-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2015; 5(3C): 53-57

doi:10.5923/c.materials.201502.11

Effect of B4C Particulates Addition on Wear Properties of Al7025 Alloy Composites

Sallahauddin Attar 1, Madeva Nagaral 2, H. N. Reddappa 1, V. Auradi 3

1Department of Mechanical Engineering, Bangalore Institute of Technology, Bangalore, India

2Aircraft Research and Design Centre, HAL, Bangalore, India

3Department of Mechanical Engineering, Siddaganga Institute of Technology, Tumkur, India

Correspondence to: Sallahauddin Attar , Department of Mechanical Engineering, Bangalore Institute of Technology, Bangalore, India.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

In the present work, an attempt has been made to develop and study the wear properties of Al7025-B4C reinforced aluminum metal matrix composites. The composites were prepared by using liquid metallurgy technique. Al7025 alloy was taken as the base matrix to which B4C particulates were used as reinforcements. 3 and 6 wt. % of B4C particulates were added to the base matrix. For each composite, reinforcement particles were pre-heated to a temperature of 500 degree Celsius to improve wettability and distribution. The microstructural study was done by using scanning electron microscope, which revealed the uniform distribution of particles in matrix alloy. A pin-on-disc wear testing machine was used to evaluate the wear rate, in which a hardened EN32 steel disc was used as the counter face. The results indicated that the wear rate of the composites was lesser than that of the Al7025 matrix. However, the material loss in terms of wear rate increased with the increase in load and sliding speed both in case of composites and the alloy. The worn surfaces were characterized by SEM microanalysis to know the different wear mechanisms.

Keywords: Al7025 alloy, Wear, B4C, Stir casting, Composites

Cite this paper: Sallahauddin Attar , Madeva Nagaral , H. N. Reddappa , V. Auradi , Effect of B4C Particulates Addition on Wear Properties of Al7025 Alloy Composites, American Journal of Materials Science, Vol. 5 No. 3C, 2015, pp. 53-57. doi: 10.5923/c.materials.201502.11.

Article Outline

1. Introduction

- In recent years there has been a considerable interest in metal matrix composites (MMCs). Metal-matrix composites (MMCS) have recently become candidates for critical structural applications because of their superior specific strength and stiffness [1-2]. The need for new wear-resistant materials for high performance tribological applications has been one of the major incentives for the technological development of ceramic particulate reinforced aluminium alloys during the last decade [3]. Continuous progress in science and technology creates an increasing demand for improved structural materials. Materials like cast iron with graphite or steel with high carbide content, as well as tungsten carbides, consisting of carbides and metallic binders, also belong to this group of composite materials. Metal matrix composites (MMCs) usually consist of a low-density metal, such as aluminium or magnesium, reinforced with particulate or fibers of a ceramic material, such as Boron carbide, silicon carbide or graphite [4-7]. Compared with unreinforced metals, MMCs offer higher specific strength and stiffness, higher operating temperature, and greater wear resistance, as well as the opportunity to tailor these properties for a particular application. Metal composite materials have found application in many areas of daily life for quite some time [8]. Substantial progress in the development of light metal matrix composites has been achieved in recent decades, so that they could be introduced into the most important applications such as in traffic engineering, especially in the automotive industry. However, despite the increased use of MMCs in recent years, the problems of poor fracture toughness and unsatisfactory fatigue properties have limited their application in certain fields [9-11]. With hard particles dispersed in a relatively ductile matrix, aluminium alloy matrix composites possess an ideal structure for wear-resistant materials. These Al alloy composites which are reinforced with ceramic particulates led to a new generation of tailorable engineering materials with improved specific properties. Most of the composites having actual or potential use as structural materials are manufactured by powder processing, casting or squeeze casting, or a method similar to one of these (such as rheocasting), although other methods are also used (e.g., spray deposition) [12-15].

2. Experimental Details

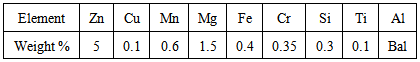

- In the present work, an experiment was made to study the wear properties of as cast and Al7025-B4C particulate composites. The composites containing 3and 6 wt. % of B4C particulates were prepared using liquid metallurgy route in particular stir casting technique. Table 1 represents the chemical composition of Al7025. Initially required amount of charge or matrix material was placed in a graphite or silicon carbide crucible, which will be placed in electric resistance furnace at a temperature of around 730C. After complete melting of Al7025 matrix degassing was carried out by using Solid HexaChloro ethane, which helps to remove unwanted adsorbed gases from the melt [16-18]. Once degassing is over, the preheated ceramic reinforcement particles (B4C) of size 80 microns were introduced into matrix in a novel way which involves two-stage additions of reinforcement during melt stirring. This novel two stage additions of reinforcement into matrix Al7025 will increases wettability of the matrix and ceramic reinforcement and there will be uniform distribution of the particles.

|

3. Results and Discussion

3.1. Microstructure

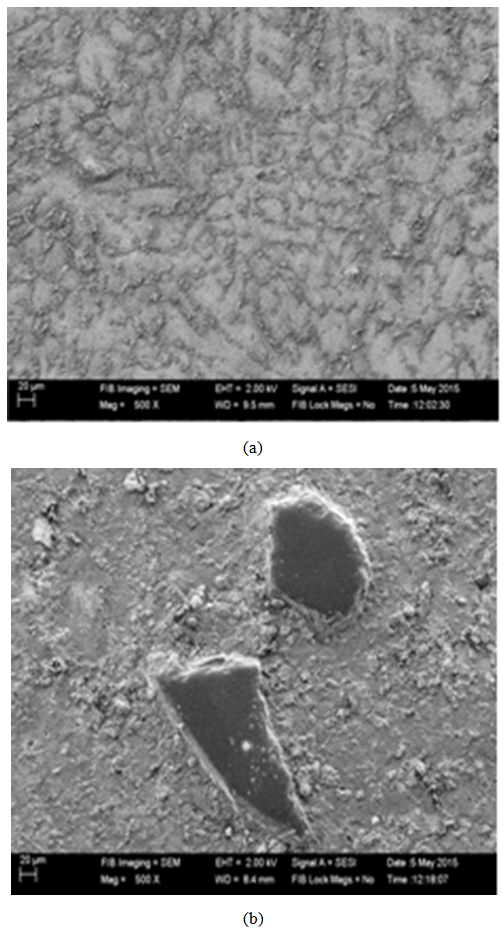

- Microstructure for different samples was studied using scanning electron microscope. Figure 1 (a)-(b) shows microstructure of as cast Al7025 and Al7025 with 6wt% B4C particulates where microstructure was viewed under scanning electron microscope. Figure 1(b) reveals the distribution of B4C particulates in specimens and it can be observed that there is fairly uniform distribution of particles. Excellent bonding between the matrix and the reinforcement is observed.

| Figure 1. Showing the SEM microphotographs of (a) as cast Al7025 alloy (b) Al7025-6% B4C composite |

3.2. Wear Properties

3.2.1. Effect of Load on Volumetric Wear Loss and Wear Rate

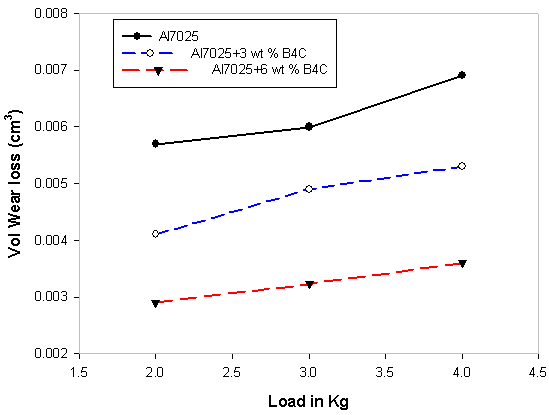

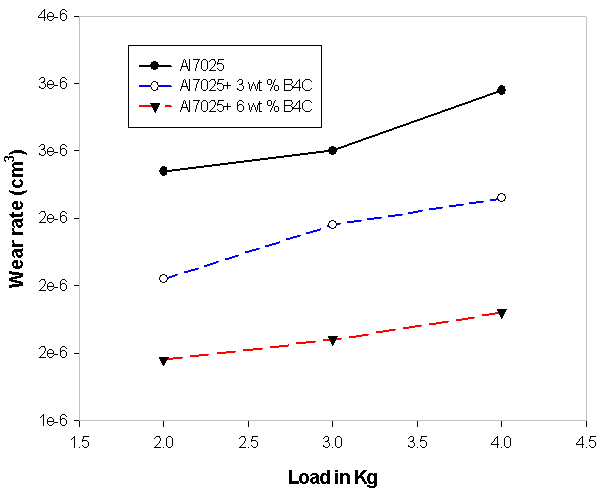

- The load on wear test plays an important role in wear. Several experiments are carried out to observe the effect of normal load on wear rate of aluminium. To study the effect of load on wear, graphs were plotted for volumetric wear loss against varying loads of 2kg, 3kg and 4kg at a constant speed of 300 rpm. Similarly for wear rate the graphs were plotted. All the tests were carried out at room temperature. From Figures 2 & 3, it is observed that volumetric wear loss and wear rate increases with the increase in load. The hard B4C particles increases the wear resistance of the composite materials, resists the cutting action of the pin surface, which results in low material removal from the pin surface. The wear rate increases with increasing applied load in all conditions. B4C particles act as load bearing element.

| Figure 2. Volumetric wear loss Vs Load at 300 rpm |

| Figure 3. Wear rate Vs load at 300 rpm |

3.2.2. Effect of Disc Speed on Volumetric Wear Loss and Wear Rate

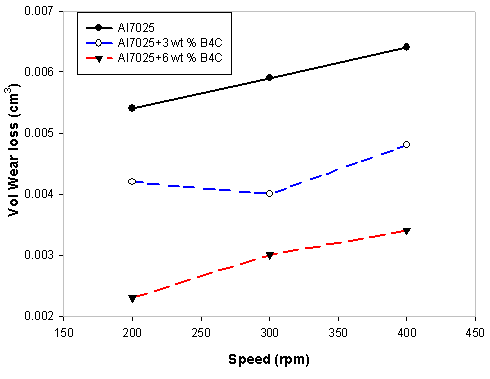

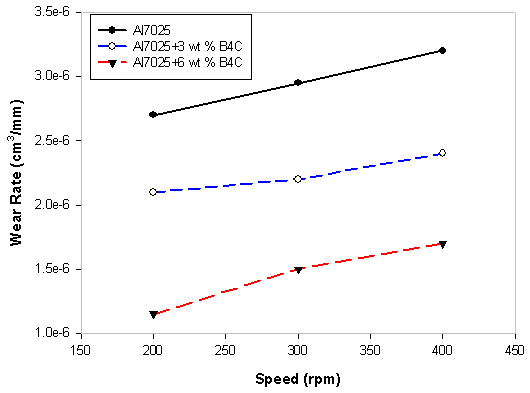

- Figures 4 & 5 shows the variation of volumetric wear loss and wear rate with the variation of speed. The test was conducted with varying disc speed of 200 rpm, 300 rpm and 400 rpm at a constant load of 3 kg. From this figure 5 it is observed that wear rate increases with the increase of sliding speed. For base alloy the effect is more compared to B4C reinforced composite.

| Figure 4. Volumetric wear loss Vs Speed at 3 kg load |

| Figure 5. Wear rate Vs Speed at 3 kg load |

3.3. Worn Surface Morphology

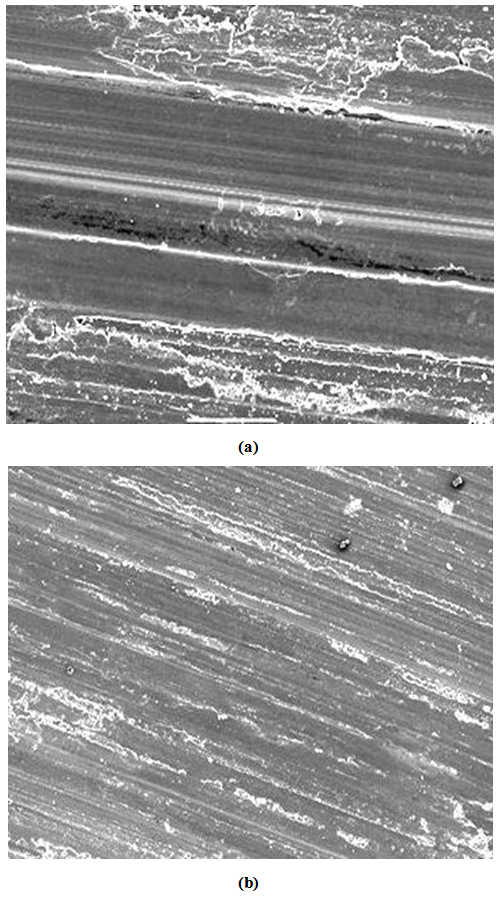

- Scanning electron microscopy was done on base alloy Al7025 and Al7025+ 6 wt. % of B4C composite samples. Figure 6 indicates the surface morphology after wear testing on base alloy Al7025 and 6 wt. % of B4C composite specimen. The images support the argument that addition of hard B4C particles improved the wear resistance of composites. It is clear from the Fig. 6 that the wear tracks and surface delamination are evident. Wear track is observed in case of Al7025, indicates the abrasive wear mechanism. Due to high temperate and friction, only oxide wear has taken place. The wear resistance is more in case of (Al7025+ B4C) composites alloy. The results revealed that the composites with B4C particulates have better wear resistance property compared to base alloy.

| Figure 6. SEM microphotographs of worn suface of (a) as cast Al7025 alloy (b) Al7025-6% B4C composite at 3 kg load and 300rpm |

4. Conclusions

- The present work on processing and evaluation of Al7025-B4C metal matrix composite by melt stirring has led to following conclusions. Al7025 alloy based composites have been successfully fabricated by melt stirring method. The scanning electron microphotographs of composites revealed fairly uniform distribution of reinforcement particulates in the Al7025 alloy metal matrix. The addition of B4C particles to Al7025 alloy matrix improves the wear resistance of the composite. The wear rate is dominated by load factor and sliding speed. The increase of loads and sliding speeds leads to a significant increase in the volumetric wear loss and wear rate. The Al7025-3 & 6 wt. % of B4C composites have shown lower rate of wear as compared to that observed in as cast Al7025alloy matrix.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML