-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Environmental Engineering

p-ISSN: 2166-4633 e-ISSN: 2166-465X

2012; 2(1): 12-18

doi: 10.5923/j.ajee.20120201.03

Decolorization of Anaerobically Digested Molasses Spentwash by Coagulation

Mrityunjay Singh Chauhan 1, Anil Kumar Dikshit 2, 3, 4

1Department of Civil Engineering, Maulana Azad National Institute of Technology, Bhopal, 462051, India

2Centre for Environmental Science and Engineering, Indian Institute of Technology Bombay, Powai, Mumbai, 400076, India

3School of Civil Engineering, Survey and Construction, University of KwaZulu-Natal, Durban, 4041, South Africa

44School of Civil and Environmental Engineering, Nanyang Technological University, 639798, Singapore

Correspondence to: Anil Kumar Dikshit , Centre for Environmental Science and Engineering, Indian Institute of Technology Bombay, Powai, Mumbai, 400076, India.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Treatment of molasses spentwash has always posed a challenge to the environmental engineers. Problem becomes more difficult in the countries like India where more harsh environmental parameters of spentwash on one hand and limitation of treatment cost on the other is crude reality. Inability to grow micro-organisms in undiluted spentwash further limits the options. In this work, various options of coagulation were tried as primary treatment to make spentwash fit for further biological treatment without dilution. Poly aluminium chloride(PAC) was found to be the best coagulant.

Keywords: Coagulation, Decolorization, Distillery, Spentwash

Cite this paper: Mrityunjay Singh Chauhan , Anil Kumar Dikshit , "Decolorization of Anaerobically Digested Molasses Spentwash by Coagulation", American Journal of Environmental Engineering, Vol. 2 No. 1, 2012, pp. 12-18. doi: 10.5923/j.ajee.20120201.03.

Article Outline

1. Introduction

- There are about 300 distilleries in India, producing about 2.75 billion litres of alcohol annually[1]. India is the fourth largest producer of ethanol in the world and the second largest in Asia. Though, the alcohol production from starchy material is also practiced on a very limited scale, most of the Indian distilleries use sugarcane molasses as raw material. About 4-10 kg of molasses is required for production of one litre of alcohol[2]. Apart from its use for beverage, medicinal, pharmaceutical and flavouring, alcohol constitutes the feedstock for large number of organic chemicals, which are used in manufacturing a wide variety of intermediates, drugs, rubber, pesticides, solvents etc.[3]. Distillery ranks as the top most industry among the list of 17 heavily polluting industries identified by Ministry of Environment & Forests, Govt. of India, and are covered under Central Action Plan. Distillery spentwash is not only high on organic and inorganic loading, but also has dark brown colour even after industry standard treatment by anaerobic digestion/ bio-methanation. The anaerobically treated spentwash does not meet Central Pollution Control Board(CPCB) standards of discharge into streams or land application. Groundwater colorization is growing concern for areas having land application of distillery spentwash. Spentwash is toxic to aquatic organisms as LC50 value for distillery spentwash was found to be 0.5% for fresh water fish Cyprinus carpio var. Communis[4]. It behaves muchmore hazardously when disposed into water bodies, since it may result in the complete depletion of dissolved oxygen and aquatic life will be destroyed[5].Rao et al. conducted laboratory scale studies on methods of removing color from distillery wastewater. Aluminium sulfate and ferric chloride were found very effective in color removal from anaerobically treated diluted molasses and distillery wastes[6]. Color removal of molasses based distillery effluent was studied by Migo et al[7] using a commercial inorganic flocculent, a polymer of ferric hydroxyl sulfate with a chemical formula of [Fe2(OH)n(SO4)3-n/2]m. For decolorization of anaerobically digested spentwash combined chemical and biological methods were also tried[8]. The first treatment included calcium oxide and hydrogen peroxide. This was followed by second treatment, which involved hydrogen peroxide and microbes at 144 hrs incubation. Goto et al.[9] reported super critical water oxidation(SCWO) of distillery wastewater for removal of its color. In this process, oxidation reaction took place in water above its critical point(647oK, 22.1 MPa). Experiments were carried out with different amounts of biopolymer chitosan. This gave decolorization of the order of 94% along with 93% reduction in COD. Ten times diluted distillery wastewater(COD as 2800 mg/L) was used for experimentation[10]. Ozonation of distillery(yeast fermented beer) waste was also tried to evaluate the process in terms of organic matter removal and decolorization efficiencies. Ozone generation system used was based on the production of ozone from the reaction of oxygen with UV light[11]. Pikaev et al[12] carried out study on combined electron beam and coagulation method for treatment of molasses based distillery effluent. Nandy et al. did their study on a bio-methanation system as pre-treatment option comprising anaerobic fixed film reactors. This wascombined with subsequent concentration through Multiple Effect Evaporators(MEE), and concentrated effluent was used for bio-composting of press-mud for production of bio-manure[13]. Color removal from biologically pre-treated molasses spentwash(COD 4580 ± 100 mg/L) by chemical oxidation through ozone was investigated by Pena et al[14]. Electrochemical treatment of digested spentwash was carried out for removal of its color. Power consumption was reported as 1.13-4.93 kWh/kg of COD[15]. Coca et al[16] studied efficiency of ozonation and effect of various operating parameters when it was used for decolorization of beet molasses fermentation wastewater. Performance of Fenton oxidation process was tested for decolorization of biologically treated effluent of baker’s yeast industry[17]. Mane et al[18] studied application of chemically treated bagasse for treatment of distillery wastewater. A hybrid nanofiltration(NF) and reverse osmosis(RO) pilot plant was used to remove colour of the distillery wastewater[19].These options were tried either on diluted and synthetic wastewater or they are energy and cost intensive. Coagulation is a very effective method of decolourisation and removal of solids from the wastewater. There are numerous references available in literature about use of common coagulants for industrial wastewater treatment. This paper addresses the pre-treatment in the form of cost effective option of coagulation of anaerobically digested molasses spentwash(ADMS) so that biological treatment can be given to it without any dilution.

2. Materials and Methods

2.1. Wastewater

- The study has been carried out on actual wastewater collected from a nearby 30 KLD distillery, producing rectified sprit using sugarcane molasses as raw material. Anaerobically digested molasses spentwash(ADMS) was collected from the overflow of the anaerobic digester and was brought to the CESE, IIT Bombay and was stored at 4oC in cold room till experimentation.

2.2. Colour Measurement

- Intensity of colour was measured in terms of absorbance at 475 nm. Samples were diluted in 1 M phosphate buffer to maintain pH of 7. Samples were centrifuged at 10,000 rpm for 10 minutes prior to absorbance determination, for eliminating hindrance due to suspended particulates in the sample. After that, the supernatant was diluted 100 times and the absorbance was measured using Thermo Spectronic visible spectrophotometer(Model Helios Epsilon, USA). Reduction in colour was estimated in terms of reduction in absorbance with reference to that of the control(original ADMS).

2.3. COD

- COD was measured by closed reflux method using HACH COD digester(Model DRB 200, USA) as given in Standard Methods(APHA-AWWA-WEF, 2005). Samples were suitably diluted with distilled water.

2.4. Other Parameters

- Tests for other parameters were carried out as per Standard Methods[20] for characterization of the ADMS and treated ADMS samples.

2.5. Coagulation Studies

- In the present study, commonly available coagulants viz. ferrous sulphate, ferric sulphate, ferric chloride, calcium chloride, calcium oxide, calcium hydroxide, alum, potash alum and poly aluminium chloride were examined for their efficiency of decolourisation and COD reduction. To simulate field conditions, all the coagulants used were of laboratory grade, procured from local market.Jar tests were performed on undiluted ADMS samples with coagulants. VELP Scientifica jar test apparatus(Model JLT6, France) was used. Six one litre samples were taken in six one litre beakers and flash mixed at 100 rpm for 2 minutes followed by slow mixing at 20 rpm for 30 minutes. After appropriate settling time varying from 1 to 8 hours, the supernatant samples were drawn for further analysis. First, the optimum pH was found on the basis of reduction in absorbance in the pH range 2 to 12. Lime or HCl was used for pH correction. At optimum pH, optimum dose was found out by varying dose of coagulant over a wide range.

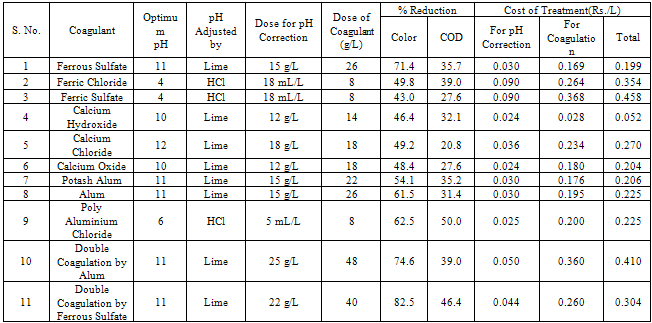

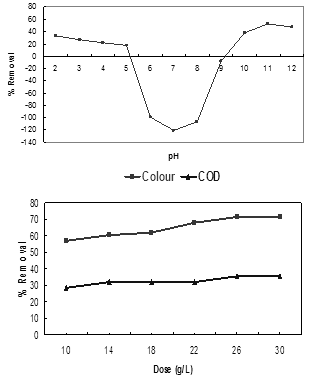

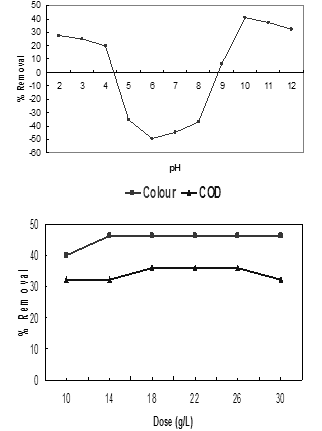

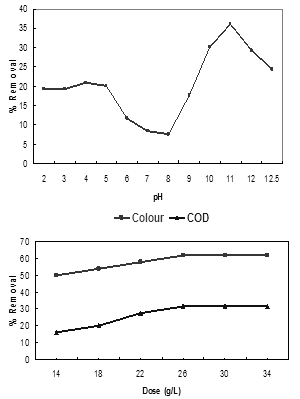

| Figure 1. Colour Removal by Coagulation with Ferrous Sulfate |

3. Results and Discussion

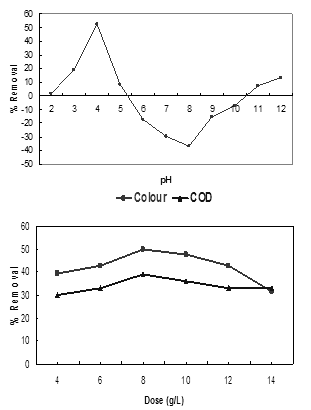

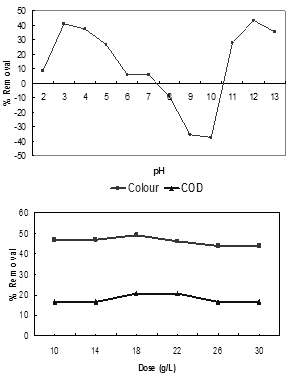

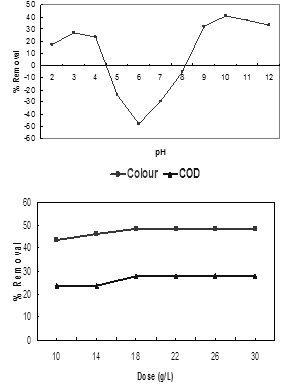

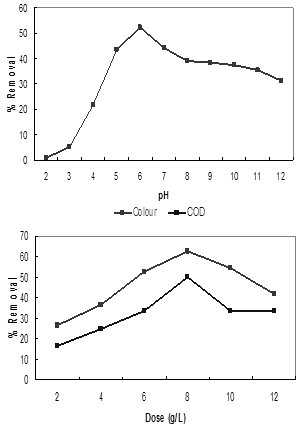

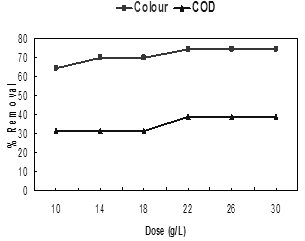

- Results of pH and dose optimization for various coagulants and spectra of 100 times diluted ADMS and coagulant treated ADMS are shown in following sections. The optimum pH for ferrous sulfate was 11 and its dose of 26 g/L gave reduction of 71% in colour and 36% in COD(Figure 1). Ferric chloride(Figure 2) is effective coagulant, widely reported in literature as this gives Fe3+ ions. Ferric chloride worked best at pH of 4, giving 50% colour and 39% COD removal at 8 g/L. Figure 3 shows optimum pH for ferric sulfate which was also 4 and addition of 8 g/L could achieve 43% reduction in colour with 28% reduction in COD. However, both the ferric salts were found to impart greenish colour to the treated sample. Even at smaller doses, although absorbance at standard wavelength(475 nm) was reduced but overall colour of the spentwash was worse than control.

| Figure 2. Colour and COD Removal by Coagulation with Ferric Chloride |

| Figure 3. Colour and COD Removal by Coagulation with Ferric Sulfate |

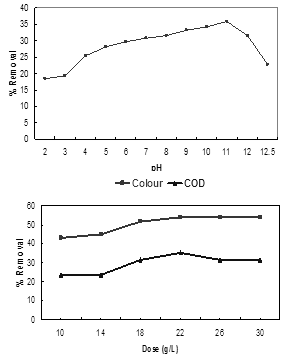

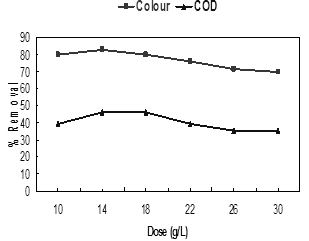

| Figure 4. Colour and COD Removal by Coagulation with Calcium Hydroxide |

| Figure 5. Colour and COD Removals by Coagulation with Calcium Chloride |

| Figure 6. Colour Removal by Coagulation with Calcium Oxide |

| Figure 7. Colour and COD Removal by Coagulation with Potash Alum |

| Figure 8. Colour and COD Removal by Coagulation with Alum |

| Figure 9. Colour and COD Removal by Coagulation with PAC |

| Figure 10. Colour and COD Removals at Different Doses of Alum at Second Stage in Double Coagulation |

| Figure 11. Colour and COD Removals at Different Doses of Ferrous Sulfate at Second Stage in Double Coagulation |

|

5. Conclusions

- Coagulation of anaerobically digested molasses spentwash(ADMS) with poly aluminium chloride(PAC) was very promising pre-treatment option which not only removed organic loading and colour of the ADMS considerably but made it suitable for biological treatment also. Further studies on rendering the fungal treatment to such primarily treated ADMS without any dilution are under the way and are showing promising results.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML