-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Nanoscience and Nanotechnology

p-ISSN: 2163-257X e-ISSN: 2163-2588

2016; 6(1A): 113-116

doi:10.5923/c.nn.201601.22

Polyimide Films under the Optimal Conditions for Organic Solar Cells

Bexultan Abylkhani 1, Kamshat Umbetova 2, Rinat Iskakov 2

1School of Engineering, Nazarbayev University, Astana, Kazakhstan

2Chemical Engineering School, Kazakh-British Technical University, Almaty, Kazakhstan

Correspondence to: Bexultan Abylkhani , School of Engineering, Nazarbayev University, Astana, Kazakhstan.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

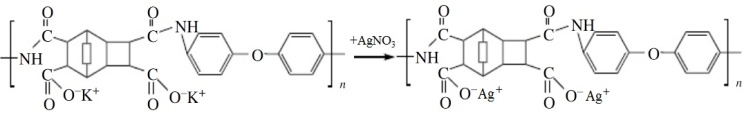

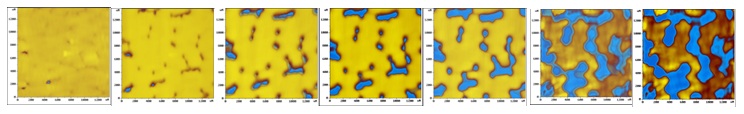

An extensive amount of research about polyimide films (PI) metallization process has been conducted over the last two decades. Earlier, it had been reported that produced films had electric and optical characteristics, which could be used in organic solar elements production. In addition to that, the process of obtaining organic solar cells has been considered. It was established that the optimum conditions for obtaining a transparent electrode are presented as the following: polyTEOS - poly(tetraethyleneoxide silane), in a solution of isopropanol, also for an active layer, P3HT (poly(3-hexylthiophene-2,5-diyl)/ PCBM ([6,6] - phenyl-C61-butyric acid methyl ester), for increasing power conversion efficiency [1, 4]. This paragraph describes the process of metallization used when the research had been undertaken. The polyimide film (PI), with pre-degreased surface, was subjected to swelling in acetonitrile for 20 minutes [6]. The next step was an alkaline hydrolysis in 0.2 M KOH solution, wherein the mixture of water - isopropanol (20:1). PI film was kept in the alkaline solution for 20 minutes. Afterwards, the PI film was washed with distilled water and transferred to 3% solution of AgNO3. Chelation process was performed for 30 minutes. The last step was the reduction of silver, made with 0.1% NaBH4 in solution isopropanol - water (1:20). The resulting samples were annealed at 85°C for 4 hours [7] and, finally, illustrated films were obtained (Fig.6). This study examined the metallization of the polyimide (PI) films under optimal conditions for alkaline hydrolysis, chelation in the aqueous solution of a metal salt and reduction with a solution of sodium tetrahydroborate. It demonstrated that the obtained metal layers tightly impregnated polymeric substrate as the chemical plating on the PI film surface. Moreover, it was found that metallized film derived from this method had optical and electrical characteristics. Accordingly, it was revealed that the metallized polyimide film could be used in the manufacture of flexible organic solar cells as shown in Fig.7.

Keywords: Polymer, Solar elements, Films, Metallization, Transparent electrode, Active layer

Cite this paper: Bexultan Abylkhani , Kamshat Umbetova , Rinat Iskakov , Polyimide Films under the Optimal Conditions for Organic Solar Cells, Nanoscience and Nanotechnology, Vol. 6 No. 1A, 2016, pp. 113-116. doi: 10.5923/c.nn.201601.22.

1. Introduction

- An organic solar cell is a type of polymer solar cell that uses organic electronics, a branch of electronics that deals with conductive organic polymers or small organic molecules, for light absorption and charge transport to produce electricity from sunlight by the photovoltaic effect. The aim of the aforementioned device is to design an organic solar element with high working characteristics due to the optimization of each stage [1].An OLED (organic light-emitting diode) is a light-emitting diode (LED) in which the emissive electroluminescent layer is a film of an organic compound which emits light in response to an electric current. This layer of organic semiconductor is situated between two electrodes; typically, at least one of these electrodes is transparent [2]. OLEDs are used to create digital displays in devices such as television screens, computer monitors, portable systems such as mobile phones, handheld game consoles and PDAs. A major area of research is the development of white OLED devices for use in solid-state lighting applications.

2. Experiment

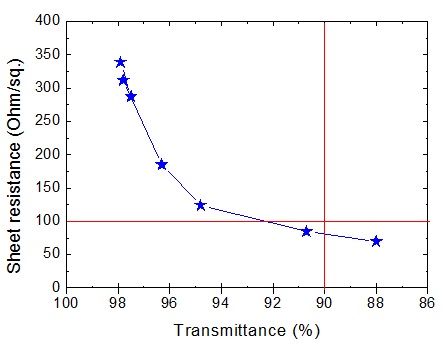

- The process of obtaining organic solar cells has been considered. It is established that the optimum conditions for obtaining a transparent electrode are as follows: polyTEOS in a solution of isopropanol (6 vol%). The criteria for the quality of the transparent electrode, wherein the transmittance – above 90%, the sheet resistance – less than 100 (Ohm / square), corresponds to the thickness of electrode 126 nm (800 rpm) and optimum annealing temperature is 140°C (Fig. 1.) [3, 4].

| Figure 1. Rsh - T% characteristics of transparent electrode |

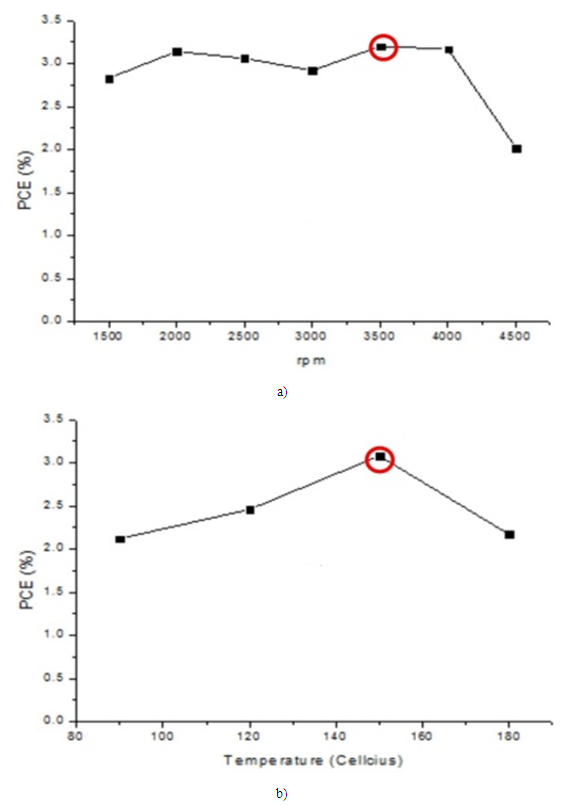

| Figure 2. a) % - Thickness characteristics. b) % - Temperature of photo active layer |

3. Metallization Process

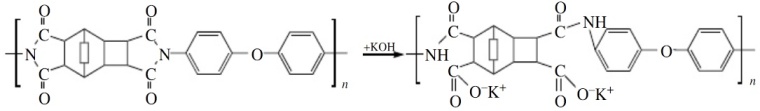

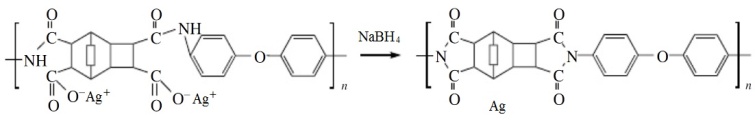

- The metallization process of the polyimide (PI) films has been studied so far. The produced films have electric and optical characteristics which can be used in the production of organic solar elements.The polyimide (PI) film with pre-degreased surface was subjected to swelling in acetonitrile for 20 minutes [6]. The next step was an alkaline hydrolysis (Fig. 3) in 0.2 M KOH solution, wherein the mixture of water - isopropanol (20:1). PI film was kept in the alkaline solution for 20 minutes.

| Figure 3. Alkaline hydrolysis |

| Figure 4. Chelation process |

| Figure 5. Reduction |

| Figure 6. The metallization process of the PI film |

4. Conclusions

- The metallization of the polyimide (PI) films has been studied, and the optimal conditions for alkaline hydrolysis, chelation in the aqueous solution of a metal salt and reduction with a solution of sodium tetrahydroborate investigated. It demonstrated that the thus obtained metal layers tightly impregnated polymeric substrate as the chemical plating on the PI film surface. Moreover, it was found that metallized film derived by this method had optical and electrical characteristics. Accordingly, it can be concluded that the metallized polyimide film could be used in the manufacture of flexible organic solar cells as shown in Fig.7.

| Figure 7. Metallized PI film used as an organic solar cell element |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML