-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2015; 5(3A): 19-25

doi:10.5923/c.jmea.201501.04

Theoretical Analysis on the Effect of Operation Strategies on the Environmental Performance of Micro Gas Turbine Trigeneration System in Tropical Region

KH Koo, MRR Chand, Hassan Ibrahim, Azizuddin Abd Aziz, Firdaus Basrawi

Energy Sustainability Focus Group, Faculty of Mechanical, Universiti Malaysia Pahang, Pekan, Malaysia

Correspondence to: Firdaus Basrawi, Energy Sustainability Focus Group, Faculty of Mechanical, Universiti Malaysia Pahang, Pekan, Malaysia.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Trigeneration system (TGS) is a type of distributed power generation system that can further utilize waste heat for heating and cooling. This will result in 60-90% of energy utilization efficiency. Micro Gas Turbine is one of attractive prime movers that can reduce environmental pollution, less maintenance, and flexible in fuel supply. However, environmental performance of MGT-TGS depends on the operation strategy employed. In order to reduce emission of CO2, NOx and CO, studied on optimum operation strategy based on environmental performance of MGT-TGS in residential building loads for tropical region was carried out. Two actual size of MGT, 30kW and 65kW were used as the prime mover, and equipment and configuration of MGT-TGS were designed to cover energy load of a residential building in tropical region. Emission reduction index was used to compare emissions of MGT-TGS with different operation strategies. Result shows that MGT with smaller capacity at higher operation load will produce least emissions. Thus, base load is the most optimum operation strategy in terms of environmental performance. Thus, the best solution is base load that used smaller MGT. However, economic performance also must be further studied because smaller MGT has higher cost per kW, and it has slightly lower power generation efficiency.

Keywords: Micro Gas Turbine, Trigeneration system, Operation strategy, Emission

Cite this paper: KH Koo, MRR Chand, Hassan Ibrahim, Azizuddin Abd Aziz, Firdaus Basrawi, Theoretical Analysis on the Effect of Operation Strategies on the Environmental Performance of Micro Gas Turbine Trigeneration System in Tropical Region, Journal of Mechanical Engineering and Automation, Vol. 5 No. 3A, 2015, pp. 19-25. doi: 10.5923/c.jmea.201501.04.

Article Outline

1. Introduction

- In traditional power plant the electricity is produced by burning fossil fuel to drive the turbine and generator. This type of power plant can produce large amount of heat in the condenser and become waste. Normally the waste heat generated in conventional power plant is about 67% of the total fossil fuel content [1]. If power plant is located close to end-user, this waste heat can be utilized for space and water heating and also cooling, this type of system that can produce electricity, heat and cooling simultaneously is called Trigeneration System (TGS).Another reason when considering that is in Malaysia around 7.5% of total electricity generation is lost during the transmission & distribution networks [2]. Due to this reason trigeneration can be used, and this will result in emission reduction, increase total energy efficiency, and potentially reducing energy costs.TGS that produces power, heat and cooling has been thought to be a significant energy proficiency measure. Especially, small TGS frameworks, for example, micro-TGSs are generally upheld by numerous governments, particularly in Northern Europe [3]. Micro-TGSs are seen as an option for delivering power supply with the extra capacity of providing residential heating capabilities, thus increase the overall energy proficiency of the system. A few studies say that its penetration could be imperative by 2050 [4].Micro-TGSs have extra value of the flexibility to the user which conventional generation is impossible to do it. Most of these technologies have flexible in its size, expandability, and operation. There are different type of operating strategies that are commonly used to meet the on-site energy loads. Selection of appropriate operation strategy is very important during system design stage, and appropriate operation strategy depends on the power, heating and cooling load of a target building. In addition, part-load operation is also important because it drastically affect the performance of TGS. Main operating strategies of TGS are:a) Power match modeMicro-TGS is specially installed to meet electric load of the user. Excess of electricity can be sold back to grid. Additional boiler may need to cover heat demand of the user.b) Heat match modeMicro-TGS is specially installed to meet heating load of the user. Excess heat can be stored in additional equipment which is heat storage tank. User may need to buy electricity from national grid to cover power demand.c) Mix match modeMicro-TGS is specially installed to meet both power and heating loads that cover the user demand in whole day. Excess or insufficient of power and heat may need additional equipment. d) Base load match modeMicro-TGS is installed to only cover base load. Thus, MGT operates at constant and full load and this will result in insufficient electricity and heat. The insufficient electricity can be bought from grid, the heating load can be stored in heat storage tank.There are a few type of prime mover for TGS including fuel cell, reciprocating engine. MGT has some advantages over other prime movers. These advantages are: compact systems and lightweight, vibration free and low noise level, lowest emission, heat recovery system is simple, require less maintenance cost and time. Furthermore, it can be operated as: stand-alone or grid connected system to produce large amount of electricity. Performance of MGT-TGS depend on operation strategy employed and pattern of building load. This operation that cover different type of building loads will lead to different operation loading of MGT-TGS, subsequently affect the emissions released from the system. Whether the MGT-TGS that is employed will be even worse, or better compared to a conventional system depends on the operation strategy employed.There are many recent studies reported on the MGT-TGS. Baswari F, et al, studied on optimum operating strategies of a stand-alone hybrid-photovoltaic MGT-TGS [5]. Bogdan AT, et al, compared economic factor of biomass internal combustion engine and natural gas MGT by using payback period in Romania [6]. Uzuneanu K, et al, evaluate the energy performance and efficiency of trigeneration system using fuel cells [7]. Xu DH, et al, analyze energy, environmental and economic performance for MGT-TGS data centers [8]. Simon PB, et al, studied performance of MGT-TGS for residential buildings assessed on the basis of the system’s energetic, environmental and economic performance [9]. Yu HD, et al, evaluate energy efficiency and emission of MGT-TGS using biofuel [10]. N Sugiartha, et al, evaluation of energy efficiency, economic and environmental performance of a MGT-TGS for supermarket applications in South England [11]. Wang JJ, et al, perform analysis on 3 criteria: primary energy saving, carbon dioxide reduction and annual total cost saving for MGT-TGS with electrical and heat demand in different climate zones of China [12]. Ebrahimi M, et al, analyze energy and exergy of micro-steam trigeneration system in residential building [13]. KC Kavvadias, et al, analyze economic performance of trigeneration system with different operation strategies for hospital building [14]. MA Lozano, et al, studied on optimum operation strategies of a simple trigeneration system by marginal cost as economic performance [15]. PJ Mago, et al, studied performance of hybrid electric-thermal operating strategies of MGT-TGS on primary and site energy consumption, carbon dioxide reduction and operational cost [16]. From the literature review, there is no finding reported on the effect of different operation strategies on the environmental performance of MGT-TGS for a residential building in tropical region. Thus, the objective of this study is to determine optimum operation strategy based on environmental performance of MGT-TGS in residential building in tropical region. Since, power, heating and cooling load are commonly used in tropical region, 4 different operation strategies of MGT-TGS with different equipment were design to cover these building loads. These strategies are power match, heat match, mix match and base load. MGT with different capacity of 30 kW and 65 kW were used as main component that produce power. All the equipment in each operation strategies was clarified by energy balance calculation. Emission reduction index of CO2, NOx and CO emission were compared with each strategies. Finally, the best strategy is chosen based on the emission reduction index.

2. Materials and Methods

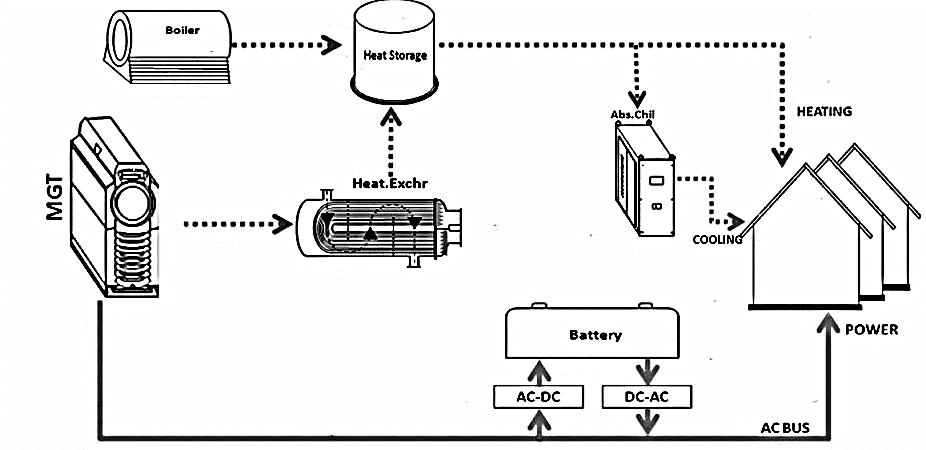

2.1. Micro Gas Turbine Trigeneration System Configuration

- Schematic diagram below shows the system configuration of the MGT-TGS studied [5]. Core component of the system is MGT 30 kW and 65 kW. Both sizes of MGT are commonly available for residential used. In power production, MGT covers the power demand. In heat production, exhaust heat recovered is used to cover water heating demand and to operate an absorption heat pump. Absorption heat pump will convert heat energy to cooling load and cover cooling demand. In power match operation, MGT loading is adjusted to cover the power demand of the building, heat match is adjusted to cover heat demand, mix match cover both power and heat demand, base load is operated with constant full load by cover base power demand. Insufficient power was bought from TNB, meanwhile heat storage was used to balance the heating demand during day and night time. In addition, boiler was used to supply insufficient heat, and excess of power produced was stored in battery.MGT is usually designed to have optimum energy and emissions performance at full load. Under partial load operation, its power generation efficiency decreases and its emissions level also increases rapidly. Thus, base load strategies with smaller MGT capacity is used to run constantly with full load. Peak demand can be covered by top up from external grid and addition of boiler is used to cover insufficient of heat supply. This operation is expected to have lowest emission but might subject to high cost due to extra power top up from external grid.

2.2. Ambient Temperature Condition

- Ambient temperature is important as the input of the calculation for MGT. Ambient temperature of Malaysia is used. As a tropical climate country, the different of the highest and lowest ambient temperature range of Malaysia is between 33°C and 24°C with average of 28°C [5].

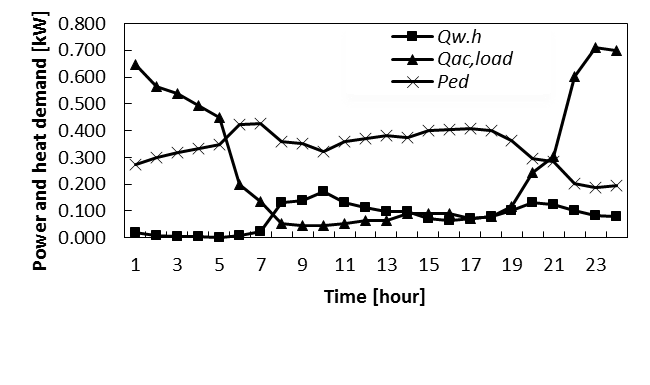

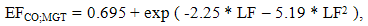

2.3. Data of Energy Demand and Residential Building

- A reference building is used to study the energy demands. This building is the most commonly built in Malaysia and the studied building is a group of 148 terrace houses. Each house is 6.5 m long and 19.8 m wide. It has four rooms and bathrooms that cover a total area of 129 m2 [5]. Data for energy load for each house was adopted from a survey. Power, heating and cooling demand of a single house are shown in Figure 1 [5]. Power demand increase during day hours whereas cooling demand increase during night time because residential use air conditioner during night time and less power is used at that period. Besides building demands, a particular length of water pipeline and power capacity of water pumps were also needed to calculate heat losses throughout the pipeline and power for water pumping.

| Figure 1. Configuration of MGT System for All Operation Strategy |

| Figure 2. Power, Heating and Cooling Demand in a Single Day |

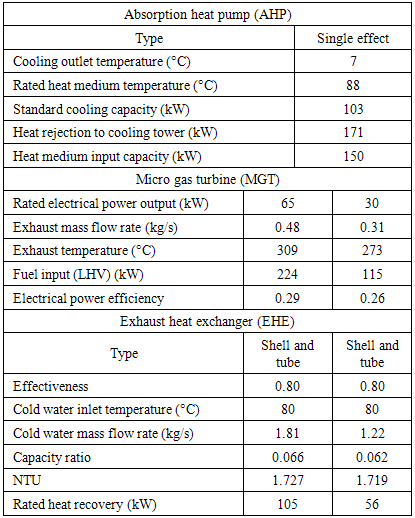

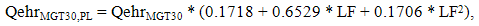

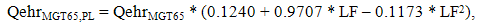

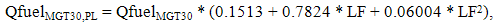

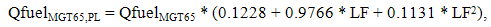

2.4. Data of Micro Gas Turbine in Tri-Generation

- MGT-TGS unit that was used in this study consisted of a water-lithium bromide absorption heat pump (AHP), recuperated single shaft MGT and an exhaust heat recovery (EHE) of tube-shell type. Table 1 shows the basic specifications of the AHP, MGT and EHE [2].

|

| (1) |

| (2) |

| (3) |

| (4) |

| (5) |

| (6) |

| (7) |

| (8) |

| (9) |

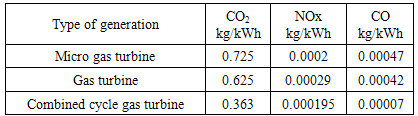

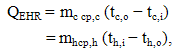

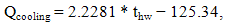

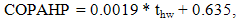

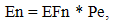

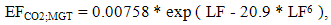

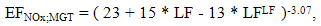

2.5. Environmental Analysis of Trigeneration System

- For the environmental analysis two conventional systems; typical and ideal were compared to the MGT-TGS. The typical system worked on a gas turbine whereas the ideal one worked on a Combined Cycle Gas Turbine. The Energy Commission of Malaysia reported the power generation efficiencies for Gas Turbine and Combined Cycle Gas Turbine to be 0.27 and 0.44, respectively. The quantity of global emissions of CO2, and local emissions of NOx and CO emissions were considered in this study. Quantities of these gaseous emissions per kWh of generated power by conventional power plants were studied. The equation given below can be used to calculate the gaseous emissions [5]:

| (10) |

|

| (11) |

| (12) |

| (13) |

| (14) |

3. Results and Discussion

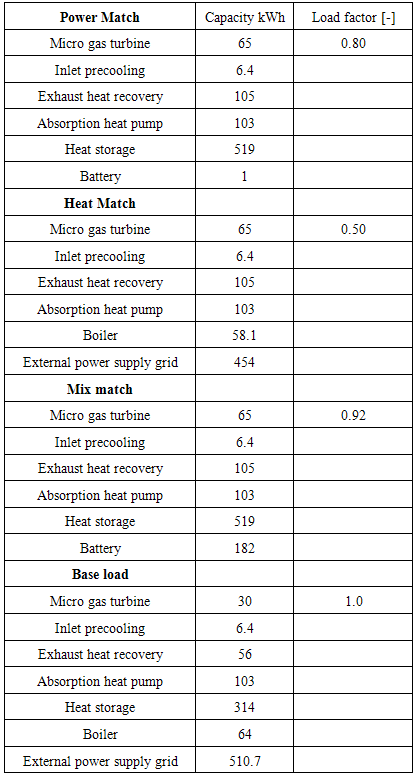

3.1. Capacity of All Equipment

- This system operated with trigeneration using MGT-65, EHE and AHP as the core components with different operating strategies. Capacity of each component used in the system is shown in Table 3.

|

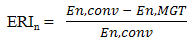

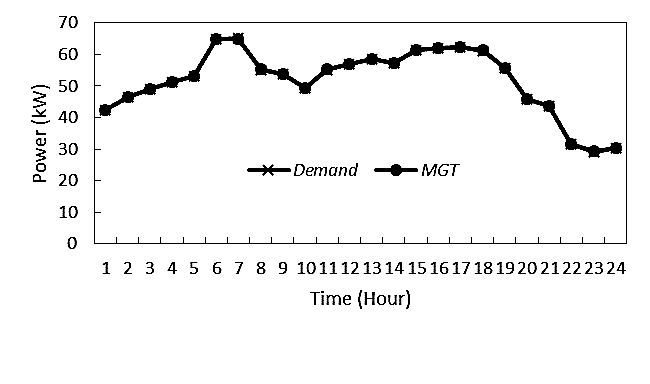

3.2. Power Supply Conditions

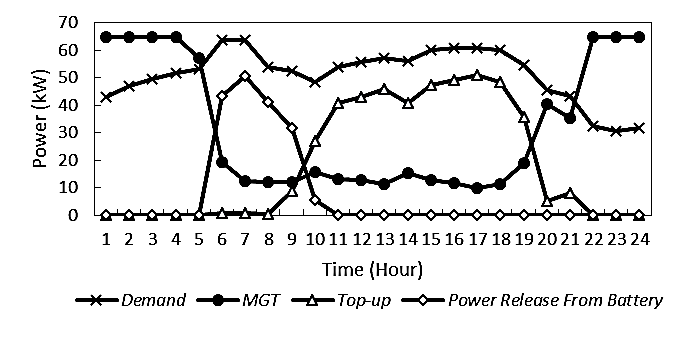

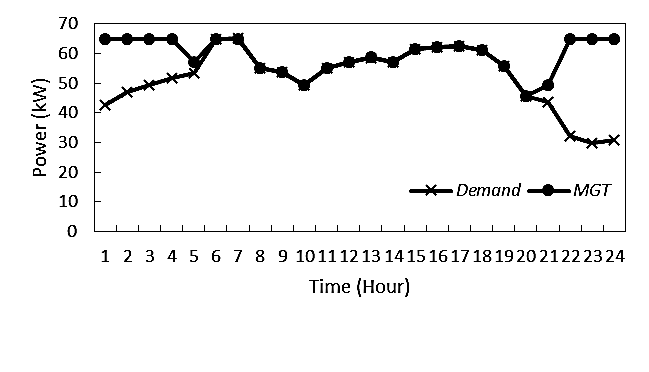

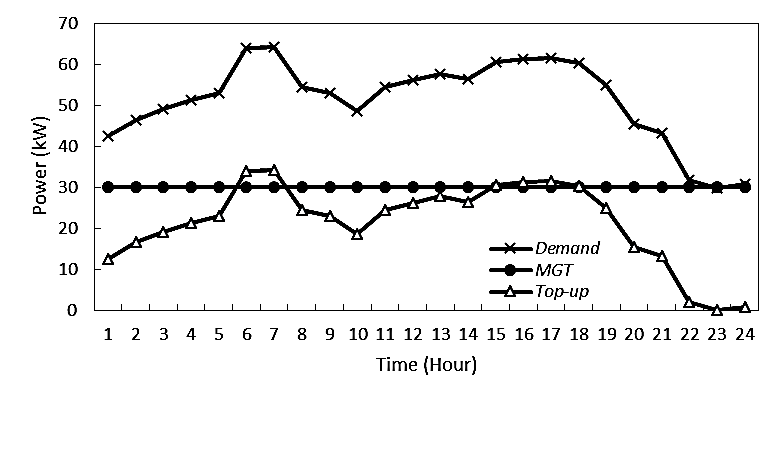

- Power demand and output conditions of MGT 65 for all the operation strategies are shown in Figure 3. Figure 3a-d represent power match, heat match, mix match and base load operating strategies respectively.

| Figure 3a. Power Match |

| Figure 3b. Heat Match |

| Figure 3c. Mix Match |

| Figure 3d. Base Load |

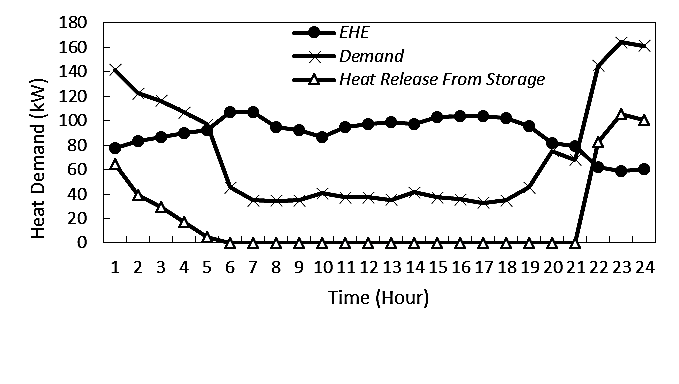

3.3. Total Heat Required

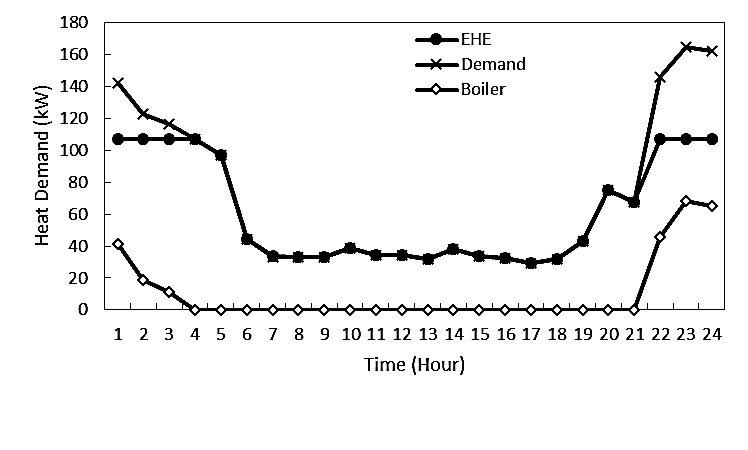

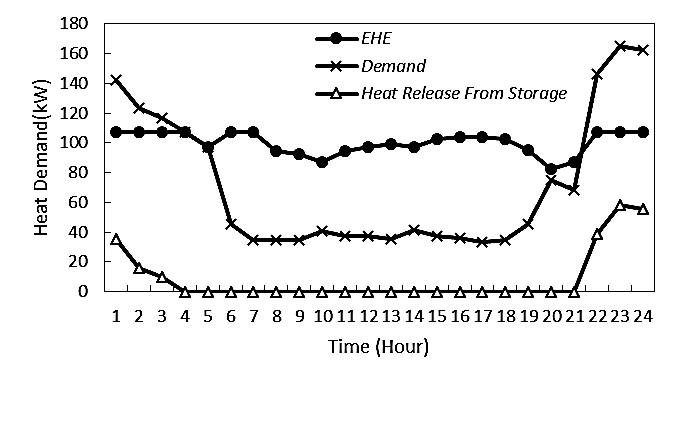

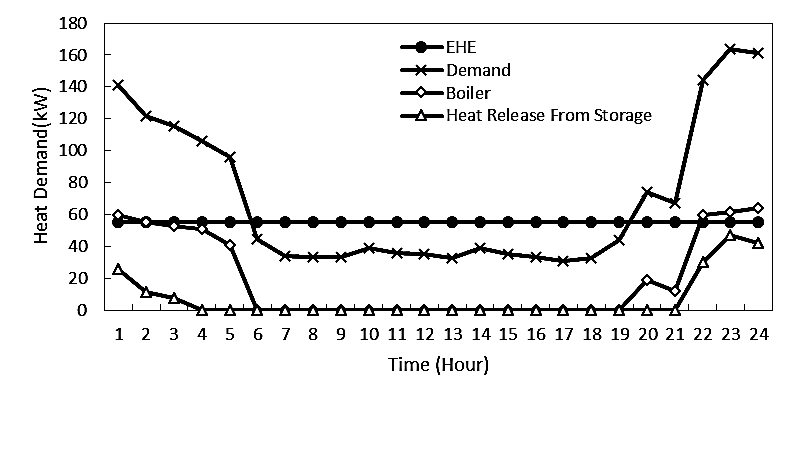

- Total heat supply by EHE and absorption heat pump are shown in Figure 4. Figure 4a-d represent power match, heat match, mix match, base load operation strategies, respectively.Figure 4 shows power and mix operating strategies supply enough heating load to meet the requirement, while heat and base load strategies cannot reach the requirement. Heat match supply enough heat from 04:00 to 20:30 because the load factor was adjusted according to heat demand. For all cases, EHE unable to supply enough heat load to absorption heat pump produce cooling load that meet the demand during night. However, extra heat load in the morning can be stored in heat storage and be used to cover the insufficient heating load during night time, as for heat match the insufficient at night time is cover using boiler since this strategy produce no extra heat during day time. Base load using both heat storage and boiler to cover and balance heat demand because the heat produce by 30 kWh MGT is lesser.

| Figure 4a. Power Match |

| Figure 4b. Heat Match |

| Figure 4c. Mix Match |

| Figure 4d. Base Load |

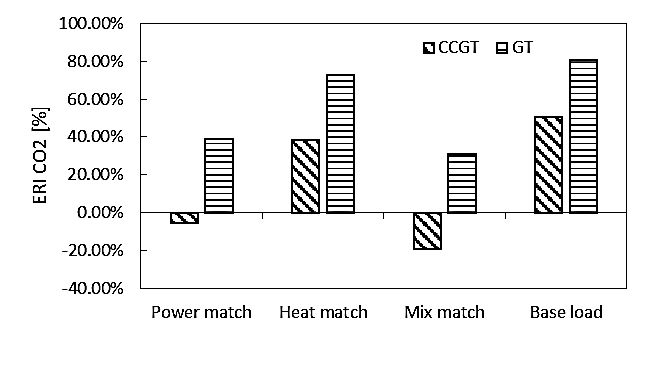

3.4. Emission Performance

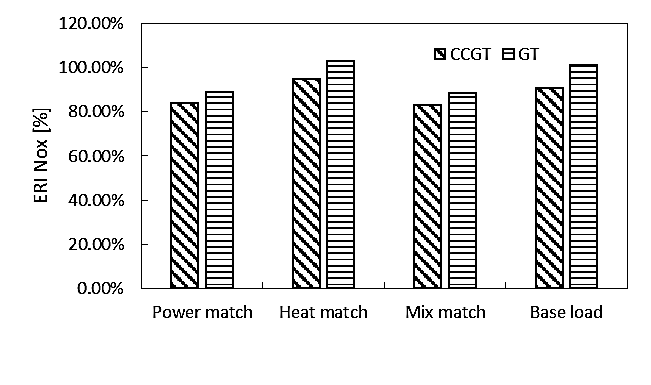

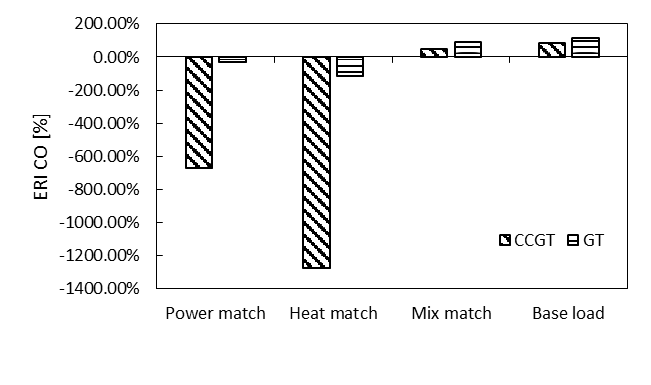

- Emission results for each operation strategy is shown in Figure 5a-c. Emission reduction index shown are for CO2, NOx and CO.

| Figure 5a. Comparison of Emission Reduction Index of CO2 |

| Figure 5b. Comparison of Emission Reduction Index of NOx |

| Figure 5c. Comparison of Emission Reduction Index of CO |

4. Conclusions

- Environmental performance of different operation strategies of MGT-TGS were studied. It was found that all operation strategies able to cover the power and heat demand of residential building through varies addition equipment and configuration of the system. MGT-TGS that compared to a combined cycle gas turbine, cannot reduce CO2 for power match and mix match, it also cannot reduce CO for power match and heat match. However, MGT-TGS was generally able to reduce all emissions when compared to a gas turbine. Only power and heat match unable to reduce CO, but that is not more than 100%. Among all operation strategies studied, base load emit the lowest emissions and it can reduce all emissions even compared to a combined cycle gas turbine. Thus, the best solution is base load that used smaller MGT. However, economic performance also must be further studied because smaller MGT has higher cost per kW, and it has slightly lower power generation efficiency.

ACKNOWLEDGEMENTS

- The authors would like to thank the Ministry of Education Malaysia for providing research most under FRGS/2/2013/TK06/UMP/02/01.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML