-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2014; 4(3A): 203-207

doi:10.5923/c.jce.201402.34

The Effect of Mix Design on Mechanical and Thermal Properties Oil Palm Shell (OPS) Lightweight Concrete

Fahrizal Zulkarnain1, Mohd. Zailan Sulieman2, Eravan Serri2

1Department of Civil Engineering, Faculty of Engineering, Universitas Muhammadiyah Sumatera Utara (UMSU), Medan, Indonesia

2School of Housing, Building and Planning, Universiti Sains Malaysia, Malaysia

Correspondence to: Fahrizal Zulkarnain, Department of Civil Engineering, Faculty of Engineering, Universitas Muhammadiyah Sumatera Utara (UMSU), Medan, Indonesia.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

This paper discusses theuse of oil palm shell (OPS) as lightweight aggregate in lightweight concrete especially in the structure application has been proven by previous researches. As industrial waste material, OPS can be the alternative material to be used in the construction industry. With its advantage as heat resistant material, this study will discuss the potential of OPS as lightweight aggregate with regard to the optimum content of OPS. A total of 15 mix design with 3 different cement/sand ratio (1.7, 1.8, 1.9) and 5 cement content in mix design (300, 350, 400, 450, 500 kg/m³) has been tested. The result showed mechanical and thermal properties for all mix.

Keywords: Oil palm shell (OPS) lightweight aggregate, Absolute volume, Thermal conductivity, Specific heat, Thermal diffusivity

Cite this paper: Fahrizal Zulkarnain, Mohd. Zailan Sulieman, Eravan Serri, The Effect of Mix Design on Mechanical and Thermal Properties Oil Palm Shell (OPS) Lightweight Concrete, Journal of Civil Engineering Research, Vol. 4 No. 3A, 2014, pp. 203-207. doi: 10.5923/c.jce.201402.34.

Article Outline

1. Introduction

- The use of concrete as building material is always in high demand. Good durability and workability of concrete makes it convenient for construction industry players. However, the high density of the concrete will result in increased dead load on building structures because a lot of use of steel reinforced. The use of lightweight aggregate as lightweight concrete is an option to reduce the dead load on a building, especially for high-rise buildings. Normally pumice and perlite are used as lightweight aggregate to produce lightweight concrete and both materials can be found at volcanic area R. (Demirboga & R. Gul, 2003 [1]). However, it has not brought much advantage to countries which do not have volcanic environment. The alternative is to use industrial waste material as aggregates for construction.One of the solid waste products that have increasingly gained researchers’ interest is oil palm shell from the processing of oil palm. Oil palm industry is a fast-growing industry and economically it is able to become the backbone of the economy. This industry also produces not only waste from palm oil processing but, all of its parts in palm tree such as fruits, trunks and leaves that can be effectively utilized for producing valuable products. For instance approximately 19 million tonnes of crop residues (empty fruit bunch, fiber and shell) were produced per year (Mustaffa et al, 2011 [2]). It was estimated that over 4.56 million tonnes of oil palm shell are produced annually (Teo et al., 2006 [3] and Sahu et al 2011 [4]) reported that the amount of oil palm shell increases every year because there are more than 270 palm oil mills operating in this country to generate the waste. The growing need for sustainable development has motivated researchers to focus their research on the use of waste or recycled materials in potential construction material.Oil palm shell is traditionally used as solid fuels for steam boiler to run turbines for electricity (Shafigh et al., 2012 [5]), used to cover the surface of the roads in the plantation area (N. Abdullah et al., 2011 [6]) densified into briquettes (Z. Husain et al., 2002 [7]), used as granular filter material for water treatment (Jusoh et al., 2005 [8]), converted to bio-oil by using pyrolysis process for biomass energy (J. N. Sahu et al., 2011 [4]), and used in the production of charcoal and activated carbon (Astimar and Ropandi, 2011 [9]). There are a number of studies related to OPS lightweight aggregate concrete especially for lightweight structure. However, there was inadequate information regarding the effect of OPS lightweight aggregate on the thermal properties, porosity, unit weight etc. of these concrete in the technical literature. Previous study only mentions that the OPS lightweight concrete has low thermal conductivity compared to normal concrete. Therefore, an experimental investigation related to effect of OPS on thermal conductivity has been carried out and the results are reported in this article.

2. Experimental Programme

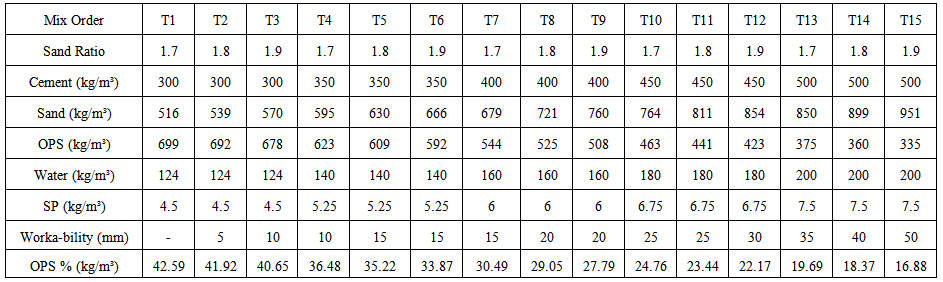

- In this study, the materials used are ordinary Portland cement (OPC) with specific gravity of 3.10 type I, river sand with specific gravity, fineness modulus, water absorption and maximum grain size of 2.67, 2.28, 0.98% and 2.36 mm, respectively. OPS are used as course aggregate and the treatment method is as mentioned by previous researcher (Shafigh et al., 2012 [5], U. Johnson Alengaram et al., 2010 [10], M. A. Mannan et al., 2006 [11]). The shells have been left outside the laboratory for 6 months to expose them with natural environment because there might be fibre and oil coating on the surface of fresh OPS. After the exposure, most of the fibres are removed from surface thus reducing the oil coating and other impurities present on the shells. Finally, OPS aggregate were rinsed with potable water to remove the detergent and then dried before being stored in containers. The OPS used has specific gravity, water absorption (24 hour), maximum grain, aggregate impact value and aggregate crushed value of 1.19, 22.1%, 14mm, 3.3% and 2.62% respectively. The OPS need be absorbed in water for 1 hour and left to saturated dry condition before it can be used. In the experiment, there are 15 mixtures with different 5 cement content (300, 350, 400, 450 and 500 kg/m³) and 3 different sand ratio mix (1.7, 1.8 and 1.9). For lightweight concrete, the amount of cement content specified is in the range of 285–510 kg/m³ (Mindess and Young, 1981 [12]). The mixture proportion is shown in Table 1.0. Effective water/cement ratio is 0.4 and it is constant in all mixture. The mix proportioning was based on the absolute volume. The unit weight of the concrete increased as a result of the increase of cement content used. The OPS was kept in water for 1 hour so that the OPS can absorb water and the effective water/cement ratio is not affected.

| Table 1. Mix Design |

3. Test Results and Discussions

- The results obtained on mix design are shown in Table 1.0. They are also displayed to some extent in graphical form (figures) and further discussed.

3.1. Workability

- As seen in Table 1.0, the mix design result of workability showed the workability of fresh concrete. Bond between aggregate and mortar phase are significantly affected by physical properties and the volume of OPS. This study used the lowest sand ratio (1.7) because it is the minimum amount based on absolute volume design for cement content as low as 300 kg/m³. Mix T1, T2 and T3 with 1.7, 1.8 and 1.9 sand ratios with cement content of 300 kg/m³ show collapse and low workability. A lot of honeycomb is present on cube surface produced from this mix proportion. The bond between aggregate and mortar is very weak because the volume of OPS is high. Therefore mix proportion with cement content of 300 kg/m³ is not acceptable. The workability increased with increased cement content and high sand ratio.

3.2. Unit Weight Density

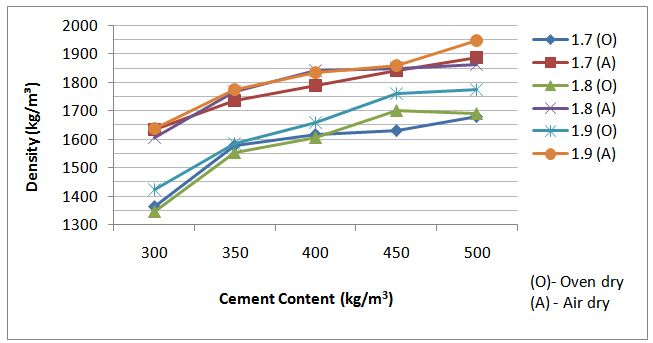

- The 28-days unit weight density of OPS concrete shows that all mix have density of below 2000 kg/m³. The changes in unit weight are shown in Figure 1.0. In average, density of oven dry OPS concrete produced in this study is approximately 8.7%-16% lighter than air dry OPS concrete. The highest gap of density (air dry to oven dry) is seen in T1 mix. The result showed that higher OPS volume will reduce density. Mix T1, T2 and T3 which contained 40% of OPS display a reduction gap of 16% of weight (air dry to oven dry density). Compared to mix T13, T14 and T15, the reduction gap of the density are only 11%, 9.2%, 8.7% respectably with 16% to 20% volume of OPS. The substantial reduction of the unit weight due to air drying is an indication of the presence of large and higher amounts of open pores on the surface.

| Figure 1. Unit Weight Density |

3.3. Compressive Strength

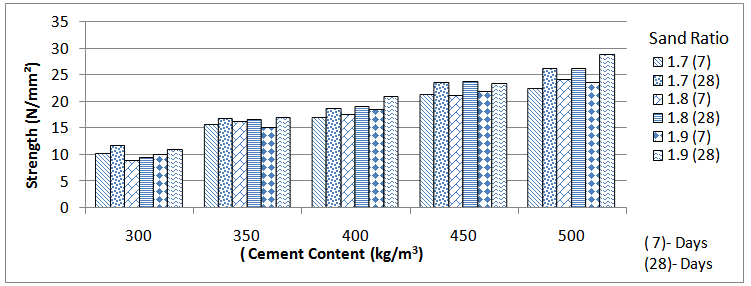

- Figure 2.0 shows the effect of cement content and sand ratio on the compressive strength of OPS lightweight concrete. As seen in the figure, compressive strength increased substantially with the increase of concrete cement content. The lowest strength is produced by T1 mix which is 11.56 N/mm and is still in the range of load bearing strength meanwhile the highest strength is produced by T15 which is 28 N/mm² which is in the range of lightweight aggregate structural concrete strength. When the relationship is shown in figure, it may be concluded that higher OPS aggregate and low cement content will produce low strength. In other words, compressive strength values changed significantly depending on cement content amount.

| Figure 2. Compressive Strength Test Result |

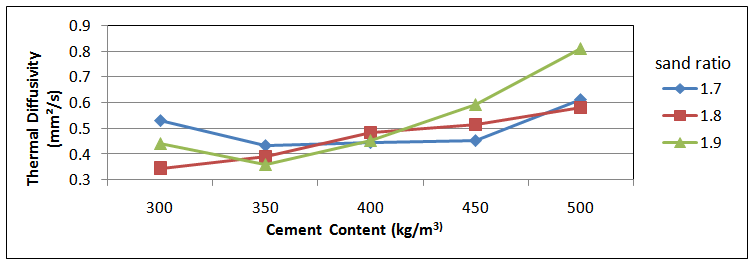

| Figure 3. Thermal diffusivity test result |

4. Conclusions

- Based on results from objective analysis and research has been conducted on oil palm shell (OPS) lightweight concrete. The main conclusions result of research carried out is as follows: 1. The workability of mix design is categorized as being low especially for mix design using high proportion OPS that have poor workability. 2. Cement/sand ratio 1.8 are the optimum ratio for load bearing strength with low thermal conductivity value. 3. The range of compressive strength for load bearing starts at 350 kg/m³ onwards.4. Pulse velocity value is of moderate quality except for mix design using 500 kg/m³ cement content that produced good quality concrete.5. Thermal conductivity that can be categorized as insulation structure is mix design using cement content of 400 kg/m³ and below. According to RILEM the value of thermal conductivity is much less than 0.75 W/mK for load bearing insulation purpose. 6. Specific heat for all mix design showed inconsistencies due to the size, shape and distribution OPS aggregate on concrete. The increase of energy required is due to moisture content of the aggregate. 7. Thermal diffusivity increase when higher cement content is used in mix design.

ACKNOWLEDGEMENTS

- We extend our gratitude to the Research Creativity and Management Office, Universiti Sains Malaysia, for funding this research and to the School of Housing, Building and Planning, Universiti Sains Malaysia for facilitating the field equipments. Specials thanks are also who rendered their timely help to the successful completion of this project research.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML