating and recovered metals for recycling[13,18]. In the United States, there are 80 WTE facilities burning 26.3 million tonnes of MSW (7.4% of US total MSW generation) and have power generation capacity of 2700 MW[19]. Incineration is the dominant technology in US where two main types are being used: mass-burn plants and derived refused-drive fuel (RDF) plants. Mass-burn plants burn the MSW in large furnaces as collected while RDF plants shred the MSW into small pieces before combustion[19]. The incineration technology is very well developed, regulated, and widely implemented both in developed and developing countries. This fact will ease the implementation and access process of WTE technology to Saudi cities. The incineration technologies shall be implemented in Saudi cities.

3. Roadmap towards WTE Facility

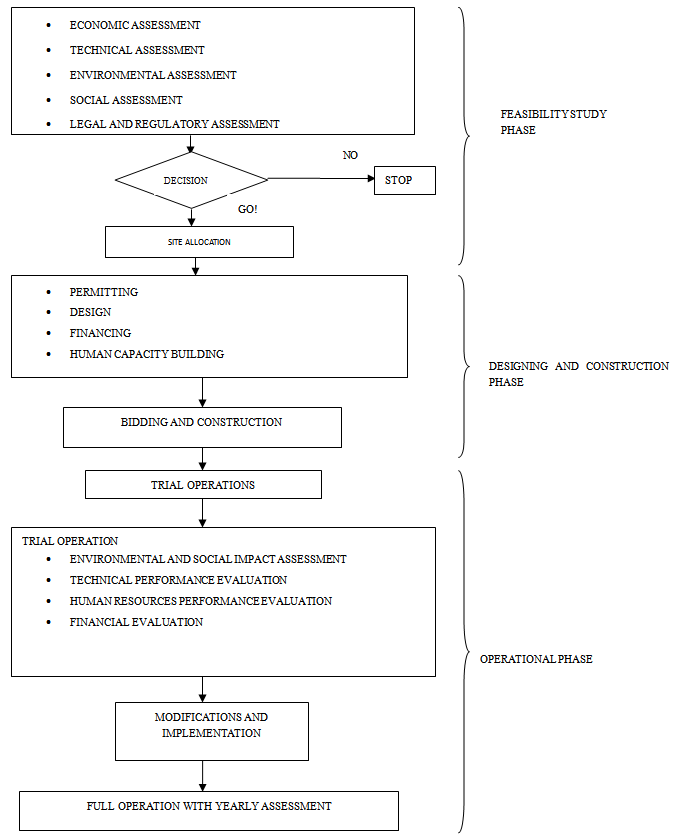

- Saudi Arabia has taken the decision to invest in renewable energy including development of WTE facility. This is an important step in the right direction and may change the MSW management in the kingdom. Construction of WTE facility requires significant investment from the community. Before embarking on a project of this magnitude, clear roadmap towards the final goal of constructing WTE facility is extremely needed. The proposed roadmap consists of three distinctive phases: Feasibility Study phase, Design and Construction phase, and Operational phase as shown in Figure 2.

| Figure 2. Proposed Roadmap for Saudi Arabia WTE Facility |

3.1. Feasibility Study Phase

- Feasibility study is the first step towards construction of WTE facility. The project scope and objectives should be completely identified at this stage. The purpose of the feasibility study (FS) is to evaluate the economical, technical, environmental, social, and legal feasibility of developing a WTE facility project.

3.1.1. Economical Assessment

- The economical feasibility includes comprehensive cash flow analysis for the project design and construction cost, annual operation and maintenance cost, and annual revenue. Potential sources for cost and revenue data include international financial institutions, NGO’s, countries with recent WTE experience, international renewable energy consultants and developers, and published literature. Financial analysis techniques such as payback period, present worth, and internal rate of return shall be conducted for alternative scenarios. The economical assessment shall provide a comprehensive view of all financial requirements of the projects and potential revenue.

3.1.2. Technical Assessment

- The technical assessment forecasts MSW quantities and compositions and reviews the WTE state-of-art technology. Various alternative WTE technologies shall be compared with each other in the aspects of their advantages/ disadvantages and the most suitable-efficient WTE technology shall be determined. This will only be a conceptual design, but detailed enough to produce a reasonably accurate cost estimate, and project schedule. At this stage, evaluation of the generation of heat/steam and the cogeneration potential (whether to generate both heat and electricity) to optimize the energy yield will be estimated. The technical feasibility identifies the: ● Amount of waste after recycling in the future,● Suitability of waste for thermal treatment,● Determination of the appropriate and efficient technology,● Local regional availability of selected technology and,● Determination of expected plant life.

3.1.3. Environmental Assessment

- Environmental assessment shall be prepared based on the chosen WTE technology. The environmental assessment includes collection of environmental baseline data such as landscape, soil quality, groundwater and surface quality, air quality, ecosystem of the surrounding area. Potential for soil, air, groundwater, surface water, and noise pollution shall be identified. Set of mitigation measures shall be developed and evaluated. Cost of mitigation measures and mitigation measures implementation schedule shall be determined and incorporated in the project cost and schedule. The chief objective of this task is to ensure that the proposed facility will comply with environmental standards of Saudi Presidency of Meteorology and Environment, the World Bank emissions criteria, the European Union’s environmental criteria, and the Kyoto Protocol Annex 1.

3.1.4. Social Assessment

- Social Assessment is extremely critical for successful completion of the project. Public acceptance and support will facilitate collection and recycling of the MSW and construction of the facility. Public consultation sessions shall be conducted as early as possible in the feasibility study phase. Attendance list shall include all sectors of community including male, female, public officials, NGOs, teachers, religious scholars, students, and others. During the session, the project idea should be clearly described. The potential project, social, economical, and environmental benefits and impacts shall be outlined. Public feedback and concerns shall be documented in the social assessment reports and incorporated in the project final design.

3.1.5. Legal Assessment

- In legal and regulatory assessment, the project team reviews pertinent local regulatory and legal framework. The review shall reflect the latest developments in the Renewable Energy and MSW related laws of local permitting and licensing requirements. Local building codes, local right-of-way, and zoning ordinances should be taken into account and reviewed. All problematic or lengthy permitting and lengthy licensing requirements need to be identified at this stage. Project team should meet with local authority officials from ministry of Water and Electricity, Municipality, Presidency of Meteorology and Environment and Ministry of Transportation. The meeting aims to introduce the project scope and objective, and gathers information about their legal and technical requirements and guidelines.

3.1.6. Findings and Site Allocation

- The feasibility study paramount is the Go/No Go decision. The decision shall be based on multi-criteria analysis of feasibility study findings. If a Go decision is taken, the next step is to scout the project site. The project site scouting shall consider existing landfill locations, MSW collection routes, and electrical grid and feed in point, local building codes, local right-of-way, and zoning ordinances.

3.2. Designing and Construction Phase

- Most of the capital investment will be spent during this phase. Since WTE facility has never previously been designed and constructed in KSA and the facility includes high technology components,Design-Build-Operate-Transfer contracts could be the right option to develop the first few projects. Technology is available and there are many international companies with strong experience in this field. The local authority shall request international companies to form joint venture with local companies to bid on the project. Joint venture will enhance technology transfer and ability of local capacity building for WTE facility design, construction and operation. Applications for the lengthy permitting and licensing have to start as early as possible. Design team has to choose the most suitable WTE technology and produce the plant-lay out. It should also design all project equipments including but not limited to the water treatment system, boilers, large pipes and high pressure steam piping, steam turbine, condenser, mechanical and electrical balance of plant, instrumentation and controls, and electrical interconnection etc. Measures to meet environmental requirements and public concerns have to be incorporated in the detailed design. As a stand-alone bidding document, the project team shall prepare a set of bidding specifications to interested parties: (a) Project Scope and Definition, (b) Technical Specifications based on the Preliminary Design and Environmental Social Impact Assessment, and (c) Draft Commercial Terms and Conditions of the Technical Specifications should be divided into sections covering; Major Mechanical, Electrical Equipment, Civil Works and Construction, Plant Narrative, Plant Performance Requirements, Start-up and Commissioning, and Project Implementation Schedule. The Commercial Terms and Conditions should include the Penalties and Liquidated Damages which would apply in case of non-compliance with the Performance and Schedule requirements. Training needs should be identified and a training program should be developed that includes a detailed cost estimate and schedule and detailed construction schedule. Cost estimation should include detailed breakdown of all major components of the projects including the training and human capacity building needs. The cost of land acquisition and cost of financing should be determined and be added to the cost estimate. The project team shall follow up with the financial institutions that have been already contacted during the feasibility study phase for its own financing strategies. The potential for private sector participation in WTE projects shall be discussed and evaluated based on the result of the feasibility study. The developer shall prepare and deliver a substantive and comprehensive final design report of all work performed. Developers shall construct the project as per design documents and WTE facility construction best practices.

3.3. Operational Phase

- The operational phase shall be started with 6 months trail operation. During the trail operation, the environmental, social, technical, human resources and financial performance should be carefully monitored and evaluated. Modifications and development plan shall be prepared and implemented to overcome any shortcomings in the project performance.

4. Benefits of WTE Projects

- Literature extensively documents the significant benefits of WTE projects on economy and environment worldwide. In this section, we will present the potential benefits of WTE facility in the KSA economy and environment.

4.1. Economical Benefits

- WTE facility is a substantial renewable energy source. In 2004, WTE industry in the US produced much more energy that all other renewable energy sources with the exception of hydropower and geothermal sources[20]. A metric ton of MSW produced almost an equivalent to the electricity production of one barrel of oil[19]. WTE plant will burn and reduce the volume of the MSW by 90%, which would otherwise be deposited in the landfills. Such volumetric reduction of MSW would significantly extend the remaining life of the landfills and reduce the amount of top soil required to cover the fresh MSW after each dumping. Implementation of WTE technology will result in increasing recycling activities. US communities with WTE facility had an average recycling rate of 21% versus the country rate of 17%[19]. During the construction of the WTE facility, new jobs in construction, technical services/engineering and landscaping, are likely to be created for two-three years. When the facility is in operation, it will require about a number of full-time operations and maintenance personnel who will require special training.

4.2. Environmental Benefits

- US EPA considers WTE technology as a renewable source of electricity with less environmental impacts than almost any other sources[21]. Modern WTE facilities do comply with the World Bank's strictest emissions criteria which is almost identical to the EU air emissions standards. Modern incineration plants are so clean that many times more dioxin is now released from home fireplaces and backyard barbecues than from incineration. WTE reduces the amount of MSW deposited at landfill sites[22.23]; typically about 90% volume reduction and 80% mass reduction are achieved depending upon composition and degree of recovery of materials such as metals from the ash for recycling. Incineration also minimizes leachate and methane formation and door emissions. Methane is 21 times more detrimental than carbon dioxide from the global warming perspective [19]. Many of landfills in KSA are mature landfills in that substantial amount of volume has already been used by municipal waste deposits. With additional dumping, the amount of undesirable by-products such as leachate, municipal waste sludge, renegade methane and odor emissions and all health hazards associated with these will keep increasing. More specifically, by employing a WTE facility at these landfill sites, the following potential environmental problems will be mitigated;● The existing leachate treatment system has a fixed membrane capacity which will be overused with the continued dumping of MSW. This in turn would increase the likelihood of groundwater contamination and the associated health risks.● If the MSW is not burnt as collected, it would keep creating waste sludge in the landfill basin which is very hard to get rid of once formed. Municipal waste sludge cannot be incinerated in self-sustaining mode. Costly mechanical or thermal pretreatment systems would be required to incinerate the sludge.● With each load of MSW deposited into landfills, additional methane would automatically be generated in six months to a year time frame. Even though the existing landfill-gas-to-energy plants suck the landfill gas out of the deposited MSW piles, the gas collection efficiency is limited to about 80% and drops significantly as the landfill expands laterally. Therefore as the landfills expand renegade methane emissions will also increase. Methane is a greenhouse gas and 21 times more hazardous than its combustion product, carbon dioxide.● Landfills cannot be expanded indefinitely; since the surroundings of large lots of land which can be used for habitation, cultivation, commerce or recreation.

5. Conclusions and Recommendations

- KSA has been going through massive industrial and constructional development during the last four decades. The development came with substantial growth of standards of living, immigration from rural to urban areas and international migrant workers. This situation resulted in rapid growth of municipal solid waste (MSW) generation. KSA generated 14 Million tonnes of MSW annually with an average kg/capita/day. KSA is proposing the most impressive plan towards renewable energy utilization on the planet including large scale WTE facilities. In this paper we presented roadmap for development of WTE Facility in Saudi Arabia and the potential benefits to Saudi Arabian economy and environment. The roadmap consists of three phases: feasibility study phase, designing and construction phase, and operational phase. Procedures were provided for successful implementation of each phase under the consideration of the KSA special institutional and regulatory establishment. A WTE facility will have a substantial positive impacts on Saudi economy characterised by new energy sources, jobs and training opportunity, and land saving. The environmental benefits include reduction of global warming gas emission, leachate production, land saving, air quality improvement and soil and groundwater protection. In conclusion, WTE technology is highly recommended and needed in the Kingdom of Saudi for its significant economical and environmental benefits. The proposed roadmap supports the initiative of renewable WTE plans and may guide the development of WTE facility in Saudi Arabia.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML