-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2016; 6(4A): 94-98

doi:10.5923/c.materials.201601.18

Effect of Alumina Nanoparticles on the Performance and Emission Characteristics of CI Engine Fuelled with Lard Oil Methyl Ester Blends

Sanjay K. C., Shreyas, Vinol Pinto, Sheikh Shoaib Abdul Gafoor, Thilak Biju, K. Raju

Department of Mechanical Engineering, St. Joseph Engineering College, Mangaluru, India

Correspondence to: K. Raju, Department of Mechanical Engineering, St. Joseph Engineering College, Mangaluru, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In the present study the effect of alumina (Al2O3) nanoparticles (ANP) on the performance and emission characteristics of blends of Lard Oil Methyl Ester (LOME) on a CI engine has been investigated. Lard oil has been extracted from pig fat and was subjected to transesterification to obtain LOME. The blend samples (B10, B20 and B30) of LOME were used for comparison. The alumina nanoparticles were dispersed uniformly at a concentration of 100 ppm by an Ultrasonicator. The results report that for B20+100ANP, the concentration of HC (ppm), CO emission (%) and smoke opacity have been reduced after the addition of alumina nanoparticles by 15, 33 and 25% respectively. The comparison of all the biodiesel blends leads to a conclusion that B20+100ANP has maximum reduction in HC concentration, CO percentage and Smoke opacity.

Keywords: Al2O3 nanoparticles, Lard Oil Methyl Ester (LOME), Transesterification, Ultrasonicator

Cite this paper: Sanjay K. C., Shreyas, Vinol Pinto, Sheikh Shoaib Abdul Gafoor, Thilak Biju, K. Raju, Effect of Alumina Nanoparticles on the Performance and Emission Characteristics of CI Engine Fuelled with Lard Oil Methyl Ester Blends, American Journal of Materials Science, Vol. 6 No. 4A, 2016, pp. 94-98. doi: 10.5923/c.materials.201601.18.

Article Outline

1. Introduction

- Nowadays diesel fuel is increasingly used in various locomotives. This leads to more requirement of diesel fuel on an average. Further, the price of petrol and diesel is increasing day by day. So a need for alternative fuel is a must. Biodiesel has the potential of overcoming the challenges that is prevailing today. In spite of the fact that CI engines are more efficient than SI engines, the emission of harmful gases from the CI engines is usually higher. It is a well known fact that the use of diesel fuel causes the emission of harmful exhaust gases such as NOX, CO and CO2. One of the existing solutions to overcome the emission of harmful gases is the use of bio-diesel blends in locomotives [1]. The biodiesel is extracted from edible and non-edible plants, chicken fats, beef tallow, pork lard and waste cooking oils by transesterification. The major advantages of using bio-diesel over diesel fuel are minimal sulfur and aromatic hydrocarbons content, higher flashpoint, higher cetane number, higher lubricity and non-toxicity [2]. Many experimental studies showed that metal oxide nanoparticle fuel additives dosed with diesel and biodiesel helped to reduce the emission of harmful gases from CI engines. Metal oxides such as Alumina (Al2O3), Cerium Oxide (CeO), Copper Oxide (CuO), Manganese Oxide (MnO), Titanium Oxide (TiO2) and Zinc Oxide (ZnO) are widely used as fuel added substances. Since nanoparticles are very small in size (ranging from 1-100 nm) they provide large surface area for combustion and hence act as a catalyst [3]. This increases the combustion efficiency and in turn reduces the emission of exhaust gases which are formed due to incomplete combustion of the fuel. However the chemical composition and size of nanoparticles, optimized fraction of amount of bio diesel and effective reaction of additive with diesel fuel can cause considerable influence on fuel consumption and exhaust emission of diesel engine.Hence this study is focused on the preparation, testing and comparison of various blends of lard oil methyl ester mixed with alumina (Al2O3) nanoparticles and suggest the optimum blend that would cause least emission without any considerable reduction in the performance of the CI engine.

2. Experimental Details

- Biodiesel is extracted from lard oil. The biodiesel is blended with diesel in different concentrations and alumina nanoparticles are dispersed in it by an Ultrasonicator. The properties of biodiesel blends are measured according to ASTM standards and tested on a variable compression ratio (VCR) diesel engine.

2.1. Transesterification

- The transesterification method has been broadly used to lessen the high viscosity of triglycerides [Figure 1]. In a round bottom flask 1000 ml lard oil is taken and heated up to 65°C and a freshly prepared solution of 300 ml methanol and 6.5 grams of NaOH are added. The solution is maintained at a constant temperature of 65°C for two hours to facilitate the chemical reaction. The solution is stirred constantly by magnetic stirrer at a speed of 600-950 rpm and the speed of the stirrer is controlled by using an indoor regulator. The solution is then taken in a separating funnel and allowed to settle for 15 hours. The glycerine collected at the bottom is separated from the lard oil methyl ester. Washing of the lard oil methyl ester is done in hot water to remove the soap and glycerine content present in it.

| Figure 1. Transesterification of Lard oil |

2.2. Sonication of Al2O3 Nanoparticles in LOME Blends

- Sonication is a process in which the particles are dispersed in liquid by using ultra sound energy. In this experiment an ultrasonic bath type sonicator was used to agitate alumina nanoparticles in various samples of lard oil methyl ester i.e. B10, B20 & B30 [Figure 2]. The additive concentration used was 100 ppm for all samples.

| Figure 2. Ultrasonicator |

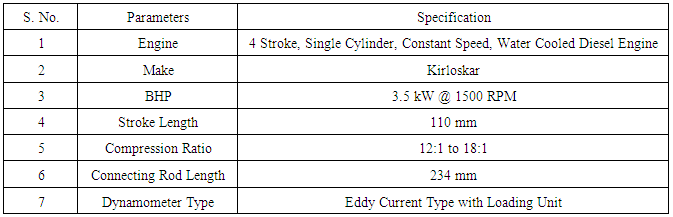

2.3. Properties of Blends of LOME with Al2O3 Nano Particles

- The physico-chemical properties of the different fuel samples are shown in Table 1. Bomb calorimeter was used for determining the higher calorific value. The kinematic viscosity of the fuel samples was found by using Redwood Viscometer. Flash and fire point of the fuel samples were found by using Cleveland open cup apparatus.

|

2.4. Variable Compression Ratio CI Engine Details

- The performance tests were performed on a Computerized Variable Compression Ratio 4-stroke single cylinder constant speed diesel engine. The rotary encoder measures the speed and load is measured with a strain gauge load cell. The specifications of the engine are shown in Table 2.

|

3. Results and Discussion

- The experiments were conducted for blends of LOME and alumina nanoparticle dispersed blends of LOME on a VCR diesel engine at a constant speed of 1500 rpm with a compression ratio of 17:1 at an injection pressure of 200 bar. For various loads, mass flow rate, emission and smoke opacity were recorded for different fuel samples. The performance parameters such as brake thermal efficiency (BTE) and brake specific fuel consumption (BSFC) were calculated.

3.1. Performance Parameters

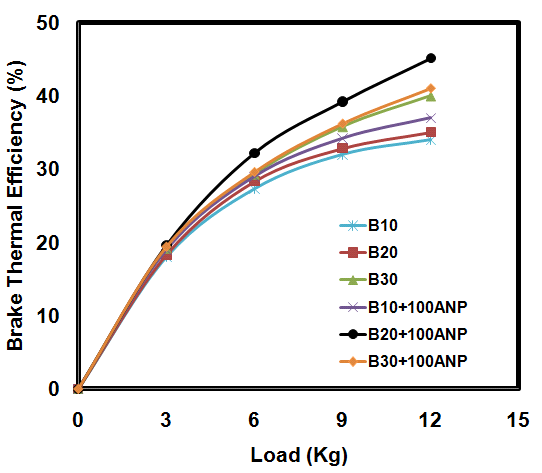

3.1.1. Brake Thermal Efficiency (BTE)

- Figure 3 shows variation of BTE with load. The results show that the BTE of VCR diesel engine increases with the addition of nanoparticles to LOME blends. It is observed that the BTE has increased by 22% for B20+100ANP when compared with B20 at full load condition. This is due to the fact that alumina nanoparticles act as an oxygen buffer and help in improved combustion of the fuel [4].

| Figure 3. Variation of Brake Thermal Efficiency (BTE) with load |

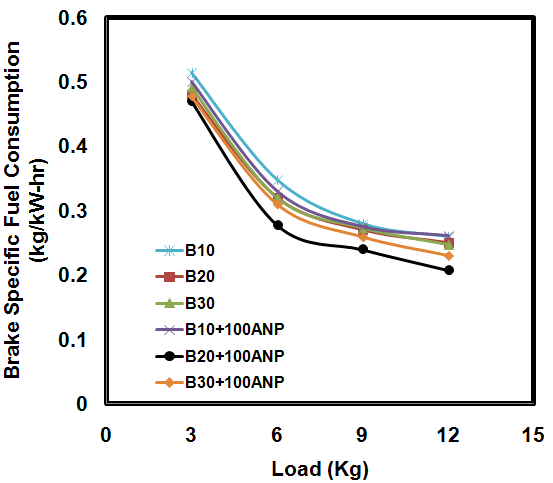

3.1.2. Brake Specific Fuel Consumption (BSFC)

- The variation of BSFC with load is shown in Figure 4. It is observed that the BSFC of VCR Engine decreases with increase in load. The BSFC has decreased by 17% for B20+100ANP when compared with B20 at full load condition. This is because of the fact that the calorific value of B20+100ANP is higher than that of B20. The fuel with higher calorific value is consumed less to produce the same power output when compared to fuel with relatively low calorific value [5]

| Figure 4. Variation of Brake Specific Fuel Consumption (BSFC) with load |

3.2. Emission Characteristics

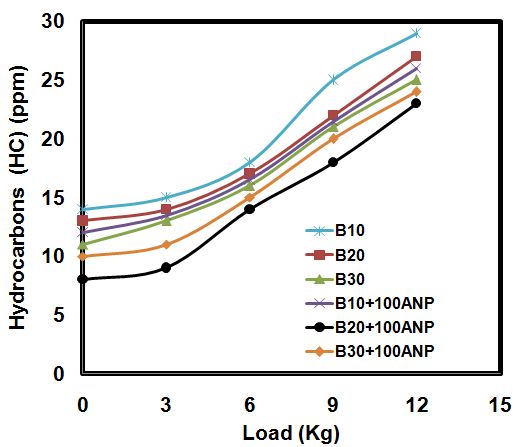

3.2.1. Hydrocarbons (HC)

- The variation of emission of HC with load is shown in Figure 5. As load increases the emission of HC increases for all blends including alumina nanoparticles dispersed blend samples. It is observed that the emission of HC has decreased by 15% for B20+100ANP when compared with B20 at full load condition. This reduction is due to the addition of alumina nanoparticles which acts as an oxygen buffer and helps in complete combustion of the biodiesel blends [6].

| Figure 5. Variation of Hydrocarbons (HC) with load |

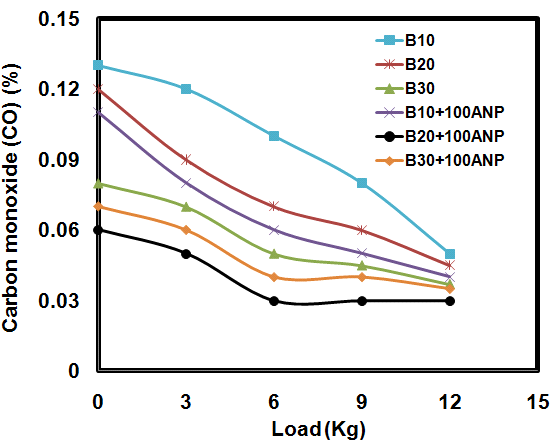

3.2.2. Carbon Monoxide (CO)

- Figure 6 shows the variation of emission of CO with load. It is observed that as the load increases the emission of CO decreases for blends of LOME and alumina nanoparticles dispersed blends. At full load condition, the emission of CO was decreased by 33% for B20+100ANP when compared with B20. The decrease in CO emission might be a direct result of alumina nanoparticles functioning as oxygen buffers for better combustion of the fuel [7].

| Figure 6. Variation of Carbon monoxide (CO) with load |

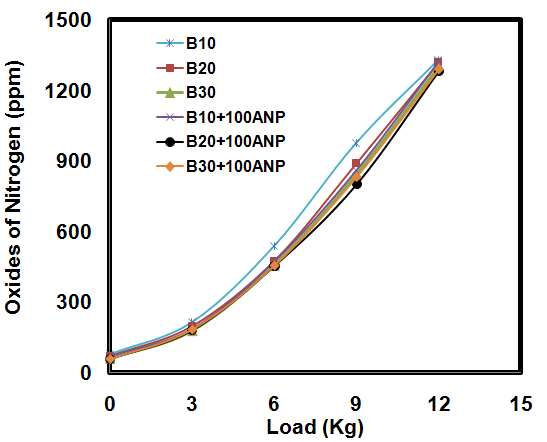

3.2.3. Oxides of Nitrogen (NOX)

- The variation of emission of NOX with load is shown in Figure 7. As the load on the engine increased, the emission of NOX increased. At full load condition, lowest amount of emission of NOX was found for B20+100ANP. High temperature and availability of oxygen are two primary reasons behind development of NOX as nitrogen and oxygen responds at higher temperature [7].

| Figure 7. Variation of Oxides of Nitrogen (NOX) with load |

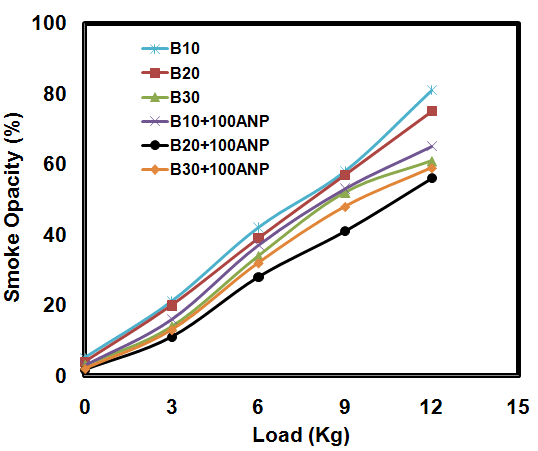

3.2.4. Smoke Opacity

- The variation of smoke opacity with load is shown in Figure 8. As the load on the engine increased, the smoke opacity also increased. The lowest percentage of smoke opacity observed for B20+100ANP was 56% at full load condition. The smoke opacity has been decreased by 25% for B20+100ANP when compared with B20. The smoke opacity decreased for the accessibility of oxygen in the nanoparticles, prompts better combustion and decreased the smoke emission [8].

| Figure 8. Variation of Smoke Opacity with load |

4. Conclusions

- The following conclusions may be drawn from the present study. As compared to B20 blend, the addition of alumina nanoparticles to B20 (LOME20) blend at full load has resulted in the following:1. The Brake Thermal Efficiency has been improved by 22%.2. The Brake Specific Fuel Consumption (BSFC) has been reduced by 17%. 3. The emissions of Hydro Carbons and Carbon monoxide have been reduced by 15% and 25% respectively. 4. The smoke opacity of has been decreased by 25%.

ACKNOWLEDGMENTS

- The authors are grateful to Department of Chemistry, NITK, Surathkal, for providing the facilities for trans esterification and sonication of bio-diesel. The authors are also thankful to Department of Mechanical Engineering, SJEC, Mangaluru, for providing the facilities to carry out the performance and emission testing.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML