-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2015; 5(3C): 48-52

doi:10.5923/c.materials.201502.10

Influence of Heat Treatment on Microstructure, Hardness and Wear Behavior of Super Duplex Stainless Steel AISI 2507

Mahesh B. Davanageri 1, Narendranath S. 2, Ravikiran Kadoli 2

1Department of Mechanical Engineering, Sahyadri College of Engineering and Management, Mangalore, India

2Department of Mechanical Engineering, NITK, Surathkal, Mangalore, India

Correspondence to: Mahesh B. Davanageri , Department of Mechanical Engineering, Sahyadri College of Engineering and Management, Mangalore, India.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

In the present work the microstructure, hardness and wear behavior of super duplex stainless AISI 2507 were investigated when it was exposed to heat treatment 850°C for one hour followed by water and oil quenching. It was found that heat treatment at 850°C duplex stainless steel precipitates secondary phase sigma  . The sigma

. The sigma  phase is a tetragonal crystal structure, originated from the phase transformation of ferrite to

phase is a tetragonal crystal structure, originated from the phase transformation of ferrite to  phase. When the ferrite to sigma

phase. When the ferrite to sigma  phase transformation occurs, the

phase transformation occurs, the  phase will precipitate in the high Cr-concentrated region of

phase will precipitate in the high Cr-concentrated region of  and is formed directly in

and is formed directly in  particles. The sigma

particles. The sigma  phase increases the hardness. The increase in hardness was found to be directly correlated with the precipitation of sigma phase in the microstructure. The microstructures of heat treated samples were examined using scanning electron microscope and X-ray diffraction analysis (XRD) and both confirm the precipitation of sigma phase. The hardness and Wear mechanisms of super duplex stainless steel AISI 2507 were studied as a function of heat treatment conditions. Wear tests were carried out using pin on disc wear testing equipment at sliding distance conditions. Results showed that existence of sigma phase, increase the hardness and wear resistance in heat treated samples.

phase increases the hardness. The increase in hardness was found to be directly correlated with the precipitation of sigma phase in the microstructure. The microstructures of heat treated samples were examined using scanning electron microscope and X-ray diffraction analysis (XRD) and both confirm the precipitation of sigma phase. The hardness and Wear mechanisms of super duplex stainless steel AISI 2507 were studied as a function of heat treatment conditions. Wear tests were carried out using pin on disc wear testing equipment at sliding distance conditions. Results showed that existence of sigma phase, increase the hardness and wear resistance in heat treated samples.

Keywords: Heat treatment, Super duplex stainless steel, Sigma phase, Sliding distance, XRD, SEM

Cite this paper: Mahesh B. Davanageri , Narendranath S. , Ravikiran Kadoli , Influence of Heat Treatment on Microstructure, Hardness and Wear Behavior of Super Duplex Stainless Steel AISI 2507, American Journal of Materials Science, Vol. 5 No. 3C, 2015, pp. 48-52. doi: 10.5923/c.materials.201502.10.

Article Outline

1. Introduction

- Duplex stainless steels (DSS) possess excellent mechanical and corrosion resistance properties approving their application in various fields including oil, chemical, structural, marine and nuclear industries [1–6]. These properties attenuate the microstructure of steels into austenite (γ) and ferrite (δ) phases. However, the distribution and partitioning of phases and alloying elements become imperative for advantageous properties [7-8]. The microstructure balancing of DSS is executed via chemical composition and heat treatment. The heat treatment tends to change the phase balance imparting distinguished properties. A balanced microstructure in duplex stainless steel is achieved by incorporating appropriate heat treatment methods. It has been reported earlier that, some temperature ranges adversely affect the balance of microstructure forming austenite-to-ferrite phase transformation [9]. For instance, heat treatment in the temperature range of 500–1000°C tend to form a friable sigma phase in duplex stainless steel [10, 11], resulting in precipitation reaction forming secondary phases such as sigma (σ), Chi (χ), secondary austenite (χ2), carbides and nitrides significantly affecting mechanical properties and the corrosion resistance [12–14]. Among all the phases, σ-phase becomes a vital phase as it significantly leads to reduction of ductility, toughness and increased hardness of the super duplex stainless steel [7-12]. Sigma phase is an iron-chromium compound with a tetragonal crystal structure which tends to precipitate at interface of ferrite and austenite [13]. However the incubation time for σ-phase precipitation is expected to evolve post five minutes owing to the temperature rise in the range of 850-900°C [14]. Although considerable amount of research on wear behavior of duplex stainless steels have been conducted, the effect of heat treatment influencing microstructure changes has gained less importance. Furthermore, very few studies focused on the influence of heat treatments on wear behavior of these steels in the literature. Hence, the present work is one such attempt to analyze the wear mechanisms subjected to heat treatment of super duplex stainless steel AISI 2507.

2. Experimental Procedure

- The following section describes about the material chemical composition, experimental procedure adopted to conduct the experiments.

2.1. Material

- The commercially received material was an AISI 2507 super duplex stainless steel of 10 mm diameter bar. The chemical composition of the super duplex stainless steel AISI 2507 examined is shown in Table 1.

|

2.2. Experimental Details

- Specimens of wear test of size Ø1030 mm were prepared as per ASTM G99A. The prepared specimens were subjected to solution heat treatment at 1050°C for two hours followed by water quenching to produce a balanced ferrite/austenite microstructure. Subsequently, to induce the sigma phase, specimens were heat treated at temperature of 850°C for 1hr and are quenched in water and oil. The heat treatment condition was selected based on literature [7-9] The microstructure study of as-received and heat treated alloys were carried by ZEISS Optical Microscope and Scanning Electron Microscopy (Model: S-3400N Hitachi Model). Dry sliding wear experiments were performed using a pin on-disc wear testing machine (Model: TR-20, DUCOM) as per ASTM: G99. The specimens were polished and then cleaned before conducting the wear tests. The wear tests were conducted under different distances varying in the range 200 m to 1000 m at constant load, velocity of 30N and 3m/s respectively. The worn surfaces were studied using scanning electron microscope. Hardness tests were performed using a Rockwell hardness testing at a load of 150kgf.

3. Results and Discussion

3.1. Solution Treatment

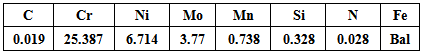

- The better mechanical and chemical characteristics of super duplex stainless steels were obtained after solution heat treatment. This is attributed to the formation of secondary phases such as sigma (σ), Chi (χ), secondary austenite (χ2), carbides, and nitrides and intermetallics originating from the cast microstructure which is dissolved at high temperatures. Water quenching prevents them from precipitating again, keeping large quantities of solute atoms in solid solution. The solution annealing heat treatment was done at 1050°C for 2 hrs followed by water quenching. The microstructure of solution annealed material is obtained by Scanning electron microscope. It was found that, the dual-phase ferrite (δ) and austenite (γ) microstructure contained no secondary phases. The microstructure consists of white etched austenite (γ) and dark shaded ferrite (δ) matrix without any precipitations. The ferrite appears darker than the austenite on the micrograph. Phase volume fraction analysis was carried out using optical image analyzer as per ASTM 562 standard. Results confirm that both austenite (51Wt%) and ferrite (49Wt%) phases exhibits approximately in equal proportion as shown in Figure 1(a) and Figure 1(b).

| Figure 1. Microstructure of solution treated AISI 2507 Super duplex stainless steel (a) Optical microscopic image (b) SEM image |

3.2. Microstructure Analysis

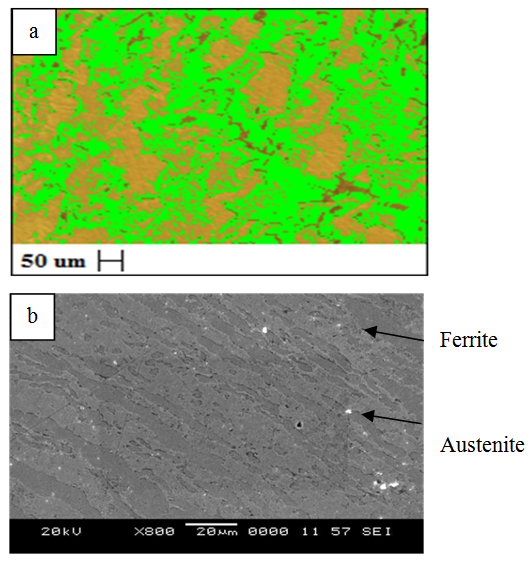

- When super duplex stainless steels were exposed to temperatures below the solution annealing temperature, the meta stable thermodynamic balance was disturbed, causing the material to search for a more stable thermodynamic state through the precipitation of inter metallic phases. The heat treatment at 850°C for 1 hr results in precipitation of secondary phase called sigma phase depletes. The sigma

phase will precipitate in the high Cr-concentrated region of

phase will precipitate in the high Cr-concentrated region of  and is formed directly in 𝛿-ferrite particles. Eutectoid-type reaction of ferrite leads to the precipitation of the

and is formed directly in 𝛿-ferrite particles. Eutectoid-type reaction of ferrite leads to the precipitation of the  -phase at the ferrite-austenite boundary. The quantification of the percentage of sigma phase present was carried out using image analysis by optical microscopy and the evolution of the sigma phase volume fraction at temperature 850°C is about 30%. Similar results are obtained by researchers [14, 15]. The microstructures of duplex stainless steel heat treated at 850°C is shown in Figure 2.

-phase at the ferrite-austenite boundary. The quantification of the percentage of sigma phase present was carried out using image analysis by optical microscopy and the evolution of the sigma phase volume fraction at temperature 850°C is about 30%. Similar results are obtained by researchers [14, 15]. The microstructures of duplex stainless steel heat treated at 850°C is shown in Figure 2. | Figure 2. Microstructure of heat treated specimen at 850°C |

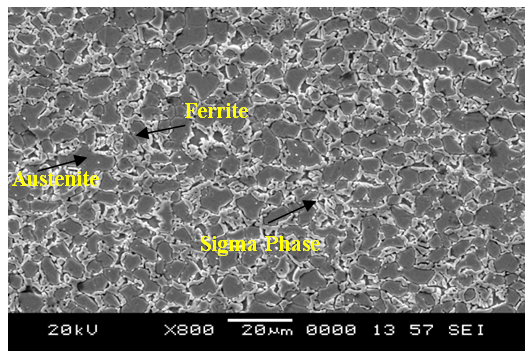

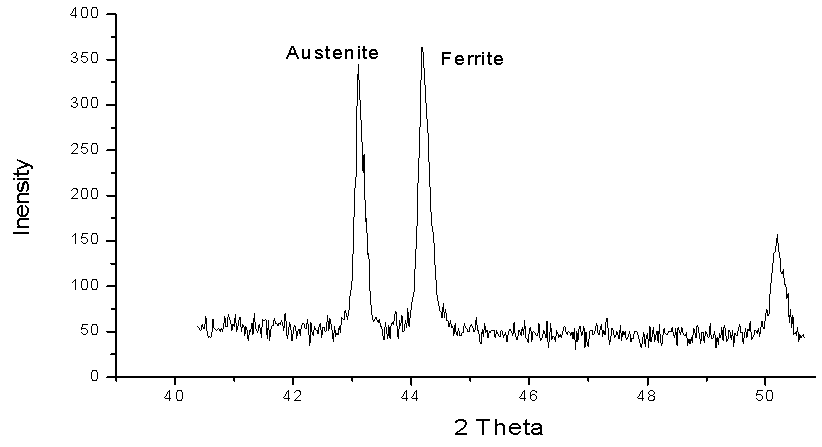

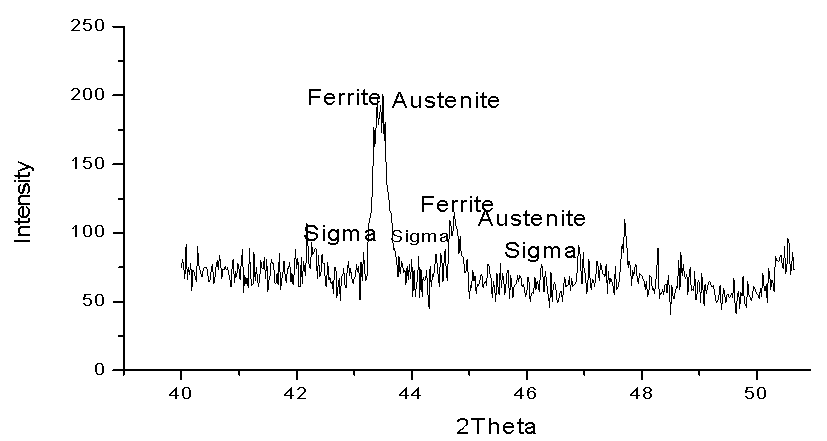

3.3. X-ray Diffraction Analysis

- The results of the X-ray diffraction experiments consist of two diffraction patterns shown in Figures 3 and 4 for the solution treated and heat treated at 850°C for 1hr. The diffraction pattern of the solution treated shows ferrite and austenite phase peaks only and do not show any peak corresponding to other phases whereas additional small peaks corresponding to sigma phase were observed in the heat treated specimen. No evidence was observed for any other precipitates such as chi phase, nitrides, and carbides which might be correlated to the low volume fraction of this precipitates. It was observed that at 850°C the amount of σ phase is about 30% and ferrite has almost.

| Figure 3. X-ray diffraction pattern of solution treated specimen |

| Figure 4. X-ray diffraction pattern of the sample heat treated at 850ºC at 1hr |

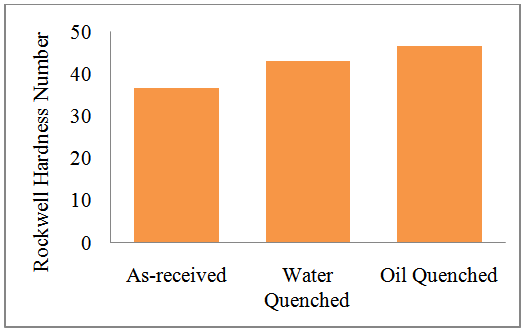

3.4. Hardness

- Three hardness measurements were taken using three nominally identical Specimens. In all cases, the three measurements were identical to within a few percent. The hardness of the sigma (σ) phase is significantly greater than that for the ferrite or austenite in fact the hardness of the sigma (σ) phase is almost twice as high as that for austenite. As the secondary phases are predominantly the σ-phase, the increase in the hardness observed in the present study is therefore associated with presence of sigma phase as well as effect of quenching media concentration of the σ phase. The average hardness for three nominally identical specimens are shown in Figure 5. The result reveals that hardness was highest in heat treated oil quenched specimens when compared to solution treated and heat treated with water quenched specimens.

| Figure 5. Rockwell hardness number for untreted and heat treated AISI 2507 super duplex stainless steel |

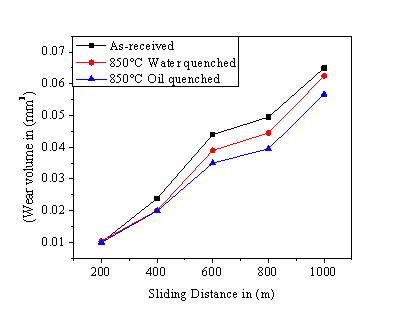

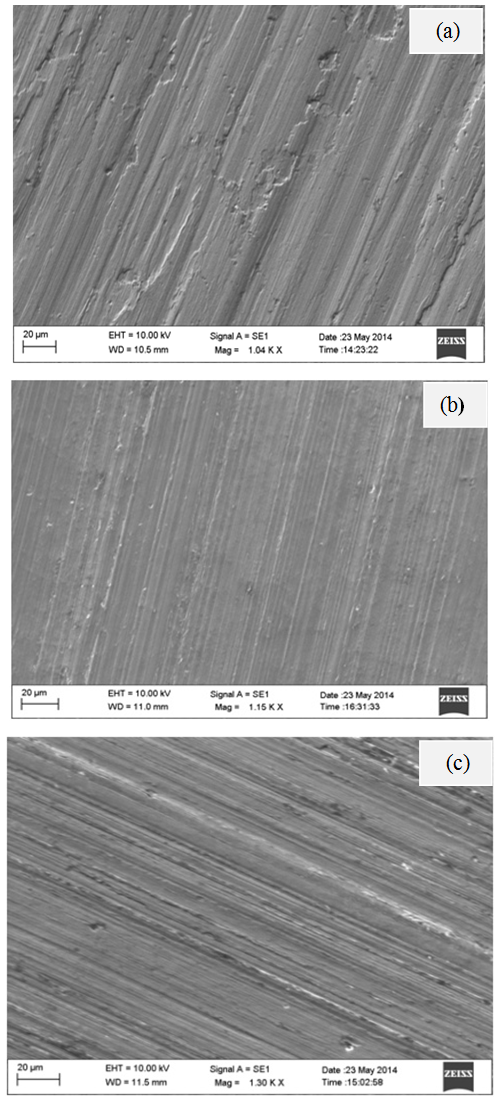

4. Wear Characteristics and Worn Surface Morphology

- Wear characteristics of AISI 2507 super duplex stainless were analyzed with different sliding distance conditions, varying from 200m to 1000m for all the specimens. The obtained result of heat treated specimen with water and oil quenched are compared with solution treated specimen and is as shown in Figure 6. It was observed that wear volume increases with increase in the distance for all specimens, irrespective of alloy processing conditions. It was observed that the existence of large amounts of sigma phase in the microstructure of heat treated specimens with water and oil quenched led to a better wear behavior. This observable fact can be explained taking into consideration, the hardness introduced by sigma phase, which strengthens the surface and contributes to get better resistance against stresses originated due to the action of the pin on the surface. Hence, hardened steel is less sensible to the repeated action of shear stresses that induce micro cracks and consequently loss of material.

| Figure 6. Variation of sliding distance vs. Wear |

| Figure 7. Worn surfaces of AISI 2507 Super duplex stainless steel (a) Solution treated (b) heat treated specimen at 850°C water quenched (c) heat treated specimen at 850°C oil quenched |

5. Conclusions

- In the present study super duplex stainless steel AISI 2507 was aged at 850°C for 1 hour followed by water and oil quenching. The effects of sigma phase

on hardness and wear properties were investigated and following conclusions were drawn:• Microstructure of heat treated super duplex stainless steel revealed that sigma

on hardness and wear properties were investigated and following conclusions were drawn:• Microstructure of heat treated super duplex stainless steel revealed that sigma  phase was precipitated on high Cr-concentrated region of

phase was precipitated on high Cr-concentrated region of  It was observed that about 30% by volume fraction got precipitated at 850°C.• Hardness of the heat treated specimens was increased when compared to solution treated specimens. This is mainly due to secondary precipitation of sigma

It was observed that about 30% by volume fraction got precipitated at 850°C.• Hardness of the heat treated specimens was increased when compared to solution treated specimens. This is mainly due to secondary precipitation of sigma  phase at 850°C.• It was concluded that as the sliding distance increases the wear volume lost for the specimens were increased. However, it is lower in case of oil quenched specimens when compared to water quenched and solution treated specimens.

phase at 850°C.• It was concluded that as the sliding distance increases the wear volume lost for the specimens were increased. However, it is lower in case of oil quenched specimens when compared to water quenched and solution treated specimens. Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML