-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Nanoscience and Nanotechnology

p-ISSN: 2163-257X e-ISSN: 2163-2588

2016; 6(1A): 35-38

doi:10.5923/c.nn.201601.06

W-Cu-CNT Nanocomposite by Vacuum Sintering and Hot Isostatic Pressing

Ayman Elsayed

Powder Technology Lab, Central Metallurgical Research and Development Institute, Cairo, Egypt

Correspondence to: Ayman Elsayed , Powder Technology Lab, Central Metallurgical Research and Development Institute, Cairo, Egypt.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Tungsten-copper composites combine high density and high electrical and thermal conductivities in a high strength mixture of insoluble phases that are easy to form by powder metallurgy. The combination of tungsten and copper optimizes properties such as ductility, strength, corrosion resistance, wear resistances, and thermal properties. Accordingly, W-Cu composites are used in electric and electronic materials such as heavy-duty electrical contacts, high current circuit breakers, resistance welding electrodes, heat sinks, and contact tips in gas-metal arc welding guns. Elemental powders of nano-sized tungsten and chemically deposited nano-sized copper were used for preparing tungsten/copper nano composites. A composite of 50.%W/50wt.%Cu composition was prepared by mixing. Then, multi-walled carbon nanotubes were added using wet mixing to be well distributed in the composite. The obtained powder blends underwent consolidation by cold compaction, then vacuum pressureless sintering. Eventually, sintered samples were finished by hot isostatic pressing. Results proved that the synthesis of the composite by the investigated route yields good performance. W-Cu-CNT manufactured nanocomposites have shown much better density than previously reported similar samples. Hot isostatic pressing has played a very important role in gaining the good density of the nanocomposite at relatively low processing temperatures.

Keywords: W-Cu-CNT Nanocomposites, Powder fabrication, Vacuum sintering, HIP

Cite this paper: Ayman Elsayed , W-Cu-CNT Nanocomposite by Vacuum Sintering and Hot Isostatic Pressing, Nanoscience and Nanotechnology, Vol. 6 No. 1A, 2016, pp. 35-38. doi: 10.5923/c.nn.201601.06.

1. Introduction

- The combination of tungsten and copper in a single composite optimizes properties such as ductility, strength, corrosion resistance, wear resistances, and thermal properties. Hence, W-Cu composites are used in electric and electronic materials such as heavy-duty electrical contacts, high current circuit breakers, resistance welding electrodes, heat sinks, and contact tips in gas-metal arc welding guns [1–6]. Tungsten-copper is a two phase composite consisting of tungsten as the base constituent forming the refractory hard phase which possess high strength and low thermal expansion coefficient. On the other hand, copper is the ductile phase having high thermal and electrical conductivities. The fabrication of a fully dense W-Cu composite is very difficult due to the big difference between the melting points of tungsten (approximately 3400°C) and copper (approximately 1083°C). Also, there is no overlap between their sintering temperature ranges. Moreover, W-Cu system has no mutual solubility, which usually results in poor sinterability [7]. Mechanical alloying is a popular technique for producing tungsten-copper homogeneous nanocomposites. Various W-Cu composites have been developed including ultrafine micro-composite structures by this technique [8]. The dispersion technique is another fabrication method that depends greatly on the powder characteristics which affects the sintering behaviour [8]. The dispersion of the copper phase and the fineness of the tungsten phase play a big role in the sinterability of W-Cu powders. The milling behavior depends on the composition, milling time, and milling atmosphere. High energy milling produces particles containing small tungsten grains embedded with copper. This type of powder significantly improves sintering in the W-Cu system [9].The aim of the current work is to synthesize (50wt.%W/50wt.%Cu) composite by mixing. Consolidation using vacuum sintering and hot isostatic pressing techniques are presented. Nanosized copper and tungsten powders were used for manufacturing the composites, where the nanosized copper powder was prepared by electroless deposition. The optimal conditions for powder blending and consolidation and their influences on the properties are reported.

2. Experimental work

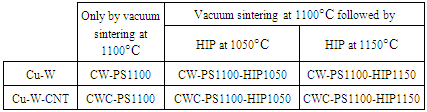

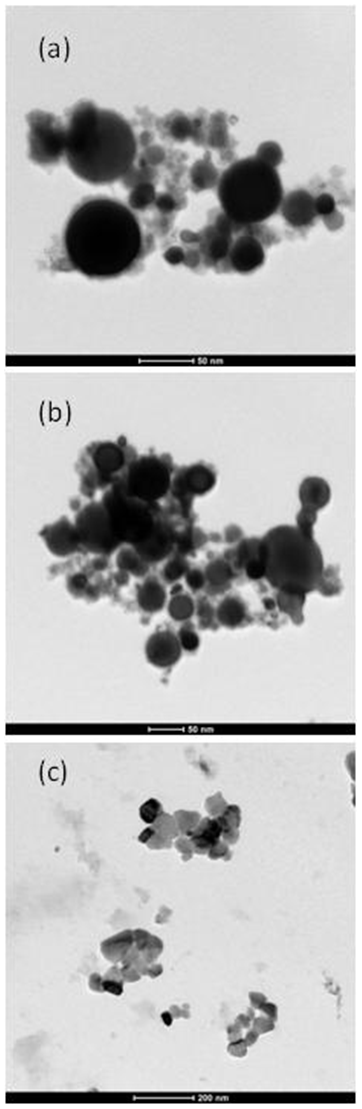

- Powder technology was used to manufacture the composite using nano-sized powders of both tungsten and copper. Nano tungsten powder with purity 99.95% and particle size ~ (40-60 nm) was provided from US Research Nanomaterials, Inc. On the other hand, a homemade nano-copper powder with an average particle size of ~50 nm has been prepared by electroless deposition using formaldehyde as a reducing agent for copper sulphate solution in an alkaline tartarate path at a pH ~ 12. For each liter of distilled water, 200 mL of formaldehyde, 35 g of CuSO4, 170 g of potassium sodium tartarate and ~50 g of sodium hydroxide were added. Then the deposited copper powder was cleaned with distilled water and dried at 120°C for 2hrs. Carbon nanotubes “CNT” were also added to some specimens to investigate their effect on the microstructure and properties of the composite. A mixture of the powders with the composition 50wt.%W/50wt.%Cu has been prepared by dry mixing in a stainless steel container of a planetary mill using a ball to powder ratio of 1:1 at 200 rpm for 2 hrs. The mixture was then cold compacted using a single action hydraulic press at 400 MPa and then consolidated by vacuum sintering at 1100°C for 1 hr using the heating rate of 4˚C/min. Some samples were further processed by hot isostatic pressing “HIP” to enhance their characteristics. HIP was performed using the pressure of 200 MPa at both 1050 and 1150°C. The microstructure investigation was performed for the consolidated specimens by using scanning electron microscopy equipped with EDS analyses (JEOL JSM5410). Hardness was measured using Vickers hardness tester (Indentec 5030 SKV) at 3 kg load for 10 s. Table 1 gives a brief illustration of the conditions used to manufacture various samples in this study.

|

3. Results and Discussion

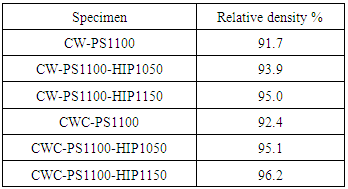

- Transmission electron microscope was used to investigate the morphology and particle size of both tungsten and copper powders. Both the tungsten and copper powders had an average particle size of slightly below 50 nm, as shown in Fig. 1(a) and (b). They both show almost perfectly spherical morphologies with considerable homogeneity of particle sizes, especially in case of Cu powder obtained by electroless deposition. The dry mixing process resulted in a mixture of powders without the formation of globules, as shown in Fig. 1(c), where there was not any sign of further particle size reduction.

| Figure 1. TEM observation of W (a), Cu (b) and mixed (c) powders |

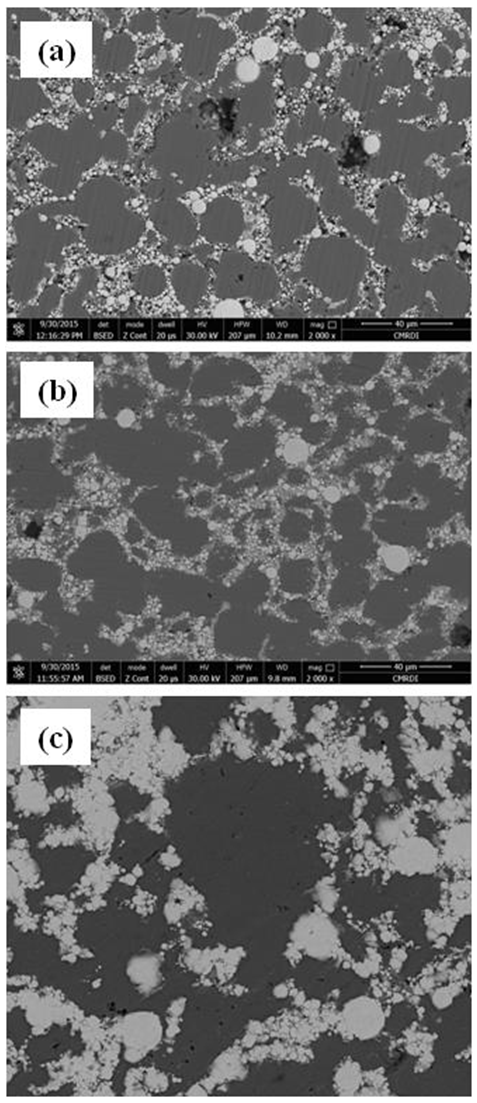

| Figure 2. SEM observation of Cu-W specimens CW-PS1100 (a), CW-PS1100-HIP1050 (b) and CW-PS1100-HIP1150 (c) |

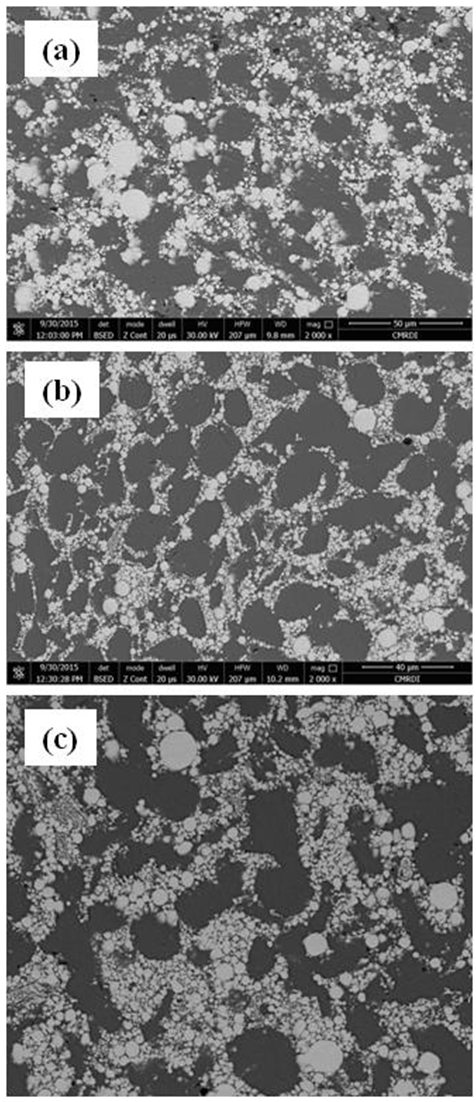

| Figure 3. SEM observation of Cu-W-CNT specimens CWC-PS1100 (a), CWC-PS1100-HIP1050 (b) and CWC-PS1100-HIP1150 (c) |

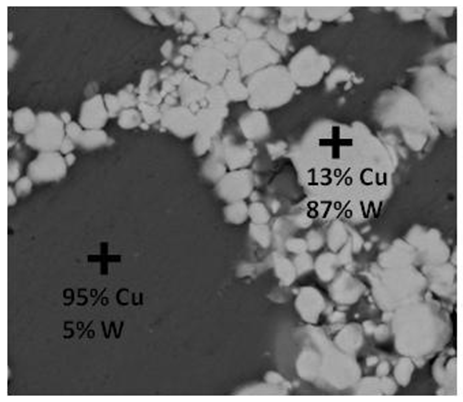

| Figure 4. EDS analysis of phase constituents in CW-PS1100-HIP1150 specimen |

|

4. Conclusions

- This study presents a suitable method for fabricating W-Cu-CNT nano composites through vacuum sintering and HIP processing. The manufacturing route resulted in specimens which show good microstructure. The grain sizes, void amounts and relative densities have shown that HIP processing has played an important role in increasing the relative density especially for Cu-W-CNT specimens.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML