-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2015; 5(3C): 107-111

doi:10.5923/c.materials.201502.22

Mechanical Behaviour of Polymer Sandwich Composites under Compression

Mohd. Zahid Ansari , Sameer Rathi , Kewal Chand Swami , Sunil, Sonika Sahu

PDPM-Indian Institute of Information Technology, Design and Manufacturing (IIITDM) Jabalpur, Khamaria, Jabalpur, India

Correspondence to: Mohd. Zahid Ansari , PDPM-Indian Institute of Information Technology, Design and Manufacturing (IIITDM) Jabalpur, Khamaria, Jabalpur, India.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

As an eco-friendly alternate to wood the present study investigates the feasibility of panels made of composite sandwich comprising closed-cell polyurethane (PU) foam core and acrylic sheet skins to be used as door in houses. Sandwich samples were fabricated and tested for their maximum compressive strength using universal testing machine. The thickness of the skin and core was 5 mm and 25 mm, respectively. The tensile strength of the acrylic skin and the compressive strain-rate sensitivity of the PU foam were determined experimentally. Finite element analysis was conducted on the samples to study the effect of reinforcement of the sandwich plate with silicon pins under different load conditions. Results show that the compressive strength of the sandwich is increased by more than 50% when the pins are used. Such an arrangement is particularly useful for increasing the impact strength of the sandwich door panels.

Keywords: PU foam, Acrylic polymer, Cellular solid, Sandwich composite, Material testing, Finite element analysis

Cite this paper: Mohd. Zahid Ansari , Sameer Rathi , Kewal Chand Swami , Sunil, Sonika Sahu , Mechanical Behaviour of Polymer Sandwich Composites under Compression, American Journal of Materials Science, Vol. 5 No. 3C, 2015, pp. 107-111. doi: 10.5923/c.materials.201502.22.

Article Outline

1. Introduction

- Sandwich composites are a class of composite material structure where two thin, high strength skin sheets are separated by a thick, low strength core. The skin material can be a simple metal alloy or polymer sheet, or it can be advanced composite material like carbon-fibre reinforced plastic and glass-fibre reinforced plastic. Similarly, the core material can be a simple wood or a cellular solid material like honeycomb and foam. The skins support normal tensile and compressive loads, whereas, the core supports mainly the shear load. These composites are especially suited to support out-of-plane compressive load and bending load [1]. Sandwich composites have many advantages over conventional materials such as lightweight, very high strength-to-weight ratio, high energy absorption and impact resistance and high thermal insulation characteristics [1-5]. Accordingly, sandwich materials are extensively used in applications like automobiles, aircraft, aerospace vehicles, ship structure, medical implants and safety equipments.Sandwich structures consisting PU foam core and thin layers of acrylic sheets are currently used in many engineering applications such as in refrigerated vehicles, cold stores, boat building, within and outside of aerospace engineering and can be used in the construction of composite panels, shells, and tubes with high structural efficiency. PU foam is a thermosetting plastic expanded to form predominately low-density cellular structure [1, 6]. It is used as core to form a sandwich composite mainly due to its light weight, high impact energy absorption and high thermal insulation features. Similarly, acrylic sheets are light weight and have higher impact-resistant than glass and have better weather resistance than other types of transparent polymers. Thus, sandwich structure made of PU foam and acrylic sheet can be used in several engineering applications with low manufacturing cost and good properties. Present study focuses on application of PU foam core with acrylic sheet skin sandwich composite as door panel and characterises its compressive strength using experimental and finite element analysis techniques.

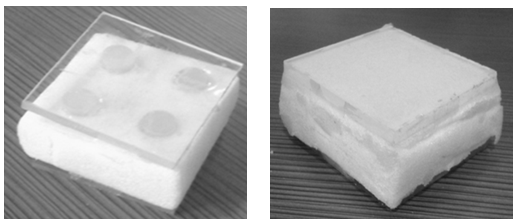

2. Experiments and Simulation

- Figure 1 shows the experimental arrangement to determine the tensile strength of the acrylic sheets and the compressive strength of the foams. Acrylic sheet of thickness 5 mm and closed-cell PU foam block of density about 40 kg/m3 were procured from local supplier. The tests were performed using high sensitive universal testing machine, Tinius Olsen H250K (USA), of maximum capacity 25 kN. The acrylic sheet was elongated at a strain rate of 0.75 mm/min, whereas, the foams were compressed under different strain rates of 0.75 mm/min, 2.5 mm/min and 5 mm/min. Typical size of the acrylic skin samples were 100×25×5 mm and that of PU foams were about 30×30×30 mm. The tests were conducted at room temperature.After characterizing the skin and core materials, sandwich composite samples were prepared. These samples were tested for maximum compressive strength. The acrylic skins were adhesively bonded to the PU core using a epoxy adhesive resin. The core thickness was 25 mm. In order to improve the compressive strength of the sandwich, four hard cylindrical silicone rubber pins were placed vertically between the skin sheets. Typical size of the sandwich sample was 50×50×35 mm. Figure 1 shows the experimental arrangement and the sandwich samples with and without the pins. To better understand and visualize the deformation and stress distributions in the sandwich composites, a commercial finite element analysis software ANSYS Workbench was used to study the compressive behaviour of the sandwich sample with and without the pins under loads conditions of 2 kN and 4 kN.

3. Results and Discussion

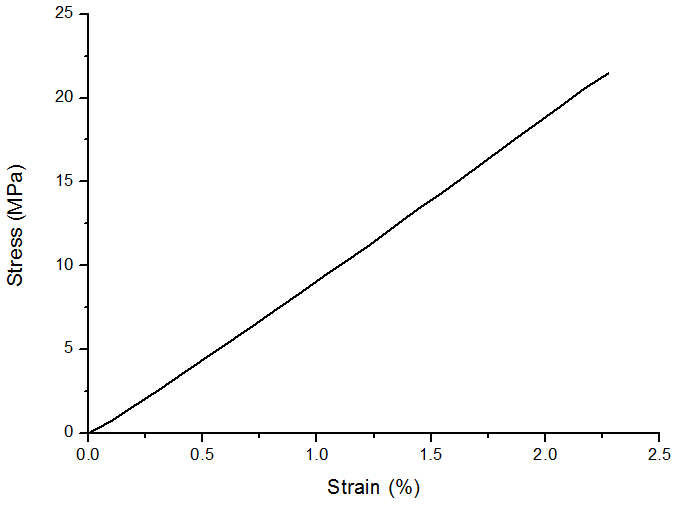

- Figure 2 presents the typical stress-strain characteristics of the acrylic sheet sample tested under tensile load. It can be seen in the figure that the stress is increasing linearly with strain and the sample is fractured at a failure strain of about 2.3%. The absence of nonlinearity, i.e. plastic zone, in the behaviour clearly shows the brittle fracture of the acrylic sheet. This behaviour can also be observed in Figure 1 above where the fractured surfaces are flat. The average elastic modulus of the samples was calculated as 1 GPa and the ultimate strength was found to be about 22 MPa. The behaviour shown in Figure 2 is typical of a hard and brittle polymer material like acrylic.

| Figure 2. Tensile stress-strain curve for acrylic polymer sheet |

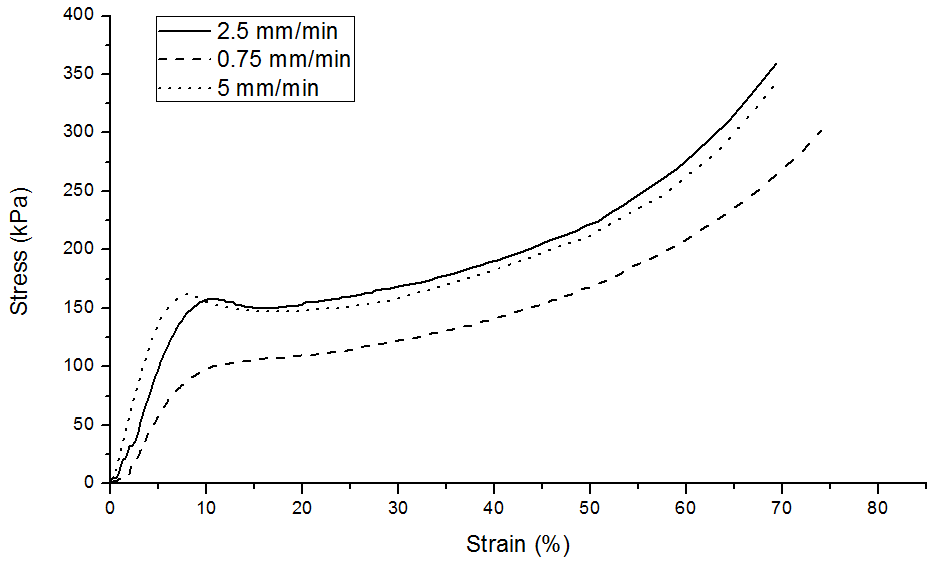

| Figure 3. Compressive stress-strain behaviour of PU foam samples under different strain rates |

| Figure 4. Deformed samples with pin (left) and without pin (right) |

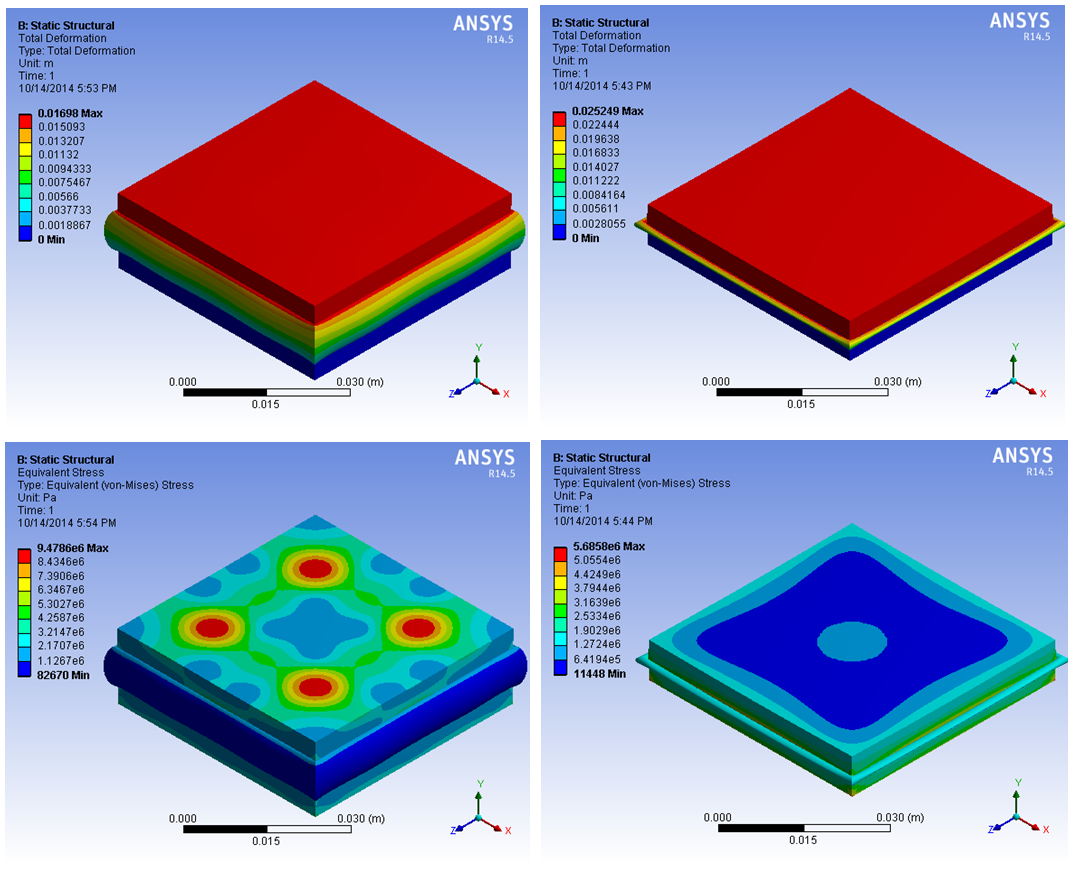

| Figure 5. FEA results for deformation (top row) and maximum stress (bottom row) for 2 kN compressive load in sandwich samples with pin (left column) and without pin (right column) |

| Figure 6. FEA results for deformation (top row) and maximum stress (bottom row) for 4 kN compressive load in sandwich samples with pin (left column) and without pin (right column) |

- The sandwich door panels presented here would have numerous advantages over wooden ones in terms of termite-proof, fire-proof, water-proof and high thermal insulation features. In addition, the door panels can be made of coloured acrylic sheets and foams making use of paints redundant and decorative patterns can be etched onto the panels. Such a sandwich panel can also be used in pre-fabricated structure form and can be transported easily to offer aid and relief and help disaster management in affected areas. In addition, the excellent thermal insulation characteristics of PU foam and acrylic sheet based sandwich composite can help save energy bill and make a comfortable living environment in extremely hot and cold climate conditions.

4. Conclusions

- This study investigated the application of polymer sandwich composite structure comprising thick PU foam core and thin acrylic sheet skins as door panel in house. Sandwich samples were fabricated with and without pin reinforcement and were subjected to static compression tests. The pin was made of hard silicone rubber. The elastic modulus and the ultimate strength of the acrylic sheet under tensile load was found to be about 1 GPa and 22 MPa, respectively. The compressive tests on PU foam showed strain-rate sensitivity and their elastic modulus for the three strain rates of 0.75 mm/min, 2.5 mm/min and 5 mm/min was found to be about 1.5 MPa, 1.8 MPa and 2 MPa. The foam samples showed a high degree of recovery of more than 70%. Tests also showed that by using pins to reinforce the sandwich, the compressive strength was increased from 2 kN to 4.3 kN. Finally, the finite element analysis results showed that pins were highly stressed during the compression and the sandwich structures are safe up to a load of 4 kN.

ACKNOWLEDGEMENTS

- This study was supported by Indian Institute of Information Technology, Design and Manufacturing-Jabalpur.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML