-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2015; 5(3C): 112-115

doi:10.5923/c.materials.201502.23

Compressive Behaviour of Polymer/Honeycomb Sandwich Composites

Mohd. Zahid Ansari , Jitendra Jangir , Lokesh Verma , Vikram Singh

PDPM-Indian Institute of Information Technology, Design and Manufacturing (IIITDM) Jabalpur, Khamaria, Jabalpur, India

Correspondence to: Mohd. Zahid Ansari , PDPM-Indian Institute of Information Technology, Design and Manufacturing (IIITDM) Jabalpur, Khamaria, Jabalpur, India.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Sandwich composites are an important class of engineering materials that provide very strong yet light weight, high impact energy absorbing and high temperature operating ability. This paper studies the compressive behaviour of honeycomb sandwich composites made of hexagonal aluminium core and acrylic polymer skin using experimental and numerical methods. Prepared sandwich samples were fabricated and tested for maximum compressive strength. In addition, finite element analysis was conducted to characterize the deformation, stress and thermal insulation properties of another aluminium alloy sandwich in out-of-plane loading. The sandwich plates were subjected to compressive load, whereas, the beams were subject to bending load. Thermal insulation study on sandwich with acrylic skin was also conducted. Experimental results showed that compressive strength of the sandwich with acrylic skin can support a distributed maximum load of 4 MPa. In addition, the thermal insulation property of this sandwich is found to be better than a wood plate.

Keywords: Honeycomb, Acrylic polymer, Cellular solid, Sandwich composite, Finite element analysis (FEA)

Cite this paper: Mohd. Zahid Ansari , Jitendra Jangir , Lokesh Verma , Vikram Singh , Compressive Behaviour of Polymer/Honeycomb Sandwich Composites, American Journal of Materials Science, Vol. 5 No. 3C, 2015, pp. 112-115. doi: 10.5923/c.materials.201502.23.

Article Outline

1. Introduction

- Honeycomb is basically a cellular structure where highly ordered thick cells are separated by thin walls of material to form a planar structure. Normally, the shapes of the cells are hexagonal, but square and rectangular shapes are also available. The structure was originally observed in natural honey beehives. Honeycomb materials belong to a special class of engineering materials called cellular solids. These solids have a highly porous structure with many voids and bobbles inside. The porosity is normally more than ninety percent by volume. Honeycombs can be made of almost any material depending on the application. The materials can be metal, polymer, ceramic and glasses. Al honeycombs are most commonly used as the core material in sandwich composites to impart lightweight and high strength properties. As such, they are used in automobiles, aerospace, naval and other lightweight yet strong load supporting application. The honeycombs have a planar structure and are normally designed to support out-of-plane compressive or bending loads. The loading can be purely compressive or bending load wherein the compressive as well as tensile loads occur simultaneously. Sandwich composites provide a number of structural advantages over conventional engineering materials such as high strength-to-weight ratio, high impact load resistance and high thermal insulation properties [1, 2]. Therefore, sandwich structures are commonly used in automobiles, aircraft, aerospace vehicles, ship structure, medical implants and safety equipments. Sandwich is basically a type of thick composite where two thin and high strength skin sheets are bonded adhesively to a thick and low strength core in between. Sandwich composites have very good out-of-plane loading strength. The skin of a sandwich supports normal tensile and compressive loads, whereas, the core supports mainly the shear load [1]. By varying the core and skin materials and designs, efficient engineering structures and designs can be achieved. The skin of the sandwich can be thin sheet of metals, alloys or another composite material like carbon-fibre reinforced plastic and glass-fibre reinforced plastic [3, 4]. Similarly, the core material can be wood or a cellular solid material like honeycomb and foam. This study uses thin acrylic sheet as skin and thick hexagonal aluminium honeycomb as the core of the sandwich in experiments. The samples were fabricated and tested for maximum through-thickness compressive load supporting ability [5]. Commercial finite element analysis software ANSYS Workbench was used to study the compressive, bending and thermal characteristics of sandwich plates and beams made of acrylic and aluminium skin and aluminium honeycomb core.

2. Experiments and Simulation

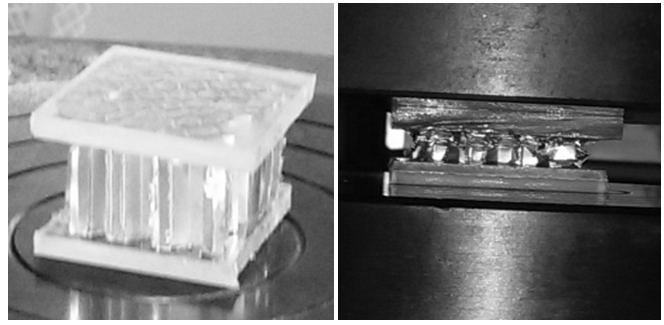

- Figure 1 shows the sandwich sample before and after the compression test. The skin was made of 5 mm thick acrylic polymer sheet and the core was made of low density aluminium honeycomb. The height of the honeycomb was 25 mm. The cell size was 6 mm and the wall thickness was 0.02 mm. The honeycomb samples were cut from the block using grinder cutter. The core was bonded adhesively to the skins using an epoxy adhesive resin. Five samples were tested for static compression using a universal testing machine. Typical sample size was 50×50×35 mm.

| Figure 1. Experimental honeycomb sandwich sample before (top) and after (bottom) the compressive tests |

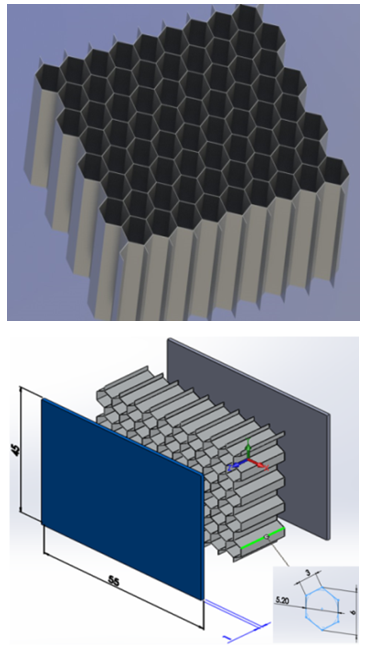

| Figure 2. CAD models of aluminium honeycomb and sandwich panel |

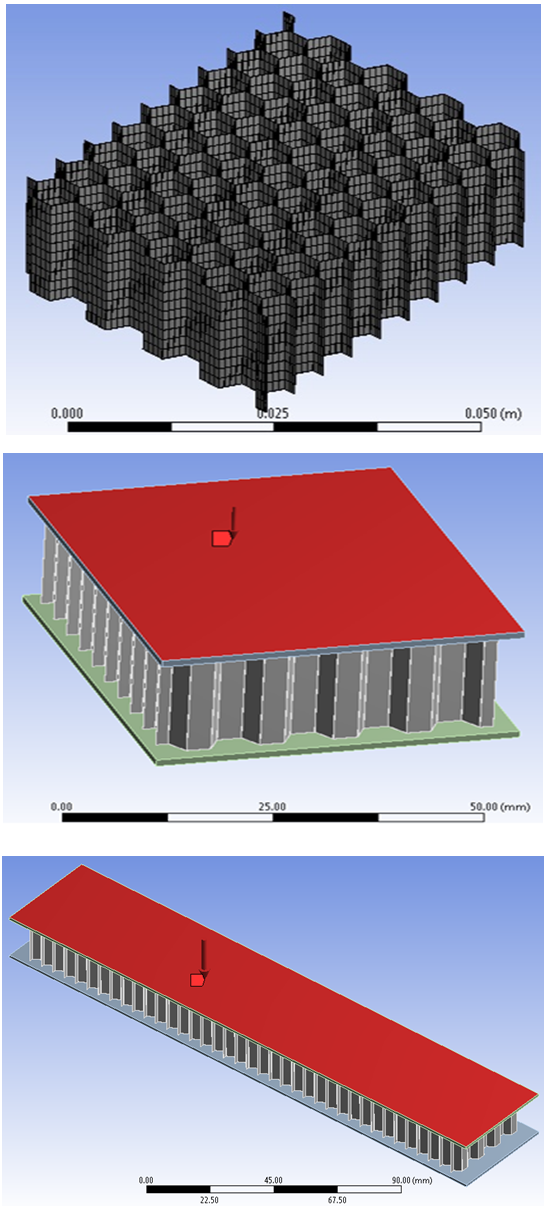

| Figure 3. Finite element models of sandwich plate and beam |

3. Results and Discussion

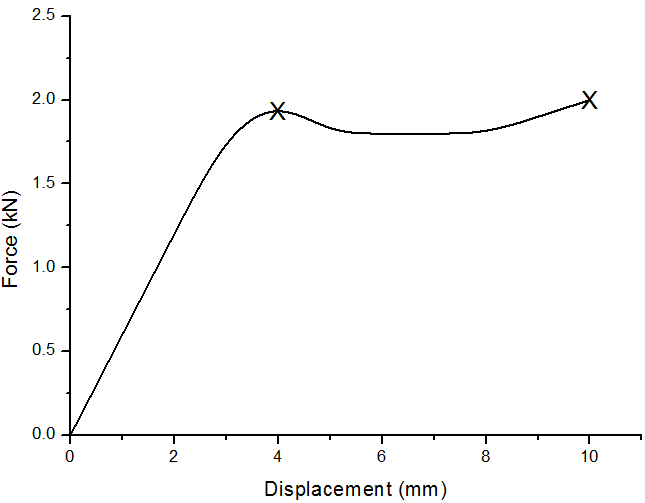

- Figure 4 presents the average force-displacement characteristics of the honeycomb core under compression. The samples were compressed by about 10 mm, which corresponds to a strain of 40%. The annotation in figure 3 indicate the experimental data for the onset of material yielding and collapsing. The curve show a behaviour typical of cellular solid like foam and honeycomb material and has three distinct deformation zones, namely linear elastic, plastic plateau and densification.

| Figure 4. Compressive force-displacement behaviour of sandwich samples |

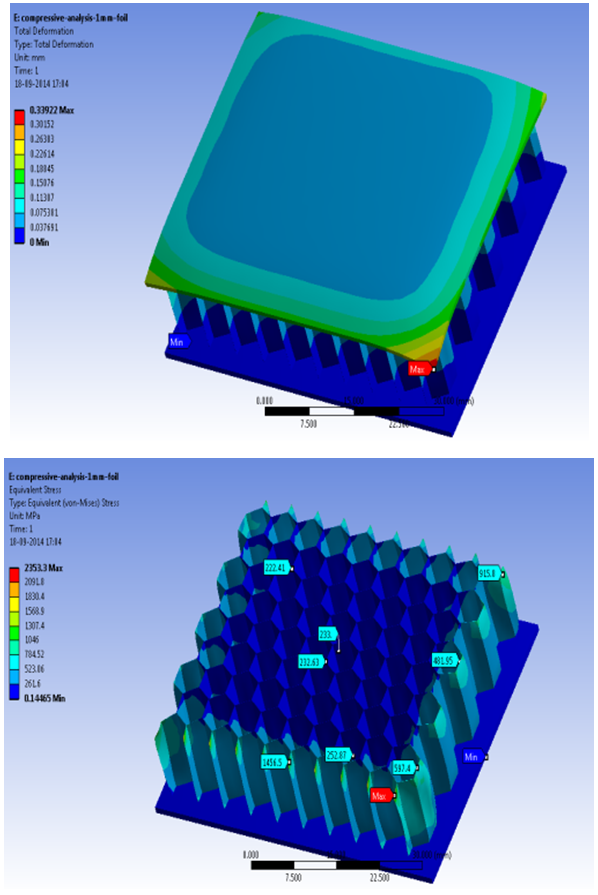

| Figure 5. FEA results for deformation (top) and maximum stress (below) for compressive load of 4 MPa in sandwich plate |

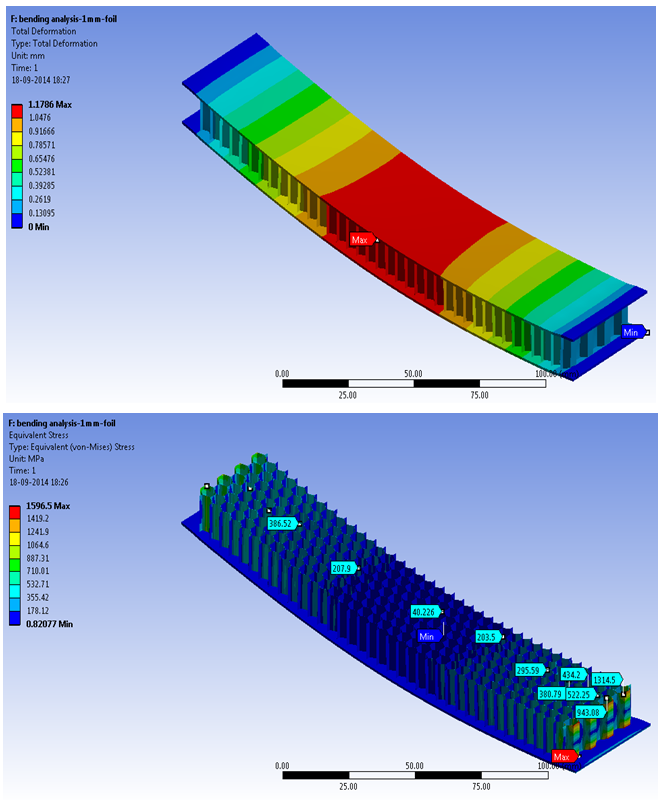

| Figure 6. FEA results for deformation (top) and maximum stress (below) for compressive load of 500 kPa in sandwich beam |

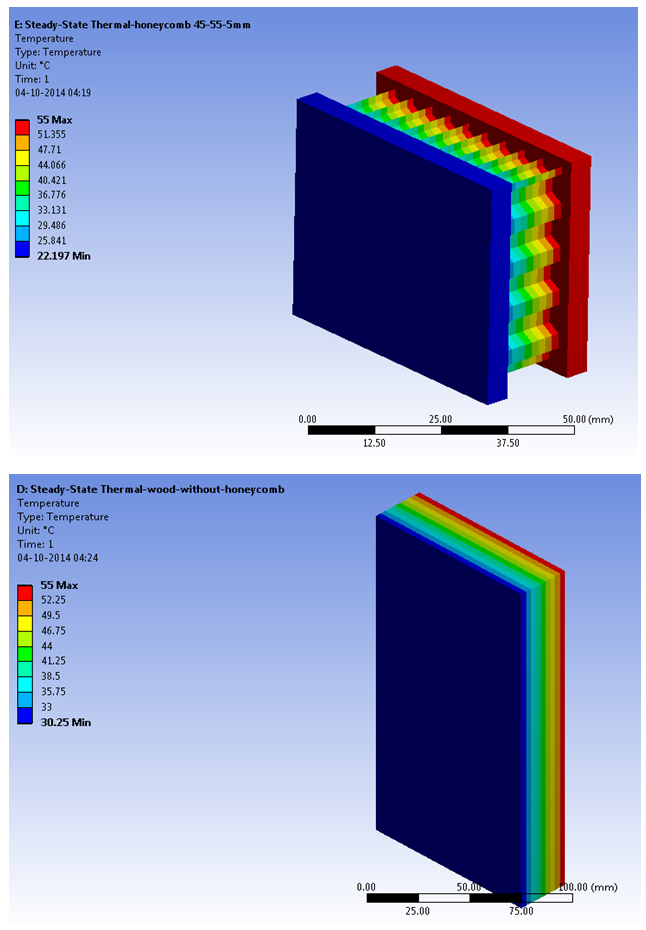

| Figure 7. FEA results for temperature distribution in sandwich (top) and wood (below) plates |

4. Conclusions

- This study used experimental method to investigate the compressive strength of aluminium honeycomb sandwich composite under compressive load. In addition, finite element analysis was conducted on aluminium alloy honeycomb sandwich with same core and skin material to study the deflection and stress characteristics of sandwich plate and beam under out-of-plane loading. During compression test, the prepared sandwich samples showed the typical force-displacement behaviour of a honeycomb sandwich with linear and plateau zones. Results showed the sandwich plate samples can support a distributed compressive load up to 4 MPa. The samples failed by yielding and buckling at this load. Numerical results using finite element analysis on aluminium alloy skin and core sandwich plates showed a maximum deflection of 1 mm occurs for the load of 4 MPa and the plates can support this load without failure. Similarly, the bending test on this sandwich beam showed a deflection 1.2 mm at distributed load of 0.5 MPa, but the sandwich will start to yield due to very high local stresses in the honeycomb. Finally, the thermal insulation results showed that sandwich composite is providing an insulation which is about 8°C than wood. Thus, honeycomb is more suitable for thermal insulation.

ACKNOWLEDGEMENTS

- This study was supported by Indian Institute of Information Technology, Design and Manufacturing-Jabalpur.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML