-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2015; 5(4A): 17-20

doi:10.5923/c.jce.201501.04

Influence of Polypropylene Fiber and Hybrid Fiber on Mechanical Properties of Lightweight Concrete

Javad Yahaghi1, Payam Shafigh2, Zakaria Che Muda1, Salmia Binti Beddu1

1Department of Civil Engineering, University Tenaga Nasional

2Department of Civil Engineering, University of Malaya

Correspondence to: Javad Yahaghi, Department of Civil Engineering, University Tenaga Nasional.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

In this study, the effect of polypropylene (PP) and hybrid (PP and Steel) fibers on the fresh and hardened properties of oil palm shell (OPS) lightweight concrete was investigated. The results indicate that adding the fibers decreased the slump value while they do not affect the density of concrete. It was observed that adding fibers slightly reduced the compressive strength of concrete. However, hybrid fiber significantly improved splitting tensile and flexural strengths. OPS concrete containing PP fiber has lower initial and final water absorptions compared to control mix and OPS concrete containing hybrid fiber. In general, from the test results, it is recommended that a hybrid of PP and steel fiber is used in OPS concrete.

Keywords: Lightweight aggregate concrete, Oil palm shell, Polypropylene fiber, Steel fiber, Hybrid fiber

Cite this paper: Javad Yahaghi, Payam Shafigh, Zakaria Che Muda, Salmia Binti Beddu, Influence of Polypropylene Fiber and Hybrid Fiber on Mechanical Properties of Lightweight Concrete, Journal of Civil Engineering Research, Vol. 5 No. 4A, 2015, pp. 17-20. doi: 10.5923/c.jce.201501.04.

Article Outline

1. Introduction

- Since the huge amount of natural resource and raw material used for producing the concrete in the world, even a small reduction of using this material will result the considerable benefit to the environment. Furthermore, since the majority of natural resources are limited, using the waste and recycled materials in concrete industry can reduce resource diminution and promote energy retention in the construction industry [1]. Oil palm shells (OPS) are an agricultural waste product obtained in the processing of palm oil. OPS is a hard endocarp which cover the palm kernel. It is also light in density compared to the normal aggregate.Although OPS concrete has sufficient strength to be accepted as structural lightweight concrete [2], but the mechanical properties of OPS concrete is less than ordinary concrete. Adding fibers to concrete mixture is one of the ways to improve the mechanical properties of OPS concrete. Fibers are categorized as metallic, polymeric or natural [3]. Among the various types of fibers, steel fiber is the most commonly used for most structural and non-structural purposes [4]. This is followed by polypropylene (PP), glass and other fibers. The main objective of this paper is to investigate the effect of PP fiber and hybrid fiber on the mechanical properties of fresh and hardened polypropylene reinforced oil palm shell concrete.

2. Experimental Details

2.1. Materials

- The materials used in this study were local mining sand with a specific gravity, water absorption, fineness modulus and maximum grain size of 2.7, 0.94%, 2.65, and 4.75 mm, respectively. The binder used was ASTM type I Portland cement. Properties of the steel and PP fibers, which provided by the manufacturer, are presented in Table 1.

|

2.2. Mix Proportions

- The mix design used in this study is shown in Table 2. The volume fractions of PP and steel fibers in OPS concrete were 0.2% and 1%, respectively.

|

2.3. Test Methods and Curing Regimes

- All materials include steel fiber except water, SP and fibers were put into a mixer and mixed and then the mixing water together with SP was added and mixed in two steps. 70% of the mixing water together with SP was added and mixed for 5 minutes. Then, the remaining water was added and mixed for another 10 minutes. At the end, fibers were spread in the mixer. The mixtures with fibers were mixed for a further 5 minutes. Before casting the samples, the slump test of the mixture was performed. The concrete specimens were cast in steel moulds and compacted on a vibration table. For each mixture, 24 cubes (100 × 100 × 100 mm3) were used for the measuring of compressive strength at 1, 3 and 28 days and water absorption; for determination of the indirect tensile strength and flexural strength 6 cylinders of 100 mm diameter and 200 mm height and 3 prisms of dimension 100 mm × 100 mm × 500 mm, were used respectively. The specimens were demolded one day after casting. For determining the effect of the curing environment on the 28-day compressive strength of OPS concrete, the specimens were cured under three types of curing conditions as given below:NC: Specimens were immersed in water at 23 ± 3°C until the age of testing.7DC: Curing in water for 6 days after demolding and then air cured in a laboratory environment with a RH% of 70 ± 10 and a temperature of 29 ± 3°C.AC: Specimens were kept in a lab environment after demolding.

3. Result and Discussion

3.1. Workability

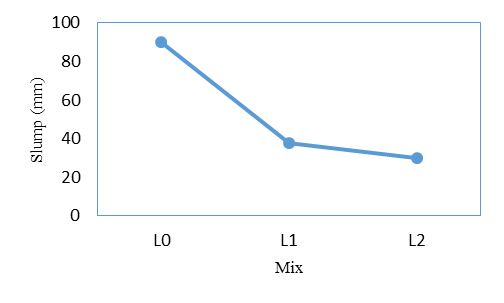

- The result of previous researchs [5, 6] show that addition of fibers reduces the slump value. The slump value for mix L0 was about 90 mm. However, after adding 0.2% PP fiber for mix L1, and 0.2% PP fiber together with 1% steel fiber for L2 the slump value reduced to 38 and 30 mm, respectively. Figure 1, shows the reduction of the slump value in different mixes.

| Figure 1. Slump value in different mixes |

3.2. Density

- The oven dried density of mix L0, L1 and L2 were 2002, 1996 and 2014 kg/m3, which shows that they can be considered as lightweight concrete. Adding PP fiber slightly reduced the density while adding steel fiber slightly increased the density of OPS concrete. However, in general, it can be said that fibers do not have effect on the dry density of OPS concrete.

3.3. Compressive Strength

3.3.1. Continuously Moist Curing

- Figure 2 presents the compressive strength development of all mixes. The compressive strength of mixes decreased at all ages with adding the PP and steel fiber. Adding 0.2% PP fiber and 1% steel fiber decreased the compressive strength by about 10% and 5% at 1 day age, 13% and 11% at 3 days age, 5% and 5% at 7 days and 6% and 6% at 28 days age, respectively. All the mixes achieved 87-89% of 28 days compressive strength after 7 days. It is clear in the figure that OPS concrete with PP and hybrid fibers showed similar performance on the development of compressive strength.

| Figure 2. Development of compressive strength |

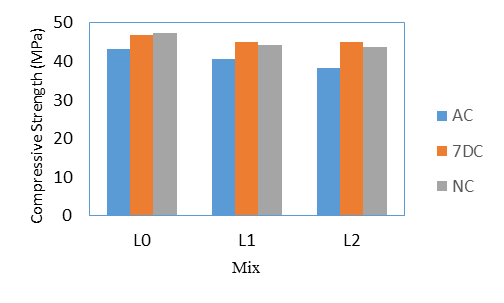

3.3.2. Effect of Curing Condition

- Curing is the maintaining of a satisfactory moisture content and temperature in concrete during its early stages so that the desired properties may develop [7]. Figure 3 shows the 28-day compressive strength of specimens in three different curing conditions. It can be seen that for mixes with PP and steel fiber content the order of strengths of concrete were for AC and 7DC but were less than NC. The compressive strength loss for 28 days of samples under AC curing compared to NC curing for mixes L0, L1 and L3 was about 9%, 8% and 13%.

| Figure 3. Compressive strength in different curing regime |

3.4. Splitting Tensile Strength

3.4.1. Continuously Moist Curing

- OPS concrete containing PP fiber and hybrid fibers increased the splitting tensile strength of OPS concrete from 3.30 to 3.71 and 4.92 MPa, respectively. The splitting tensile strength for mix L0, L1 and L2 was about 7%, 8.4% and 11% of the compressive strength. Generally, the splitting tensile strength of concrete is 8–14% of the compressive strength [8]. As can be seen in the results, this ratio for plain OPS concrete is out of normal range. It shows that OPS concrete has lower tensile strength than normal concrete at the same compressive strength. However, it was shown that PP and hybrid fibers transferred this ration into normal range. The performance of hybrid fiber is significantly more than PP fiber.

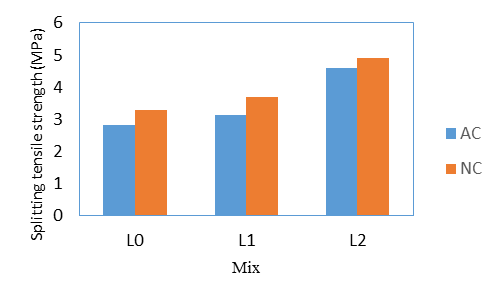

3.4.2. Effect of Curing Condition

- Figure 4 illustrates the 28-day splitting tensile strength of specimens in two curing conditions of continuous curing (NC) and air drying in lab environment (AC). It can be seen that the order of strengths of concrete was NC > AC. The loss of splitting tensile strength in AC compared to NC for mixes of L0, L1, and L2 is about 14%, 15% and 7% respectively.

| Figure 4. Splitting tensile strength in different curing conditions |

3.5. Flexural Strength

- Figure 5 shows the 28-day flexural strength of mixes. By adding 0.2% PP fiber to OPS concrete the flexural strength slightly decreased while by adding hybrid fiber it was significantly improved from 4.97 to 5.62 MPa.

| Figure 5. Flexural strength of different mixes |

3.6. Water Absorption

- Results of initial (30 minutes) and final (72 h) water absorptions at the age of 28 days are shown in Fig. 6. As can be seen in this Figure, adding PP and hybrid fiber improved the water absorption of OPS concrete. It was reported that good concretes have initial and final water absorption below 3% and 10% by mass, respectively [9, 10]. Therefore, all concretes can be considered as good concrete. It was reported that high strength OPS concretes have the lowest water absorption of 3.12% and the highest of 6.20% [11]. For OPS concretes with conventional compressive strength, water absorption of more than 10% has been reported [12].

| Figure 6. Water absorption of different mixes |

4. Conclusions

- The aim of this study is to investigate the effect of adding PP fiber and hybrid fiber on some engineering properties of OPS lightweight concrete. Test results showed that although additional PP and hybrid fibers may slightly reduce the compressive strength of OPS concrete, however, hybrid fiber can improve the splitting tensile and flexural strength, significantly. From the result of this study it can be conclude that in general hybrid fiber is a better choice for improving engineering properties of OPS lightweight concrete compared to PP fiber.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML