-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Biochemistry

p-ISSN: 2163-3010 e-ISSN: 2163-3029

2013; 3(4): 93-96

doi:10.5923/j.ajb.20130304.02

Anaerobic Digester Considerations of Animal Waste

Stephen, Chinwendu, Ukpabi Chibueze, Esihe Tochukwu E.

Department of Chemistry Abia State Polytechnic, Aba

Correspondence to: Chinwendu, Department of Chemistry Abia State Polytechnic, Aba.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

A study of the biogas production potential of animal dung which include cow dung (CD) and swine dung were investigated. These were subjected to anaerobic digestion less than 25 days retention period and mesophilic temperature range of 26℃-43℃. The physicochemical and microbial parameters of the dung were determined. The proximate analysis show that the energy value of the CD (592.73 ±0.00KJ/100g) was higher than the SD (433.25±0.00KJ/100g). Two setups was adopted, denoted as digester A and B having feedstock of CD and SD with water in ratio 1:1 respectively. The volume of gas produced was monitored everyday and the CD and SD started production of gas on the 1st (1.20±0.00cm3) and 3rd (0.5±0.00 cm3) days respectively. Average daily volume of gas production for each of the systems was 16.47±0.00cm3 and 3.70±0.00 cm3/ total mass slurry (TMS) respectively. The research indicated that CD has a superior quality for biogas production over the SD achieving high cumulative biogas yield with stable performance. Anaerobic digestion provides an alternative option for energy recovery and waste treatment.

Keywords: Cow Dung, Swine Dung, Anaerobic Digestion, Biogas Production

Cite this paper: Stephen, Chinwendu, Ukpabi Chibueze, Esihe Tochukwu E., Anaerobic Digester Considerations of Animal Waste, American Journal of Biochemistry, Vol. 3 No. 4, 2013, pp. 93-96. doi: 10.5923/j.ajb.20130304.02.

Article Outline

1. Introduction

- The rising energy prices and waste treatment/management challenges as well as concerns about the possible shortage in fossil fuels in many parts of the world have brought renewable energy source to the forefront. Biogas is a colorless, flammable gas produced via anaerobic digestion of biogenic wastes to give mainly methane (50-70%), CO (20-40%) and traces of other gases such as H2S, NH3, CO, N2, H2, O2 and water vapour etc.[4]. The composition of the gas depends on the source of feedstock and the management of the digestion process[3]. The gas becomes flammable when the methane content is at least 45%[1]. Biogas production is a three stage complex biochemical process that takes place under anaerobic conditions in the presence of highly pH sensitive biocatalysts that are mainly bacteria. The process involves solublization (hydrolysis), acidification (Acidogenesis / Acetogenesis) and methane formation (methanogenesis). The methanogens also operate within three temperature ranges namely; Psychrophilic temperature (< 25°C), mesophilic (25-40°C) and thermophilic (45-60°C)[6]. Potentially, all organic waste materials contain adequate quantities of the nutrient essential for the growth and metabolism of anaerobic bacteria in biogas production. Livestock manure in the absence of appropriate disposal methods can cause adverse environmental and health problems such as pathogen contamination, odour and borne ammonia, green house gases etc. Anaerobic digestion provides an alternative option for energy recovery and waste treatment. In this paper, animal dung was assessed for the use of anaerobic digestion with objectives of treating the dung waste to decrease disposal costs and to generate biogas. The biogas production contains mainly methane and carbon dioxide, and can be used as a source of renewable energy. The aim of this paper was to investigate the effectiveness and the effect of blending of animal dung (cow and pig) in anaerobic digestion for biogas production in batch operation.

2. Materials and Methods

2.1. Waste Collection

- Feedstock for this work were cow (CD) and swine (SD) dung which was collected from slaughter house and animal farm respectively in Ogbor Hill, Aba, Abia State Nigeria.

2.2. Sample Preparation

- The wastes were sorted to separate domestic and plant materials and were subsequently characterized. The cow and swine dung were mixed with water at the ratio 1:1 respectively. The mixing of the cow and swine dung was done outside the digester.

2.3. Anaerobic Digester

- This study comprised of three experimental setups (digester A and B) which was carried out anaerobically at mesophilic condition (40℃). Digester A was fed with 150g of the cow dung and water was added in ratio 1:1 while digester B contained 150g of the swine dung and water at the same ratio respectively. The digest was connected to a calibrated measuring cylinder with paraffin oil displacement arrangements to measure the volume of biogas produced. The slurry was allowed to ferment anaerobically for 25 days under mesophilic temperature of 26-43℃.

2.4. Analyses of Wastes

2.5. Proximate and pH Determination

- Ash, moisture and fiber contents were determined using[2]. Fat, crude nitrogen and protein contents were determined using Soxhlet extraction and micro-Kjedhal methods described in[16]. Energy content was calculated using the AOAC method described in[13]. The pH of each of the digester system was determined before digestion using pH meter.

2.6. Microbial Analysis

- Total viable counts (TVC) for both the cow and swine dung were carried out to determine the microbial load of the samples using the modified Miles and Misra method described in[10].

3. Results/Discussion

3.1. Characterizations of the Dung

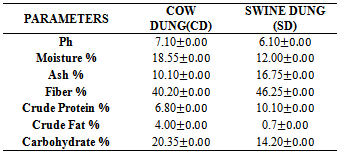

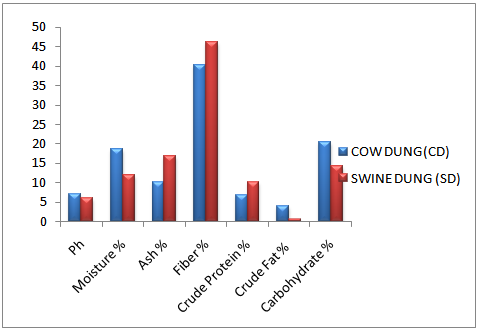

- The composition of the dung is presented in the Table 1. It was observed from the table that the energy value (kJ/100g) of the cow dung (CD) (592.73±0.00kj/100g) was significantly (p>0.05) higher than the swine dung (CD) (433.25±0.00KJ/100g). Proximate analysis of the dung showed that moisture (18.55 ±0.00%), crude protein (6.80±0.00%), carbohydrate (20.35±0.00%) and crude fat (4.00±0.00%) were higher in the cow dung than their corresponding values of moisture (12.00±0.00%), crude protein (10.10±0.00%), carbohydrate (14.20±0.00%) and crude fat (0.7±0.00%) in the swine dung. Only fiber (46.25 ±0.00%) was higher in the swine dung than the cow dung (40.20±0.00%). This result showed that all the energy yielding macro nutrients were present with carbohydrate being the most abundant. The crude protein, carbohydrate, moisture, and fiber showed significant difference while fats did not show significant difference between the dung. However feeding pattern for the two animals may be responsible for the difference in the energy yield, swine is fed purely on feed materials while cow may be given other materials such as fresh grass. The bacterial load in the dung before the digestion showed Cow dung has higher bacterial load than the swine dung. The pH of the induced and the combine dung ranged between 6.10 and 7.00. Various research reports have attained that the methanogenic bacteria which are obligate anaerobes are highly PH sensitive and survive optimally in the PH range of 6.5 to 7.5[8]. Cows are rumen animals which the digestive systems contain obligate anaerobes. Rumen animals already have the native microbial flora within their digestive systems so that the presence of these microbes in their faeces would have created a favorable environment that aided faster digestion and average yield of biogas. Even though swine are not rumen animals but their dung may have brought an abundant micro flora.

3.2. Table 1

|

| Figure 1. Physiochemical Properties Of Cow And Swine Dung |

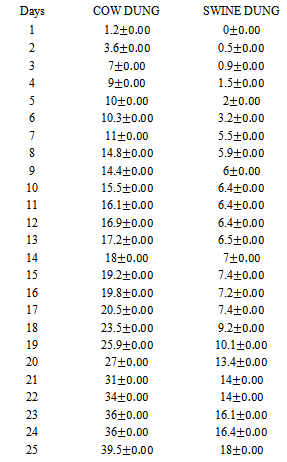

3.3. Biogas Production

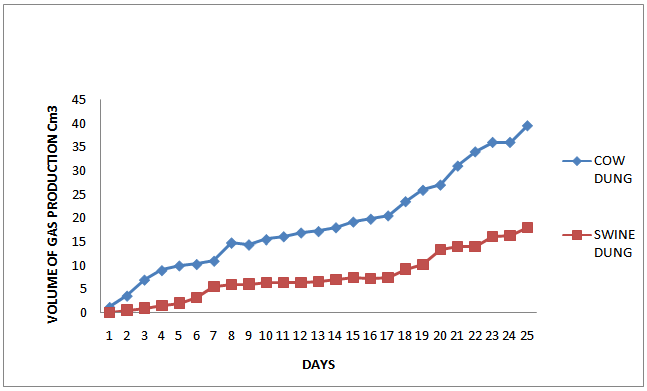

- The experiment was carried out under daily mean ambient temperature range of 26oC to 32oC. After the digestion period of 25 days the total amount of biogas generated in the digester A and B containing 150g of dung were found respectively to be 39.5±0.000cm3, 18.00±0.00 cm3. Average daily volume of gas production for each of the systems was 16.47±0.00cm3 and 3.70±0.00cm3/total mass slurry (TMS), respectively. The result indicated that the swine dung affected the total biogas yield. This may be because the cow dung had high carbohydrate and fat content which shows that it contains high energy yielding nutrients. Similarly swine dung had high protein and fiber contents which indicate that it contains a lot of cellulose, semi-celluloses lignin and pectin. Lignin is very difficult to biodegrade and a major rate determining step in anaerobic digestion process[8]. The physiochemical properties shown in Table 1 indicates that that highest producing dung which is cow dung had adequate nutrients (fat, protein and fiber), energy content and solids which is the biodegradable portion of the dung.cow dung has been establish by researchers as being superior in quality biogas production over the dung[5].

3.4. Table 2

|

| Figure 2. daily biogas production from the respective dung |

4. Conclusions

- This study investigated the effectiveness of animal dung like cow and swine dung for biogas production. The result show that cow dung might be one of the best feedstock for biogas production and that the swine dung reduced gas production throughout the digestion period. The swine dung gave the least result in terms of onset of gas production and average volume of biogas yield. Waste degradation which is advantageous to the environment was also achieved in the process. Thus disposal problems of waste can be solved alongside energy generation.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML