-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2016; 6(5A): 93-96

doi:10.5923/c.jmea.201601.17

Design and Fabrication of Arecanut Tree Climbing and Spraying Machine

M. Tony, C. Johny, S. Sayooj, K. Yathish, J. P. Vas

Department of Mechanical Engineering, St Joseph Engineering College, Mangalore, India

Correspondence to: C. Johny, Department of Mechanical Engineering, St Joseph Engineering College, Mangalore, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The design and fabrication of arecanut tree climbing and spraying machine is presented in this paper. The device consists of a triangular base frame which supports all the components to be built upon. It is fitted with three DC motors - nylon tyres with rubber grippers at 120 degrees each other for ease of the operations. A specially designed remote controlled spraying unit is mounted on the frame. Power from the battery is supplied to the motors using flexible wires and DPDT (Double Pole Double Throw) switch is used to control the movement of climbing machine as well as spraying unit. DC geared motors having reduction gears which ensures self-locking of the tyres and thus maintains the height. To accommodate for change in the diameter of arecanut tree as the device moves up and down, a spring loaded mechanism is used for exerting sufficient tension required for gripping the tree. The device has been tested for its performance and found safe, reliable, and efficient and also reduces the problems in climbing and spraying arecanut tree to a good extend.

Keywords: Tree climbing machine, Arecanut, Spraying machine

Cite this paper: M. Tony, C. Johny, S. Sayooj, K. Yathish, J. P. Vas, Design and Fabrication of Arecanut Tree Climbing and Spraying Machine, Journal of Mechanical Engineering and Automation, Vol. 6 No. 5A, 2016, pp. 93-96. doi: 10.5923/c.jmea.201601.17.

Article Outline

1. Introduction

- Researchers all around the world work on developing climbing machines, most of these climbing machines are capable of climbing regular structures like poles, walls etc. But a very few are capable of climbing trees, main reason being irregular surface and variation of diameter with length [1-4]. It also requires greater agility and high manoeuvrability to be used as a product. Also the bark of some trees may not be strong enough to bear the weight of the climbing device, hence conventional climbing machine cannot be used for tree climbing applications [5-7]. Many trees like coconut tree, arecanut tree, and palm trees are so tall that climbing them becomes risky. Hence harvesting fruits and nuts and maintaining them becomes difficult. So development of a unique tree climbing mechanism is necessary which may be used for maintaining and harvesting applications.In recent years, labour scarcity has emerged as one of the foremost challenges in farming. One crop that has been most affected by this is the arecanut. Arecanut trees attain a height of about 60-70 feet. It is mandatory to climb the trees a minimum of five times a year for a successful harvest - twice for the preventive spray against fungal disease, and thrice to harvest the arecanut.Only skilled labourers can carry out these farming operations. They have to climb the trees using muscle power. As this involves real hard, physical exertion, younger generations of labourers are losing interest, with potentially harsh implications for arecanut cultivation. The spraying is done in monsoon, while harvest time is typically in summer.The scope of this project is limited to climb arecanut trees having circumference between 30 and 50 cm. Therefore, maintaining sufficient friction force capable of handling the self-weight, maintaining the stability of the structure while in motion, reducing the total weight, and achieving the precise gripping are the important parameters that have to be considered. The machine should be capable of adjusting to the varying cross-section of the tree during upward and downward movements. The machine should grab the tree firmly to maintain its positions during the operation. The geared motor should be powerful enough to carry the payloads and weight of the machine. The tension maintained by the spring must be good enough to maintain the gripping force between the wheel and the tree. In this study, considering all the above parameters, a safe, reliable and efficient climbing and spraying machine is designed and fabricated.

2. Climbing Mechanism and Working

- The arecanut tree climbing and spraying machine works on the basic principle of friction that is the relative lateral motion of two solid surfaces in contact. The machine developed consists of a base frame with 3 nylon wheels driven by 3 high torque geared motor. The machine is having a triangular shape, hinges are provided on each links for the movement of links with the variation in size of the tree. A spring is used to provide sufficient grip to the wheel on the tree according to the change in the size of the tree. Pulley and a brake cable is used to ensure smooth movement of the links. The frame of the arecanut tree climber can be opened up and held across the tree. The setup is connected across the tree with the help of a brake cable. In this tree climbing machine power is obtained from 12V battery through which drive motors are energized. The remote is used to control the motor. When the drive motor is switched on, the motor rotates the shaft which in turn rotates the wheels. Due to the friction between drive wheel and the bark of the tree machine rises up along the length of the tree. The contact friction between the wheel and tree is maintained with the help of tension springs and grippers on the wheels. The only component which is in contact with the tree is the wheels which are made up of nylon. Hence it doesn’t cause any damage to the bark of the tree. When the setup reaches on top of the tree the drive motor is switched OFF in the remote control unit. The tension of the spring helps to retain the machine at the required height. Now the motors for controlling the nozzle attachment is switched ON with the help of remote, then these motors start to rotate. The motor unit is capable of rotating in 360˚. The nozzle is mounted on top of the guide way motors. Guide way motors are rotated to the required position in order to spray pesticide to the crop. The nozzle is positioned near the arecanut with the help of guide way motors and then the guide way motors are switched OFF. Then the wiper pump motor is switched ON. Then the pesticide is being sprayed .After which the pump is stopped, the whole setup is being brought back by changing the polarity of the switch so that the drive motor rotates in opposite direction there by making the wheels rotate in opposite direction. After reaching the ground the ground the setup is removed from the tree and attached to the next tree for spraying.

3. Calculations

3.1. Force Calculation

- Assuming weight of the machine, W = 5.5 kgW = 5.5x9.81W = 53.955 NAssuming coefficient of friction between tree and rubber grip, µ = 0.3Actual Force to be lifted, F=W/µF=53.955/0.3F = 179.85 N

3.2. Selection of the Wheel

- Average Change in circumference of the tree is taken as 30cm to 50cm. It was observed that the maximum circumference of an arecanut tree is 50 cm and minimum circumference at the top is 30 cm. 10 cm wheel is used in this machine for the torque restriction of the motor.

3.3. Length of Link

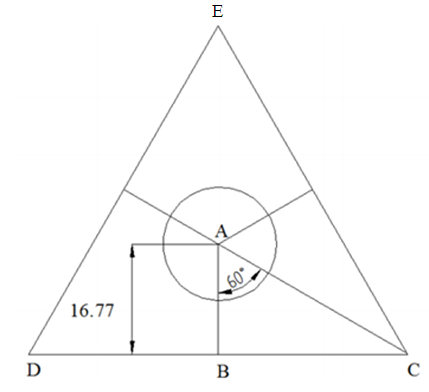

- Length of each link is taken as 58 cm, the calculations are shows below and line diagram to calculate length of the links is shown in figure 1.From figure 1;tan60° =BC/ABtan60°×16.77=BCBC=29.046cmSo total length of the link,DC=BC×2DC=58.09cm × 58cm

| Figure 1. Line diagram to calculate Length of the links |

| Figure 2. Arecanut climbing and spraying machine |

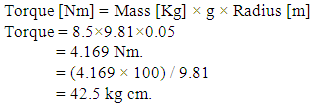

3.4. Torque Calculation

- Calculating motor torque,

4. Specifications and Functions of Parts Used

4.1. Motors

- Five motors are used in this machine, in which 3 motors are used to drive the wheels, other 2 motors are used to controlling the nozzle attachment for spraying pesticides.The DC motor used to drive wheel is square geared DC motor. It is the heart of the setup. It is the main source through which torque is generated. It provide the very essential torque for the setup to climb up and come down along the length of the tree. Specifications are given below;Volt: 12 V Speed: 100 rpmTorque: 42.5 kg-cm

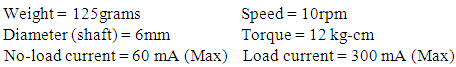

4.2. Nozzle Motor and Pump

- Nozzle motor is used to control the nozzle attachment for spraying purpose. Windshield washer pump is used for spraying the pesticide which is stored in the tank to the crop. The pesticide is being transported from the tank to the nozzle with the help of plastic tubes. The specification of nozzle motor is listed below.

4.3. Wheels

- In this machine three driving wheels are used. Driving wheels are machined from nylon rods having diameter of 100 mm which is used to provide firm grip and also to operate the machine so that it climbs the tree easily.

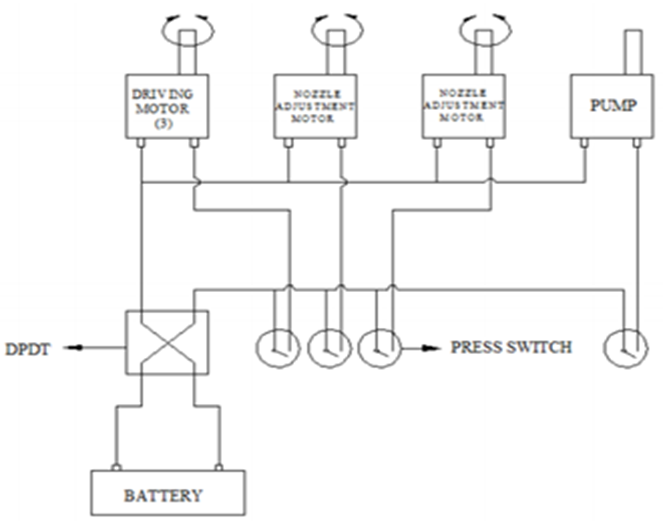

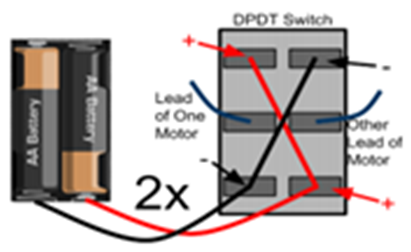

4.4. Remote Control Unit

- The remote consists of one Double Pole Double Throw (DPDT) and five press switches in which one press switch is dummy. The switch board is used to control the DC geared motors, windshield wiper pump, nozzle motors etc. The remote control circuit and DPDT switch are shown in the figure 3 and figure 4 respectively.

| Figure 3. Remote control circuit |

| Figure 4. DPDT- Double Pole Double Throw |

5. Conclusions

- After testing the machine on the arecanut tree, it has been found that,Ÿ The design is efficient in climbing the tree very smoothly without damaging the tree.Ÿ The climbing mechanism and spraying unit was working according to the requirement. Ÿ The design is simple and appealing to the majority. An unskilled labour can also operate the machine safely and efficiently.

ACKNOWLEDGEMENTS

- The first and second authors would like to acknowledge the Management, the Principal, and Head of the department – Department of Mechanical Engineering, St Joseph Engineering College, Mangalore for their support to carry out the research work.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML