-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2015; 5(4A): 11-16

doi:10.5923/c.jce.201501.03

The Effects of Nano Silica Particles on the Physical Properties and Storage Stability of Polymer-Modified Bitumen

Dhawo Ibrahim Alhamali1, Nur Izzi Md. Yusoff1, Jiantao Wu2, Quan Liu2, Shaban Ismael Albrka1

1Dept. of Civil and Structural Engineering, Universiti Kebangsaan Malaysia, Malaysia

2College of Civil and Transportation Engineering, Hohai Universiti, China

Correspondence to: Dhawo Ibrahim Alhamali, Dept. of Civil and Structural Engineering, Universiti Kebangsaan Malaysia, Malaysia.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

This study was conducted to investigate the physical and morphological properties and storage stability of polymer modified bitumen’s (PMB) mixed with nanosilica (NS). Polymer modified bitumen, PG-76 and NS were mixed with concentration of bitumen’s weight at 0, 2, 4 and 6%. Throughout the process, the binders were regulated at 163°C and blended using a shear rate of 3000 rpm for 1 hour. Microscopic examinations of the bituminous binders were then carried out using a scanning electron microscopy (SEM); the SEM images show that the NS particles disperse well in the bituminous binder matrix. The NS’ effect on the physical properties and an additional NS in the PMB identified to some extent reduced viscosity and ductility at 2 and 4% of NS, at 6% were stable to increase. Additionally, the NS-PMBs binders softening point increased and penetration decreased. Furthermore, NS-PMBs binders’ storage stability depended mainly on NS content and the storage stability succeeded with NS at concentration 6% by weight of bituminous binder. As result, the nanosilica particles are a good modifier in inhibiting oxidizing reactions in the bitumen binder.

Keywords: Nano-polymer modified bitumen, Nano Silica Particles, Physical properties, Storage stability

Cite this paper: Dhawo Ibrahim Alhamali, Nur Izzi Md. Yusoff, Jiantao Wu, Quan Liu, Shaban Ismael Albrka, The Effects of Nano Silica Particles on the Physical Properties and Storage Stability of Polymer-Modified Bitumen, Journal of Civil Engineering Research, Vol. 5 No. 4A, 2015, pp. 11-16. doi: 10.5923/c.jce.201501.03.

Article Outline

1. Introduction

- Bitumen is made up of complex composition of chemical that displays viscous and elastic properties equally which rely comprehensively on time and temperature [1]. Researchers and engineers have tried to utilize different types of modifiers to amend and better how bitumen materials perform, together with styrene butadiene styrene (SBS) [2]. Many researchers have revealed how polymer-modified bitumens better the possible deficiencies with the asphalt mixture pavements overall performance [3]. The styrenic block copolymers (e.g. styrene–butadiene– styrene, SBS) seem to have the highest potential to benefit bitumen modification [4]. And it was known that the addition of SBS can improve conventional bitumen compositions physical and mechanical properties [5]. Nevertheless, the stability of the SBS-modified bitumen storage is generally poor when temperatures are raised due to the SBS and bitumen weak compatibility. Several methods have been established to prepare stable practical storage SBS-modified bitumen. The succeeding growth of polymer nanocomposites has caused a great interest in academic and industrial communities. Essentially, polymer nanocomposites are made up of a blend of one or more polymers with various nanomaterials such as nanoclays, carbon nanotubes, etc. [6].The use of nanomaterial in asphalt pavement started rather late. Nano-technology is utilized as a new material, device and system at the molecular stage. Several nano-materials which have been or have the possibility to be utilized to modify bitumen, such as nano-clay, nano-silica, nano-hydrated lime, nano-sized plastic powders, or polymerised powders, nano-fibres, nano-tubes to name a few [7].Yao et al. [4] gauge the rheological properties and bituminous binders which have been modified with nano are blended with nanosilica chemical bonding. In this research, adding nanosilica to the control bitumen at contents 4% and 6% decided on the bituminous binders’ weight. The study showed that the antiaging property, rutting and fatigue cracking nanosilica modified binders’ performance are improved, and nanosilica added in the control asphalt mixture considerably betters in terms of dynamic modulus, flow number, and resistant to rutting (permanent deformation).Nano-SiO2 powder and SBS probable benefits were reported for the asphalt mixtures used on pavements. A primary study was carried out to determine bituminous binder and modifiers physical properties. The results of this investigation showed that the modification of asphalt mixture by 5% SBS plus 2% nano-SiO2 powder could give the better results in the tests conducted in the current study, so this modification can increase bituminous binder and mixtures physical and mechanical properties [8].In this paper, laboratory tests of the physical properties with a number of polymer-modified bitumen (PMB) and nanosilica (NS) were examined and evaluated. Henceforth, nanosilica-polymer modified bitumens (NS-PMBs) have been laboratory produced by mixing with three NS contents. It was added into PMB at concentrations of 2, 4 and 6% by weight of PMB. The SEM images produced to show the NS particles, where, the NS-PMBs tests the conventional properties, the rotational viscosity (RV) and storage stability test were carried out for NS-PMBs binders’ characteristics evaluation.

2. Experimental Design

2.1. Binder

- PG-76 (Dorotech Hr-Super) polymer modified bitumen, is the control sample. The tropical regions climatic conditions are consistently fair throughout the world and the availability of performance graded (PG) binder in this region are based on the higher temperatures. This study does not take into consideration the environments’ low temperature as the tropical countries’ temperature seldom drops below 30°C for the duration of daylight hours and regularly lies within the range of 35- 45°C.

2.2. Nano-Silica

- Silica is a rich international compound that is largely used in industries producing silica gels, colloidal silica, and fumed silica, etc. [9]. Nanosilica composites have fascinated several scientific interests too. The benefit of these nano-materials existing in low cost production and the high performance features [10]. According to Yao et al. [4], nanosilica is a material with a vast surface area, robust adsorption, good dispersion, high chemical purity and excellent stability.

2.3. Sample Preparation

- This nanosilica used to regulate binder was altered in the laboratory. The addition of nanosilica material into the control binder at concentrations of (PMB), 2% (NS-PMB2), 4% (NS-PMB4) and 6% (NS-PMB6) by weight of the binder and mixed in the high shear rate machine. It was detected that when nanosilica disperses and melts in the control bituminous binder, the binder’s surface had a few floating bubbles. While mixed, the binder samples were kept at 163°C and combined using a shear rate of 3000 revolutions per minute (rpm) for duration of one hour.

2.4. Scanning Electron Microscope (SEM)

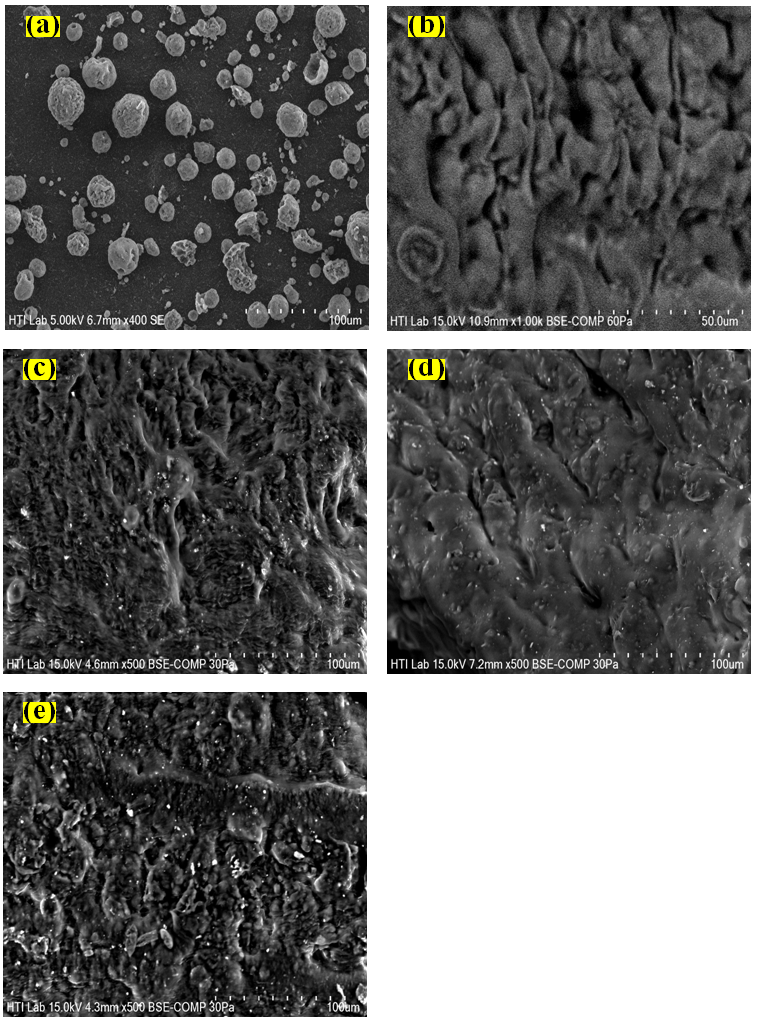

- SEM, using a focused electron beam to scan the surface of a sample, generates a variety of signals [11]. The three most common modes of operation in SEM analysis are backscattered electron imaging (BSE), secondary electron imaging (SEI), and EDS [12]. In this study, BSE was used to observe the surface morphology and analyses microstructure characteristics of the PMB and NS-PMBs samples.

2.5. Conventional Physical Properties Tests

- Conventional physical tests include penetration test at 25°C [13], softening point [14], ductility at 25°C [15], and viscosity test using Brookfield viscometer (model DV-II) [16] were carried out on PMB and NS-PMBs samples.

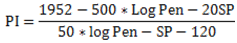

2.6. Temperature Susceptibility

- Changing the temperature susceptibility with NS was investigated with a calculating penetration index (PI). The higher the PI value of bitumen, the lower is its temperature susceptibility. For PI, the temperature susceptibility for the binders is measured by calculating the PI using the penetration at 25°C and softening point results. Penetration index is calculated using Equation 1 [17]:

| (1) |

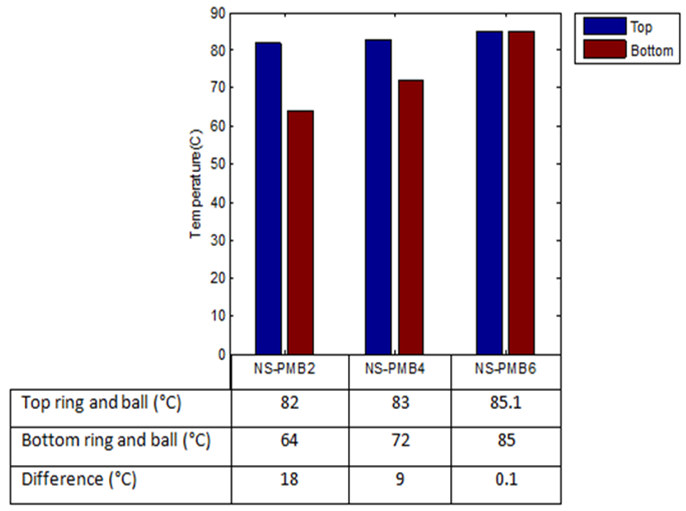

2.7. Storage Stability Test

- Hot storage stability test is utilized for evaluation of modified bitumen high temperature storage stability [18]. The binder is empty into an aluminum foil tube 30 cm in height and 3 cm in diameter. The binder is kept straight up in an oven at 163 ± 5°C for 48 hours without interruption. Then the binder is permitted to cool, and it is cut horizontally into three pieces. The top and the bottom parts are placed separately into beakers and tested for their softening point. If the softening point difference is less than 2.5°C, then the binder can be considered a storage stable [19].

3. Results and Discussion

3.1. Scanning Electron Microscope (SEM)

- The SEM images of nanosilica modified bitumen are helpful in understanding the microstructure change of modified bitumen, as well as the physical dispersion of nanosilica particles. As shown in Figure 1, the SEM images of NS-PMBs present the well-dispersed nanosilica particles in the bitumen matrix. Due to the agglomeration of nanosilica, the surface of nanosilica group reacts with the PMB. The new structure of nanosilica modified bitumen binder is formed.

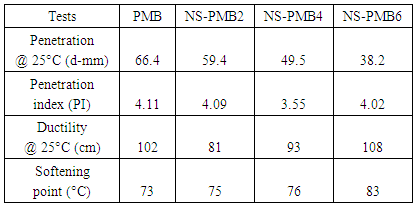

3.2. Conventional Physical Properties

- Nanosilica’s effects when it is added on PMB physical properties as indicated in Table 1. As the penetration values decrease and the softening points increase with the increasing nanosilica contents, this validates the increased hardness and stiffness of the NS-PMBs. The higher ductility value was NS-PMB6, with unstable behavior at value of NS-PMB2 and NS-PMB4 were lower than PMB. In contrast, the stability of the behavior when ductility is increased at NS-PMB6 which show the higher ductility value for NS-PMBs as shown in Table 1. This behavior can be attributed to be indicative of the different modified chemical structures of the PMB.

|

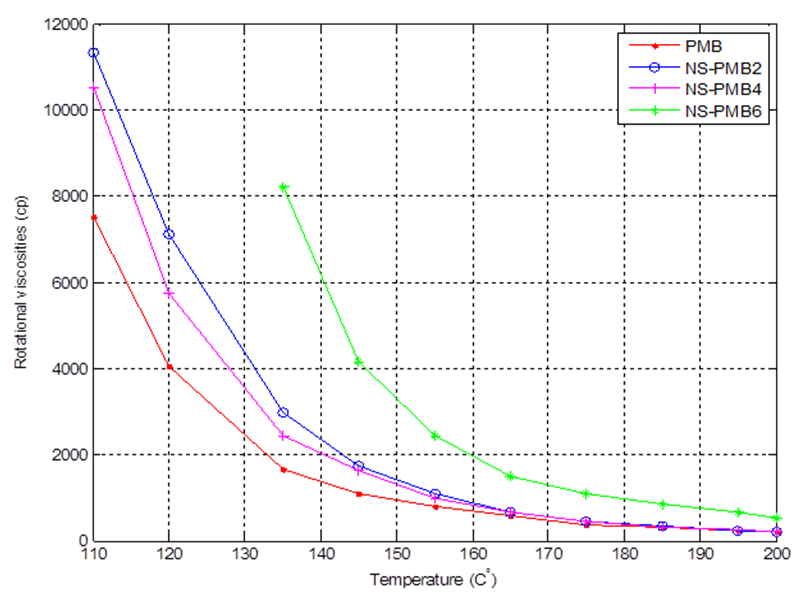

| Figure 2. Rotational viscosities for the PMB and NS-PMBs binders |

3.3. Temperature Susceptibility

- Penetration index (PI) used to approximate the expected temperature susceptibility for bitumen. The PI value for base penetration bitumens normally ranges from approximately -3 (for high temperature susceptible bitumens) to approximately +7 for highly blown (low temperature susceptible) bitumens [17]. As indicated in Table 1, the PI values were obtained nearly comparable with the addition of NS. Therefore, NS preserve the PMB temperature susceptibility.

3.4. Storage Stability Test

- Hot storage test for the NS-PMBs was carried out to check its storage stability at high temperatures. Figure 3 shows that the softening point differed between bottom and top in NS-PMB6 are less than 2.5°C, showing that these binders can remain stable if stored at high temperatures. With a lower percentage of nanosilica (NS-PMB2 and NS-PMB4) a continuous binder phase with dispersed nanosilica attained.

| Figure 3. Softening point differences between bottom and top of the NS-PMBs binders |

4. Conclusions

- The study concludes that nanosilica was added into the PMB to improve the binder properties. The resulting SEM images show good dispersion of the nanosilica particles in the bituminous binder matrix. Based on the physical properties tests and storage stability test, the NS-PMBs binder mixed and prepared assumption that nanosilica may have chemical reactions and physical dispersion with the PMB, it was noted at 2 and 4% of nanosilica on NS-PMB2 and NS-PMB4 binders in elastic properties (viscosity and ductility result). Softening point, ductility and viscosity were increased and penetration was decreased. Therefore, nanosilica could improve PMBs performance properties. Increasing PMB storage stability; this considered as the most important advantage in high temperature storage stability. It could obviously be bettered by selecting proper amount of nanosilica. Moreover, storage stability test results indicated that 6% of nanosilica content for binder was stable to be used at high temperatures. To conclude, the nanoslica particles material is a reputable modifier in inhibiting oxidizing reactions in the bitumen binder.

ACKNOWLEDGMENTS

- The authors express their gratitude to the Universiti Kebangsaan Malaysia (DLP-2013-028) and the National Natural Science Foundation of China (No.51108157) for the financial support of this work.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML