-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2015; 5(3B): 39-42

doi:10.5923/c.jmea.201502.08

Processing of Waste Plastics into Building Materials Using a Plastic Extruder and Compression Testing of Plastic Bricks

Noel Deepak Shiri , P. Varun Kajava , Ranjan H. V. , Nikhil Lloyd Pais , Vikhyat M. Naik

Department of Mechanical Engineering, St Joseph Enginnering College, Mangaluru, India

Correspondence to: Noel Deepak Shiri , Department of Mechanical Engineering, St Joseph Enginnering College, Mangaluru, India.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

The main aim of this work is to reduce the plastic waste that is rising in the present world and to achieve this; a system is designed incorporating a plastic extruder which plays a prominent part in recycling waste plastic into useful products. This work uses waste plastics and converts them into building materials with the help of an extruder, thereby reducing the plastic waste which is a key factor for environmental pollution. Presently waste plastics are effectively converted into useful building materials like bricks, interlocks, roof tiles, railway sleepers, paving slabs, retaining blocks etc., using either single origin plastic waste material or a mixture of different plastic wastes along with waste rubber powder as filler. After conducting several trials with the variety of plastic wastes processed into composite brick, it was observed that the maximum compressive load sustained by the Polypropylene/Rubber composite brick is 17.05 tons followed by LDPE/Rubber composite brick with 16.55 tons which is much higher than the clay brick which sustained only 9.03 tons.

Keywords: Waste Plastics, Plastic Extruder, Plastic/Rubber Composite Brick, Compression Testing

Cite this paper: Noel Deepak Shiri , P. Varun Kajava , Ranjan H. V. , Nikhil Lloyd Pais , Vikhyat M. Naik , Processing of Waste Plastics into Building Materials Using a Plastic Extruder and Compression Testing of Plastic Bricks, Journal of Mechanical Engineering and Automation, Vol. 5 No. 3B, 2015, pp. 39-42. doi: 10.5923/c.jmea.201502.08.

Article Outline

1. Introduction

- Waste is now a global problem, and one that must be addressed in order to solve the world's resource and energy challenges. Plastics are made from limited resources such as petroleum, and huge advances are being made in the development of technologies to recycle plastic waste among other resources [1]. Plastics are non-biodegradable, synthetic polymers derived primarily from petro-fossil feedstock and made-up of long chain hydrocarbons with additives and can be moulded into finished products. These polymers are broken in presence of suitable catalyst, into monomers such as ethylene, propylene, vinyl, styrene and benzene [2]. These monomers are then chemically polymerized into different categories of plastics. Plastics are generally categorised as Thermoplastics and Thermoset Plastics. Thermoplastics can be heated up to form products and then if these end products are re-heated, the plastic will soften and melt again. These include PET, HDPE, LDPE, PP, PVC, PS etc. Thermoset plastics can be melted and formed, but once they take shape after they have solidified, they stay solid and, unlike thermoplastics cannot be re-melted. These include Multilayer and Laminated Plastics, Bakelite, Polycarbonate, Melamine, Nylon etc. [3]. Mechanical recycling methods to make plastic products and feedstock recycling methods that use plastic as a raw material in the chemical industry have been widely adopted, and awareness has also grown recently of the importance of Thermal recycling as a means of using plastics as an energy source to conserve petroleum resources [1]. The world's annual consumption of plastic materials has increased from around 5 million tons in the 1950s to nearly 100 million tons today. Plastics constitute approximately 3-7% of municipal waste. Presently, municipal garbage disposal departments burry the plastics along with other materials in landfill without even recognizing its ill effects. Municipal solid waste in India contains 1-4% by weight of plastic waste. India’s rate of recycling of plastic waste is the highest (60%) in the world as compared to other countries (China 20%, Europe 20-40%, Japan 39%, South Africa 16%, England 17.7% and USA 28%). In India, there are three common ways of getting rid of plastics - by dumping them in landfills, by burning them in incinerators or by littering them. In the case of littering, plastic wastes fail to reach landfills or incinerators. It is the improper way of disposing plastics and is identified as the cause of manifold ecological problems [2]. Extrusion plays a prominent part on the plastics industry. Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion is a continuous process, as opposed to moulding, which is a cyclic process. Approximately 65% of all plastics in use today pass through an extruder [4].In more recent times, a number of companies are selling composite railroad ties manufactured from recycled plastic resins, and recycled rubber. Plastic/Composite ties (P/C ties) can be made of recycled plastics, generally polyethylene, but often include other materials such as steel fibre, steel reinforcing bar, shredded used tires, mineral filler, virgin plastic, or concrete. The modelled representative P/C tie is assumed to be 8% virgin HDPE plastic, 7% talc (mineral filler), and the balance a mixture of post-consumer recycled milk bottles, grocery bags, and tires. Electric energy is required to process the mixture and extrude the P/C product. The spacing of the P/C product and the required steel used to fasten the P/C tie to the track are assumed the same as creosote-treated crossties [5].

2. Design Aspects

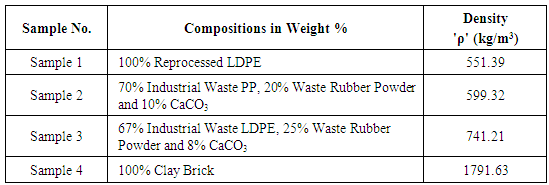

- The design concept consists the following:a) Maximum volume of the melt needed to fill the mold. This entails length of the screw conveyor (l), diameter of the barrel (d), melt density (ρm) and melt mass (m);b) Design of barrel which entails diameter of the barrel.c) Design for screw conveyor.While the design analysis entails the following units:a) The Extruder unit comprises of the hopper, barrel, band heater, nozzle, screw conveyor, bearing housing and gear boxb) The clamping unit consists of the mold and clamping for locking device.c) The electrical panel comprises of temperature control box, and thermocouple.

3. Machine Construction

- The major techniques employed in construction of the designed machine include machining operation on lathe machine, drilling operations on drilling machine, boring operation on lathe machine, keyway cutting on slotting machine, flame cutting using oxyacetylene gas welding machines, grinding for good finishing, electric welding using arc welding machine. Basically, these constructional techniques were broken down into four sub-heading namely; cutting operation, machining operation, welding operation and assembly; and finishing operation. The line diagram the machine is shown in the Figure 1.

| Figure 1. Final Setup of the Extruder for Recycling Waste Plastics |

3.1. Materials Selection

- Materials are selected based on designed and metallurgical properties of the materials such as machinability, formability, weldability that greatly influence the construction methods and other joining methods. Other factors considered are cost of the materials; and mechanical properties of the materials.

3.2. Equipment

- The parts used are as follows: 3 phase, 2HP, Induction motor, 1:10 Worm gear reduction box, tapered and ball bearing, ceramic band heaters, thermocouples, Temperature control box other such as mainframe is cut into sizes using oxyacetylene gas welding, grinding and welding operation on mold box, barrel and Screw conveyor were faced using the lathe machine, drilling, milling, using drilling machine, milling machine and respectively. Drilling operation on the lathe machine was performed on the components such as the mold, barrel, flanges, and the supporting frame. Milling operation was carried out on the barrel. All the general finishing operation was carried out on the machine such as grinding of all rough edges using a hand grinding machine. Cutting saw or frame cutting were used for cutting the various metals into sizes and required shapes. The photograph of the machine is shown in the Figure 2.

| Figure 2. Final Assembled Photograph of the machine |

4. Working

- The operational principle of this machine is as follows:(a) Switch on the heater and set the required temperature slightly above the melting point of different waste plastics. (b) Mixing waste plastics, rubber composites and calcium carbonate in required quantity and is poured into the hopper when the required temperature in the control box has reached.(c) Switch on the motor and the screw conveyor starts rotating at 80 rpm.(d) The waste plastics from the hopper gets melted and conveyed towards the nozzle.(e) A brick mold is kept at the end of the nozzle tip and the molten plastic/rubber composite material starts filling the mold box. After the mold is filled completely the mold box is removed from the nozzle tip dipped in the water bath and kept inside the bath for an hour for proper cooling.(f) The final product is removed from the mould box and is sent for compression testing using Hydraulic Brick testing machine.

5. Testing of the Product

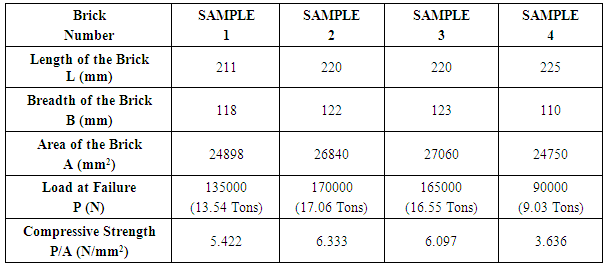

5.1. Different Types of Brick Materials Tested

- Various waste plastic sample bricks are produced from the machine and its details are given in Table 1.

|

5.2. Experiment Setup and Procedure

- The equipment used for testing various samples is Hydraulic Brick Testing Machine (shown in Figure 3) which can apply a maximum compressive load of 2000kN.

| Figure 3. Hydraulic Brick Testing Machine |

| Figure 4. Testing of LDPE/Rubber Composite Brick (Sample 3) |

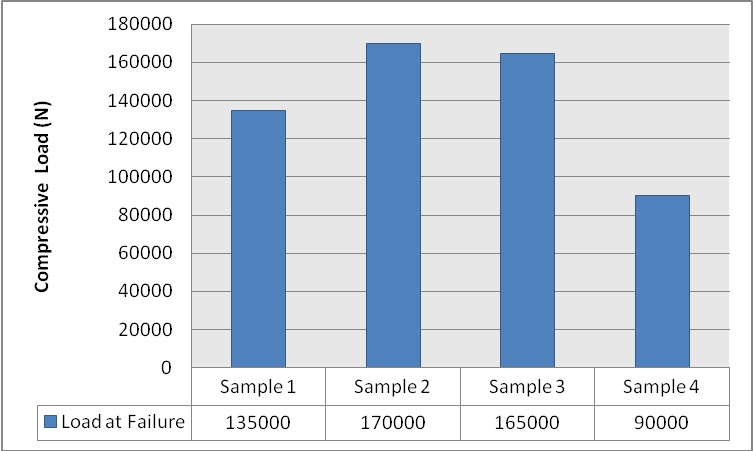

6. Results and Discussion

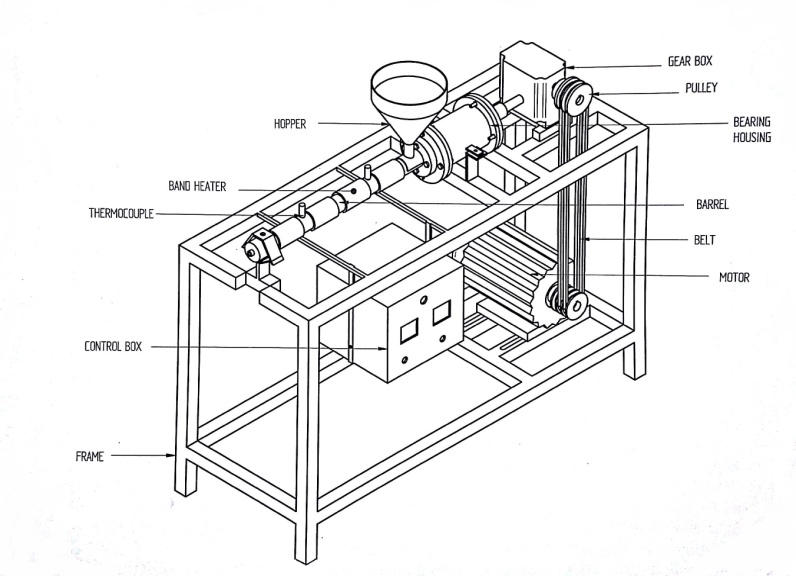

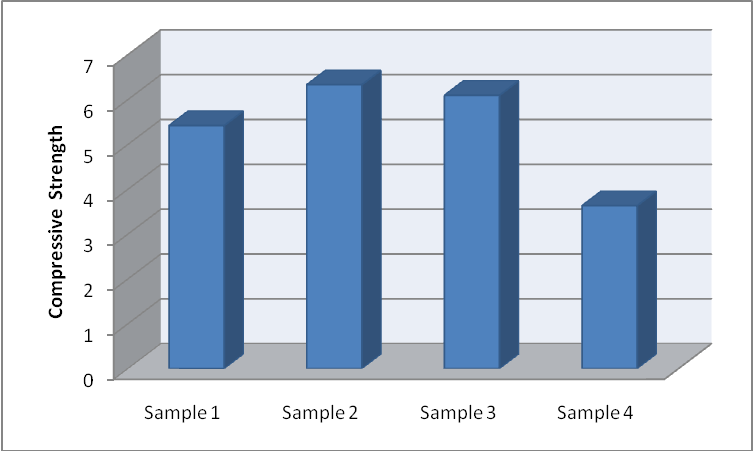

- Compression tests were conducted for all the 4 samples and the average values of 3 trials are noted and presented in Table 2.

|

| Figure 5. Failure of Bricks at Different Loads |

| Figure 6. Compressive Strength of different bricks |

7. Conclusions

- This work effectively converts waste plastic into useful building materials like building bricks and floor interlocks which can effectively reduce the environmental pollution and further decreases the problem of waste plastics in the society. Rather than the waste plastics going into the landfill or incinerators it can be used as construction materials at a much lower cost after undergoing certain specific processing. It also reduces the construction cost by eliminating the use of mortar during construction by using recyclable plastic/composite bricks and floor interlocks. From the compression testing results we come to know that waste plastics material when effectively mixed with Rubber powder and Calcium Carbonate gives the highest compressive strength and sustains high compressive load.

ACKNOWLEDGEMENTS

- We are extremely grateful to Dr. Joseph Gonsalvis, Principal, St Joseph Engineering College, Mangaluru for his invaluable suggestions, comments, and enthusiasm that gave us direction for the success and completion of this project. We would like to thank the Mr. Ashok, Technical Engineer, Gurucharan Industry, Baikampady Industrial Area, Mangaluru for helping with the fabrication of many key components of plastic extruder.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML