-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Biochemistry

p-ISSN: 2163-3010 e-ISSN: 2163-3029

2016; 6(1): 1-5

doi:10.5923/j.ajb.20160601.01

Influence of Tempering with Ozonated Water on Physico-chemical Properties of Sudanese Wheat Flour

Hassan A. Mudawi1, Gadien K. A.2, Abdel Moneim E. Sulieman3

1Department of Food Science & Technology, Faculty of Agriculture, University of Khartoum, Shambat, Sudan

2Ministry of Agriculture, State of Khartoum, Khartoum, Sudan

3Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia

Correspondence to: Abdel Moneim E. Sulieman, Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This Study was carried out to investigate the effect of ozonated tempering on physicochemical properties of two Sudanese wheat cultivars. Two local cultivars: Debaira and Elneelain were treated with two doses of ozone (1.0 and 5.0 ppm). Proximate composition was carried out for the two wheat cultivars (72% extraction rate). In addition, sedimentation value, falling number value and gluten quality & quantity were determined for ozonated and non-ozonated Sudanese wheat flours. Results indicated significant difference in the quality of the flours of the two varieties. The two cultivars had low falling number (584 and 364 sec). Sedimentation value (28 and 20 cm3) for Debaira and Elneelain, respectively. Treatment of ozonated tem-pering of the two wheat cultivars didn’t significantly affected the quality with exception of falling number and gluten index.

Keywords: Wheat, Falling number, Moisture, Protein, Ash

Cite this paper: Hassan A. Mudawi, Gadien K. A., Abdel Moneim E. Sulieman, Influence of Tempering with Ozonated Water on Physico-chemical Properties of Sudanese Wheat Flour, American Journal of Biochemistry, Vol. 6 No. 1, 2016, pp. 1-5. doi: 10.5923/j.ajb.20160601.01.

Article Outline

1. Introduction

- Wheat belongs to the grass family (Gramineae) genus (Triticum). Wheat is an important human food, its production being second to maize among the cereal crops; rice ranks third. Wheat grain is a stable food used to make flour for leavened, flat and steamed breads, cookies, cakes, pasta, noodles and couscous and for fermentation to make beer, or biofuel [1].Wheat was cultivated in the Sudan since B.C but until 1940’s production was confined to the northern region (16-22°N) whose inhabitants are traditionally wheat consumers. During the Second World War and be-cause of the difficulties of importing wheat it was produced from local resources. Hence 20 000 feddans of irrigated clays of central state (Gezira scheme) were cultivated and the trial was a considerable success. The varieties grown were Giza 155 and Mexicani [2].However, in spite of success no wheat was produced in Gezira scheme after the war was over. This was partly because it became possible to import wheat and partly because the Gezira scheme tenants who had al-ready developed a taste for sorghum found it difficult with their dura production, a commodity which they considered safeguard for their maintenance and subsistence. In addition to the above reason, land and irrigation water formerly allocated to wheat production were needed for other crops within the rotation. After 1960’s wheat growing area had been extended southward to warmer regions to include New - Halfa and White Nile (12-15°N) in addition the irrigated scheme in Gezira.Wheat in Sudan is grown under irrigation during the dry and comparatively cool winter season which extends from November to February. With the present commercial varieties, potential yield is limited by day temperature above 35°C at any stage of crop development. The season with acceptable heat limit is short (90 – 110 days) [3].The production of wheat is increasing progressively in developing countries that it has become one of the cheap food grains, and yet great efforts are made to raise its production level to meet the great demand for the crop. These efforts can’t be completed unless some efforts are made to reduce losses that occur between harvest and consumption.During harvesting and processing, and even during distribution, wheat products may lose some nutrients. For this reason, preservation of the nutrient value is highly desirable and the application of ozone may be a method of choice, particularly considering destruction of various nutrients by the use of heat to decontaminate or problems related to the use of chemical preservatives. Objective of the study is to investigate the possible effect of ozonated water given to Sudanese wheat varieties (Debaira and Elneelain) during tempering on the physicochemical properties of wheat grains.

2. Materials and Methods

2.1. Materials

- Two local wheat cultivars, Debaira and Elneelain were obtained from Agricultural Research Corporation (ARC), Sudan (Harvest season 2007/2008). The grains were cleaned by hand, and all kernel samples were stored under ambient temperature during the study, all chemicals and reagents used were of analytical grade.

2.2. Ozonated Water

- Ozonated water was obtained from an ozone generator (Promaqua, Prominen company, type OZVa, TUV) using atmospheric air. Two concen-trations were used, 1 mg/liter and 5 mg/liter.

2.3. Tempering

- Clean wheat samples were tempered with distilled and ozonated water, each sample was transferred to tight glass jars and left for 24 hours. The amounts of tempering water were calculated according to the initial moisture content of the wheat.

2.4. Laboratory Milling

- Tempered wheat samples were milled in a Brabender Quadrumat junior mill (Brabender OHG, Germany) to white flour (72% extraction rate). All flours were mixed well and stored in tight jars.

2.5. Chemical Properties of Wheat Flour (Proximate Composition)

- The moisture, crude protein, crude fat, ash, crude fiber and carbohydrate content of ozonated and non-ozonated wheat flour samples were carried out on dry weight bases as follows:

2.5.1. Moisture Content (%)

- Moisture content was determined according to the method of AOAC [4]. The percentage moisture content was calculated using the following equation:Moisture content (%)={(W2–W1)/weight of samples}x100Where:W1 = the weight of the empty crucible.W2 = the weight the crucible + sample after drying.

2.5.2. Protein Content (%)

- The protein content of the samples was determined by the micro kjedahl technique according to the AOAC [4] method. The total nitrogen and protein were calculated using the following formula: N (%) = (volume of HCL x N x 14 x 100) / (S x 1000) Protein content = N x 6.25Where:N% = Crude nitrogen; N = Normality of HCL; 14 = Equivalent weight of nitrogen; S = Weight of sample; 6.25 = Conversion factor.

2.5.3. Fat Content (%)

- The fat content was determined using Soxhlet apparatus. The percentage crude fat content was calculated using the following equation:Crude fat content (%)=(W2–W1)/(weight of sample) x 100Where: W1 = the weight of empty extraction flask.W2 = the weight of extraction flask after the extraction process with fat.

2.5.4. Ash Content (%)

- The ash content of the sample was measured according to the method of AOAC [4] method. The ash content was calculated as follows:Crude ash (%) = (W2 – W1) / (weight of sample) x 100Where: W1 = weight of empty crucible; W2 = weight of crucible with ash

2.5.5. Crude Fiber Content (%)

- The crude fiber was calculated using the following equation:Crude fiber content (%) = (W2 – W1) / (weight of sample) x 100 where: W1 = weight of empty crucible and sample after incineration. W2 = weight of empty crucible and sample oven dried.

2.5.6. Carbohydrates Content (%)

- The total carbohydrates were calculated by difference according to AOAC [4] method, using the following equation:Total CHO = 100 - (moisture% + fat% + protein% + ash% + fiber%).

2.6. Gluten Quality and Quantity

- Gluten quantity and quality were carried out for ozonated and non ozonated wheat four according to the ICC [5] method by using Glutomatic instrument (type 2200).Wet gluten content (%) = (weight of wet gluten)/(weight of sample) x 100Dry gluten content (%) = (weight of dry gluten)/(weight of sample) x 100Gluten index (%) = (total wet gluten wt -- passed gluten wt)/(total wet gluten wt).

2.7. Falling Number (seconds)

- Measurement of alpha-amylase activity was carried out on ozonated and non ozonate wheat flour according to Perten [6].R.W.g = 7 x (100 – 14)/(100 – m)Where: m = Actual moisture percentage of the sample.R.W. = Required weight of flour sample used for determination.

2.8. Sedimentation Value

- Sedimentation value was carried out on ozonated and non ozonated wheat flour according to Approved Methods of American Association of Cereal Chemists (AACC) [7] method.

2.9. Statistical Analyses

- Analysis of variance (ANOVA), followed by the least significant difference test (LSD test), was applied to all data obtained. All analyses were performed in triplicate (n=3). The level of significance used was 95% [8].

3. Results and Discussion

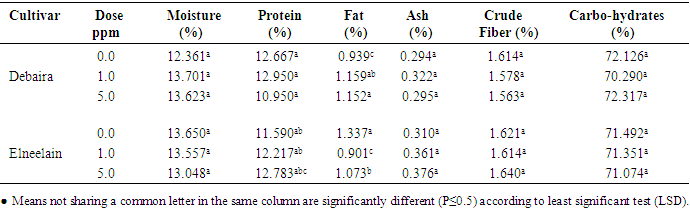

3.1. Effect of Ozonated Tempering on Chemical Constituents of Ozonated and Non-ozonated Sudanese Wheat Cultivars

- Effect of ozonated tempering on chemical constituents of ozonated and non-ozonated Sudanese wheat cultivars of the season 2007/2008 is shown in Table (1).

|

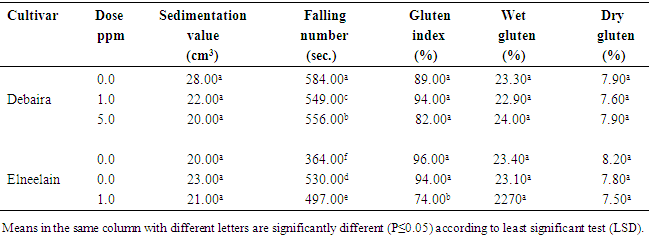

3.2. Effect of Ozonated Tempering on Sedimentation Value (cm3)

- Sedimentation values of ozonated and non-ozonated Sudanese wheat cultivars are shown in Table (2). Sedimentation values ranged from 20.00 to 28.00 cm3. The results indicated that the sedimentation values of the two cultivars were not affected by the ozone treatment. Generally, Debaira gave the highest values of sedimentation compared to Elneelain cultivar. Statistical analysis of the results showed non-significant differ-ences (P≤0.05) among the two cultivars in their sedimentation values, these results are relatively similar to those obtained by Hassan [12] who reported that the sedimentation value of wheat ranged between 3 and 70 cm3. Elfadal [11] showed that the values of different Sudanese wheat cultivars (Debaira and Sasaraib) ranged between 24.76 to 30.33 cm3 and Bashir [12] reported that the sedimentation values of Sudanese wheat cultivars (Debaira and Elneelain) ranged between 19.60 and 23.30 cm3.

|

3.3. Effect of Ozonated Tempering on Falling Number Values (sec)

- Falling number values of ozonated and non-ozonated Sudanese wheat cultivars are shown in Table (2). The present study indicated that the falling number values ranged from 549 to 584 sec. for Debaira wheat flour and from 364 to 530 sec. for Elneelain wheat flour. Analysis of variance showed significant differences (P≤0.05) among the two Sudanese cultivars in their falling numbers. The results were relatively in good agreement with data reported by Badi et al., [2] who found that the falling number values of Sudanese wheat cultivars was abnormally high, compared to European wheat cultivars.

3.4. Effect of Ozonated Tempering on Gluten Quality and Quantity

- Gluten values (wet, dry and gluten index) of ozonated and non-ozonated Sudanese wheat cultivars are shown in Table (2). Wet gluten content ranged from 22.7 to 24.0%. The Debaira wheat flour with ozonated tempering dose 5 ppm gave the highest value, whereas the lowest value was observed in Elneelain wheat flour with ozonated tempering dose 5.0 ppm. Dry gluten content ranged from 7.5 to 8.2%. Elneelain wheat flour with-out ozonated treatment gave the highest value, also Elneelain with ozonated tempering dose 5.0 ppm gave the lowest value.Gluten index values were found to be in the range of 74.0 to 96.0%, Elneelain wheat flour without ozonated treatment gained the highest value, whereas the lowest value was gained by Elneelain wheat flour with ozonated dose 5.0 ppm. These results are lower than those obtained by Bashir [12] who found that the dry, wet and gluten index content of Sudanese wheat cultivars (Debaira and Elneelain) ranged between 8.90 and 12.75%; 37.60 and 28.05%; and 64.53 to 86.71%, respectively. According to the results no significant differences exist in wet and dry gluten content and gluten index except in the case of Elneelain ozonated with 5.0 ppm.

4. Conclusions

- Based on the results, the overall average dose of ozonated tempering was very effective in mold de-contamination; ozonated tempering has no direct effect on the nutritional value of wheat flour. However, after ozonated treatment, Elneelain cultivar gave the best flour quality for bread-making compared with Debaira cultivar. On the other hand, there were some parameters that did not show significant differences, such as ash, fiber, carbohydrate content, wet and dry gluten as well as sedimentation values.Taking into account the above conclusions, it is highly recommended to use the process of ozonated tempering as disinfection process in wheat flour. Further studies are needed to investigate the effect of ozonated tempering on vitamins and enzymes of wheat flour of local cultivars as well as on the protein fractionation of wheat fllour of local cultivars.

ACKNOWLEDGEMENTS

- The authors express their sincere gratitude to the technicians of the Department of Food Science and Technology, Faculty of Agriculture, Khartoum university for their assistance.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML