Girisha N.1, Manikumar K. C.1, Manjunath H. N.1, Sushanth H. Gowda2, N. Kapilan3

1Department of Mechanical Engineering, Nitte Meenakshi Institute of Technology, Bengaluru, India

2Department of Mechanical Engineering, ST Joseph College of Engineering, Mangaluru, India

3Department of Mechanical Engngineering, Nagarjuna college of Engineering and Technology, Bangalore, India

Correspondence to: Manjunath H. N., Department of Mechanical Engineering, Nitte Meenakshi Institute of Technology, Bengaluru, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

In recent years, R134a is the most widely used refrigerant in the domestic refrigeration system as it was considered as a replacement of R12 refrigerant. However, the R134a refrigerant has higher global warming potential and hence it has to be phase out as per the Kyoto Protocol. Hence in this work, R152a is used as a substitute for the R134a refrigerant. Various mixtures of R134a and R152a are used, in the proportion of 70:30, 60:40 and 50:50 by mass and studied the effect of alternative refrigerant on the performance of the domestic refrigeration system. The performance of the domestic refrigeration system was studied at various thermostat settings.

Keywords:

Alternative Refrigerant, Refrigerator, Performance, Adsorption Refrigeration System

Cite this paper: Girisha N., Manikumar K. C., Manjunath H. N., Sushanth H. Gowda, N. Kapilan, A Study on Effect of Alternative Refrigerant on the Performance of a Domestic Refrigerator, Journal of Mechanical Engineering and Automation, Vol. 6 No. 5A, 2016, pp. 138-141. doi: 10.5923/c.jmea.201601.26.

1. Introduction

Refrigeration is widely used in varieties of thermal engineering application. Refrigeration system defined as the process of removal of heat from an enclosed space and rejecting it elsewhere for the primary purpose of lowering the temperature of the enclosed substance and then maintaining that lower temperature. Refrigeration system works on a vapor compression cycle which consists of compressor, condenser, expansion valve or capillary tube, evaporator, compressor and finally condenser. A working fluid used in the refrigeration system is R152a and R134a refrigerant mixture. The domestic refrigerator start when the refrigerant mixture enters the compressor at high pressure of vapor and it is compressed isentropically to the condenser pressure. Further the refrigerant mixture enters the condenser as superheated vapor and leaves as saturated liquid as a result of heat rejecting to the surrounding. The saturated liquid refrigerant mixture is throttled to the evaporator pressure by passing it through the capillary tube. During this process, refrigerant mixture temperature falls below the refrigerant Mixture enters an evaporator part as a low quality saturated mixture and it is completely evaporated by heat absorbed from the refrigerated space. The refrigeration cycle is complete as the refrigerant mixture leaves the Evaporator and re-enters the compressor and is shown in the fig. 1. | Figure 1. Vapour Compression Refrigeration System |

M.Abuzar Qurshi Shikha Bhatt [1] carried out a work on comparative analyze of COP using R134a and R600a refrigerant in domestic refrigerator at steady state condition. The two refrigerants are R134a and R600a.In the domestic refrigerator are used to obtain result from R134a and using 50g of R600a which indicates the similar result as R134a. Based on result R600a charge amount, compressor, condenser and evaporator, COP selected for design. In general condition refrigerant charge requires a 50g of R600a, 66% lower than R134a one which is not economics. Present work comparisons of COP using R134a and R600a refrigerant in steady state condition of the system. The result indicates that R600a COP more than R134a.Gaurav, Dr. Raj Kumar [2] analyses the thermo physical properties of refrigerant such as R134a and R12.R134a is used in domestic refrigeration and vapor compression system. In this work find out the alternatives to R134a from flammability, toxicity, thermodynamics, thermo economics and environment safety. This work represents the recent development done on alternative to R134a.B.O, M.A Akintude and T.O. Falade [3] conducted the performance studies of three ozone friendly hydro-flouro-carbon refrigerants (R152a, R134a, R32) in a vapor compression refrigeration system were worked experimentally and compared. The result obtained from the experiment shows that R32 refrigerant yielded undesirable characteristics such as low COP and high pressure. After completion of experiment shows that result of R134a and R152a have same performance, but the best performance was obtained from the use of R152a in the system. As a result, R152a could be used as a drop in replacement for R134a in a refrigeration system. The COP of R152a is higher the R134a and R32 by 25% and 14.7% respectively.The energy cost has been increasing exponentially in a worldwide. In the field of industrial cooling is a one of the most energy using sector. Because of this intention it is been planned to use the solar energy for cooling. Solution lies in the adsorption cooling system. In this type of cooling system the CFCs are not used, so our ozone layer is safer than when CFC’s are used. Generally green house gases and their damaging effects on an atmosphere have been received raised attention of following the release the scientific data by a Programme (UNVP) and the (WMO) that show a carbon dioxide to be the main contributor to improve the global warming. HFC-134a are used to operate the domestic freezers, contribute indirectly on a global warming by the amount of a carbon dioxide produced by means of power plant by generating the electricity to operate the over a unit of its lifetime.The solar energy is unlimited and also it is environmentally friendly. Solar radiation can be transformed into the usable forms of a energy such as electricity or heat. Photovoltaic (PV) devices are used to converting solar irradiation to an electricity while solar thermal collectors that can convert the solar irradiation to a heat which powers a steam generator, i.e. solar thermal power, or for the domestic applications.Akira Akahira et al., 27 [2004], 225-234 [4] carried out a performance study of two beds, Mass recovery process of silica adsorption refrigeration cycle for water and silica-gel. The relatively low source temperature is used to drive cycle with mass recovery. The pressure in adsorber and desorber are different in an absorption refrigeration cycle. The refrigerant mass circulation is enhanced by pressure difference of the chiller with mass recovery process utilization. The operating condition is influence to analyses by cycle simulation computer program which were used to calculate cooling capacity and coefficient of performance (COP). This cycle is compared with conventional cycle. The results conveys that the mass recovery process is high useful for lesser regenerating temperature and cooling capacity is better than that of the conventional cycle.Buczek, Klimowskar and Vogt et al., 2003, 30-059 [5] in thermodynamic system such as cooling systems and as heat pumps uses an active carbon methanol adsorption highly among the solid-gas adsorption process. The abrasion in spouted bed produces successive removal of external layers from a particle surface which modifies the porous structure of an active carbon. The nitrogen adsorption data is used for evaluation of demineralization and oxidation for methanol.

2. Materials and Methods

A domestic refrigeration system was modified and converted to work as the test-rig. The pressure gauges were added to the system to measure the condenser side and evaporator side pressures. A digital thermocouple was used to measure the temperature at different locations. An energy meter was used to measure the power consumed by the compressor. The capacity of the refrigerator used in this work is 175 Liter. The refrigerant used in the refrigeration system is R134a and R152a refrigerant was used as a partial substitute in the refrigeration system. Fig. 2 shows the vapor compression refrigeration system which was used as an experimental setup. Fig.3 and fig.4 shows the pressure gauges and thermocouple used in this work. | Figure 2. Experimental setup |

| Figure 3. Pressure Gauges |

| Figure 4. Digital Thermocouple |

2.1. Results and Discussions

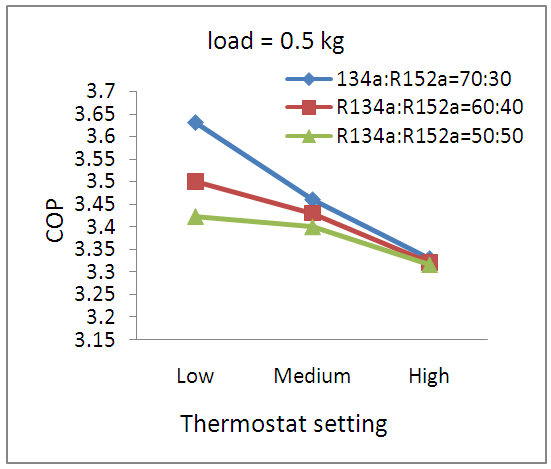

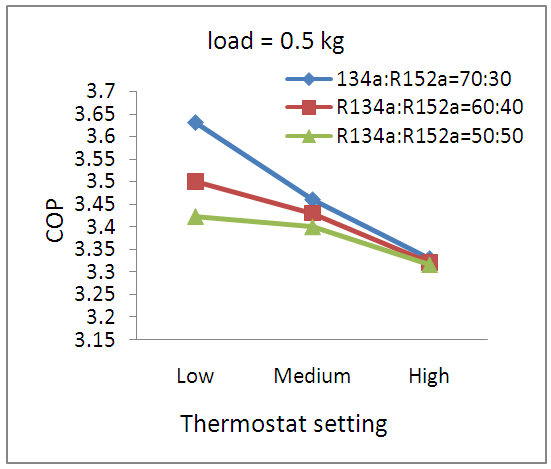

The experiment was conducted at a room temperature of 28 degree Celsius. The co-efficient of performance of a refrigerator and power consumed by the compressor were calculated and discussed in the following paragraphs. Fig. 5 shows the effect of thermostat setting on the COP of the refrigeration system at a load of 0.5 kg. From the figure it is observed that, as the thermostat setting value increases from low value to high value, the COP of the refrigeration system decreases. The addition of the alternative refrigerant significantly affects the performance of the vapor compression refrigeration system. The refrigerant mixture of 50:50 gives lower COP as compared to other mixtures. The refrigerant mixture ratio of 70:30 gives higher COP as compared to other mixtures. | Figure 5. Variation in COP at various thermostat setting |

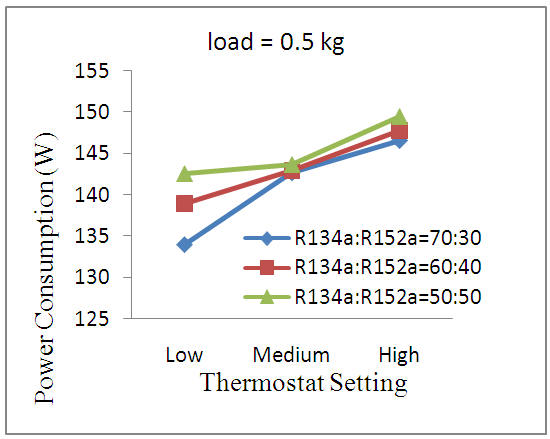

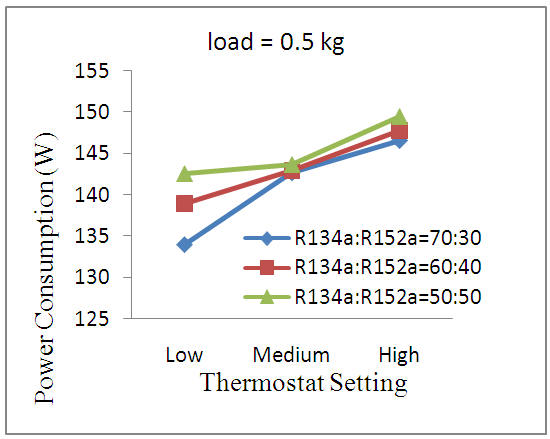

Fig. 6 shows the effect of thermostat setting on the power consumption of the refrigeration system at a load of 0.5 kg. From the figure it is observed that as the thermostat setting value increases the power consumption of the refrigeration system also increases. The addition of the alternative refrigerant significantly affects the performance of the vapour compression refrigeration system. The refrigerant mixture of 70:30 consumes lower compressor power as compared to other mixtures. The refrigerant mixture ratio of 50:50 consumes higher power as compared to other mixtures.  | Figure 6. Variation in power consumption at different thermostat setting |

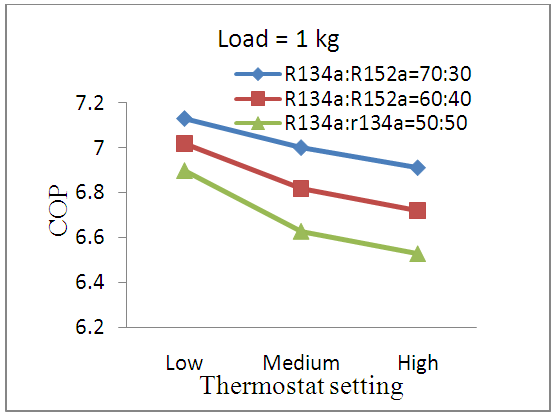

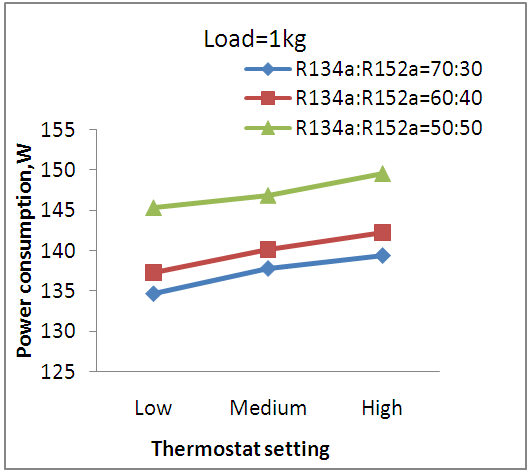

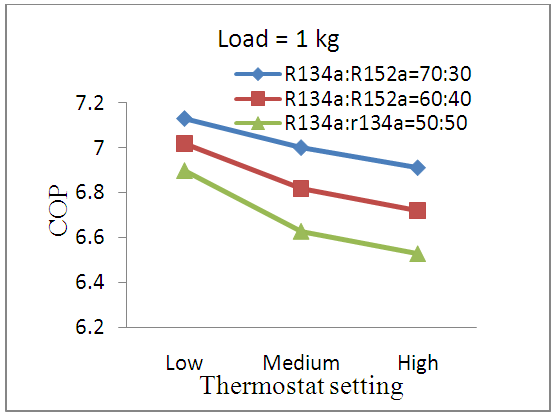

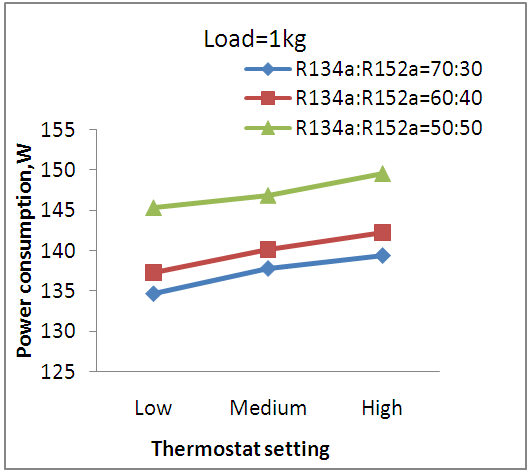

Fig. 7 shows the effect of thermostat setting on the power consumption of the refrigeration system at a load of 1 kg. From the figure it is observed that as the thermostat setting value increases the power consumption of the refrigeration system decreases. The addition of the alternative refrigerant significantly affects the performance of the vapor compression refrigeration system. The refrigerant mixture of 70:30 gives higher COP as compared to other mixtures. The refrigerant mixture ratio of 50:50 gives lower power as compared to other mixtures. Figure 8 shows the effect of thermostat setting on the power consumption of the refrigeration system at a load of 1 kg. From the figure it is observed that as the thermostat setting value increases the power consumption of the refrigeration system increases. The addition of the alternative refrigerate significantly affects the performance of the vapour compression refrigeration system. The refrigerant mixture of 70:30 consumes lower compressor power as compared to other mixtures. The refrigerant mixture ratio of 50:50 consumes higher power as compared to other mixtures. | Figure 7. Variation in COP at various thermostat setting |

| Figure 8. Variation in power consumption at various thermostat setting |

3. Conclusions

In this work, a domestic refrigeration system is modified to work as an experimental setup and conducted the performance tests with R134a and R152a refrigerants. From the experimental results, it is observed that the domestic refrigerator works smoothly with the mixture of R134a and R152a refrigerants and also without making any modification in the compressor. From the experimental results, it is observed that the addition of 152a significantly affects the performance of the domestic refrigeration system. Also from the results, it is observed that the thermostat setting significantly affects the performance of the refrigerator. The refrigerant mixture of 70:30 (R132a:R152a) gives higher COP as compared to other mixtures at the cooling load of 1 kg. From this work, it is concluded that R152a can be used as a partial substitute for the R134a without making any modification in the domestic refrigerator.

References

| [1] | Bolaji BO, CFC refrigerants and stratospheric ozone: past, present and future, Book of Readings of Environment Conservation and Research Team 37 (2005) 231-239. |

| [2] | Akira Akahira et al., 27[2004], 225-234, Study the performance of two beds using silica-gel and water. |

| [3] | Buczek, Klimowska and Vogt et al., 2003, 30-059, have been worked on the heat pumps and cooling systems. |

| [4] | Bolaji. B.O, Investigating the performance of some environment-friendly refrigerants as alternative to R12 in vapor compression refrigeration system, PhD Thesis in the Department of Mechanical Engineering, Federal University of Technology Akure, Nigeria (2008). Journal of energy technology and policy ISSN 22250573, volume 3, no 5 2013. |

| [5] | ASHRAE, Thermo physical Properties of Refrigerants Chapter 20, ASHRAE Fundamental, Inc. Atlanta 20 (2001), 1-67. |

| [6] | Rotchana Prapainnop, K O Suen (2012). “Effect of Refrigerant Properties on Refrigerant Performance Comparision: A review,” International Journal of Engineering and Research and Applications Vol.2, pp.486-493. |

| [7] | Mahesh, S C Kaushik have done the work on solar adsorption refrigeration system using different mass of adsorbents in the year 2003. |

| [8] | G Grebner J. J and R. R. Crawford, 1993. Measurement of pressure temperature–coefficient relations for mixtures of R12/mineral oil and R134a synthetic-oil. ASHRAE Transactions, 99; 387-396. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML