Manjunath B. A.1, K. Sabeel Ahmed2, L. K. Sreepathi2

1Mechanical Department, SJEC, Mangalore, India

2Mechanical Department, JNNCE, Shivamogga, India

Correspondence to: Manjunath B. A., Mechanical Department, SJEC, Mangalore, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Pongamia pinnata has been identified as a potential source for bio-fuel production in the wake of the world fuel crisis. Before the oil extraction from Pongamia pinnata seeds, its shelling process is very important and essential. This study presents the design and fabrication of a small scale pongamia pinnata decorticator for bio-fuel production in rural areas. The developed machine consists of hopper, frame, de-shelling chamber, blower and outlet tray. The machine is powered using a 1Hp motor through the belt drives. The de-shelling of pongamia pinnata takes place due to the combination of various forces like shear, compressive and impact. These forces are exerted by series of bolts arranged in the shaft assembly within the deshelling chamber. Provision is made to vary the arrangement of bolts and the gap between the bolts and deshelling chamber. Performance test was conducted by varying the position and orientation of bolts. The result of the performance test revealed that an average de-shelling efficiency of 97.95% can be achieved with a seed damage up to 28.75%. All materials used in the fabrication of this decorticator are of standard specification and locally available materials. The estimated cost of the machine is Rupees Twenty Thousand approximately.

Keywords:

Decorticator, De-shelling chamber, Pongamia pinnata

Cite this paper: Manjunath B. A., K. Sabeel Ahmed, L. K. Sreepathi, Design and Fabrication of Pongamia Pinnata Decorticator, Journal of Mechanical Engineering and Automation, Vol. 6 No. 5A, 2016, pp. 1-7. doi: 10.5923/c.jmea.201601.01.

1. Introduction

Oil seeds are widely used in applications ranging from extraction of edible oil to chemical processing of same oil to get green diesel (Bio-diesel). As India is energy hungry nation huge research for alternative sources of energy are continuously in progress. Bio-diesel is also one of the alternative solutions for petrol and diesel. For large scale production of Bio-diesel mechanization of equipment are badly in need. Non-edible oil seeds are not used for kitchen purpose, hence they are available in large quantity. Therefore, lots of research has been conducted on non-edible oil as a replacement for diesel.The present work is focused mainly on the “De-shelling” which is a crucial part of the Bio-diesel production by designing and developing a decorticator to de-shell almost all kinds of non-edible oil seeds.A decorticator (from Latin: Cortex, bark) is a machine for stripping the skin off bark, wood, nuts, grain, plant staller etc. in preparation for further processing.Pongamia is a medium sized, evergreen and a very useful tree. The trees are grown for their shades and as an ornamental tree. It is also called as Honge or Karanja. The seeds of this tree have been important since ages. There will be 460-530 seeds in one kg. If Pongamia seeds are stored properly, they have a 60-85 percent germination capacity. These seeds contain 30-35% of oil and the oil characteristics are almost similar to that of diesel. Pod length, thickness varied significantly from the sources of seeds. Pod weight varied at about 2.80g to 7.64g. Similarly, seed length also varied but its maximum length was 27.75mm, which weighed about in an average of 3.18g was observed. Variance of pod length from 14.50mm to 69.69 mm [1]. Oil extracted from the seeds was used to light lamps in houses. Now research has shown that pump set, generator, tractor, power tiller, buses, railway engines can be run on Pongamia oil. Pongamia oil is used in tanning, soap manufacture and its oil cake is used as excellent organic manure. Indian In-stitute of Science in 1997 started research on the use of the pongamia seed oil as a vegetable oil for electricity in stationary generators and irrigation pumps in the rural areas of Andhra Pradesh, Maharashtra and Karnataka. Research has been carried out on the material left after oil extraction as a feeding material for sheep, cattle and poultry as this byproduct contains 30% of protein. It is also used as a natural insecticide.The shelling efficiency and time taken for de-shelling has become a high priority of designers and researchers. Recent developments in the field of bio-fuel production as an alternate fuel for diesel have gained much importance in the field of research and development. Decortication efficiency and percentage of seed damage decreased with increase of moisture content of pongamia pods [2]. Ketan K Tonpe et al. [3] worked on the coconut de-shelling machine. A cutter disc was used to de-shell the coconut husk without the nut breakage and also its average de-shelling efficiency was 90% and 195 coconuts were de-shelled per hour. Ikechukwu Celestine Ugwoke et al. [4] developed a manually operated groundnut sheller to reduce the breakage of groundnuts. Hence, a special de-shelling chamber was developed and a transmission mechanism which runs without more effort on the driving system. More recent models developed by Abubakar Mohammed et al. [5] and Oladeji Akanni Ogunwole et al. [6] have gained popularities in decortication of groundnut seeds. The decorticating chamber consists of inner drum with the brushes above the drum. These brushes in rotation, peels of the groundnut seeds. The peeling efficiency when electrically operated was higher as compared to that of manual operation because the inner drum maintains a steady and uniform speed. Abdulkadir baba Hassan et al. [7] worked on cassava peeling machine. The machine peeled a linear tube 20-30mm of length in a time span of 15-20 seconds. The efficiency of the machine was recorded about 65.55% at 4-5kg/min while in operation. A.R. Lende et al. [8] developed the tamarind cover and seed separation machine. 90% cover was removed and seed removal was only 20-25%. The results of tamarind cover removal were better than the seed removal process. M. A. Helmy et al. [9] evaluated a peanut sheller by removing the two gates of old shelling house and conveyor belt was used to increase the frictional area of the shelling house. After modification the performance of peanut sheller was better when compared to the older machine because the efficiency was increased to 98.55%, seeds unshelled was decreased to 1.15%, seeds which were damaged was reduced to 1.36% and total losses was about 2.51%.In this work a pongamia pinnata decorticator is designed and fabricated. The performance evaluation of the decorticator was done based on the bolt arrangement inside the drum. The ultimate goal is to de-shell the pongamia pinnata pods and separate the seeds from pods.

2. Proposed Mechanism of the Machine

2.1. Design Considerations

The pongamia pinnata decorticator was designed based on the following considerations:• Locally available materials were used to reduce the cost of production and for machine maintenance.• Mild steel bolts and square rods were used in order to de-shell the pods by combined loading condition.• The machine must de-shell the pods with good efficiency and also the percentage of seeds breakage should be reduced.

2.2. Proposed Mechanism

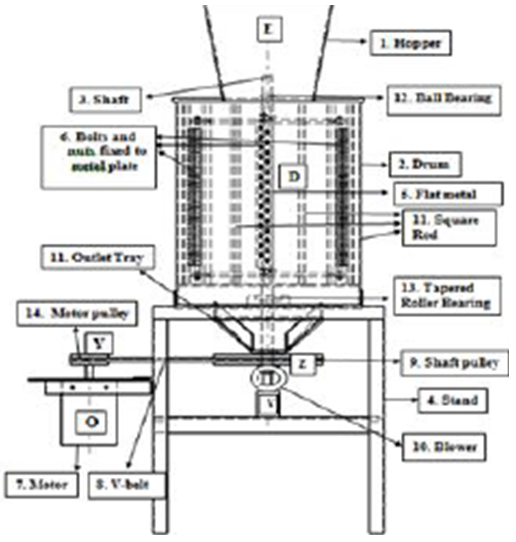

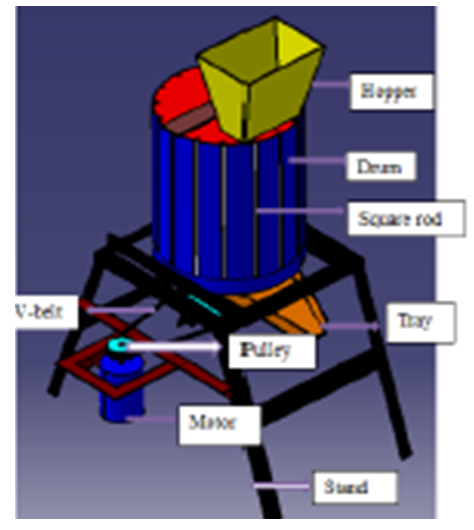

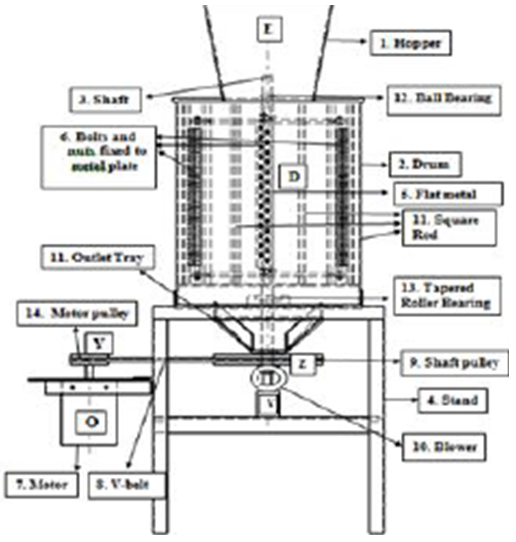

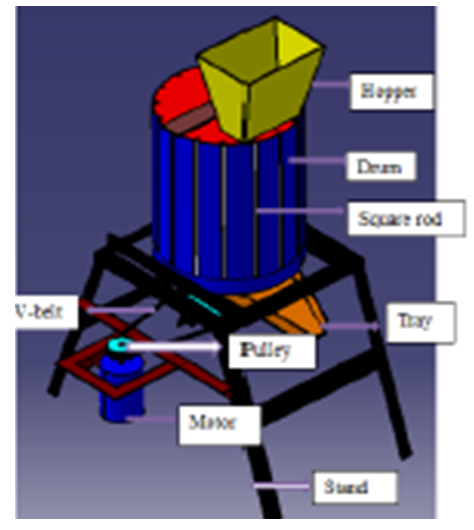

The proposed mechanism consists of a hopper, de-shelling chamber, machine stand (frame), outlet tray, blower and motor.The taper shaped hopper (1) which is mounted on the plate above the drum (2) through which the pongamia pinnata pods are fed into the de-shelling chamber. The de-shelling chamber consists of a drum (2) which is a stator and the shaft (3) is a rotating member. The drum is mounted on the machine stand (frame) (4). Rectangular flat metals (5) are joined to the shaft with the collar material. Bolts and nuts (6) are fitted in to rectangular flat material for the de-shelling operation to takes place. Single phase 1Hp electric motor (7) is used as a prime mover to drive the v-belt (8) which in turn is connected to the shaft pulley (9). Seeds and waste pods are separated by the hand blower (10) placed near the outlet tray (11). The machine stand (frame) (4) is the mounting support for all the components of the machine. Ball bearing (12) is used at the top of the decorticator to support the shaft in rotational motion and tapered roller bearing (13) is used at the bottom of the de-shelling chamber to support pure radial, pure axial and any combination of two types of loading conditions. The 2-D diagram of the proposed mechanism is shown in Figure 1. | Figure 1. Schematic diagram of proposed mechanism |

In the proposed mechanism, the deshelling of pongamia pinnata pods takes place by the combined action of compression, shearing and impact. Provision will be made in the deshelling chamber to adjust the bolts and nuts arrangement and the gap between bolts and the chamber surface for better results.

3. Design Analysis

3.1. Design Calculations

3.1.1. Design of Peeling Chamber

In order to de-shell a large quantity of pongamia pinnata pods a peeling chamber is required. This chamber is cylindrical in shape. The volume of outer drum (D) is calculated using the equation (1). | (1) |

Where, d1 is the diameter of the drum = 500 mm, h is the height of the drum = 500 m, V1 is found to be 98174770.43 mm3. Series of square rods (16 number) are welded in the circumferential surface of the drum at equal distances throughout the cylinder. These square rods also help to strengthen the drum and acts as rib of the drum. It also helps in shearing of the pods during decorticating process. The volume of square rod is calculated using equation (2). | (2) |

Where, l is the length of the square rod = 15 mm b is the breadth of the square rod = 15 mm h is the height of the square rod = 500 mm Volume of each square rod is found to be 112500 mm3. Total volume of 16 square rods is calculated using the equation (3),  | (3) |

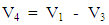

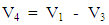

V3 is found to be 1800000 mm3.The total volume of inner chamber is found out using the equation (4). The remaining space inside the chamber V4 is 96374770.43 mm3. | (4) |

3.2. Design of Transmission System

A prototype has been fabricated using proposed mechanism and tested by varying the speed of the shaft. It was observed that the optimum speed required to decorticate the shells with minimum damage was ranging from 450 – 500 rpm.

3.2.1. Selection of Electric Motor

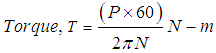

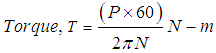

Motor is selected based on the existing decorticating machine. Therefore, single phase 1HP motor of 745.7 watts is used. Maximum torque produced by the electric motor is calculated using the equation (5).  | (5) |

Where, P is the electric motor power = 745.7 Watts N is the rpm of the electric motor = 1440 rpm Torque (T) produced by the electric motor is found to be 4.945 N-m.

3.2.2. Design of Belt Drive

Diameter of the shaft pulley is calculated using velocity ratio equation (6) | (6) |

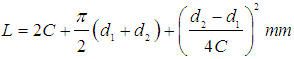

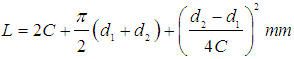

Speed of the motor (N1) =1440 rpm, Speed of the shaft to rotate (N2) = 480 rpm, Diameter of the motor pulley (d1) = 100 mm. Diameter of the shaft pulley (d2) is found to be 300 mm.Length of the belt is calculated using the equation (7). Type ‘A’ section V-belt is suitable for the drive which transmits less than 0.81kW power. C is distance between centers of two pulleys = 500 mm. Length of the belt (L) to transmit the power is 1648.32 mm.  | (7) |

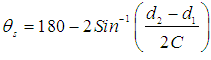

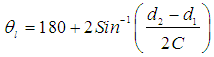

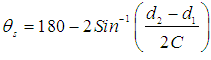

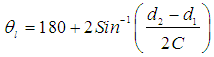

Lap angle for smaller pulley and larger pulley of an open belt drive is calculated using the expression (8) and (9).For smaller pulley (motor), | (8) |

Larger pulley (shaft), | (9) |

Lap angle for smaller pulley and larger pulley are 2.74 and 3.54 rad respectively. Angle of lap for smaller pulley is considered for the design of belt drive.The tension in the tight side and slack side of the belt is found out using the equation (10) | (10) |

Where, T1 is tension on the tight side, T2 is tension on the slack side. Belt material as rubber fabric and the pulley material as cast iron, μ = 0.3 for rubber fabric on cast iron. Taking 2α =35. Half groove angle α = π/2 =17.5. For V-belt, belt tension ratio is | (11) |

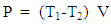

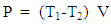

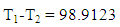

The power transmitted by a V-belt is given by an equation (12), | (12) |

Where, P is power in watts = 745.7 Watts.Velocity of the belt is given by an equation (13), | (13) |

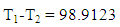

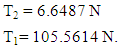

Velocity (V) is found to be 7.539 m/s.From equation (12) (T1-T2) is found to be, | (14) |

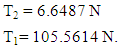

From equations (11) in (14) the tensions in the tight side and slack side are found to be

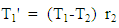

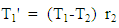

3.2.3. Determination of Shaft Torque

The shaft torque is calculated using the equation (15), | (15) |

Where, r2 is radius of the shaft pulley = 150 mm.The shaft torque is found to be, T1' = 14836.905 N-mm.

3.2.4. Cutting Force Calculation

The force required to de-shell the pongamia pinnata pods is calculated by using the equation (16). | (16) |

Where, T1' is shaft torque = 14.8369 N-m.Rcutting tip is radius from the centre of the shaft to cutting tip i.e bolt head. Ft is cutting force (shear force) is found to be

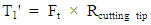

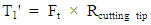

3.2.5. Design of Shaft

The shaft made up of mild steel was taken which carried combined load of bending and torque. | Figure 2. Force diagram of the shaft. (All dimensions in mm) |

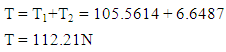

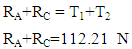

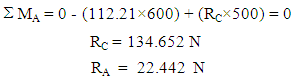

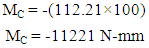

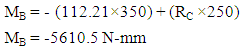

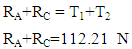

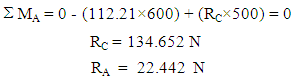

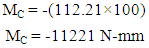

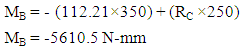

Total tension acting on the shaft, Bending moment at A and D is zero, resolving the forces we get,

Bending moment at A and D is zero, resolving the forces we get,  | (17) |

Taking moment about A, | (18) |

Bending moment at C is Bending moment at B is

Bending moment at B is  The diameter of the shaft is calculated using the equation (19),

The diameter of the shaft is calculated using the equation (19), | (19) |

Taking maximum shear stress SS [6] of mild steel rod to be 42 MPa.Where, M is the maximum bending moment = 11.221 N-mT is the shaft torque = 14.837 N-m The diameter of the shaft was 13.114mm.The de-shelling of pongamia pinnata takes place due to the combination of various forces like shear, compressive and impact. However, the magnitudes of these forces are difficult to predict. So, considering the effect of these forces and for safer load condition diameter of the shaft taken was 30mm.

The diameter of the shaft was 13.114mm.The de-shelling of pongamia pinnata takes place due to the combination of various forces like shear, compressive and impact. However, the magnitudes of these forces are difficult to predict. So, considering the effect of these forces and for safer load condition diameter of the shaft taken was 30mm.

4. Performance Test and Evaluation

4.1. Performance Evaluation Procedure

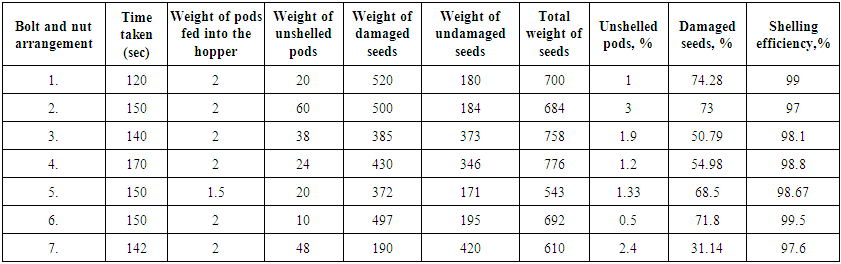

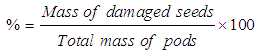

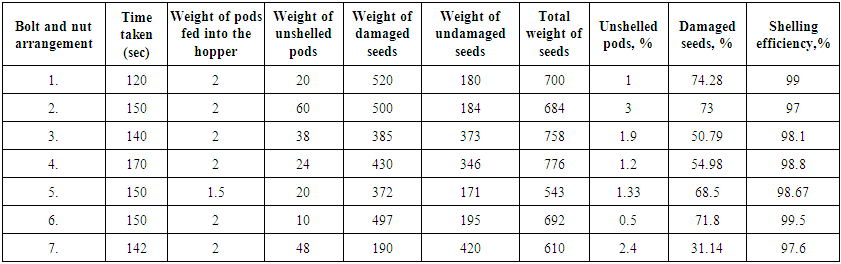

The pongamia pinnata pods are weighed and fed into the drum through the hopper as shown in fig 3 and 4. The bolts in the rectangular flat shears the pods in contact with the square metal rods. The de-shelled pods and seeds flow out of the drum through the tray kept below the drum opening. Seeds and waste pods are separated by the hand blower after passing through the tray. Time taken to complete the de-shelling was recorded by using the stop watch. The de-shelled pongamia pinnata seeds were collected and separated into two categories. The two categories are damaged seeds and undamaged seeds. | Figure 3. CAD model assembly of pongamia pinnata decorticator |

| Figure 4. Prototype model of pongamia pinnata decorticator |

| Figure 5. Side view and top view of pongamia pinnta decorticator |

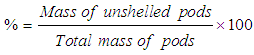

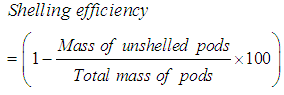

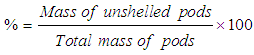

The technical terms in the present performance was determined as follows:Damage percentage, Unshelled pods percentage,

Unshelled pods percentage, Shelling efficiency was determined by using the formula,

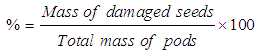

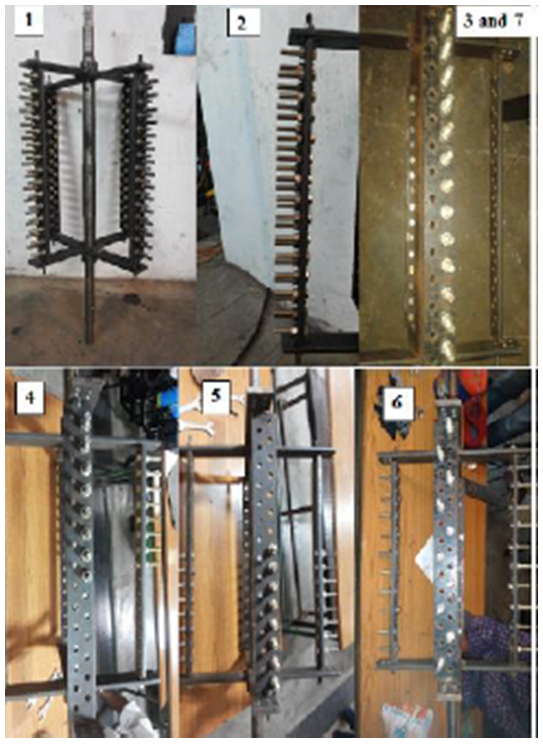

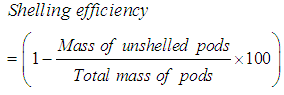

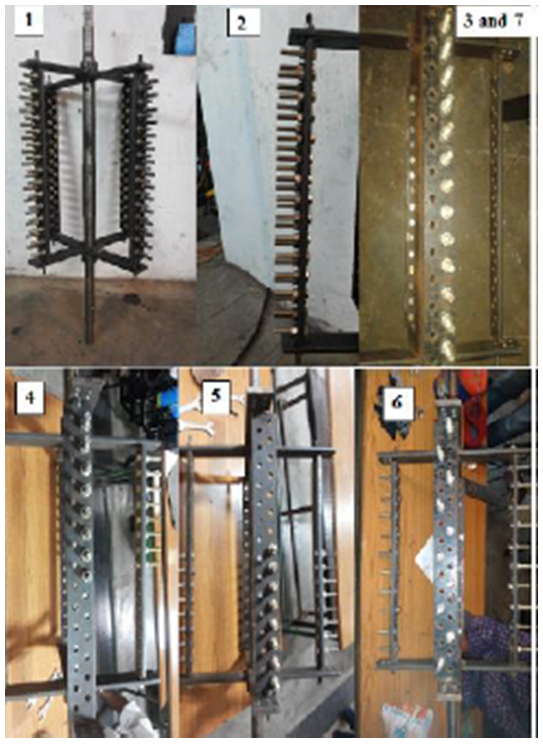

Shelling efficiency was determined by using the formula, Performance tests were conducted by varying the number of bolts and nuts and their arrangements in seven different patterns as mentioned below.1. 120 bolts, nuts and washers were fitted into four rectangular flat metal plate in the assembly.2. 60 bolts, nuts and washers were removed from two rectangular flat plate in the assembly which were in opposite directions.3. 15 bolts, nuts and washers were fitted in to each plate in a single row of rectangular flat metal plate.4. 8 bolts, nuts and washers were fitted into the top portion of the four rectangular flat metal plate in a single row.5. 8 bolts, nuts and washers were fitted into the bottom portion of the four rectangular flat metal plate in a single row.6. 10 bolts were used in zig-zag direction leaving space of 45mm between the two bolts center.7. 15 bolts, nuts and washers were fitted in to two plate in opposite direction in the rectangular flat plate.The results obtained during the performance test were tabulated as shown in table 1 respectively. The machine parameters after performance were calculated from the results also shown in table 1.

Performance tests were conducted by varying the number of bolts and nuts and their arrangements in seven different patterns as mentioned below.1. 120 bolts, nuts and washers were fitted into four rectangular flat metal plate in the assembly.2. 60 bolts, nuts and washers were removed from two rectangular flat plate in the assembly which were in opposite directions.3. 15 bolts, nuts and washers were fitted in to each plate in a single row of rectangular flat metal plate.4. 8 bolts, nuts and washers were fitted into the top portion of the four rectangular flat metal plate in a single row.5. 8 bolts, nuts and washers were fitted into the bottom portion of the four rectangular flat metal plate in a single row.6. 10 bolts were used in zig-zag direction leaving space of 45mm between the two bolts center.7. 15 bolts, nuts and washers were fitted in to two plate in opposite direction in the rectangular flat plate.The results obtained during the performance test were tabulated as shown in table 1 respectively. The machine parameters after performance were calculated from the results also shown in table 1. | Table 1. Result of performance evaluation of pongamia pinnata decorticator |

4.2. Total Losses

The damage seeds percentage was increased by increasing the number of bolts and nuts in the rectangular flat plate. The damaged seeds ranged from 30 to 75% at different condition of arrangement. The unshelled pods percentage was decreased by increasing the number of bolts and nuts in the rectangular flat plate in the assembly. The unshelled pods ranged from 1 to 3% at different conditions of assembly arrangement. The total losses of damaged seeds increased and unshelled pods decreased with increase in number of bolts in the assembly and vice-versa.

4.3. Shelling Efficiency

Shelling efficiency of pongamia pinnata decorticator increased by increasing the number of bolts and nuts in the rectangular flat plate in the assembly. The shelling efficiency ranged from 97 to 99.5% for different combination of bolts and nuts arrangement.

4.4. Time Taken

The result obtained when 2 kg of pongamia pinnata pods were fed into the hopper. The time taken to de-shell the pods ranged between 120 to 200 seconds. In order to reduce the weight of damaged seeds the best result was evaluated. The best result obtained from all the conditions by considering the mass of damaged seeds was evaluated by conducting three more tests on the same condition to get the best result out of it. | Figure 6. Different pattern of bolt and nut arrangement |

5. Conclusions

A decorticator to deshell the pongamia pinnata shells has been designed and developed. Performance test was conducted on the developed machine and following important conclusions are drawn.1. The operation of this machine makes it a unique type compared to existing ones. The operation was performed automatically and did not require high skilled labour.2. An average de-shelling efficiency of 97.38% was observed when 2 kg of pongamia pinnata pods are fed into the hopper and damaged seeds of 60.64% were recorded. The average time taken to de-shell 2 kg of pods was found to be about 153 seconds for all the 7 types of bolts and nuts arrangement.3. Out of 7 different arrangements the least percentage of damaged seeds was obtained for the arrangement no. 7. Hence, arrangement 7 was tested for 3 more trials to confirm the results. 4. The average percentages of unshelled pods, damage seeds and shelling efficiency were 2.05%, 28.75% and 97.95% respectively.5. The developed decorticator unit can be successfully and efficiently used by farmers, to produce pongamia pinnata seeds thus resulting in great saving in time and effort.6. The decorticator was designed based on the physical and mechanical properties of pongamia pinnata.

ACKNOWLEDGEMENTS

The authors are very grateful to the Faculty of Department of Mechanical Engineering, JNNCE Shivamogga, for using their workshops and Lab facilities.

References

| [1] | S. S. Raut, “Seed and Fruit Variability in Pongamia Pinnata pierre from Konkan Region of Maharastra,” Journal of Biodiversity, 2(1): 27-30 (2011). |

| [2] | G.D. Vasantha Kumar., and K. Rajesh, “Performance evalua tion of a pongamia decorticator,” International Journal of Agricultural Engineering, Vol. 8, Issue 1, April, 2015, pp: 66–69. |

| [3] | Ketan K. Tonpe, “Design & Performance of Coconut De-shelling Machine,” International Journal of Engineering Research and Applications, Vol. 4, Issue 7, July 2014, pp: 39-44. |

| [4] | Ikechukwu Celestine Ugwuoke., “Design and Development of Manually Operated Roasted Groundnut Seeds Peeling machine,”, International Journal of Recent Development in Engineering and Technology, Vol. 2, Issue 4, April 2014. |

| [5] | Abubakar Mohammed., “Design and Evaluation of a Motorized and Manually operated Groundnut Shelling Machine,” International Journal of Emerging trends in Engineering and Development, Vol. 4, Issue 2, May 2012. |

| [6] | Oladeji Akanni Ogumwole., “Design, Fabrication and Testing of a Roasted Groundnut Decorticating Machine,” International Journal of Food science and Quality management, Vol. 14, 2013. |

| [7] | Abdulkadir Baba Hassan., “Design and Fabrication of a Cassava Peeling Machine,” IOSR Journal of Engineering, Vol. 2, Issue 6, June 2012, PP 01-08. |

| [8] | A. R. Lende., “Design and Fabrication of Tamarind Cover and Seed Separation Machine,”, International Journal of Engineering and Innovative Technology, Vol. 1, Issue 2, Feb 2012. |

| [9] | M. A. Helmy., “Modification and Evaluation of a Reciprocating Machine for Shelling Peanut.” J. Ag. Eng., April 2007. |

| [10] | Khurmi, R.S. and Gupta, J.K.. A Textbook of Machine Design (S.I. Units), Eurasia publishing House (PVT) Ltd., Ram Nagar, New Delhi-11005s, 2005. |

Bending moment at A and D is zero, resolving the forces we get,

Bending moment at A and D is zero, resolving the forces we get,

Bending moment at B is

Bending moment at B is  The diameter of the shaft is calculated using the equation (19),

The diameter of the shaft is calculated using the equation (19),

The diameter of the shaft was 13.114mm.The de-shelling of pongamia pinnata takes place due to the combination of various forces like shear, compressive and impact. However, the magnitudes of these forces are difficult to predict. So, considering the effect of these forces and for safer load condition diameter of the shaft taken was 30mm.

The diameter of the shaft was 13.114mm.The de-shelling of pongamia pinnata takes place due to the combination of various forces like shear, compressive and impact. However, the magnitudes of these forces are difficult to predict. So, considering the effect of these forces and for safer load condition diameter of the shaft taken was 30mm.

Unshelled pods percentage,

Unshelled pods percentage, Shelling efficiency was determined by using the formula,

Shelling efficiency was determined by using the formula, Performance tests were conducted by varying the number of bolts and nuts and their arrangements in seven different patterns as mentioned below.1. 120 bolts, nuts and washers were fitted into four rectangular flat metal plate in the assembly.2. 60 bolts, nuts and washers were removed from two rectangular flat plate in the assembly which were in opposite directions.3. 15 bolts, nuts and washers were fitted in to each plate in a single row of rectangular flat metal plate.4. 8 bolts, nuts and washers were fitted into the top portion of the four rectangular flat metal plate in a single row.5. 8 bolts, nuts and washers were fitted into the bottom portion of the four rectangular flat metal plate in a single row.6. 10 bolts were used in zig-zag direction leaving space of 45mm between the two bolts center.7. 15 bolts, nuts and washers were fitted in to two plate in opposite direction in the rectangular flat plate.The results obtained during the performance test were tabulated as shown in table 1 respectively. The machine parameters after performance were calculated from the results also shown in table 1.

Performance tests were conducted by varying the number of bolts and nuts and their arrangements in seven different patterns as mentioned below.1. 120 bolts, nuts and washers were fitted into four rectangular flat metal plate in the assembly.2. 60 bolts, nuts and washers were removed from two rectangular flat plate in the assembly which were in opposite directions.3. 15 bolts, nuts and washers were fitted in to each plate in a single row of rectangular flat metal plate.4. 8 bolts, nuts and washers were fitted into the top portion of the four rectangular flat metal plate in a single row.5. 8 bolts, nuts and washers were fitted into the bottom portion of the four rectangular flat metal plate in a single row.6. 10 bolts were used in zig-zag direction leaving space of 45mm between the two bolts center.7. 15 bolts, nuts and washers were fitted in to two plate in opposite direction in the rectangular flat plate.The results obtained during the performance test were tabulated as shown in table 1 respectively. The machine parameters after performance were calculated from the results also shown in table 1.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML