-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2014; 4(3A): 187-190

doi:10.5923/c.jce.201402.32

The Utilization of can Waste as Fibre and the Addition of Fly Ash to Mechanical Characteristic of Concrete

Nursyamsi, Luhut Parulian Bagariang

Department of Civil Engineering, Universitas Sumatera Utara, Medan, Indonesia

Correspondence to: Nursyamsi, Department of Civil Engineering, Universitas Sumatera Utara, Medan, Indonesia.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

One such effort is the utilization of can waste processed into fibers and coal combustion wastes such as fly ash. Can waste and fly ash can be used as an additive in concrete mixture. In this study, can fiber and fly ash are added in the concrete mixture. Variation I is a normal concrete, variation II with the addition of can fiber by 20%, and variation III with the addition of can fiber by 20% and fly ash by 15% of volume of cement. Tests are conducted in form of slump test, compressive strength, split tensile strength and absorption of concrete. From the test result, it is obtained the increase in the compressive strength, split tensile strength, and absorption. But the biggest improvement is the wet treatment compared to initial wet treatment for 7 days and initial dry treatment for 7 days. The best increase in compressive strength is variation III with 8,333% of normal concrete. Split tensile strength were increased by 18,414% of normal concrete. Concrete absorption decreased by 0,183% and 0,392% of normal concrete.

Keywords: Fibre cans, Fly ash, Compressive strength, Split tensile strength, Absorption

Cite this paper: Nursyamsi, Luhut Parulian Bagariang, The Utilization of can Waste as Fibre and the Addition of Fly Ash to Mechanical Characteristic of Concrete, Journal of Civil Engineering Research, Vol. 4 No. 3A, 2014, pp. 187-190. doi: 10.5923/c.jce.201402.32.

1. Introduction

- In general, concrete is used as a construction material that is often used in building. Due to the amount of the use in concrete, while the constituent materials are limited and expensive, it appears breakthroughs being made to replace the constituent materials without reducing the quality of the concrete itself. One form of these is done by replacing the material with other material such as using waste around us. Thus, these wastes can be used optimally, so as to have a higher value. Tin cans used are wastes from the former site of food that can be found in the area around where we live such as beverage cans, food, and others. Waste cans need to be utilized more optimally in order to have a higher sale value. One of the waste utilization is by modifying it into a fiber as an ingredient of concrete. Fiber cans are those derived from waste cans then processed into small fibers of a certain size (Marsudi, 2009 [3]). Previous research has been conducted by Marsudi, 2009 [3], with a length of 10 mm and a width of 1 mm with a compressive strength testing of K-150 and K-450, and research by Nursetiaji Pamungkas 2006, with a length of ± 20 mm and a width of 2 mm with compressive strength testing of K-225. While this research itself goes on the utilization of waste cans as modified fiber 1 x 20 mm mixed as much as 20% of cement volume and fly ash 15% of cement volume on high strength concrete f'c 25 MPa. Coal fly ash, the fine grained material that is apozzolanic, is a natural or artificial material obtained from coal combustion and heat generation plants. Fly ash itself does not have the ability to bind as well as cement. But with the presence of water and a fine particle size, silica oxide contained in fly ash will chemically react with the calcium hydroxide formed in the cement hydration process and produce a substance that has the ability to bind.The purpose of this study was to determine the workability of fresh concrete using fiber cans and fly ash as an ingredient added to concrete, as well as to determine the mechanical behavior of concrete using fiber cans and fly ash as an ingredient added to concrete and compared to normal concrete. Mechanical behavior that was studied included: compressive strength, split tensile strength and absorption.The problems in this study are as follows:1. Quality of the concrete is f’c 25 MPa 2. A mixed fiber material and fly ash cans 3. The addition of fiber cans and fly ash were 20% and 15% of the volume of cement. 4. Specimens used for compression test, pull apart, and the absorption are a cylinder with a diameter of 15 cm and a height of 30 cm.5. Curing done by 3 methods: wet, initial wet 7 days, and initial dry 7 days. 6. Testing conducted on the compressive strength of the test specimen 28 days. 7. Tests performed on split tensile test specimens 28 days 8. Absorption tests carried out on test specimens 28 days.

2. Methodology

- Material being used is fine aggregates and coarse aggregates (split stone) from quarry Sei Wampu, Binjai and cement used is Portland type 1 – Padang Cement, and water taken from PDAM Tirtanadi, at Construction Laboratory Civil Engineering USU, Medan. Tin fibre used is the one that has been processed into fibre 1x20 mm and fly ash is obtained from PLTU Labuhan Angin. The tools are those to examine fine and coarse aggregates and concrete compressive and tensile testing machine. The mould sizes in cylinder, diameter 15 cm, height 30 cm. Preparation of test specimens are 63 cylinders. It is conducted at the Laboratory of Civil Engineering USU.

3. Result and Discussion

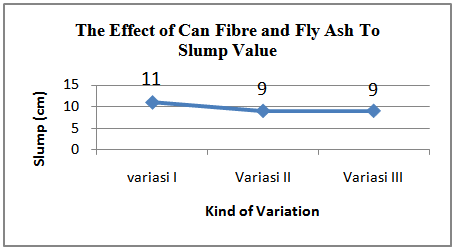

- The entire stages of the test objects such as preparation, inspection, casting, as well as the maintenance have been done according to procedure. At this stage the testing is carried out in the Laboratory of Civil Engineering USU. Cylindrical test specimens that have been aged 28 days can be tested their compressive strength, split tensile, as well as the absorption of concrete. Test results obtained is the raw data that must be recalculated and analyzed to determine the effect of added can fiber material and fly ash in the concrete mixture.Slump ValueThe workability of concrete can be seen through slump value. From the figure 1 it can be seen that with the addition of can fiber and fly ash, slump value obtained is also lower. This is because can fiber and fly ash can absorb water, thus making the workability of concrete variation II and III is more difficult than that of normal concrete.

| Figure 1. Graphic of Slump Value of Each Variation |

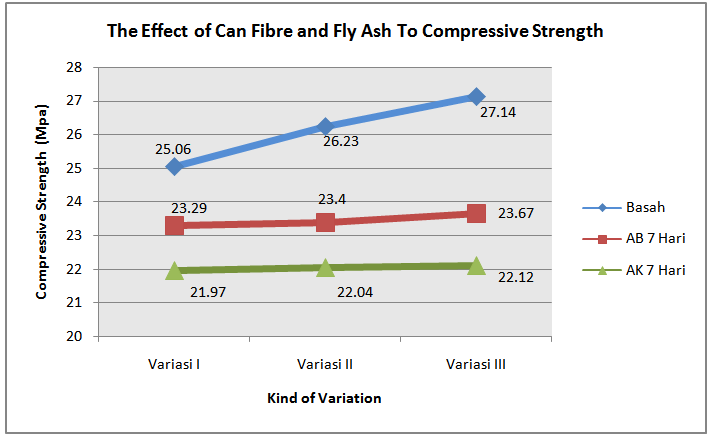

| Figure 2. Graphic of Compressive Strength of Each Variation |

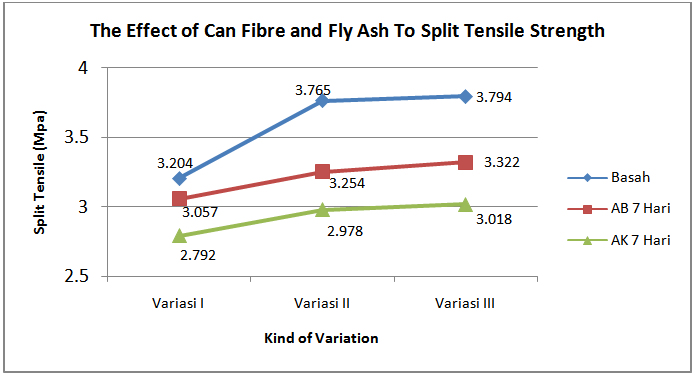

| Figure 3. Graphic of Split Tensile of Each Variation |

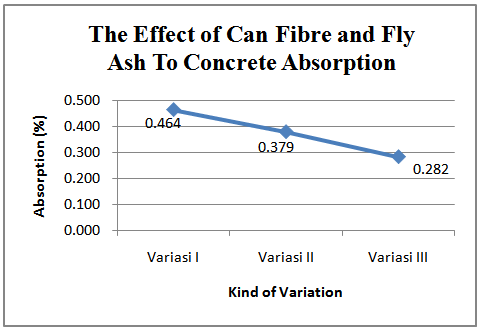

| Figure 4. Graphic of Concrete Absorption of Each Variation |

4. Conclusions

- From the test results done on the can fibre and fly ash, then some conclusions can be drawn: 1. The use of can fiber and fly ash in concrete mixture with the addition of 20% can fiber (variation II) and 20% can fiber + 15% fly ash (variation III) of cement consumption can decrease the slump value so that the workability of the concrete is reduced. 2. The use of can fiber and fly ash in the concrete mixture can increase the compressive strength of concrete. The most significant improvement is obtained in the wet curing, which increases by 4,669% of the normal concrete on the second variation and increases by 8.3% oft the normal concrete on the third variation. Whereas in the split tensile strength test, the most significant improvement is also obtained in the wet curing, which increases by 17.509% of the normal concrete on the second variation and increases by 18,414% of the normal variation on the third variation. Therefore, can fiber is excellent in improving the quality of concrete, especially on concrete tensile strength. 3. Absorption of concrete also decreases with can fiber and fly ash, because can fiber and fly ash in concrete is able to fill the voids and reduce water absorption. Fly ash can fill the cavity so as to keep the concrete from the relatively high evaporation. From the results of compressive strength and split tensile strength it can also be seen that initial wet curing 7 days compressive strength and split tensile strength of the smallest among treatments early wet and wet treatments 7 days. This is because the initial treatment of dry concrete with 7 days of water shortage in the binding process. As a result, the binding process which occurs is not perfect and have a negative impact on the quality of the concrete itself as reduced compressive strength and tensile strength of concrete.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML