-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2014; 4(3A): 59-62

doi:10.5923/c.jce.201402.09

Effect of Additive to the Moisture Content at Different Decomposition Level of Peat

Junita Abd Rahman1, Chee-Ming Chan2

1Faculty of Civil and Environmental Engineering, Universiti Tun Hussein Onn Malaysia, Johor, Malaysia

2Faculty of Engineering Technology, Universiti Tun Hussein Onn Malaysia, Johor, Malaysia

Correspondence to: Chee-Ming Chan, Faculty of Engineering Technology, Universiti Tun Hussein Onn Malaysia, Johor, Malaysia.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

The decomposition of peat soil is largely influence by its fiber content. The fiber has a high potential to retain water thus make peat soft and tender. The high water content owned by peat soil, is one of the reason of its easily compressible and low shear strength. Hydration water in soil was studied to understand the effect of additive in helping to reduce the water content of peat soil. Mixtures of peat soil with OPC and peat soil with bottom ash (BA) were tested using cone penetration limit method. The effect of BA in controlling peat water content was analyzed and compared with widely known hydration agent, ordinary portland cement (OPC). OPC was found to be effective to minimize the amount of water in peat soil. The hydration reaction between calcium in OPC with water to form C-S-H gel has lessen the amount of water in the mixture. On the other hand, the presence of BA does not show a significant decrease of water in the mixture. However, thixotropic effect was observed at day 3 for mixture of BA and peat soil at all decomposition level.

Keywords: Peat, Ordinary portland cement (OPC), Bottom ash, Cone penetration, Moisture content, Thixotropic

Cite this paper: Junita Abd Rahman, Chee-Ming Chan, Effect of Additive to the Moisture Content at Different Decomposition Level of Peat, Journal of Civil Engineering Research, Vol. 4 No. 3A, 2014, pp. 59-62. doi: 10.5923/c.jce.201402.09.

Article Outline

1. Introduction

- The decomposition of peat soil is largely influence by its fiber content. The less decompose will give a bigger size of fiber and known as fibric peat soil. The fiber has a high potential to retain water thus make peat soil soft and tender. The high water content owned by peat soil, is one of the reason of its easily compressible and low shear strength.Fabric peat soil (F) generally retained more water, if compared to hemic (H) (moderately decomposed) and sapric (S) (most decomposed) peat soil. Thus, the amount of hydration agent should be applied to the peat soil must be differ. According to Mitchell and Soga (2005), there are three types of water that presence naturally in soil. Based on the binding forces acting on the water molecules in the soil matrix, soil–water can be classified into: 1) hydration water; 2) bound water; and 3) free water. Hydration water is chemically bound water which is an integral part of soil minerals. Bound water refers to those water molecules physically bound in the vicinity of soil particles (double layer) by adhesive forces. Free water is the loosely held water which is controlled by surface tensional forces and gravity. In conventional soil mechanics, pore water in the soil matrix is comprised of bound water and free water.Hydration water in soil was studied to understand the effect of additive in helping to reduce the moisture content of peat soil. Additive that commonly use in peat soil treatment is ordinary portland cement (OPC). The hydration reaction between OPC and soils leads to initial gain in strength as the cementation product is formed due to drying up of water.Bottom ash (BA) was introduced in this study to know its potential in controlling peat soil water content. BA is currently a waste product of coal power plant. Therefore, any usage of BA is considered as cost wise. Bottom ash is normally porous and contain high minerals especially quartz. The particle size is varies starting from as big as aggregates to the size of fine sand. The high value of silica and alumina in bottom ash is a key for pozzolan that will takes place with the presence of water and calcium hydroxide. Through x-ray fluoresence analysis, calcium presence in peat soil is around 0.54 % of total mass of dry peat soil. The effect of BA in controlling water content in peat soil is to be compared with widely known hydration agent, OPC.

2. Method

2.1. Peat Soil Sampling

- Three types of peat soil was excavated at a maximum of 1.3 m depth at Pontian, Johor. Peat soil was physically and visually identified its decomposition level according to von post scale [2]. All samples were kept in tight container with plastic cover at the top of the peat soil to prevent moisture loss to the ambient. The containers were then placed in a curing chamber and ready for mixing step. A basic physical and chemical properties test of peat soil were conducted.

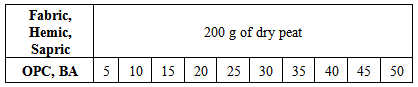

2.2. Preparation of Sample - Peat Soil

- Three types of peat soil at different decomposition level namely fibric, hemic and sapric were used in this study. Wet peat was sieved passed through 2 mm sieve size. The peat was mixed thoroughly by hand for about 3 minutes. This was to ensure that only homogenous wet peat was used for mixing. The peat sample was mixed using food mixer at low speed for 1 minute followed by medium speed for another 4 minutes. The mixer was stopped and the material was scraped off the paddle and sides of the bowl before resuming mixing for another 3 minutes. This process was completed in duration of 8 minutes. EuroSoilStab (2002) suggesting 10 minutes of blending to achieved sufficiently uniform dispersion mixture. The peat was ready for mixing process.

2.3. Cement

- The cement was first oven dried to ensure moisture free and kept in tight container. The amount of cement was calculated based on dry weight of peat soil.

2.4. Bottom Ash

- Bottom ash (BA) was gained from local coal power plant at Pontian, Johor. Variety of sizes owned by BA was recorded, starting from aggregates to fine sand. BA was first oven dry at 105℃ for 24 hours. BA was then sieve at 2 mm and kept in airtight container. The 2 mm size and below was chosen to be used in this study because the BA still consist of porous materials and some may have pozzolan effect. Furthermore, bigger size may cause misleading of cone penetration reading as the cone might penetrate on the aggregates, not the mixture.

2.5. Mixing

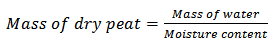

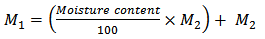

- The OPC or BA was added to the soils as per one scoop at a time. The mixture was first mix using hand before continue using food mixer for 5 minutes. The steps were repeat until all OPC or BA was fully mixed with the soils. The hydration process of cement is almost immediately and can last for 24 hours [3]. The mixture must be moulded into specific test specimen right after mixing before the cementation takes place where the sample hardens. The calculation of the mixture was based on the dry weight of soils (Eq. 1);

| (1) |

| (2) |

|

2.6. Cone Penetration Test

- Cone penetration test was used in this study to understand the mixture behaviour. The higher penetration recorded will represent the lower stiffness of the sample and vice versa. The samples were filled into cone penetration equipment for cone penetration test. The cone was penetrating into the sample and left for 5 seconds. The reading of penetration in cm was recorded. 3 consecutive reading were taken for each samples.

2.7. Moisture Content Tests

- 30 g of samples were taken out from mixture after one hour of mixing and heated at 105℃ for 6 hours. Samples were then weight. The different between the wet samples and dry samples will be calculated to find its moisture content. The moisture content was measured at Day 0 (D0) and Day 3 (D3) of the mixture.

3. Results and Discussions

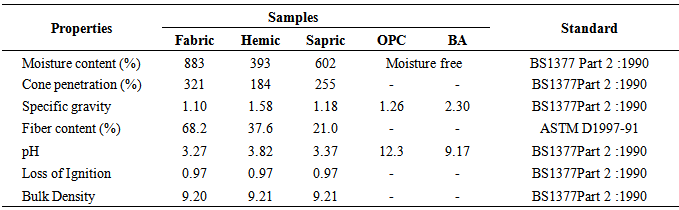

3.1. Basic Physical and Chemical Properties of Peat and Hydration Agent

- Basic physical and chemical properties were determined using simple laboratory test as in Table 2.

|

3.2. Effect of Additive to the Peat at Different Decomposition Level

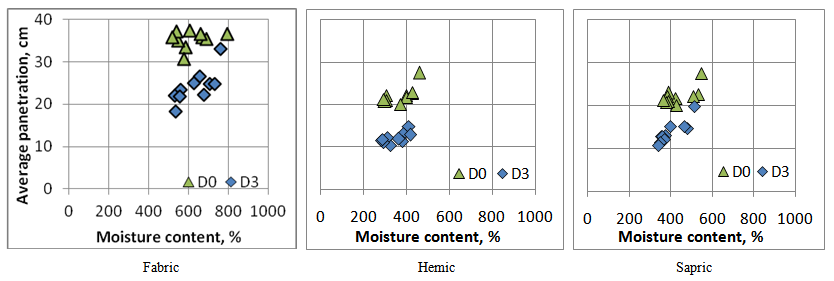

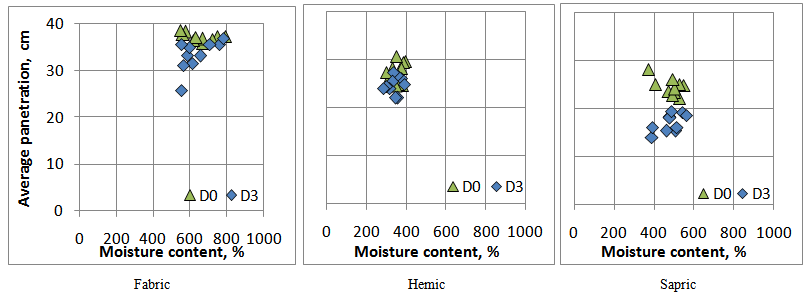

- The cone penetration test has been conducted to all types of mixtures. All mixtures were tested for D0 and D3. D0 was chosen to look into the fresh condition before any reactions take place. Horpibulsuk found that fewer than 7 days, only early stage of hydration happens [4]. This is the reason of considering curing times when a study on soil stabilization is to be conducted. While D3 was chosen as to look into hydration effect if there is any. The patterns of the stiffness of mixture for all three types of peat (Fig.1) with OPC and BA were compared.

| Figure 1. Average penetration for mixture of peat and OPC |

| Figure 2. Average penetration for mixture of peat and BA |

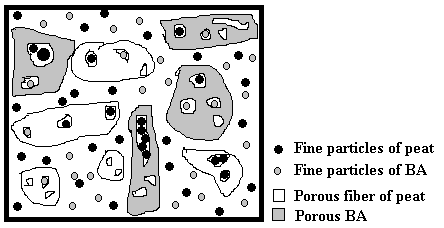

| Figure 3. Illustration of fine particles filling porous spaces in BA and peat |

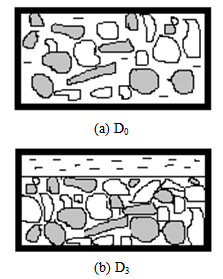

| Figure 4. Illustration of peat-BA mixture |

4. Summary

- The reaction between OPC and hydration water in peat shows that OPC is always the most practical additive for controlling water content during peat treatment. As for comparison, BA is not suitable to be used as dehydration agent but it is good to work as filler. The pozzolanic reaction may happen when peat is mix with BA but the study should be extend to 28 days to confirm the hypothesis.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML