-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Biochemistry

p-ISSN: 2163-3010 e-ISSN: 2163-3029

2016; 6(6): 145-148

doi:10.5923/j.ajb.20160606.02

Novel Closed System Extraction of Essential Oil: A Green Approach

Dalila Nasshorudin, Muhammad Syarhabil Ahmad, Awang Soh Mamat

School of Bioprocess Engineering, Universiti Malaysia Perlis, Malaysia

Correspondence to: Dalila Nasshorudin, School of Bioprocess Engineering, Universiti Malaysia Perlis, Malaysia.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Anovel and green approach for the extraction of essential oil from fresh plant materials have been developed based on of bulb to bulb distillation technique. This solvent and water free approach is based on a simple principle involves the application of vacuum system in a closed system under a reduced pressure and temperature to extract the essential oil. The extraction has been compared with a conventional technique, hydro distillation. Essential oil isolated by solvent free extraction were quantitatively (yield) and qualitatively (aromatic profile) better to those obtained by hydro distillation. The present apparatus permits fast and efficient extraction, avoids water and solvent consumption, less contamination, lesser processes and allows substantial energy savings. The results showed that by using this solvent free extraction technique, the essential oil produced is colorless, higher yield, contains cleaner and distinguishable peaks in GC representing better purity and produced a stronger aromatic flavor compared to the essential oil produced from hydro distillation.

Keywords: Extraction, Essential oil, Solvent free, Green

Cite this paper: Dalila Nasshorudin, Muhammad Syarhabil Ahmad, Awang Soh Mamat, Novel Closed System Extraction of Essential Oil: A Green Approach, American Journal of Biochemistry, Vol. 6 No. 6, 2016, pp. 145-148. doi: 10.5923/j.ajb.20160606.02.

Article Outline

1. Introduction

- Essential oils are concentrated complex mixtures of many natural components that contain volatile aromatic compounds extracts from fragrant plants. It can be extracted from the seeds, flowers, leaves, wood bark, stems, fruits, rhizomes and roots, from a wide variety of plant shrub and tree species. Essential oils are an important source of raw material to the pharmaceutical, cosmetic and food industries. The constituent of essential oil are synthesized in plant by the secondary metabolites and stored in grandular trichomes, oil cells or ducts in plant tissue [1]. Essential oil compositions are commonly mixture of terpenes, mainly monoterpenes and sesquiterpenes, aliphatic compound and aromatic compound [2].Currently, the conventional methods for extraction of essential oil that are widely used by the industry are steam distillation, hydro-distillation and solvent extraction. These methods have some weaknesses which is highly affecting the yield and quality of the essential oil. For steam distillation and hydro-distillation, the high temperature used can cause chemical modification of the essential oil component especially to the heat sensitive volatile compound [3]. Furthermore, the use of solvent extraction is not an effective way due to the present of solvent residue in the product and also resulting in the loss of the highly volatile component of the essential oil [4]. However, referring to [5] this technique is not cost effective due to the use of super critical fluid for extraction and other compound is also extracted such as resins and the vegetable waxes.Considering the fact that the pure form of essential oil with best quality is hard to get, this new method of extraction is invented and tested to discover its potential. Solvent free essential oil extraction method works on the principle that boiling point of a substance is lowered when the pressure is reduced. This technique only applies to any plant that has volatile compounds. The extraction process is done in a vacuum closed system. Vacuum condition is needed to distill and release the oil from the plants oil cells or duct under reduced pressure. The pressure in the system is reduce, making it possible to boil the liquid at lower temperature. The essential oil produced from this technique will be more pure as no solvent used for extraction. This technique was developed because most essential oils cannot be distilled at atmospheric pressure because the boiling point is too high and distilling at normal boiling point will cause decomposition of compound. So by using this technique, extraction of essential oil can be done at lower temperature to preserve the phytochemical constituents. This solvent free extraction technique can produce high quality essential oil with higher yield.

2. Materials and Methods

2.1. Closed System Extraction and Solvent Free Extraction Technique

- Fresh leaves of aromatic plants were grinded and to break them into smaller pieces and increasing the area of contact. Then, the grind leaves were put in a flask which was connected to another flask as a receiving flask. Firstly, the raw material was cooled down to a very low temperature to prevent decomposition and to avoid premature oil evaporation. Vacuum and nitrogen gas was applied on and off to remove air and replacing it with nitrogen. Then vacuum was applied lastly before extraction begun. Then the receiving flask was cooled to a very low temperature where the essential oil would be condensed. Heat was placed below the raw material flask at certain temperature according to the targeted compound range temperature and pressure. Vapors containing water and essential oil were collected at the receiving flask at the end of the extraction process. Water and oil was separated and anhydrous sodium sulfate was used to dry the excess water.

2.2. Gas Chromatography (GC) Analysis

- The essential oil extracted was analyzed by using Gas Chromatography to study the composition of the oil. The gas phase chromatography analysis was carried out using Gas Chromatography equipped with a flame ionization detector and BPX70 column (25 m x 0.25 mm, df: 0.25 µm) with a spilt flow rate of 60 mL /min, nitrogen gas as carrier gas and temperature programming 5 min at 50°C and 6°C /min up to 200°C, injector temperature was 220°C and detector temperature was 235°C.

3. Results and Discussion

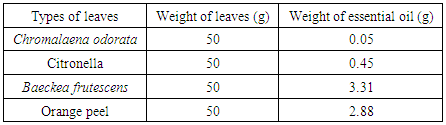

3.1. Yield Analysis

|

|

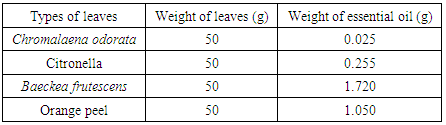

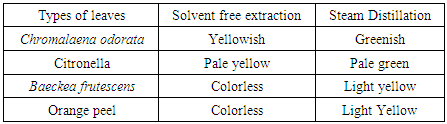

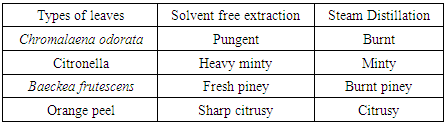

3.2. Physical Characterization

|

|

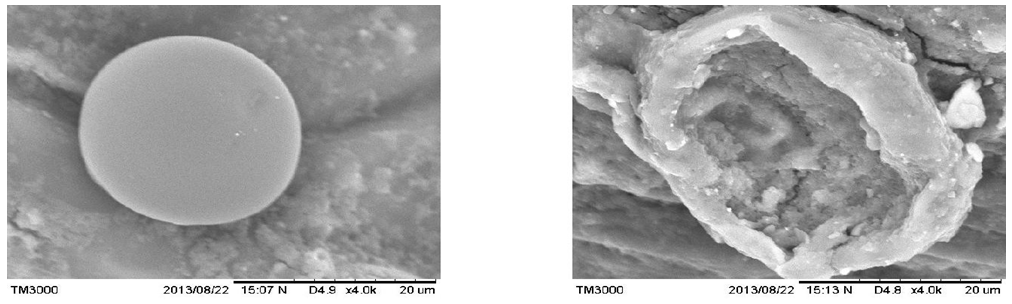

3.3. Scanning Electron Microscope (SEM)

| Figure 1. Essential oil gland (oil cell) before extraction and ruptured essential oil gland after extraction with solvent free extraction |

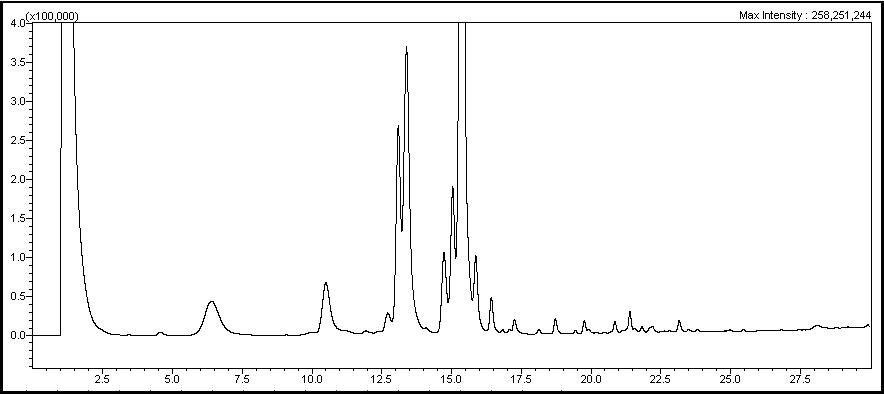

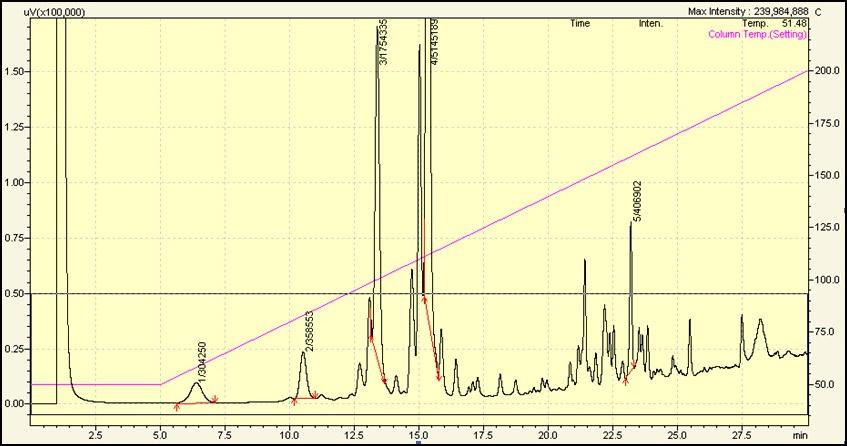

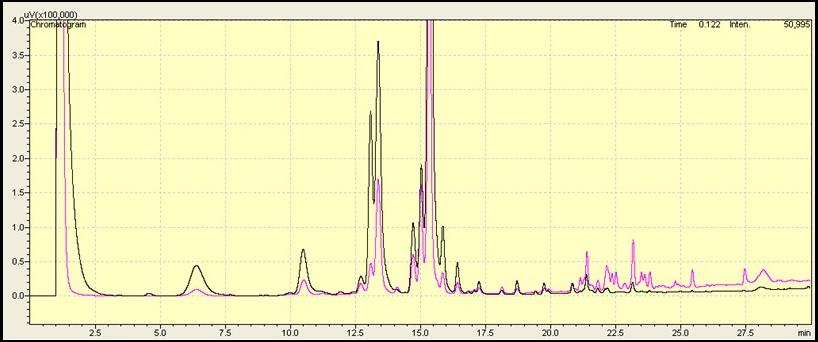

3.4. Analysis by Gas Chromatography (GC)

- From the superimposed graph between solvent free extraction technique and steam distillation in Figure 4, it can be observed that same compound is available in essential oil obtained from the two different techniques. For solvent free extraction technique [Figure 2] the compound detected at retention time of 6 minute to 20 minute showed higher amount of the compound as the entire peak height is higher compared to the peak for hydro-distillation. The compounds detected at retention time longer than 20 minutes were lesser but distinguishable, on the other hand for the steam distillation technique [Figure 3], more peaks showed up after 20 minutes and the compound peaks are messier. This implies that new compounds were generated during the extraction which have reduced the intensity peaks for the lower retention time compounds.

| Figure 2. Graph for GC analysis of extraction by solvent free extraction technique |

| Figure 3. Graph for GC analysis of extraction by steam distillation technique |

| Figure 4. The superimposed graph between the solvent free extraction techniques indicated by black line and the extraction by steam distillation by pink line |

4. Conclusions

- The important key point in producing high quality of essential oil is through low pressure and low temperature proccessing. Boiling points of the essential oil component and heat used to extract the component are the limitations in choosing the right technique to extract the essential oil. So in order to overcome the limitations during the extraction process, this new solvent free closed system extrcation were invented. Closed system extraction technique produced superior quality essential oil and higher yields due to zero loss to surrounding or vacuum. This essential oil extraction technique can be the future of essential oil extraction in the industry. This technique can revolutionize and increase and hasten the amount of study on essential oil in the future. This technique is saves time and cost efficient since the extraction has fewer processes, no purification needed, contains less impurities and saves energy. The solventless extraction technique is applicable in extraction of essential oil for any plant species that contain volatile compound and sublimation property. This technique is better than the current conventional technique because it can be used to extract essential oil from heat sensitive botanical material since the extraction can be done at room temperature or temperatures below 100°C.

ACKNOWLEDGEMENTS

- This research project was financially supported by Fundamental Research Grant Scheme and Prototype Research Grant from Ministry of Education Malaysia. This new technology has been patented in Malaysia (PI 2012001977).

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML