-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2016; 6(5A): 8-12

doi:10.5923/c.jmea.201601.02

Hardness and Tensile Behavior of Al2219-TiC Metal Matrix Composites

Jayasheel Harti1, T. B. Prasad2, Madeva Nagaral3, K. Niranjan Rao3

1Assistant Professor, East Point College of Engineering & Technology, Bangalore, India

2Professor, Shri Siddharth Institute of Technology, Tumkur, India

3Design Engineer, Aircraft Research & Design Centre, HAL, Bangalore, India

Correspondence to: Jayasheel Harti, Assistant Professor, East Point College of Engineering & Technology, Bangalore, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The work is carried out to investigate and study the mechanical properties of TiC reinforced Al2219 alloy metal matrix composites. In the present work Al2219 alloy was taken as the base matrix and TiC particulates as reinforcement material to prepare metal matrix composites by stir casting method. For metal matrix composites the reinforcement material was varied from 0 to 6 wt. % in steps of 2 wt. %. For each composite, the reinforcement particulates were preheated to a temperature of 600ºC and dispersed into a vortex of molten Al2219 alloy. The microstructural characterization was done using scanning electron microscope. Mechanical properties like hardness, ultimate tensile strength, yield strength and percentage elongation were evaluated as per ASTM standards. Further, scanning electron microphotographs revealed that there was uniform distribution of TiC particulates in Al2219 alloy matrix. Hardness, ultimate tensile strength and yield strength increased as wt. % of TiC increased in the base matrix. Results also indicated that as wt. % of reinforcement increases, there was decrease in ductility.

Keywords: Al2219 alloy, TiC, Mechanical properties, Ultimate tensile strength, Hardness, Stir casting, Metal matrix composites

Cite this paper: Jayasheel Harti, T. B. Prasad, Madeva Nagaral, K. Niranjan Rao, Hardness and Tensile Behavior of Al2219-TiC Metal Matrix Composites, Journal of Mechanical Engineering and Automation, Vol. 6 No. 5A, 2016, pp. 8-12. doi: 10.5923/c.jmea.201601.02.

Article Outline

1. Introduction

- Metal matrix composites are increasingly becoming attractive materials for advanced aerospace, automobile industries due to light weight, low cost, easy fabrication and ever increasing demands of modern technology. Metal matrix composites are the combination of soft base metal with hard refinement material and have recently found special interest because of their specific strength and specific stiffness at room or elevated temperature. With the advancement of modern technology, there is a everlasting demand for an economical, light weight harder, stronger and energy saving material in the area of space, aircraft, advanced defense fighter jets and automobile application, aluminum matrix composites (AMC) found application in these areas [1, 2]. Many modern fabrication techniques where in use for the manufacture of MMC materials according to the type of base material and the type of reinforcement used like stir casting, squeeze casting, liquid metal infiltration and spray co-deposition. Among the above, stir casting technique is the simplest and most economical used technique is known as ‘vortex technique’ or stir casting technique’ it is attractive because of simplicity, low cost of processing, flexibility, most economically for large sized components to be prepared as well as production of near net shaped components.Due to advancement in technology, there is enlarged demand for an economical, light weight, harder, stronger and energy saving material in the area of space, aircraft, defence and automotive application and aluminum matrix found applications in these areas [3]. Aluminum alloy reinforced with hard ceramic particles of WC, SiC, Al2O3, B4C and graphite for forming a composite to realize improvements in mechanical properties such as hardness, young’s modulus, yield strength and ultimate tensile strength of the MMCs, The composites finds application in aerospace and automobile industries [4]. Though stir casting is the most commonly methods employed for the MMCs, wettability is the main problem associated with stir casting. To overcome the wettability problem occurring commonly, wetting agent namely magnesium has been found out by several researchers.AMCs with SiC as the reinforcement particle, SiC has a tremendous advantage of improving the properties like low density, high strength, low thermal expansion, high thermal conductivity, high hardness, high elastic modulus, excellent thermal shock, resistance and superior chemical inertness. Priority has been emphasized for developing affordable Al-based MMCs with various hard and soft reinforcements like SiC, Al2O3, zircon, graphite and mica [5]. Qiurong Yang et al. analyzed that the tensile test, elongation of the composites shows a sharp increase from 4.5% to 13.5% due to woven carbon fibers. Meanwhile the tensile strength of the composite is increased slightly from 168Mpa to 202MPa compared to that of ZL205A alloy. The good conductivity of the composite is ascribed to the cracks deflection, fibers pulling out, debonding and breakage mechanism [6].There has been tremendous research work carried for the mechanical behavior and for the wear. As per the research carried out so far, it was revealed that the reinforcement particulate graphite increases the wear resistance and with another reinforcement of Al2O3 in a hybrid matrix, mechanical properties where improved and also at elevated temperatures [7]. Even for the Al alloy A356 and reinforcement of SiC composites, it has been investigated for dry sliding wear studies, shows better mechanical behavior compared to those without coating [8, 9].From the literature survey, there is a lack of data available for mechanical behavior of Al2219 reinforced with TiC particulates. The present work “Hardness and tensile behavior of Al2219-TiC metal matrix properties” has been fabricated and characterized. The microstructure and the mechanical behavior of Al2219 alloy matrix with reinforced TiC particulates have been studied. Mechanical properties like hardness (BHN) and tensile strength of Al2219 alloy and Al2219 alloy with 2, 4 and 6 wt. % of TiC composites were evaluated as per ASTM standards.

2. Experimental Details

2.1. Materials Used

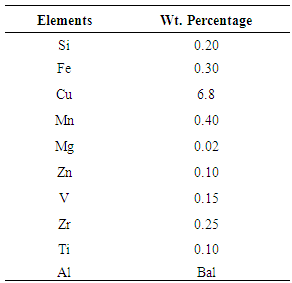

- For the metal matrix composite the base alloy Al2219 is reinforced with Titanium carbide powder of 50-60 microns in size and is fabricated as Al2219-TiC metal matrix composites. Density of Al2219 is 2.84 g/cc and that of the reinforcement particle is 4.93g/cc. The chemical composition of Al2219 base alloy is shown in Table 1.

|

2.2. Composite Preparation

- The metal matrix composites of Al2219-TiC have been produced by simplest and most economical used technique known as vortex technique or stir casting technique. As per the ASTM standards of casting procedure Al2219 was heated to the temperatures of 730ºC in the electrical resistance furnace. The addition of reinforcement particulate TiC varied from 2 to 6 wt. % insteps of two by mechanical stirring. Due to the increase in the weight percentage of reinforcement particulates TiC porosity defect may occur during metal matrix composite [10] where as increasing the stirring time reduces the porosity level [11]. The temperature of the electric furnace was controlled to an accuracy of ±30ºC using a digital temperature controller. Degassing agent solid hexachloroethane (C2Cl6) was added to expel all absorbed gases from the molten metal once the temperature have been reached. Before the addition of TiC particulates, mechanical stirring process was carried out with the help of zirconia coated stirrer to form a fine vortex. The speed of the stirrer is rotated for 5-8 mins at a spindle speed of 250 rpm. The TiC particulates were preheated to a temperature of 600ºC in a preheater to increase the wettability. The stirrer was immersed into the molten metal in the crucible at a depth of 2/3 from the bottom. The addition of the TiC particulates to the molten metal was divided into two equal weights rather adding all at once to avoid agglomeration of the matrix. At every stage, stirring was carried out before and after introduction of reinforcement particulate TiC to the molten metal. Before pouring the molten metal into the mould die, the molten metal was heated for about 5 mins. The melt poured into a preheated cast iron mould dimension of 140mm x 25mm diameter.

2.3. Testing

- Microstructure and mechanical behavior of the Al2219 alloy and its composites were carried out. A metallographic examination was carried out by using scanning electron microscope. The sample preparation for microstructural study was carried out first by polishing the sliced samples with emery paper up to 1000 grit size, followed by polishing with Al2O3 suspension on a grinding machine using velvet cloth. Finally, the samples were polished by using 0.3 microns diamond paste. The polished surface was etched with Keller’s reagent and examined with a scanning electron microscope. The tensile properties of the specimen were measured by using an electronic tensile testing machine at room temperature based on ASTM standard. Hardness tests were performed on as cast Al2219 alloy and Al2219-TiC composites to know the effect of TiC particles in the matrix material. The polished specimens were tested for their hardness, using Brinell hardness testing machine having ball indenter for 250 kg load and dwell time of 30 sec. Five sets of readings were taken at different places of the specimen and an average value was used for calculation.

3. Results and Discussion

3.1. Microstructural Analysis

- Figure 1 (a) - (d) shows the Scanning Electron Microscope (SEM) micrographs of as cast Al2219 alloy and its composites. Figure 1 (b) – (d) shows the SEM micrographs of 2, 4 & 6wt. % of TiC particulate composites. This reveals the uniform distribution of TiC particles and very low agglomeration and segregation of particles. The vortex generated in the stirring process breaks solid dendrites due to higher friction between particles and Al matrix alloy, which further induces a uniform distribution of particles.

| Figure 1. Showing the SEM microphotographs of (a) as cast Al2219 alloy (b) Al2219-2 wt. % TiC (c) Al2219-4 wt. % TiC (d) Al2219-6 wt. % TiC |

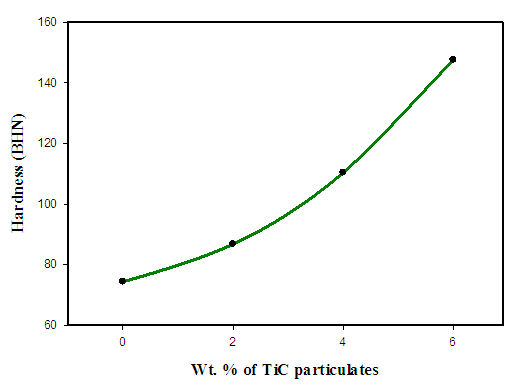

3.2. Hardness Measurements

- From the figure 2, it is observed that there is an increase in the hardness of Al2219 with addition of 2, 4 and 6 wt % of TiC particulate. The graph shows the variation of hardness of Al2219 alloy with TiC reinforcement particulate. It can be concluded that the addition of wt. % of TiC particulate results in increasing the hardness. The hardness of a soft material such as Aluminum matrix is increased when it is reinforced with a hard particulate i.e., TiC [12].

| Figure 2. Variation of Al2219 with wt. % of TiC particulates in Hardness before and after addition |

3.3. Ultimate Tensile Strength

- Figure 3 shows the variation of ultimate tensile strength (UTS) of base alloy, when reinforced with 2, 4 and 6 wt. % of TiC particulates. The ultimate tensile strength of Al2219- TiC composite material increases as compared to the cast base Al2219 alloy. The microstructure and properties of hard ceramic TiC particulates control the deformation of the composites. Due to the strong interface bonding, load from the matrix transfers to the reinforcement resulting in increased ultimate tensile strength. This increase in ultimate tensile strength mainly is due to presence of TiC particles which are acting as barrier to dislocations in the microstructure [13]. The improvement in ultimate tensile strength may also be due to alloy strengthening of the matrix, followed with a reduction in grain size of the composites, and the formation of a high dislocation density in the Al2219 alloy matrix due to the difference in the thermal expansion between the metal matrix and the TiC reinforcement [14].

| Figure 3. Variation of Al2219 with wt. % of TiC particulates in ultimate tensile strength |

3.4. Yield Strength

- Figure 4 shows variation of yield strength (YS) of Al2219 alloy matrix with 2, 4 and 6 wt. % of TiC particulate reinforced composite. It can be seen that by adding 6 wt. % of TiC particulates yield strength of the Al2219 alloy increased from 122 MPa to 206 Mpa. This increase in yield strength is in agreement with the results obtained by several researchers, who have reported that the strength of the particle reinforced composites is highly dependent on the volume fraction of the reinforcement. The increase in YS of the composite is obviously due to presence of hard TiC particles which impart strength to the soft Aluminum matrix resulting in greater resistance of the composite against the applied tensile load [15]. In the case of particle reinforced composites, the dispersed hard particles in the matrix create restriction to the plastic flow, thereby providing enhanced strength to the composite [16].

| Figure 4. Variation of Al2219 with wt. % of TiC particulates in yield strength |

4. Conclusions

- The present work entitled, “Hardness and Tensile Behavior of Al2219-TiC Metal Matrix Composites”, has led to following conclusions:• Al2219-TiC particulate composites were successfully produced by liquid stir casting route with different weight percentage (viz 2, 4 and 6) of reinforcement.• Aluminum based metal matrix composites have been successfully fabricated by liquid stir casting method by two step addition of reinforcement combined with preheating of particulates.• The densities of Al2219-2, 4 and 6 wt. % TiC composites increased with the addition of TiC particulates in Al2219 base alloy.• Improvements in ultimate tensile strength of the Al2219 alloy matrix were obtained with the addition of TiC particulates. The extent of improvement obtained in Al2219 alloy after addition of 2, 4 and 6 wt. % TiC particulates were 6.4, 21.10 and 48 percentages respectively.• Improvements in yield strength of the Al2219 alloy matrix were obtained with the addition of TiC particulates. The extent of improvement obtained in Al2219 alloy after addition of 2, 4 and 6 wt. % TiC particulates were 20.42, 41.60 and 68.5 percentages respectively.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML