-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2016; 6(5A): 28-31

doi:10.5923/c.jmea.201601.06

Effect of Titanium Dioxide and Calcium Carbonate Nanoadditives on the Performance and Emission Characteristics of C.I. Engine

Rolvin D’Silva1, Vinoothan K.1, Binu K. G.1, Thirumaleshwara Bhat2, Raju K.1

1Department of Mechanical Engineering, St Joseph Engineering College - Vamanjoor, Mangaluru, Karnataka, India

2Department of Mechanical Engineering, Shree Madhwa Vadhiraja Institute of Technology, Udupi, Karnataka, India

Correspondence to: Binu K. G., Department of Mechanical Engineering, St Joseph Engineering College - Vamanjoor, Mangaluru, Karnataka, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

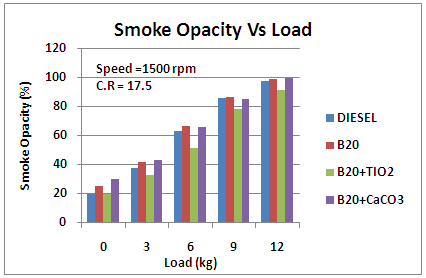

In this paper an attempt is made to use titanium dioxide and calcium carbonate nanoparticles as fuel additive in a C.I. Engine. Dispersion of nanoparticles in B20 methyl ester of pongamia pinnata oil is carried out using a probe sonicator. The physiochemical properties are characterized. The fuel samples are then tested in C.I. Engine test rig. Results reveal that use of titanium dioxide nanoparticles as fuel additives lead to enhanced performance and emission characteristics in comparison to plain fuel and calcium carbonate nanofuel samples. The brake thermal efficiency of the engine is improved by 2% with the usage of TiO2 nanoparticles in B20 blend, when compared with fuel sample without nanoadditive. A 6% reduction in BSFC value is observed for TiO2 nanofuel in comparison to plain oil. It is observed that the blend B20 with TiO2 nanoparticles result in an average 16% lesser smoke emission compared to plain B20.

Keywords: Performance and Emission of C.I.Engine, Titanium dioxide nanoparticles, Calcium carbonate nanoparticles

Cite this paper: Rolvin D’Silva, Vinoothan K., Binu K. G., Thirumaleshwara Bhat, Raju K., Effect of Titanium Dioxide and Calcium Carbonate Nanoadditives on the Performance and Emission Characteristics of C.I. Engine, Journal of Mechanical Engineering and Automation, Vol. 6 No. 5A, 2016, pp. 28-31. doi: 10.5923/c.jmea.201601.06.

Article Outline

1. Introduction

- Industrialization is leading to rapid consumption of fossil fuels and petroleum products. Researchers worldwide are forced to move on to alternate fuels. Biodiesel has emerged as an effective alternative fuel. Biodiesel is derived from vegetable oil, animal fats or waste cooking oil. The viscosity of vegetable oil and animal fats is high, so its usage in engines will lead to various problems. Hence it has to undergo esterification process. In this process the oil is mixed with calculated amount of alcohol to form methyl esters which is known as biodiesel. Biodiesel has many advantages over diesel. Biodiesel is renewable source of energy and its usage in engines can reduce the exhaust emissions of the engine. Different types of biodiesel have been experimented in C.I.Engine and they have proved that the emissions can be reduced [1]. The brake thermal efficiency of the engine is bit lower when biodiesel is used compared to diesel fuel because of lower calorific value of biodiesel [2, 3]. Studies were carried out to improve the properties of biodiesel by adding certain fuel additives.Investigation carried out by Ali Keskin et. al., where tall oil resinic acids were reacted with Magnesium oxide and Molybdenum dioxide stoichiometrically for the production of metal-based fuel additives (combustion catalysts) revealed that, both of the metal-based additives improved flash point, pour point and viscosity of the biodiesel fuel, depending on the rate of additives. Engine performance values did not change significantly with biodiesel fuels, but exhaust emission profile was improved. CO emissions and smoke opacity decreased by 56.42% and by 30.43%, respectively [4]. Investigations were also done by modifying the test rig to reuse the exhaust gas in the cylinder together with additives. The effects of ethyl tert-butyl ether (ETBE) addition to diesel fuel on the characteristics of combustion and exhaust emissions of a diesel engine with high rates of cooled exhaust gas recirculation (EGR) were investigated by Tie Lee at.al. It is found that increasing ETBE fraction in the fuel helps to suppress the smoke emission increasing with EGR, but a too high fraction of ETBE leads to misfiring at higher EGR rates. While the combustion noise and NOx emissions increase with increases in ETBE fraction at relatively low EGR rates [5]. Ethers have a positive effect on diesel fuel lubricity, and slightly decrease its viscosity. Blends with 1 and 2.5 wt.% oxygen concentrations were used in order to determine their influence on emissions at both full and medium loads and different engine speeds. It showed that ether reduce CO, and hydrocarbon emissions, but not smoke [6].Oxygenated additive like methoxyethyl acetate (MEA) has been found to decrease exhaust smoke. Under the same speed and load conditions, the maximum cylinder pressure decreased when fuelled with the blends with MEA, while the ignition delays and the combustion duration become shorter. The engine emissions of HC and CO are reduced when MEA is added in diesel. However, MEA had a little effect on NOx emissions and engine’s thermal efficiency had an increase about 2% [7].Nanoparticles have been used as fuel additive in recent researches. They tend to improve the properties of the base fuel which tends to the better combustion of fuel and reduction in emissions [8]. S. Karthikeyan [9] observed that Cerium oxide nanoadditive in the fuel for C.I.Engine increased the heat release rate and thermal efficiency and also reduced the fuel consumption. According to the micro-explosion theory, the turbulence between air and fuel mixture increases resulting in better atomisation of fuel. Ferrofluid when used in biodiesel have been found to enhance the combustion characteristics and reduce NOx [10]. The impact of aluminium nanofluid in petroleum diesel was studied by Kao et al. [11]. Here the efficiency was found to be better and BSFC, NOx, smoke has decreased. Copper Oxide (CuO) nano particles (50 ppm) in B20 blend of Mahua methyl ester reduced HC, CO and smoke emissions up to 5.33%, 33% and 12.5% compared with biodiesel blend [12]. It was reported that adding 40–60nm of aluminium nanofluid to diesel, a reduction of 4.1% in smoke emissions and 6.2% in NOx emissions were found. Zinc Oxide nanoparticles when used with anola methyl ester have found to be giving 2.79% better efficiency than the anola methyl ester without nanoparticles. Also NOx emissions have been found 3.82% lesser and smoke 7.2% lesser when zinc oxide nanoparticles are used [13].In this present work a comparative study is done between titanium dioxide nanoparticles and calcium carbonate nanoparticles used as fuel additive in B20 blend of pongamia pinnata methyl ester.

2. Experimental Setup

2.1. Preparation of Nanofuel

- Probe sonication is a highly effective means of creating dispersions of nanoparticles in a liquid, capable of remaining in suspension for many days. Ultrasonic waves are generated in a liquid suspension by immersing an ultrasound probe or horn in to the suspension. The required quantity of the nanoparticle for each sample was accurately measured using a precision electronic balance and was mixed with the fuel by means of a probe sonicator, passing ultrasonic waves for a time period of 30 minutes to produce a uniform suspension. The modified fuel was utilized immediately after preparation, in order to avoid any settling or for sedimentation to occur. In the present work 100ppm of nanoparticles are dispersed in the fuel sample to form a nanofuel and the base fuel used is B20 blend of pongamia pinnata methyl ester.

2.2. Measurement of Properties of Nanofuel

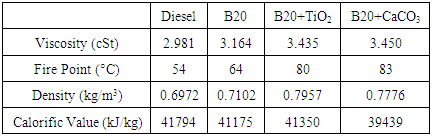

- The fuel samples are tested for their physiochemical properties like viscosity, fire point, density and calorific value following the ASTM methods. These properties affect the performance and emission features of an engine. Redwood viscometer is used for viscosity measurement, Penksy Martin apparatus is used for measurement of fire point. Calorific value is found out using bomb calorimeter.

2.3. Performance and Emission Testing

- A computerized single cylinder four-stroke, naturally aspirated, Direct Injection and water-cooled, variable compression ratio diesel engine test Rig of 3.5 kW rated power is used to conduct the test. The compression ratio of the engine can be varied from 12:1 to 18:1.It is directly coupled to an eddy current dynamometer. The setup has standalone type independent panel box consisting of air box, fuel tank, manometer, fuel measuring unit, transmitters for air flow and fuel flow measurements, process indicator and engine indicator. For measurement of water flow rate for engine cooling and exhaust gas calorimeter, rotameters are provided. An AVL Digas 444 five gas Exhaust gas analyzer, is used to measure the NOx (ppm), CO (%), CO2 (%) and HC (ppm) emissions in the exhaust. Smoke meter is used to measure the smoke opacity. The compression ratio is fixed at 17.5 and injection pressure at 200 bar. The load is varied from 0 kg to 12kg in steps of 3 kg increment and the readings of speed, fuel consumption and emission readings are noted down.

3. Results and Discussion

3.1. Property Study

- The result of the property study of fuel samples is shown in the table 1. The experiments are conducted as per the ASTM standards.

|

3.2. Engine Performance Study

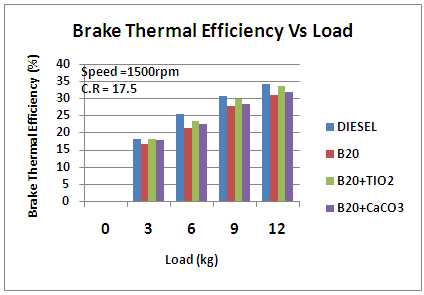

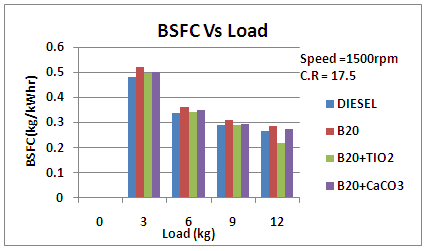

- The prepared fuel samples are then subjected to engine study. Diesel, B20, B20 with 100 ppm titanium dioxide nanoparticles and B20 with 100ppm of calcium carbonate nanoparticles are the four fuel samples tested. Brake thermal efficiency and brake specific fuel consumption are calculated to study the performance of the C.I.Engine.Brake thermal efficiency is a measure of performance of the engine. As load increases the brake thermal efficiency of the engine increases. Among the fuel samples used apart from Diesel, the blend B20 with titanium dioxide nanoparticles gives better brake thermal efficiency. It is observed from the Figure 1, that there is an increase in brake thermal efficiency when nanoparticles are used as fuel additive. Compared to B20, there is 2% increase in brake thermal efficiency at higher load when Titanium dioxide nanoparticles are used.

| Figure 1. Variation of Brake Thermal Efficiency Vs Load for different fuel samples |

| Figure 2. Variation of Brake Specific Fuel Consumption Vs Load for different fuel samples |

3.3. Engine Exhaust Emissions Study

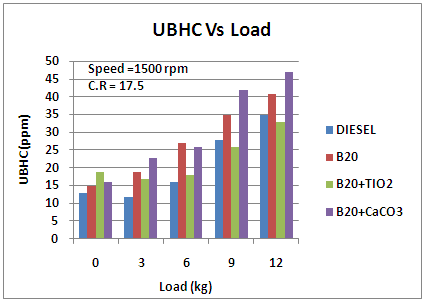

- Emission of hydrocarbon in the exhaust is not desirable as it shows the inadequacy of the engine to burn the fuel, resulting in loss of power and efficiency. It is observed from Figure 3, that the unburnt hydrocarbon emissions increase with the load. Comparing the two fuels samples with nanoparticles as additives, it is observed that the blend B20 with titanium dioxide nanoparticles has considerable lesser UBHC in the exhaust at higher loads. The reason for reduction in UBHC may be TiO2 nanoparticles acting as oxygen buffers resulting in better combustion.

| Figure 3. Variation of Unburnt Hydrocarbons Vs Load for different fuel samples |

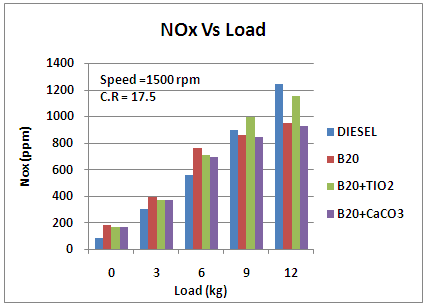

| Figure 4. Variation of Nitrogen Oxides Vs Load for different fuel samples |

| Figure 5. Variation of Smoke Opacity Vs Load for different fuel samples |

4. Conclusions

- The nanoparticle dispersions were obtained by sonication using a probe sonicator. The engine test revealed that by dispersing nanoparticles to the fuel, affects the performance and emission of the C.I.Engine. In the present work titanium dioxide and calcium carbonate nanoparticles were used as fuel additive. It is observed that the fuel sample with titanium dioxide nanoparticles shows better result. There is 2.05% increase in brake thermal efficiency and 5.7% reduction in BSFC at most of the loads. Among emissions, the unburnt hydrocarbons and smoke are found to be less in case of fuel sample with TiO2 nanoparticles. NOx emissions are slightly higher at higher loads when TiO2 nanoparticles are used. Hence titanium dioxide nanoparticles with concentration of 100ppm in the B20 sample shows better performance and emission characteristics.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML