-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2016; 6(4A): 25-30

doi:10.5923/c.materials.201601.05

Effect of Ageing on the Tribological Behavior of Inconel 690 Using Taguchi’s Method

Joel Immanuel Concessao1, Jaimon D. Quadros2, Vaishak N. L.3

1PG Scholar in Mechanical Machine Design, Department of Mechanical Engineering, Sahyadri College of Engineering & Management, Mangalore, India

2Department of Mechanical Engineering, Birla Institute of Technology, Ras Al Khaimah, UAE

3Department of Mechanical Engineering, Sahyadri College of Engineering & Management, Mangalore, India

Correspondence to: Joel Immanuel Concessao, PG Scholar in Mechanical Machine Design, Department of Mechanical Engineering, Sahyadri College of Engineering & Management, Mangalore, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Many of our modern technologies in the present day require materials with different combinations of properties that can be used for various applications. One such material is the Inconel 690 possessing various properties like high strength at elevated temperature, toughness, resistance to degradation in corrosive or oxidizing environment, etc. The present work is mainly focused on the study of Tribological properties of Inconel 690 at As Forged condition and at ageing conditions of 725°C for 4 hours respectively. The influences of process parameters like normal load, sliding distance and sliding velocity on the wear loss was studied using pin-on-disc apparatus. The experiments show that normal load is the most significant factor that influencing the wear loss. The work concluded that the combination of parameters that yields to minimum wear loss is not affected by ageing of the Inconel specimen to 725°C.

Keywords: Inconel, Wear, S/N ratio

Cite this paper: Joel Immanuel Concessao, Jaimon D. Quadros, Vaishak N. L., Effect of Ageing on the Tribological Behavior of Inconel 690 Using Taguchi’s Method, American Journal of Materials Science, Vol. 6 No. 4A, 2016, pp. 25-30. doi: 10.5923/c.materials.201601.05.

Article Outline

1. Introduction

- The evolution of super alloys is mainly due to the significant development in gas turbines. Today in many industries metallic alloys are been used at high temperatures and corrosion-resistant applications. Moreover the service temperature even goes above 0.7 of the melting point of the metallic alloys frequently for some applications. Such metallic alloys which possess an extraordinary combination of properties like high temperature strength, toughness and resistance to the degradation in corrosive or oxidizing environment are called super alloys. Basically super alloys are divided into three categories: cobalt based, nickel based and iron nickel based alloys. One of the new nickel based super alloy having excellent resistance to corrosion and elevated temperatures is Inconel 690.The high chromium nickel content gives the alloy an excellent resistance to various corrosive aqueous media and high-temperature applications. It can also endure the sulfidation which takes place at high temperatures. Owing to its anticorrosive properties, the Inconel 690 possesses strong metallurgical stability which permits it to retain structural integrity in various applications. Furthermore Inconel 690 has high strength, excellent metallurgical stability and also favorable fabrication conditions. An outstanding resistance to oxidizing chemicals and to high-temperature oxidizing gases is obtained by the substantial chromium content in the alloy. With the high level of nickel, the alloy exhibits resistance to stress-corrosion cracking in chloride-containing environments and to sodium hydroxide solution.The investigation on the diverse characteristics such as cutting force, temperature, surface roughness, wear and surface integrity etc., of nickel based super alloys was carried out by a lot of researchers. Out of these different characteristics, the prediction of wear was studied by many researchers using Taguchi’s Design of experiments and Artificial Neural Network (ANN). They heat treatment process for the test specimen was conducted in two steps; solution annealing (at high temperature) and thermal treatment (at low temperature) to obtain a change in their microstructure. Observations of microstructure indicated that the temperature and duration of solution annealing affect the grain size of Inconel 690 [1]. The examination on the wear properties of Inconel 690 steam generator tubes in various environmental conditions like temperature variation, air environment and water environment to determine the occurrence of reciprocating sliding wear, with the aid of SEM analysis confirmed that the wear loss variation with temperature was due to the formation of oxide layers on worn surfaces [2]. The identification of iron rich Tribological oxide layers formation under the higher loads resulted to be the prime reason of decrease in the wear rate of Nickel Titanium alloys [3]. The sliding and fretting wear tests of thermal treated Inconel 690 has better wear resistance than high temperature mill annealed Inconel 600 and that the wear and tear due to stick-slip has a very strong effect on the fretting wear behavior of the steam generator tubes [4]. It was noted that wear rate was independent of the apparent contact area and conclusion was drawn that Inconel 600 had 17% higher wear resistance when compared to Inconel 690 at loads varying from 2.5 N to 12.5 N [5]. The conventional sliding tests performed using a pin-on-disk apparatus to compare the test result observed that frictional force was mainly due to the normal loads and vibrating amplitudes and coefficients of friction decreases with the increase in the normal loads and reduction of vibrating amplitudes. Hence Inconel 690 can result in lesser friction forces and also exhibits less wear resistance than Inconel 600 in room temperature water [6].

2. Materials and Methods

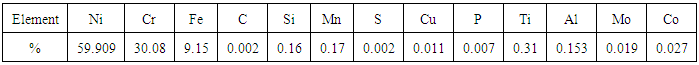

- Inconel 690 is a nickel-chromium based alloy that is well suitable for elevated temperature applications. The high chromium nickel content gives the alloy an excellent resistance to various corrosive aqueous media and high-temperature applications that require resistance to heat and corrosion. The material has high mechanical strength and can be readily formed, machined and welded. Table 1 gives the chemical composition of As forged Inconel 690.

|

|

3. Experimentation

- The Taguchi technique is one of the powerful designs of experiments tool for the acquisition of data in a controlled way and to analyze the influence of process variables over some specific variable which is an unknown function of these process variables [7]. It efficiently obtains the combinations of optimum factor level to achieve a minimum standard deviation (variation) while the mean is kept on the target. It is also a most efficient problem solving tool that updates or improves the performance of the product or process design and system with a sufficient experimental data [8]. This type of approach to experimentation helps in providing an orderly way to collect, analyze, interpret data that satisfies the objectives of the study. The advantage of using this method is that all parameters are varied and at the same time the effect of the performance and their interactions can be learnt simultaneously.

4. Results & Discussion

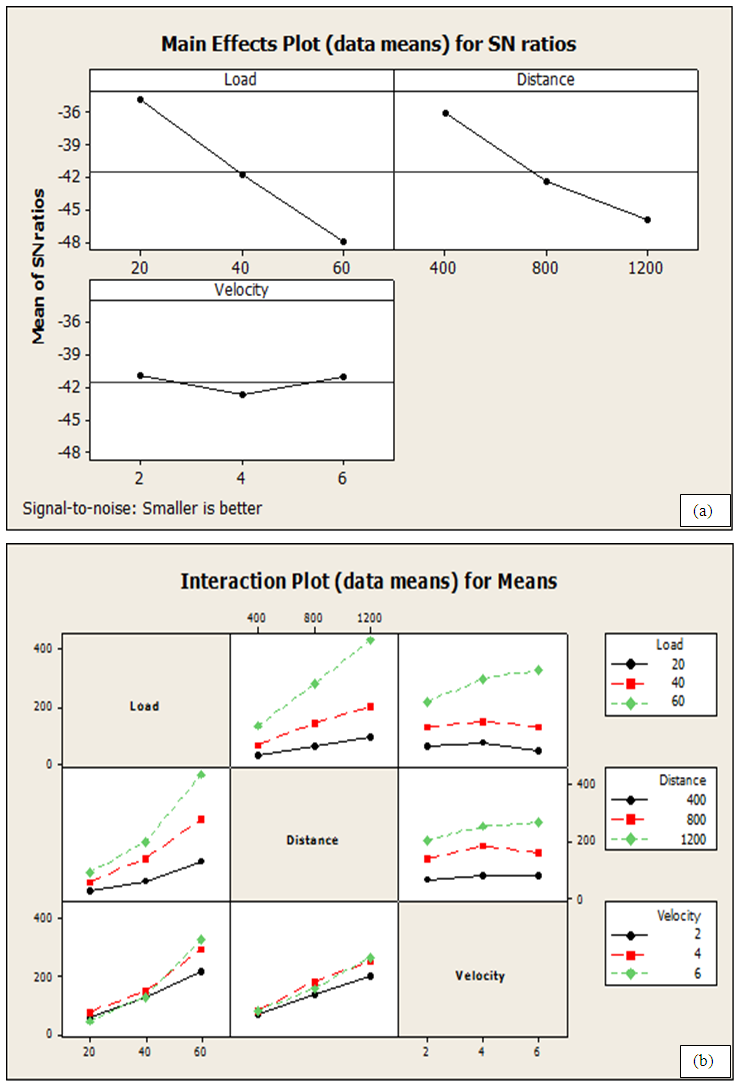

- The experimental wear test results were analyzed using the Taguchi’s Design of Experiments method and main effect and interaction plots were made use to investigate the influence of different process parameters on the wear loss. The popular software MINITAB 14 was made use to statistically analyze the wear study experiments. The wear test results of As Forged Inconel 690 and Inconel aged at 725°C according to Taguchi’s set of experiments are given in Table 3. The experimental results are then transformed into S/N ratios. Wear loss of as forged Inconel 690 and aged Inconel 690 was conducted for 27 test runs according to Taguchi’s design of experiments.

|

| Figure 1. Main effect and Interaction plots for as forged Inconel 690 specimen |

| Figure 2. Main effect and Interaction plots for Inconel 690 specimen aged at 725°C |

5. Conclusions

- The present work is mainly focused on the study of Tribological properties of Inconel 690 at As Forged condition and at ageing conditions of 725°C for 4 hours respectively. The study is conducted as per Taguchi’s design of experiment. Following conclusions are drawn:Ÿ Ageing Heat treatment on Inconel 690 increases the wear loss because it softens the material.Ÿ The normal load was found to be the strongest influencing parameter or factor on the wear loss for both as forged and aged Inconel 690, followed by sliding distance.Ÿ The combination of 20 N, 400 m and 2 m/s gives the minimum wear loss for As Forged and aged specimens.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML