-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Biomedical Engineering

p-ISSN: 2163-1050 e-ISSN: 2163-1077

2015; 5(3): 94-99

doi:10.5923/j.ajbe.20150503.03

Evaluation of the Protective Padding in Professional Ice Hockey Gloves

Constance Maglaras1, Antonio Valdevit1, Martin A. Posner2

1Department of Chemistry Chemical Biology and Biomedical Engineering, Stevens Institute of Technology, Hoboken, U.S.A

2Department of Orthopaedic Surgery, NYU – Hospital for Joint Diseases, New York, U.S.A

Correspondence to: Constance Maglaras, Department of Chemistry Chemical Biology and Biomedical Engineering, Stevens Institute of Technology, Hoboken, U.S.A.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

The objectives of this study were to determine the energy forces on the padded surfaces of professional hockey gloves from pucks striking them at high speeds and the effectiveness of the gloves to dissipate those forces. Hockey gloves used by players in the National Hockey League (NHL) were studied. The impact force of a puck striking their padded dorsal surfaces at high speed was simulated using a gravity based drop system, and the forces measured using thin film flexible force sensors. One sensor was positioned on the outside of the glove on its dorsal surface directly over the distal portion of the index metacarpal, and two were positioned inside the glove, one over that same metacarpal and the other more distal over the proximal phalanx of the index finger. Impact forces on each glove were analyzed with respect to time lag; the time difference from the initial impact force at the exterior sensor and the peak force transmitted at each internal sensor location. No differences in time lag or force transmission were observed over the index finger metacarpal or proximal phalanx regardless of variations in the padding configurations that sometimes included thin polyethylene shell inserts. However, differences were noted when the types of padding material were studied. Single and dual density foam materials were significantly more effective than multi-density materials in reducing force transmission. More effective padding materials combined with alterations in the manner they are configured would likely reduce the incidence of hand injuries in hockey players. Our studies showed that of the padding materials currently used in NHL hockey gloves, single and dual padding materials were more effective than multi-density padding in dissipating force transmissions from pucks striking at high speeds. However, for many gloves, those forces still remain too high.

Keywords: Hockey gloves, Impact forces, Metacarpal, Phalanx

Cite this paper: Constance Maglaras, Antonio Valdevit, Martin A. Posner, Evaluation of the Protective Padding in Professional Ice Hockey Gloves, American Journal of Biomedical Engineering, Vol. 5 No. 3, 2015, pp. 94-99. doi: 10.5923/j.ajbe.20150503.03.

Article Outline

1. Introduction

- The incidence of serious injuries in ice hockey players is one of the highest among athletes participating in team sports and exceeds those that occur in soccer, basketball, volleyball, and baseball. [1] Hockey is a team sport characterized by high velocity impacts with players being struck by pucks and sticks, as well as collisions with other players and with the boards that surround hockey rinks. Impact forces up to 5560N have been reported for a 100 mph slapshot. [2] An investigation of the fracture load of porcine metacarpals revealed fracture loads of 482.8N (range 360N-779.2N). [3] Protective equipment which can effectively dissipate forces greater than the forces required for injury is essential. In one study, collisions with other players and with the boards accounted for the majority of injuries to the wrist and hand (45%) followed by slashes from hockey sticks (19%), and puck impacts (12%). [4] Lower rates of injury occur during practice (40%) as compared to game-time competition (60%) even though ice time for players is longer during practice. The likely reason is that player-to-player impacts are less forceful during practice sessions than during games when the intensity of competition is much greater. [5] In a 16-year study between 1990-2006 an average of 20,000 ice hockey injuries were treated yearly in hospital emergency departments in the United States, with the incidence of hand fractures ranging from 5.7% to 48.1% of all injuries. [6, 7, 4] In the NHL hand fractures are also common injuries. In the 5-year period from 2006 – 2011, The NHL Health Management Panel reported 148 players who sustained game-time fractures to either a metacarpal or phalanx. These injuries resulted in a total of 1,581 lost playing days that obviously had significant impacts on the respective teams. An analysis of injuries among adult recreational ice hockey players reported injuries to the upper extremity to account for 21% of total injuries, with 29% of those injuries occurring at the hand. Fracture accounted for 29% of upper extremity injury diagnoses, however, the instance of fracture to the hand was not specifically reported. [8] A 7-year study of injuries in the men’s International Ice Hockey Federation World Championship tournaments reported 528 total injuries with 21.8% involving the upper extremities. Of those injuries, 14.2% occurred in the fingers, 10.8% at the hand and 10.8% at the wrist. [9] Despite the high risk of injury, ice hockey is a popular sport in the United States with a reported 500,000 amateur players participating in 2010-2011. [10]Epidemiological studies on ice hockey injuries and understanding mechanisms of injury for different injuries have increased with the growing concern for reducing their incidence and, if possible, their prevention. This has led to improvements in equipment and rule changes, as well as a greater awareness among athletic trainers and coaches of the importance of proper conditioning and training. [4] Studies have been performed on the protection provided by hockey helmets and have resulted in improved material and design changes. [11] Helmets as well as face protectors are currently evaluated using impact testing under American Society for Testing and Materials (ASTM) standards and are certified by the National Operating Committee on Standards for Athletic Equipment (NOCSAE). [12] There are no similar standards or certifications for hockey gloves. Our study evaluated the efficacy of professional hockey gloves having different padding designs and compositions. Our objective was to establish a testing mechanism that would evaluate the ability of the gloves to dissipate sudden high impact forces in order to determine those gloves that were most effective and therefore more likely to protect the hand from significant injury.

2. Main Body

2.1. Materials and Methods

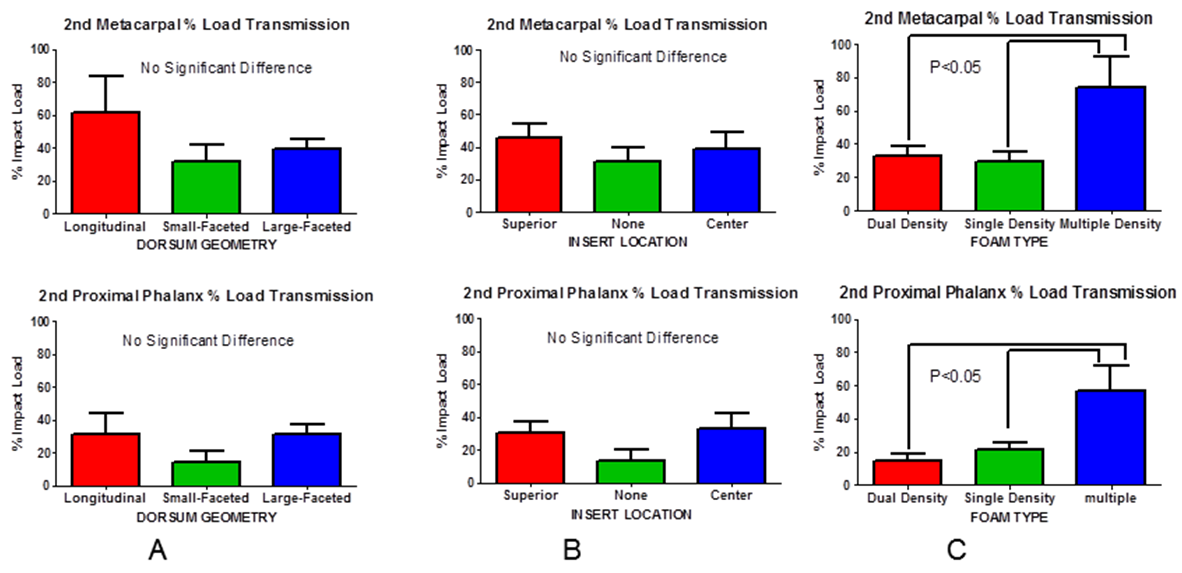

- A total of 18 pairs of new gloves from 6 different manufacturers whose gloves are currently used by players in the NHL were studied. The gloves tested had a variety of padding configurations on their dorsal surfaces, and the padding itself also varied and consisted of 3 types of foam: single, dual and multi-density. (Figure 1A) Each type sometimes included a thin, hard polyethylene shell that some manufacturers inserted in their gloves. With respect to the padding configurations, three groups were classified based on the their configurations on the dorsal surface of the fingers: gloves having three rolls over index finger and two rolls over the other fingers (designated as longitudinal geometry), gloves having three rolls over all four fingers (designated as small-faceted geometry) and gloves having two rolls over all four fingers (designated as large-faceted geometry). (Figure 1B)

| Figure 1. A) Three types of padding used in professional hockey gloves. B) Dorsal padding configuration; three classifications |

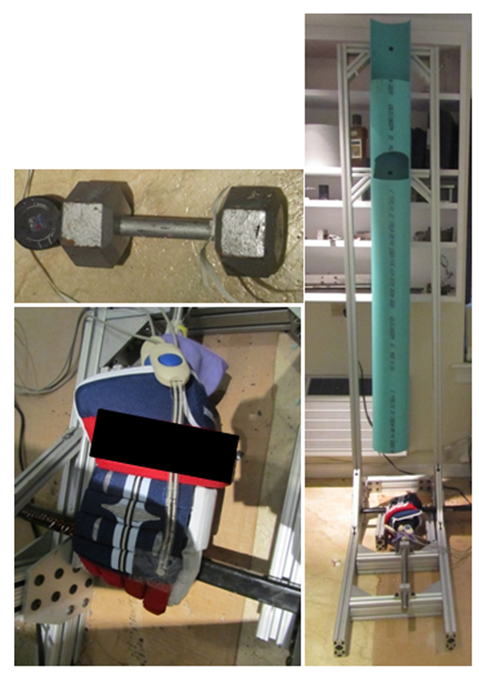

| Figure 2. A regulation NHL hockey puck secured to a 20 lb. weight was dropped from a pre-specified height to impact hockey gloves with the fingers positioned around a NHL hockey stick |

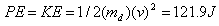

| (1) |

| (2) |

| (3) |

2.2. Results

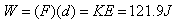

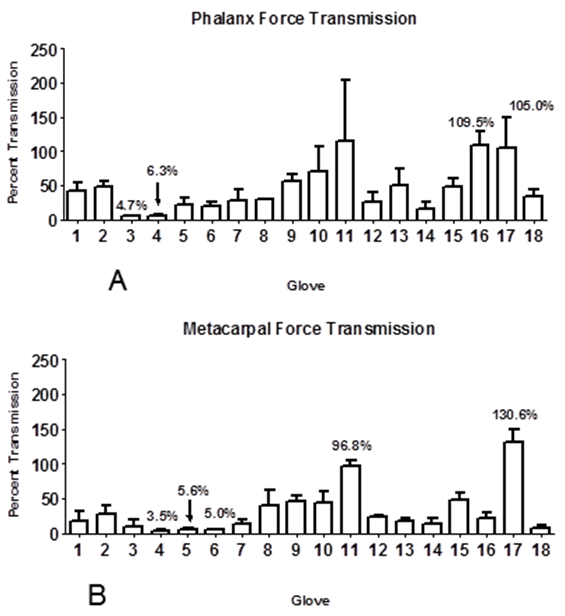

- A typical impact response was characterized by an initial rise in force on the exterior of each glove (sensor #1) followed by subsequent force increases on the inside of each glove at sensors #2 and #3, located over the index metacarpal and proximal phalanx of that finger respectively. (Figure 4)

| Figure 4. Typical impact response showing the forces at all 3 sensors |

| Figure 5. Force transmissions for the 18 gloves tested expressed in percentages over A) the proximal phalanges and B) the second metacarpals |

| Figure 6. Results of force transmissions according to A) dorsal geometry, B) polyethylene inserts (when present), and C) type of foam padding |

2.3. Discussion

- Protective designs for hockey gloves have traditionally been based on player experience, and trial-and-error engineering and manufacturing. We evaluated 18 different gloves, many with different designs that are currently used by players in the NHL using an impact testing apparatus and thin film force sensors that were located on the outside and inside of the gloves; a test configuration that has not been previously reported. Our studies determined the time lag from initial peak impact on the outside of each glove to peak impacts at two locations on the inside of each glove. The force transmission from outside to inside was determined as a percentage of the maximum impact force and was calculated to be approximately 6100N. While this computation is valid, it does not account for the lack of geometric conformation between the puck and force sensor. A decrease in the contact area would result in a reduced voltage output from the sensor and therefore, reduced impact force values. Within each glove, compression of the padding material will ensure a more uniform contact between the padding and the contact sites of the sensors. In order to account for slight variations in contact under impact with respect to the exterior sensor, the transmitted forces were expressed as a percentage of the impact force. We achieved a force of 4939N that was comparable to the 5560N that was recorded in a study using high-speed cinematography of a puck travelling at 100mph. [2]Ochman et.al. investigated a metacarpal fracture model under bending at a rate of 100mm/min. using porcine metacarpals. [3] Intact second metacarpal specimens displayed a mean yield load of 303N (range 200N-500N) and a mean fracture load of 482.8N (range 360N-779.2N). In comparison to the absolute values obtained in this study, most of the gloves examined would provide protection as in this study the maximum load transmitted was 558.4N (in middle of the range for fracture as reported by Ochman), while the low-end transmission was less than 110N. When evaluating protective characteristics of hockey gloves, it would be unrealistic to assume that injuries can be completely eliminated. Regardless of the configuration of the padding or the composition of that padding, injuries will still occur. However, their incidence can be reduced if impact forces on gloves are dissipated below levels that result in significant soft tissue and bony injuries. The key is the dissipative qualities of the padding material. An improvement in that padding would be manifested through an increase in the time between initial impact and force transmission to the hand, namely the lag time. In our study, we expressed that parameter as a percentage of the impact force. With respect to the polyethylene inserts, no statistical differences were observed in time lag or force transmission to either proximal phalanx or second metacarpal. These results implicate the ineffectiveness of polyethylene insert inclusion to improve force dissipation. A study which examined the impact absorption and dissipation of ethylene vinyl acetate mouth guards with and without a thin titanium layer produced comparable results. No statistical differences were observed between the mouth guard with and without the titanium layer, suggesting no beneficial effect of the added layer on the impact absorption and dissipation. [13]Differences in glove geometry had no statistical differences in time lag or force transmission for both the proximal phalanx and second metacarpal, however, a trend of reduced force transmission is observed for small-faceted geometry. Though not statistically significant, this observation may be attributed to a better resistance of force transmission in smaller sized foam segments than larger. The smaller segments may be restricting the parameters associated Poisson’s ratio, thereby limiting expansion of the material upon impact. The effect of material properties on energy dissipation in helmets has been widely documented, showing that an increase in foam density and stiffness yields an increase in energy dissipation capabilities. [14] However, analyses of protective equipment employing multiple density foams compared to use of a single density foam is lacking. In this study, single and dual density materials were comparable with respect to the percent of the transmitted force. However, multi-density materials significantly increased the percent of transmitted force over both the second metacarpal and proximal phalanx of that index finger as compared to single and dual density foams on an order of 2.5 to 3 times. That increase is probably because multi-density materials permit only a gradual change in modulus over the thickness of the material when subjected to an impact force. As a consequence of this gradual change in modulus, there is little diminution of the impact force and it is simply transmitted to the inside of the glove. In contrast, a significant change in modulus at the interface between materials that comprise the padding will more likely dissipate and scatter an impact force, and decrease its transmission. This also accounted for the lack of statistical differences with respect to the lag time data. The transmission of the impact wave may not necessarily decrease in velocity but may simply decrease in amplitude. The initiation for data acquisition in our study was a force of 5N or 0.5% of the sensor capacity and the lag time data was computed based upon the differences in the peak forces. It may be appropriate to consider time differences with respect to the initiation of the force profiles although this method may be more subjective in establishing exact time points for force initiation.Based upon the findings of our study, manufacturers of protective equipment should avoid using multi-density foam materials for padding that were not nearly as effective as single and dual density foams in reducing force transmissions. The challenge for future glove designs is to achieve better energy dissipation using materials that are durable, lightweight and comfortable, and perhaps also altering the manner in which they are configured.

3. Conclusions

- This study showed that of the padding materials currently used in NHL hockey gloves, single and dual padding materials were more effective than multi-density padding in dissipating force transmissions from pucks striking at high speeds. However, for many gloves, those forces still remain too high. More effective padding materials combined with alterations in the manner they are configured would likely reduce the incidence of hand injuries in hockey players.

ACKNOWLEDGEMENTS

- The authors appreciate the assistance provided by the National Hockey League Health Management Panel for providing hand injury statistics in the league and for providing the gloves we tested. The authors also thank Glen Sather, President and General Manger of the New York Rangers; Jim Ramsay, the Head Athletic Trainer; and Acasio Marques, the Head Equipment Manager, for their encouragement in carrying out this study and their insight into hockey injuries based on their many years of experience in the sport.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML